Design and Characterization of a Three-Axis Hall Effect-Based Soft Skin Sensor

Abstract

:1. Introduction

2. Related Works

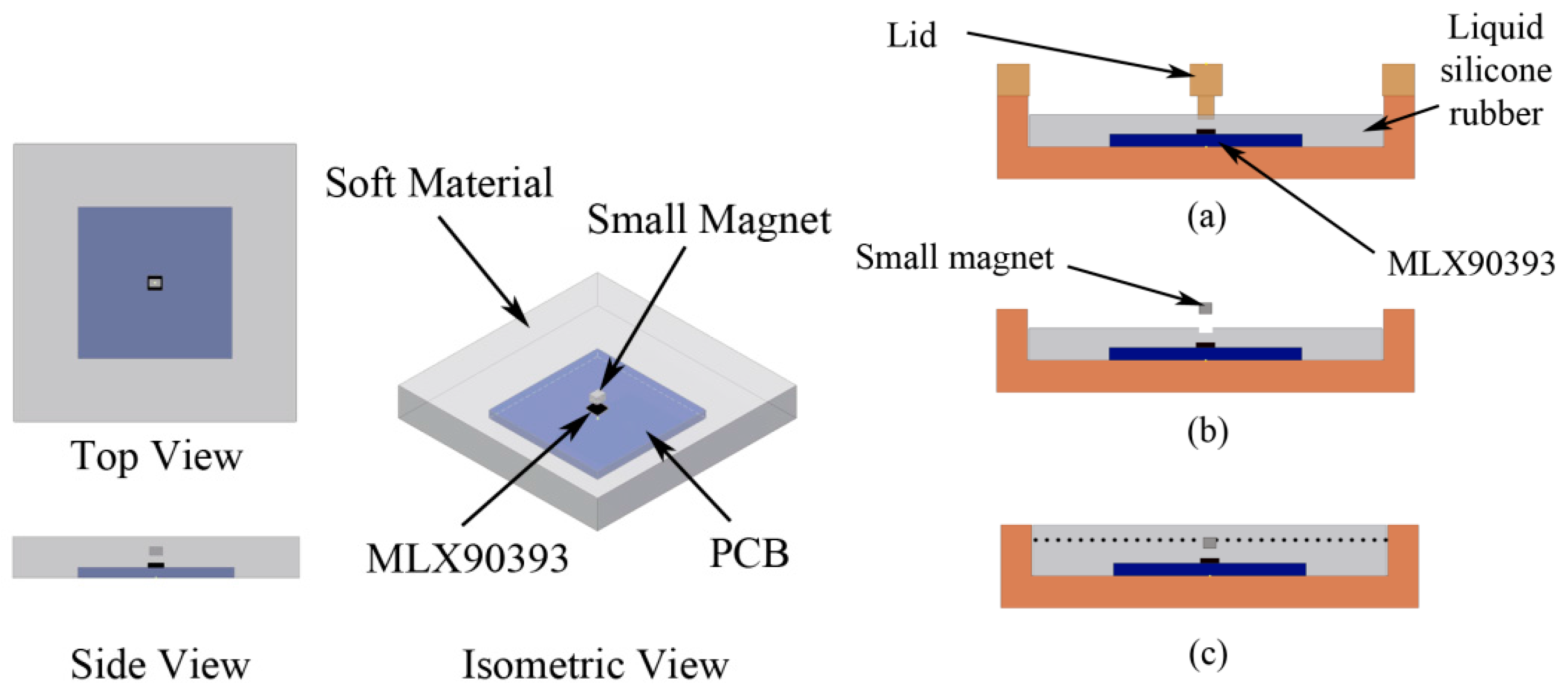

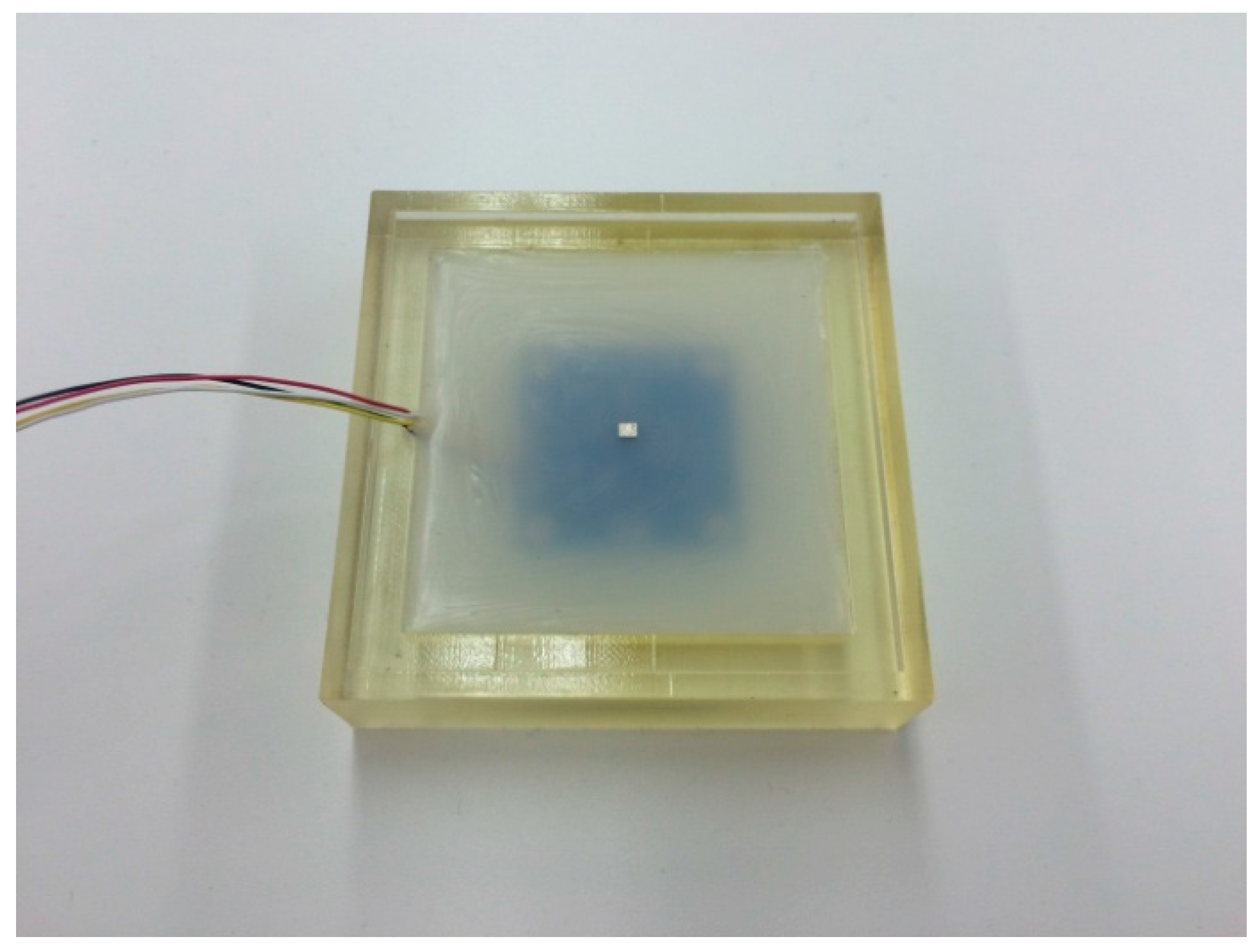

3. Sensor Description

3.1. Sensor Concept

3.2. Soft Outer Layer

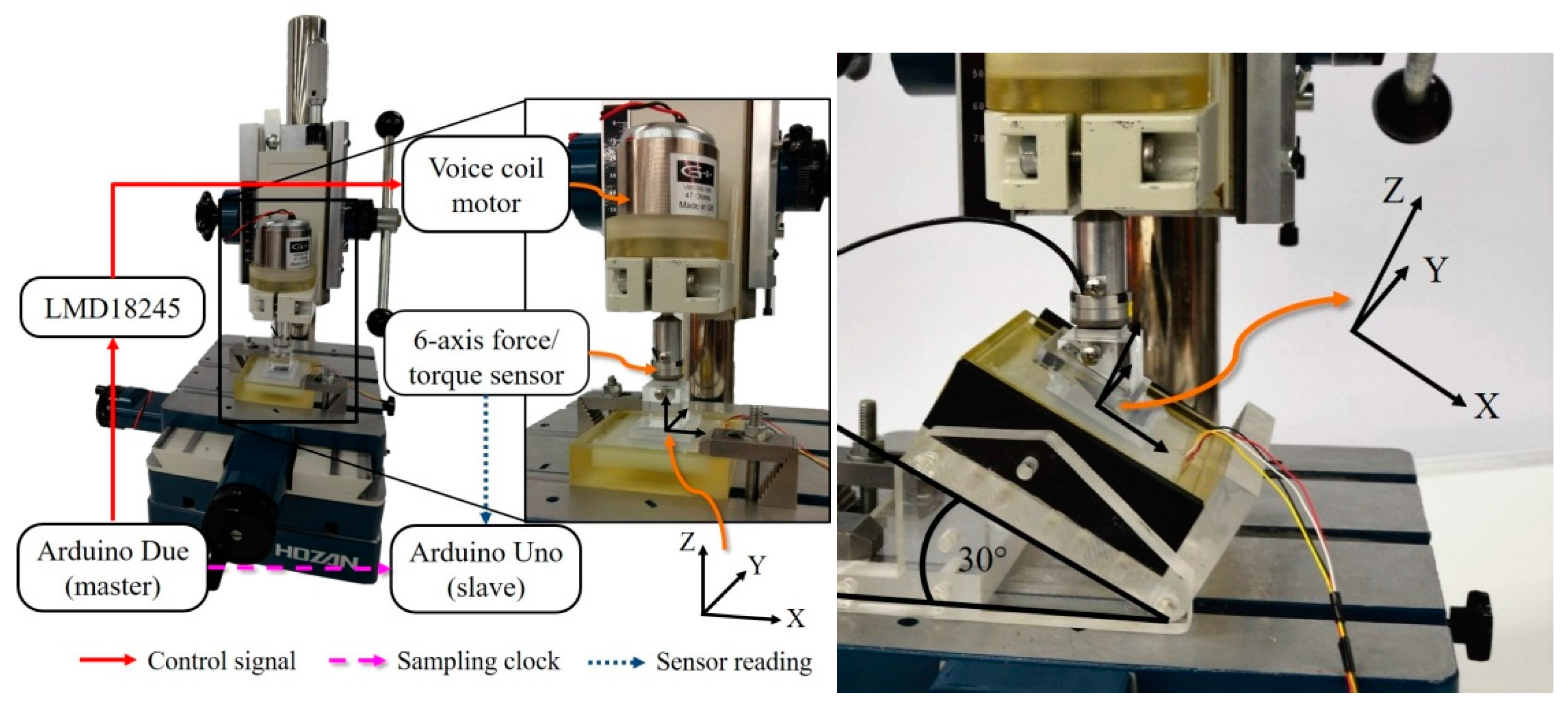

4. Experimental Setup

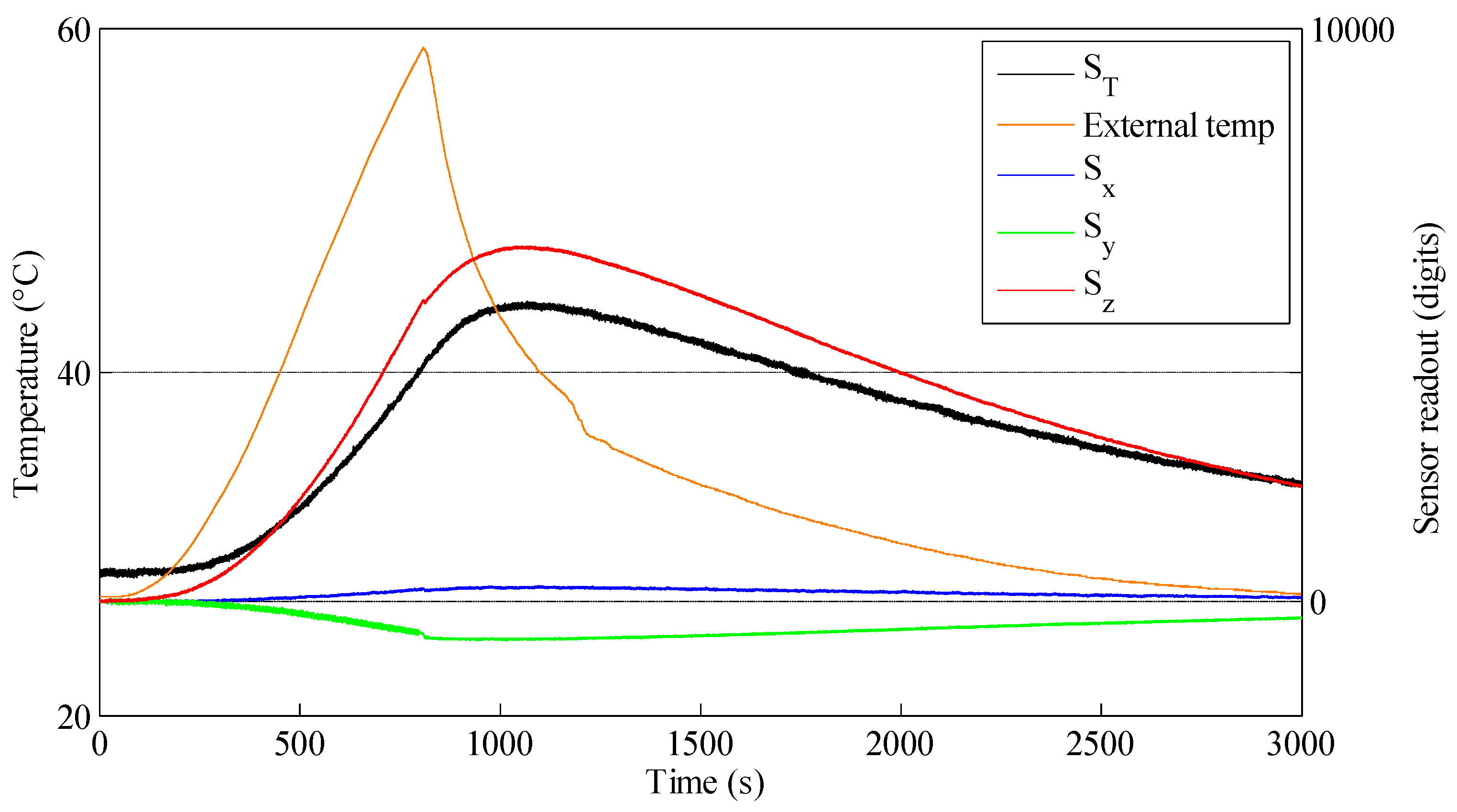

4.1. Temperature Drift Test

4.2. Hysteresis Test

4.3. Load Test

5. Results and Discussion

5.1. Thermal Drift Evaluation

- •

- i is each axis of the skin sensor (x, y and z).

- •

- Si and Si,T are the skin sensor readout and compensated value, respectively.

- •

- ΔST is the temperature change measured by the MLX90393 built-in temperature sensor.

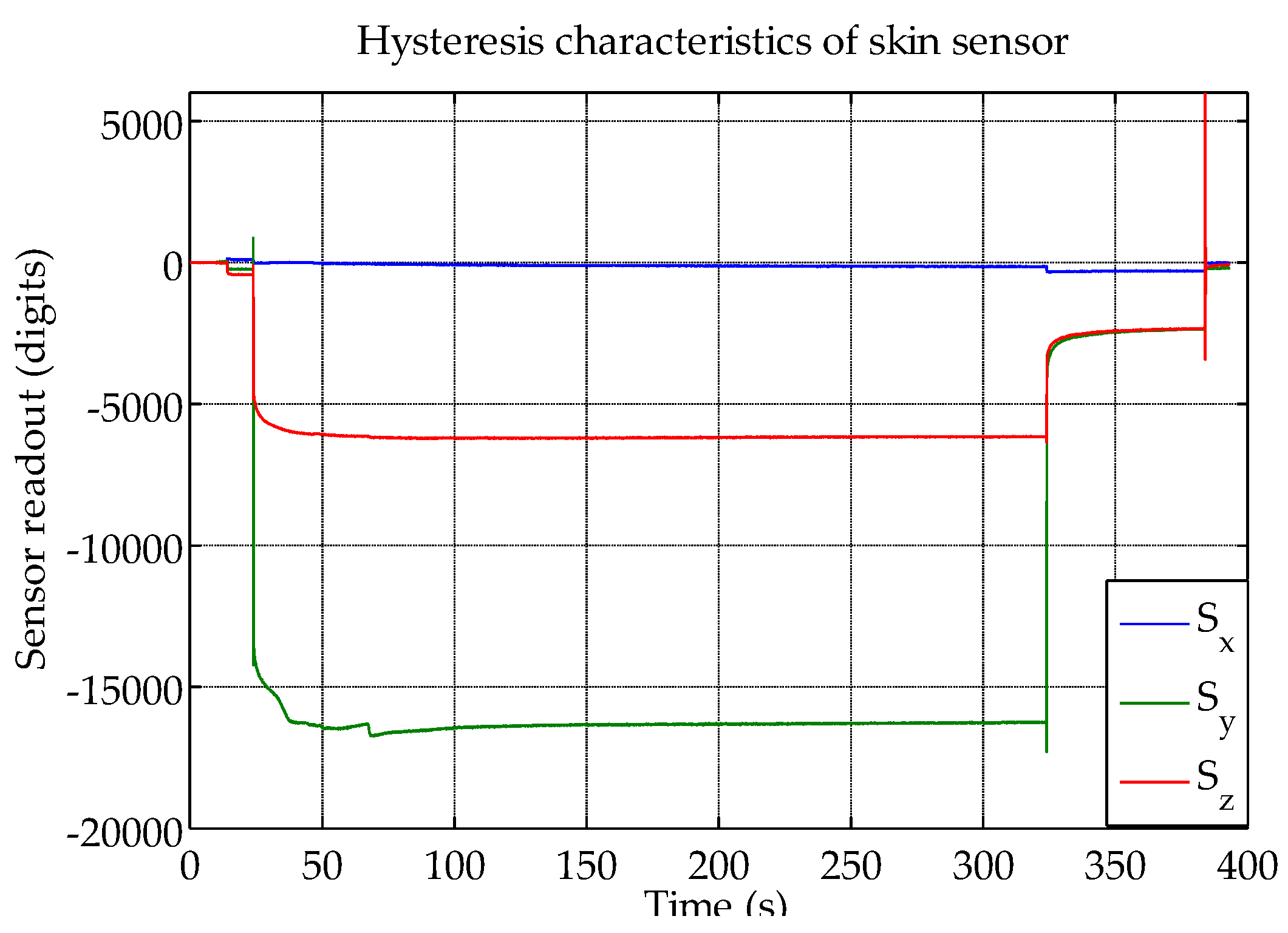

5.2. Hysteresis Evaluation

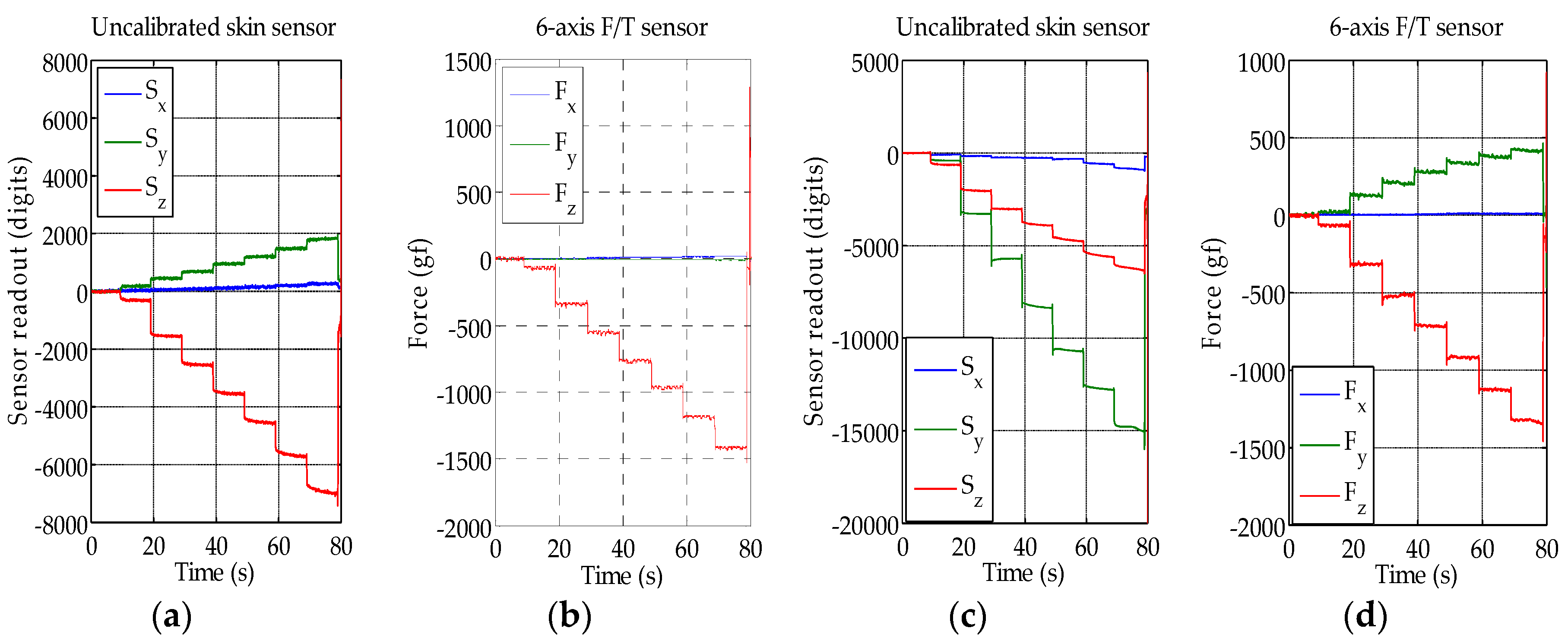

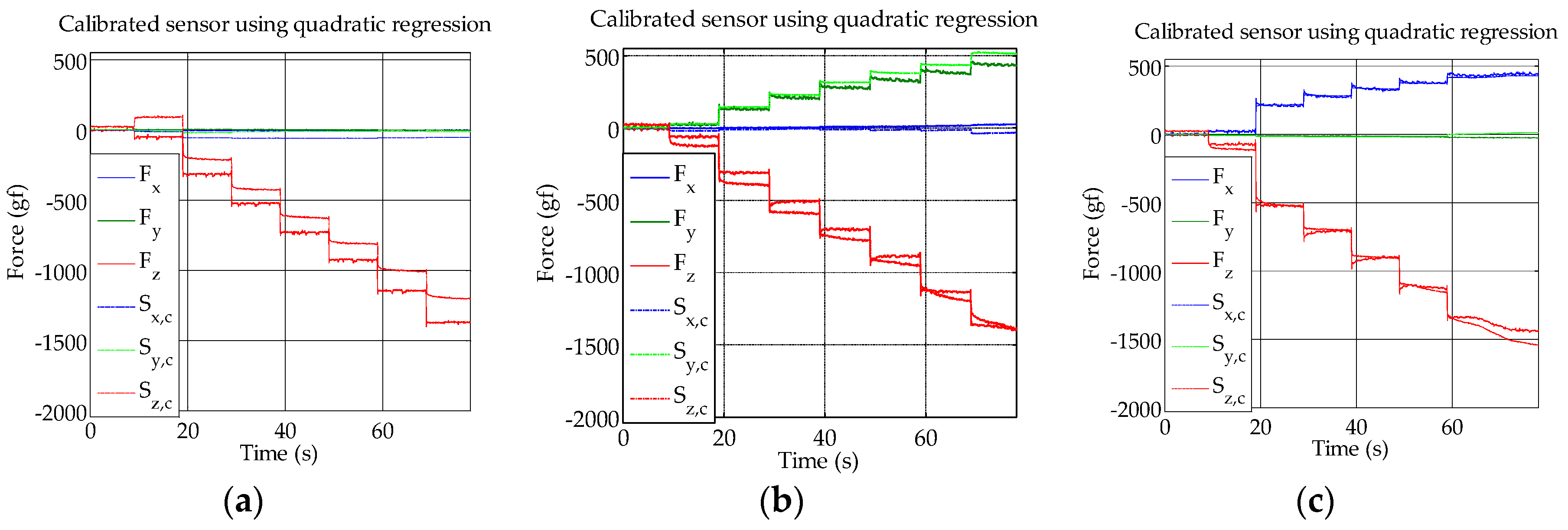

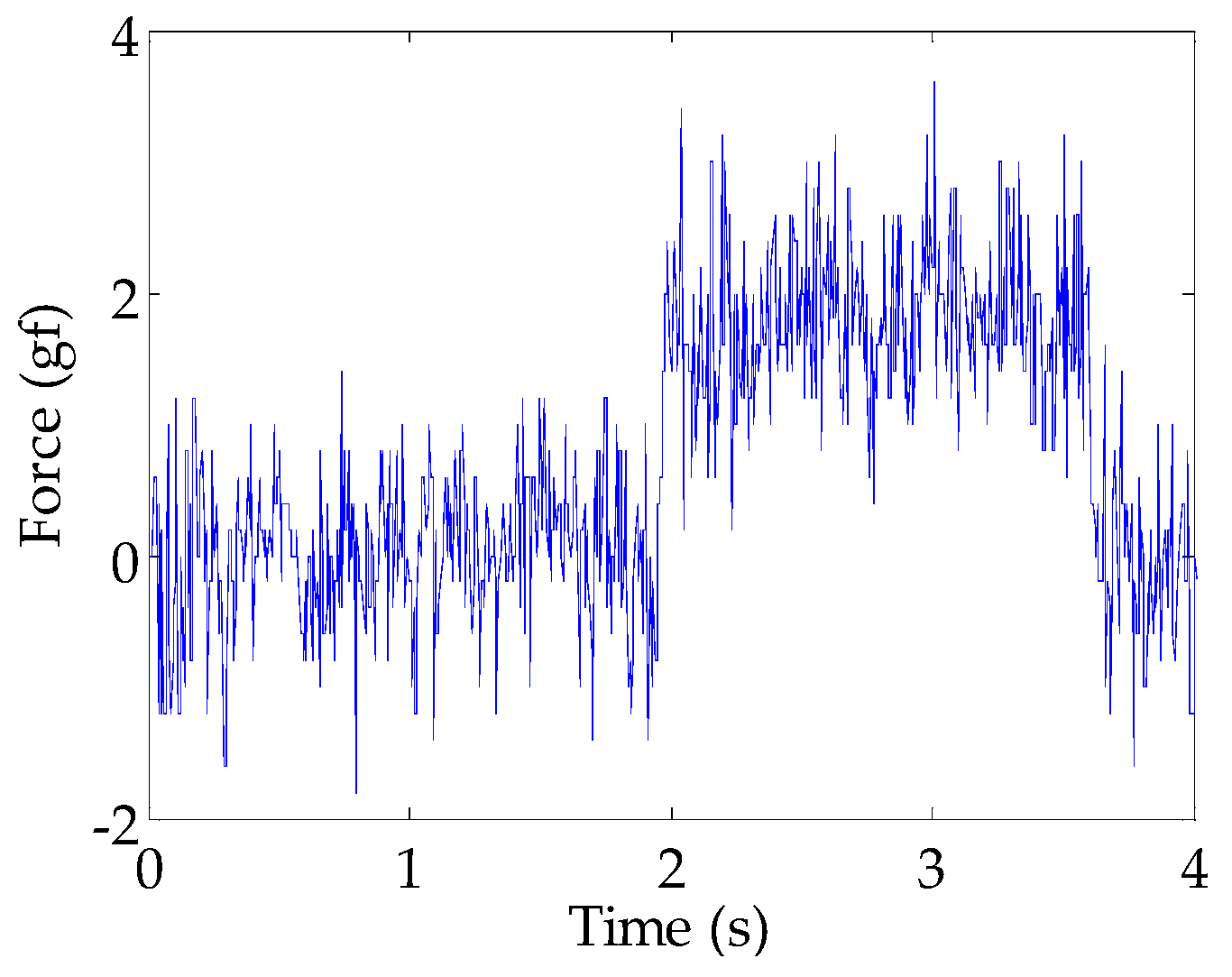

5.3. Load Tests and Calibration

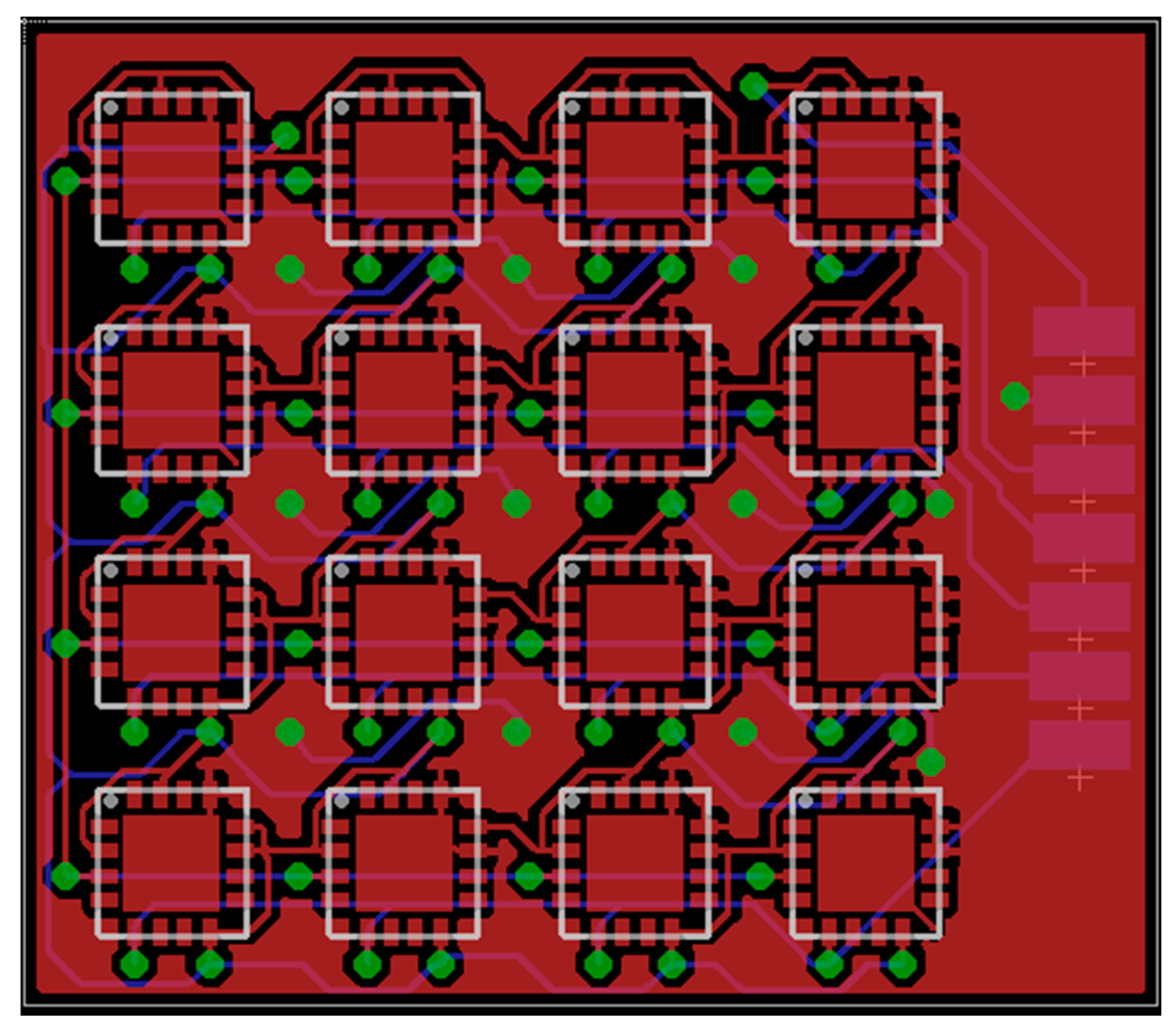

6. Design of PCB for Distributed Sensors

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PCB | Printed circuit board |

| MEMS | Microelectromechanical system |

| F/T | Force/torque |

| SD | Secure digital |

References

- Dahiya, R.S.; Mittendorfer, P.; Valle, M.; Cheng, G.; Lumelsky, V.J. Directions toward effective utilization of tactile skin: A review. IEEE Sens. J. 2013, 13, 4121–4138. [Google Scholar] [CrossRef]

- Somlor, S.; Hartanto, R.S.; Schmitz, A.; Sugano, S. A Novel Tri-axial Capacitive-Type Skin Sensor. Adv. Robot. 2015, 29, 1375–1391. [Google Scholar] [CrossRef]

- Tomo, T.P.; Somlor, S.; Jamone, L.; Schmitz, A.; Hashimoto, S.; Sugano, S. Development of a Hall-Effect Based Skin Sensor. In Proceedings of the IEEE Sensors Conference, Busan, Korea, 1–4 November 2015.

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile Sensing—From Humans to Humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- ShokacPot™ ShokacCube™, Innovation unique ‘Soft’ tactile sensor. Available online: http://www.touchence.jp (accessed on 6 April 2016).

- Yamada, K.; Goto, K.; Nakajima, Y.; Koshida, N.; Shinoda, H. A sensor skin using wire-free tactile sensing elements based on optical connection. In Proceedings of the 41st SICE Annual Conference SICE, Osaka, Japan, 5–7 August 2002; pp. 131–134.

- Yoshikai, T.; Hayashi, M.; Ishizaka, Y.; Fukushima, H.; Kadowaki, A.; Sagisaka, T.; Kobayashi, K.; Kumagai, I.; Inaba, M. Development of robots with soft sensor flesh for achieving close interaction behavior. Adv. Artif. Intell. 2012. [Google Scholar] [CrossRef]

- 3D Force Sensor (OMD) Datasheet. Available online: http://optoforce.com/ (accessed on 6 April 2016).

- Oddo, C.M.; Controzzi, M.; Beccai, L.; Cipriani, C.; Carrozza, M.C. Roughness encoding for discrimination of surfaces in artificial active-touch. IEEE Trans. Robot. 2011, 27, 522–533. [Google Scholar] [CrossRef]

- Clark, J.J. A Magnetic Field Based Compliance Matching Sensor for High Resolution, High Compliance Tactile Sensing. In Proceedings of the 1988 IEEE International Conference Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988.

- Nowlin, W.C. Experimental Results on Bayesian Algorithms for Interpreting Compliant Tactile Sensing Data. In Proceedings of the 1991 IEEE International Conference Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991.

- Ledermann, C.; Wirges, S.; Oertel, D.; Mende, M.; Woern, H. Tactile sensor on a magnetic basis using novel 3D Hall sensor-First prototypes and results. In Proceedings of the 17th International Conference on Intelligent Engineering Systems (INES), San Jose, CA, USA, 19–21 June 2013; pp. 55–60.

- Youssefian, S.; Rahbar, N.; Torres-Jara, E. Contact Behavior of Soft Spherical Tactile Sensors. IEEE Sens. J. 2014, 14, 1435–1442. [Google Scholar] [CrossRef]

- Jamone, L.; Metta, G.; Nori, F.; Sandini, G. James: A Humanoid Robot Acting over an Unstructured World. In Proceedings of the 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006; pp. 143–150.

- Jamone, L.; Natale, L.; Metta, G.; Sandini, G. Highly sensitive soft tactile sensors for an anthropomorphic robotic hand. IEEE Sens. J. 2015, 15, 4226–4233. [Google Scholar] [CrossRef]

- Torres-Jara, E.; Vasilescu, I.; Coral, R. A soft touch: Compliant tactile sensors for sensitive manipulation. Available online: https://www.researchgate.net/publication/37992348_A_soft_touch_Compliant_Tactile_Sensors_for_Sensitive_Manipulation (accessed on 6 April 2016).

- Magnetic Based Tactile Sensor (MTS). Available online: http://bl-autotec.co.jp/ (accessed on 6 April 2016).

- Melexis, MLX90393 Micropower Triaxis® Magnetometer Datasheet. Available online: http://www.melexis.com/Position--Speed-Sensors/Triaxis%C2%AE-Hall-ICs/Triaxis%C2%AE-Micropower-Magnetometer-829.aspx (accessed on 6 April 2016).

| Linear + Huber | Quadratic + Huber | Feedforward Neural Network | |

|---|---|---|---|

| Normal Force | 0.8634 | 0.8925 | 0.9368 |

| Shear 45—y | 0.8634 | 0.9418 | 0.8275 |

| Shear 45—x | 0.9272 | 0.9744 | 0.9644 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomo, T.P.; Somlor, S.; Schmitz, A.; Jamone, L.; Huang, W.; Kristanto, H.; Sugano, S. Design and Characterization of a Three-Axis Hall Effect-Based Soft Skin Sensor. Sensors 2016, 16, 491. https://doi.org/10.3390/s16040491

Tomo TP, Somlor S, Schmitz A, Jamone L, Huang W, Kristanto H, Sugano S. Design and Characterization of a Three-Axis Hall Effect-Based Soft Skin Sensor. Sensors. 2016; 16(4):491. https://doi.org/10.3390/s16040491

Chicago/Turabian StyleTomo, Tito Pradhono, Sophon Somlor, Alexander Schmitz, Lorenzo Jamone, Weijie Huang, Harris Kristanto, and Shigeki Sugano. 2016. "Design and Characterization of a Three-Axis Hall Effect-Based Soft Skin Sensor" Sensors 16, no. 4: 491. https://doi.org/10.3390/s16040491

APA StyleTomo, T. P., Somlor, S., Schmitz, A., Jamone, L., Huang, W., Kristanto, H., & Sugano, S. (2016). Design and Characterization of a Three-Axis Hall Effect-Based Soft Skin Sensor. Sensors, 16(4), 491. https://doi.org/10.3390/s16040491