Developing an Ear Prosthesis Fabricated in Polyvinylidene Fluoride by a 3D Printer with Sensory Intrinsic Properties of Pressure and Temperature

Abstract

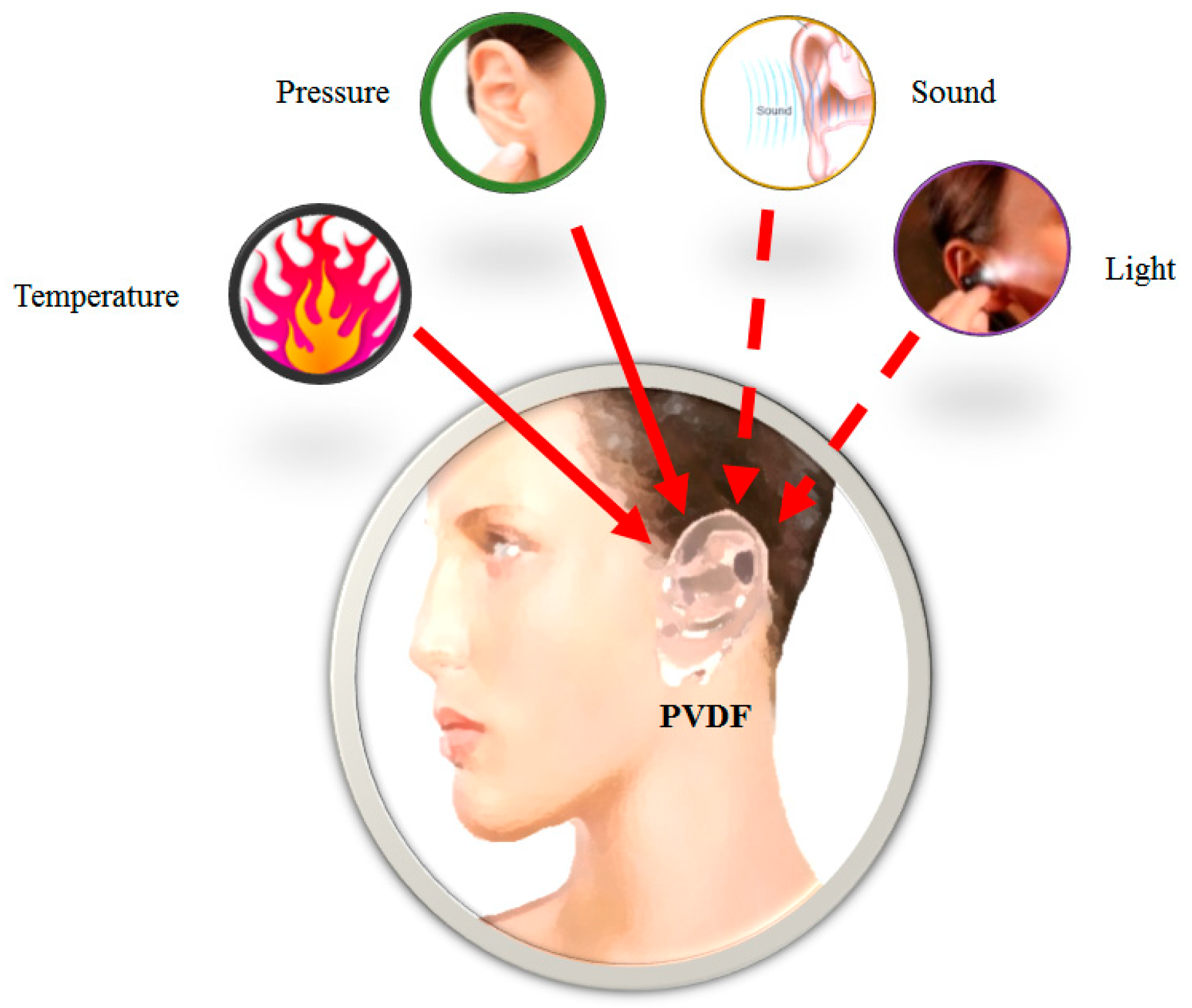

:1. Introduction

2. Experimental Section

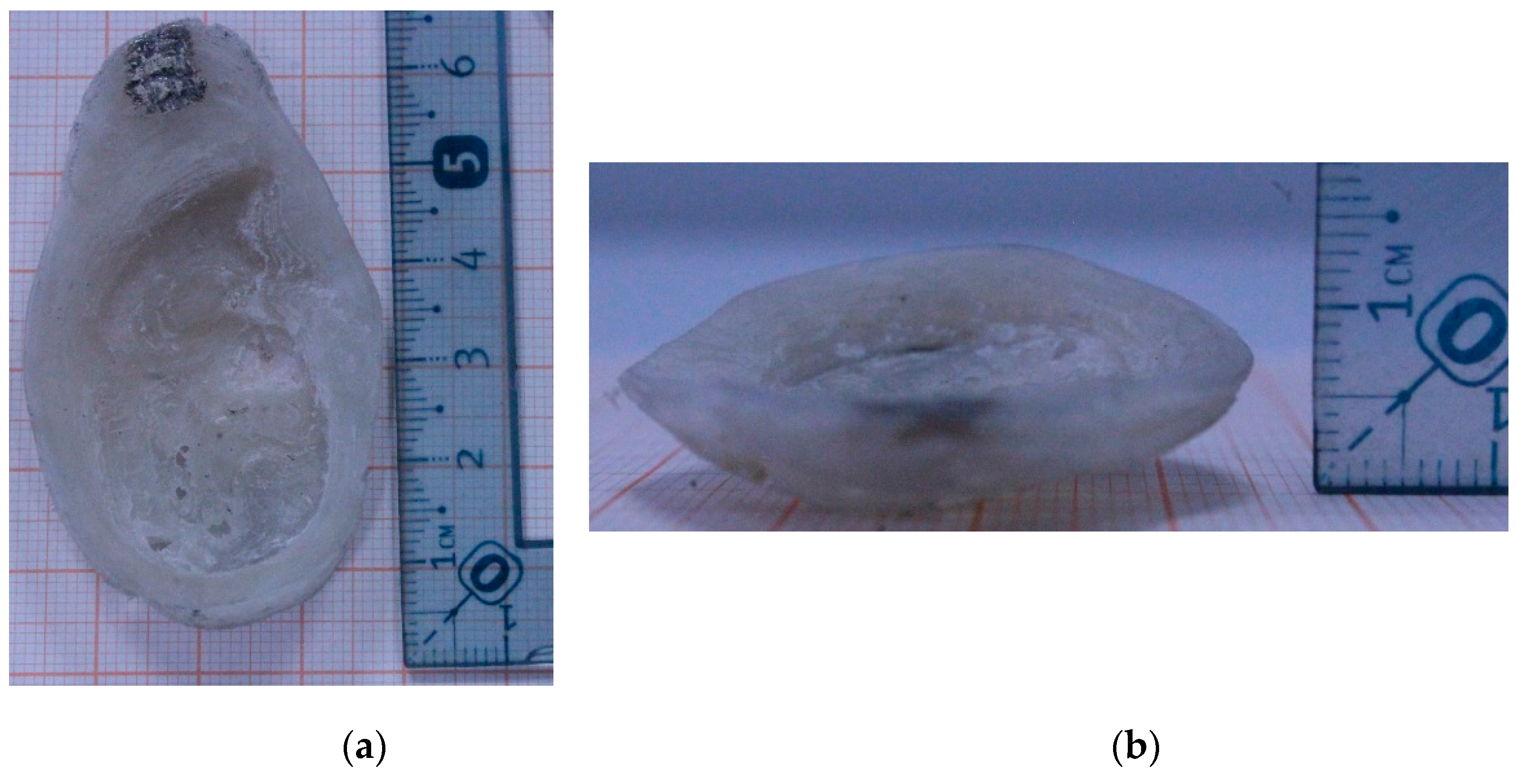

2.1. Design and Manufacturing

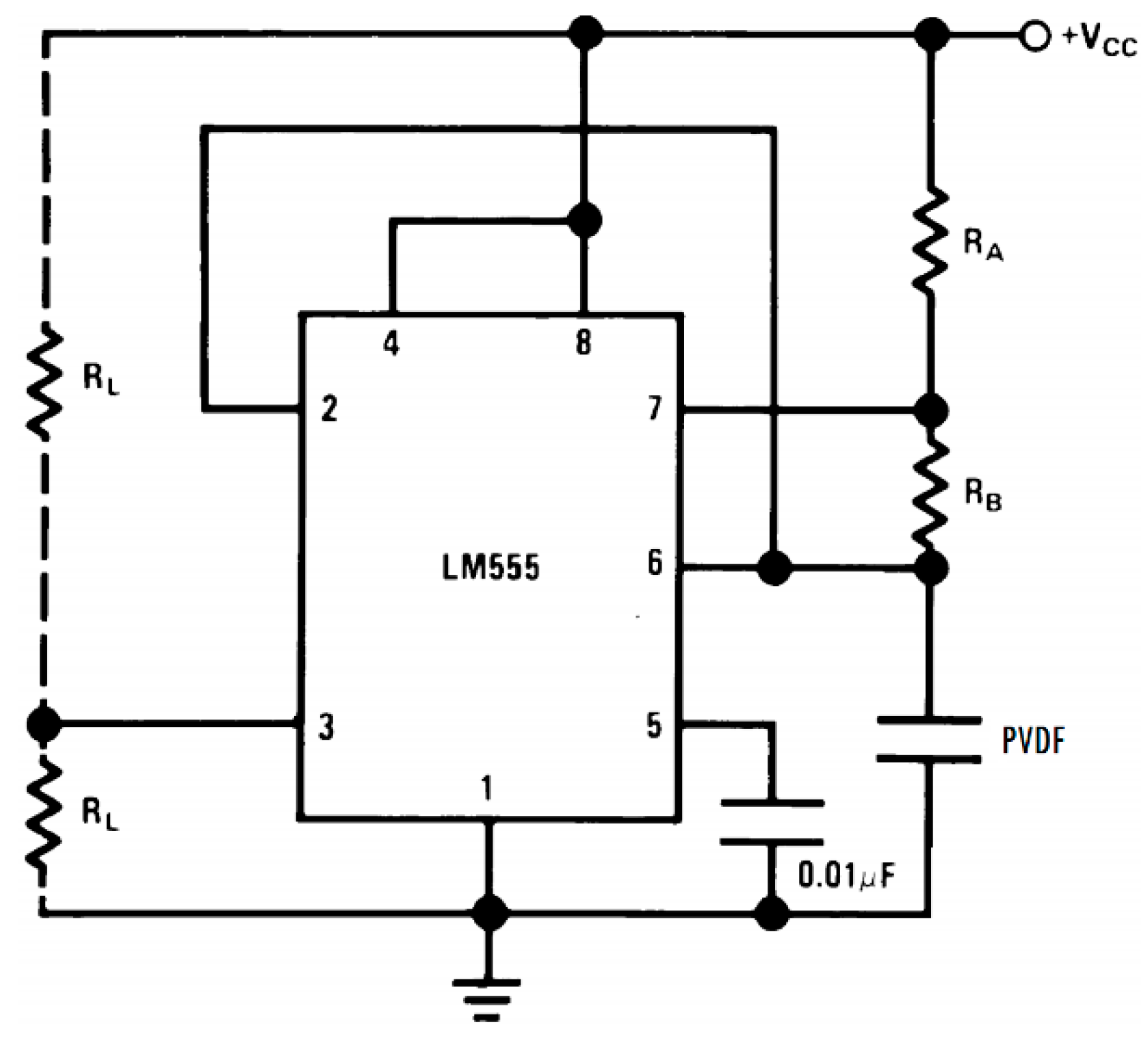

2.2. Polarization

2.3. Characterization

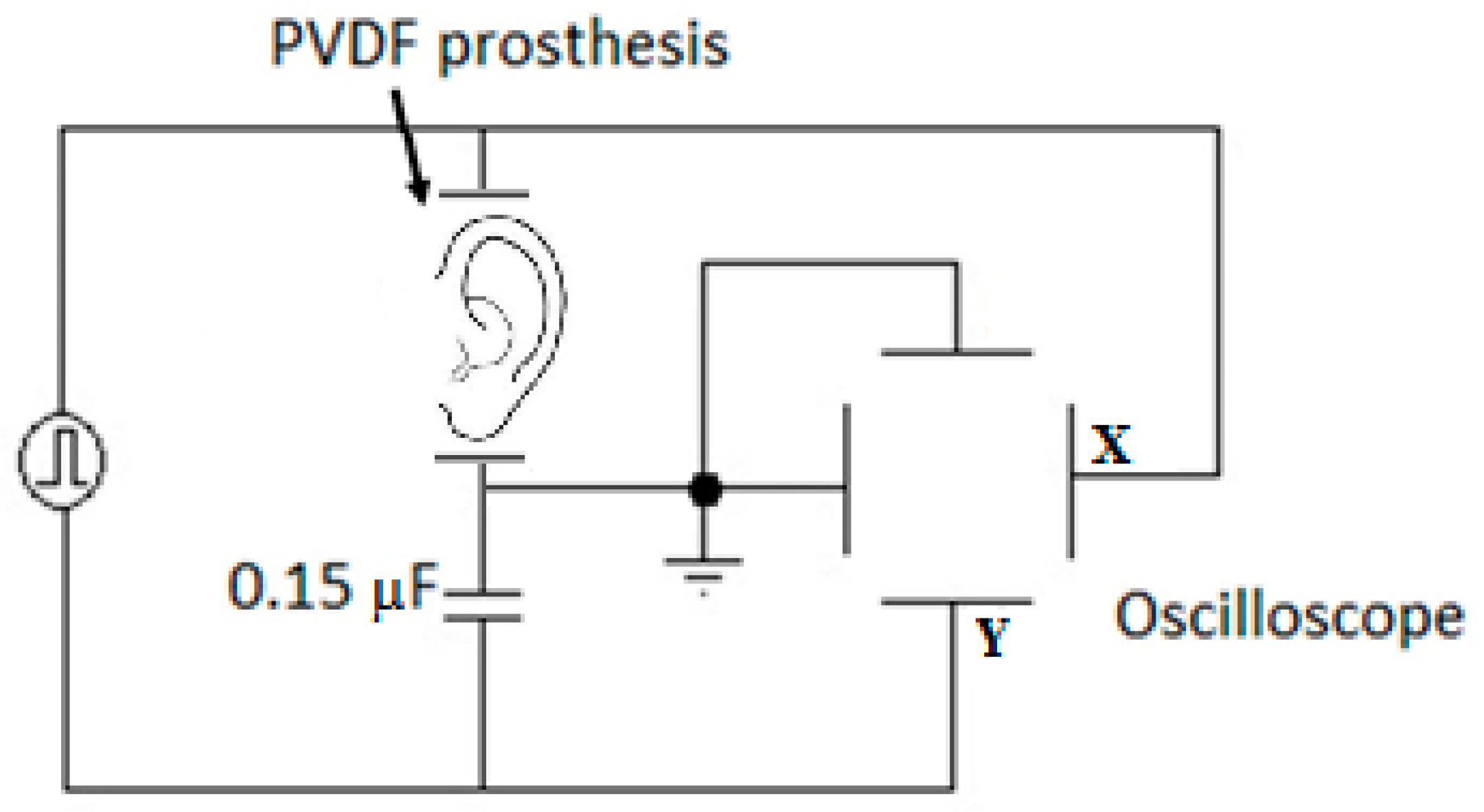

2.4. Characterization of the Ferroelectric Properties of PVDF

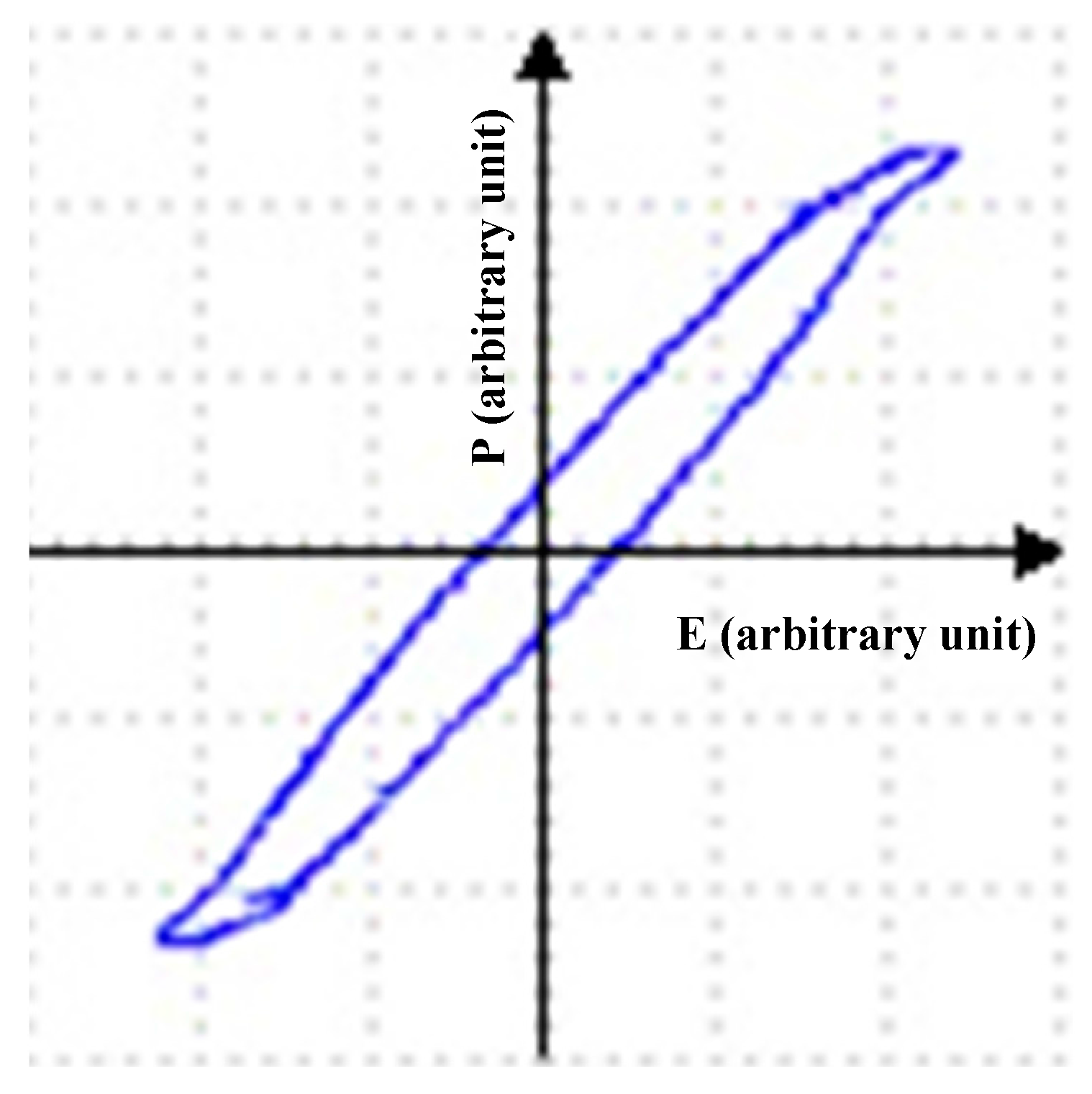

2.4.1. Hysteresis Loop

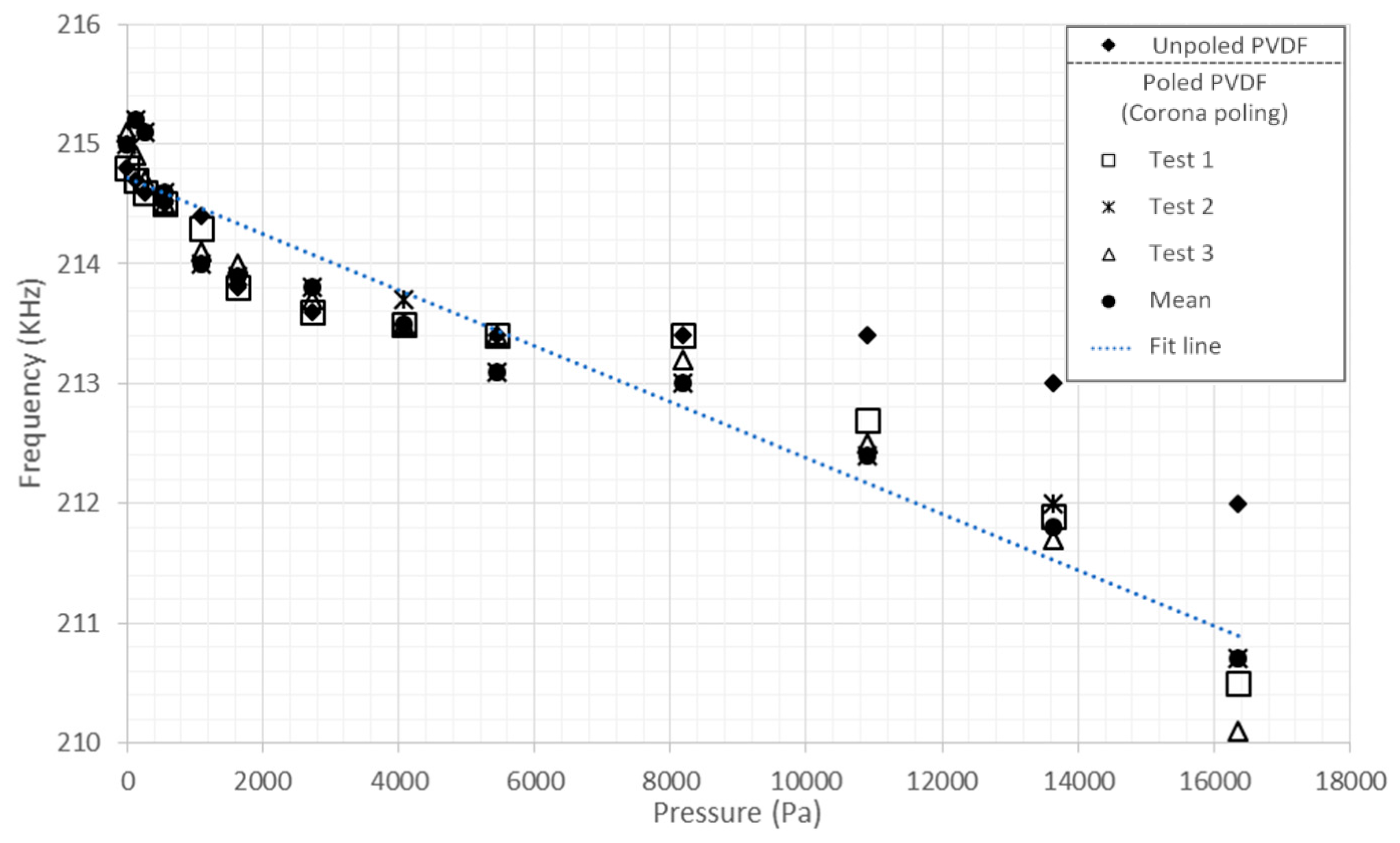

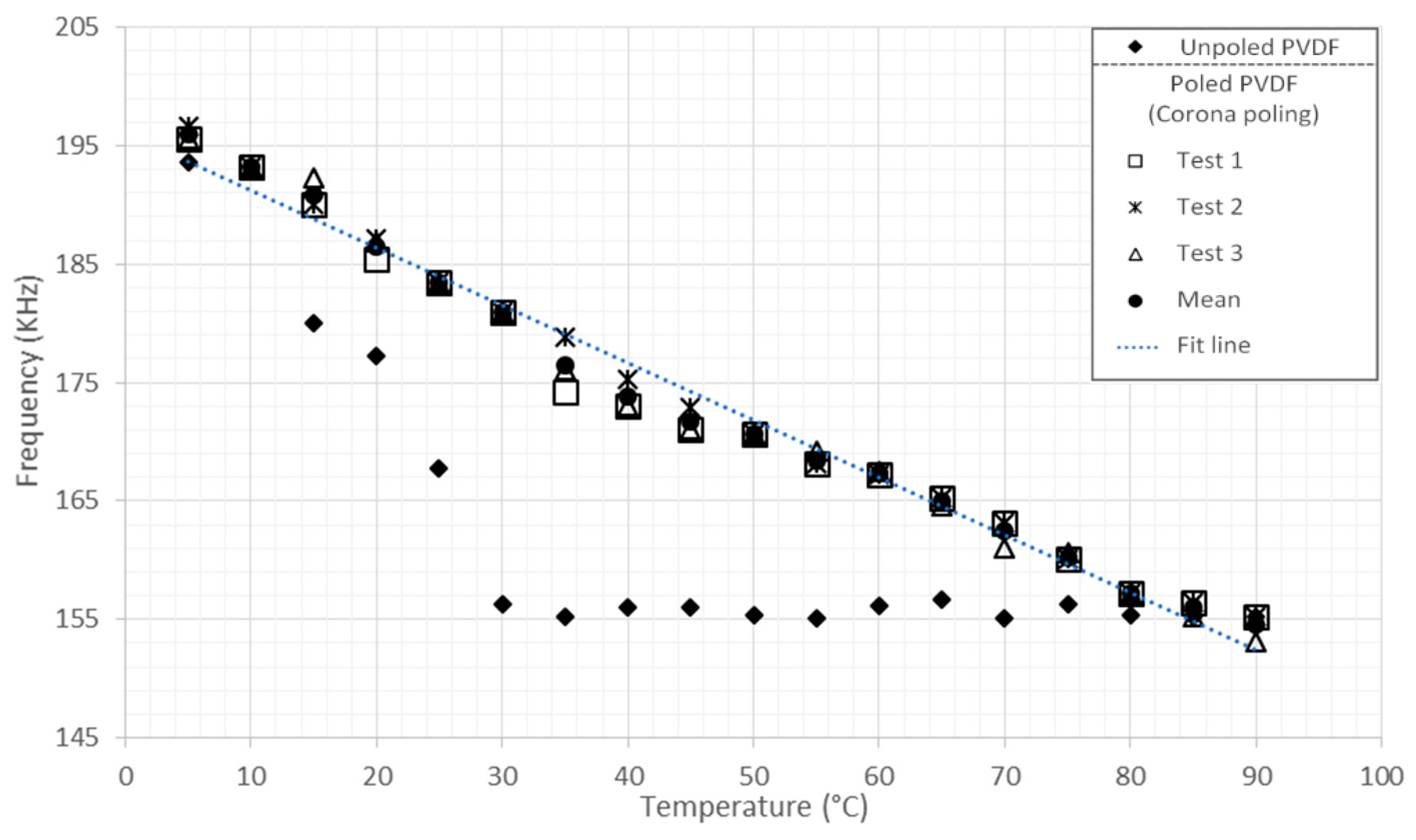

2.4.2. Pressure and Temperature Characterization

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Park, C.; Yoo, Y.-S.; Hong, S.-T. An update on auricular reconstruction: Three major auricular malformations of microtia, prominent ear and cryptotia. Curr. Opin. Otolaryngol. Head Neck Surg. 2010, 18, 544–549. [Google Scholar] [CrossRef] [PubMed]

- Escoto-Mora, G.; Gonzalez-Moran, C.O.; Suaste-Gomez, E. Development of poly(vinylidene flouride) polymer applied in force sensors for gait analysis in Wistar mice of physiology research laboratory. Jpn. J. Appl. Phys. 2008, 47, 4769–71. [Google Scholar] [CrossRef]

- Gallantree, H.R. Review of transducer applications of polyvinylidene fluoride. IEE Proc. I Commun. Speech Vision 1983, 130, 219–224. [Google Scholar] [CrossRef]

- Ueberschlag, P. PVDF piezoelectric polymer. Sens. Rev. 2001, 21, 118–126. [Google Scholar] [CrossRef]

- Lee, J.S.; Shin, K.-Y.; Cheong, O.J.; Kim, J.H.; Jang, J. Highly sensitive and multifunctional tactile sensor using free-standing ZnO/PVDF thin film with graphene electrodes for pressure and temperature monitoring. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Moran, C.O.G.; Ballesteros, R.G.; Guzman, M.; Gomez, E.S. Polyvinylidene flouride polymer applied in an intraocular pressure sensor. Jpn. J. Appl. Phys. Part 2 Lett. Expr. Lett. 2005, 44, 885–887. [Google Scholar] [CrossRef]

- Lovinger, A.J. Ferroelectric Polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- González-Morán, C.O.; Zamora-Pérez, G.A.; Suaste-Gómez, E. System for controlling the moisture of the soil using humidity sensors from a polyvinylidene fluoride fiber mats. Adv. Sci. Lett. 2013, 19, 858–861. [Google Scholar] [CrossRef]

- Fedosov, S.N.; Sergeeva, A.E.; Giacometti, J.A.; Ribeiro, P.A. Corona poling of a ferroelectric polymer (PVDF). Proc. SPIE 1999, 4017, 53–58. [Google Scholar]

- Davis, G.T. Piezoelectric and Pyroelectric Polymers. In Polymers for Electronic and Photonic Applications; Wong, C.P., Ed.; Academic Press, Inc.: Boston, MA, USA, 1993; p. 435. [Google Scholar]

- Jafer, E.; Arshak, K. The use of PE/PVDF pressure and temperature sensors in smart wireless sensor network for environmental monitoring system developed. Sens. Lett. 2008, 6, 1–13. [Google Scholar] [CrossRef]

- Casar, G.; Li, X.; Koruza, J.; Zhang, Q.; Bobnar, V. Electrical and thermal properties of vinylidene fluoride-trifluoroethylene-based polymer system with coexisting ferroelectric and relaxor states. J. Mater. Sci. 2013, 48, 7920–7926. [Google Scholar] [CrossRef]

- Jia, Y.; Ni, Q.; Chen, X.; Ju, C.; Xing, K.; Jin, T. Simulation and Experiment of PVDF Temperature Sensor. In Sensors, Measurement and Intelligent Materials; Yun-Hae, K., Prasad, Y., Eds.; Trans Tech Publication: Dürnten, Switzerland, 2013; pp. 109–113, 303–306. [Google Scholar]

- Gan, R.Z.; Feng, B.; Sun, Q. Three-dimensional finite element modeling of human ear for sound transmission. Ann. Biomed. Eng. 2004, 32, 847–859. [Google Scholar] [CrossRef] [PubMed]

- Sforza, C.; Grandi, G.; Binelli, M.; Tommasi, D.G.; Rosati, R.; Ferrario, V.F. Age- and sex-related changes in the normal human ear. Forensic Sci. Int. 2009, 187, 110.e1–110.e7. [Google Scholar] [CrossRef] [PubMed]

- Ciocca, L.; Mingucci, R.; Gassino, G.; Scotti, R. CAD/CAM ear model and virtual construction of the mold. J. Prosthet. Dent. 2007, 98, 339–343. [Google Scholar] [CrossRef]

- Kahue, C.N.; Carlson, M.L.; Daugherty, J.A.; Haynes, D.S.; Galsscock, M.E., III. Middle ear implants for rehabilitation of sensorineural hearing loss: A systematic review of FDA approved devices. Otol. Neurotol. 2014, 35, 1228–1237. [Google Scholar] [CrossRef] [PubMed]

- Tysome, J.R.; Moorthy, R.; Lee, A.; Jiang, D.; O'Connor, A.F. Systematic review of middle ear implants: Do they improve hearing as much as conventional hearing aids? Otol. Neurotol. 2010, 31, 1369–1375. [Google Scholar] [CrossRef] [PubMed]

- Wolframm, M.D.; Opie, J.M.; Muehloecker, C. Active middle ear implants (AMEIs) in patients with mixed or conductive hearing losses—A review and analysis of the literature. Hearing Res. 2010, 263, 246–246. [Google Scholar] [CrossRef]

- Buyens, W.; van Dijk, B.; Wounters, J.; Moonen, M. A stereo music preprocessing scheme for cochlear implant users. IEEE Trans. Biomed. Eng. 2015, 62, 2434–2442. [Google Scholar] [CrossRef] [PubMed]

- D'Alessandro, H.D.; Filipo, R.; Ballantyne, D.; Attanasio, G.; Bosco, E.; Nicastri, M.; Mancini, P. Low-frequency pitch perception in children with cochlear implants in comparison to normal hearing peers. Eur. Arch. Otorhinolaryngol. 2015, 272, 3115–3122. [Google Scholar] [CrossRef] [PubMed]

- Farinetti, A.; Roman, S.; Mancini, J.; Baumstarck-Barrau, K.; Meller, R.; Lavieille, J.P.; Triglia, J.M. Quality of life in bimodal hearing users (unilateral cochlear implants and contralateral hearing aids). Eur. Arch. Otorhinolaryngol. 2015, 272, 3209–3215. [Google Scholar] [CrossRef] [PubMed]

- Cox, A.; Sabbagh, W.; Gault, D. Costal Cartilage or Conchal Cartilage for Aesthetic and Structural Reconstruction of Lower Pole Ear Defects. Aesthet. Surg. J. 2012, 32, 271–274. [Google Scholar] [CrossRef] [PubMed]

- Kiefer, J.; Staudenmaier, R. Combined Aesthetic and Functional Reconstruction of Ear Malformations. In Advances in Oto-Rhino-Laryngology, Aesthetics and Functionality in Ear Reconstruction; Staudenmaier, R., Ed.; S. Karger AG: Basel, Switzerland, 2010; pp. 81–94. [Google Scholar]

- Younis, I.; Gault, D.; Sabbagh, W.; Kang, N.V. Patient satisfaction and aesthetic outcomes after ear reconstruction with a branemark-type, bone-anchored, ear prosthesis: A 16 year review. J. Plast. Reconstr. Aesthet. Surg. 2010, 63, 1650–1655. [Google Scholar] [CrossRef] [PubMed]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D printed bionic ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef] [PubMed]

- Edwars, C.; Marks, R. Evaluation of biomechanical properties of human skin. Clin. Dermatol. 1995, 13, 375–380. [Google Scholar] [CrossRef]

- Pailler-Mattei, C.; Bec, S.; Zahouani, H. In vivo measurements of the elastic mechanical properties of human skin by indentation tests. Med. Eng. Phys. 2008, 30, 599–606. [Google Scholar] [CrossRef] [PubMed]

- Laroche, G.; Marois, Y.; Guidoin, R.; King, M.W.; Martin, L.; How, T.; Douville, Y. Polyvinylidene fluoride (PVDF) as a biomaterial—From polymeric raw-material to monofilament vascular suture. J. Biomed. Mater. Res. 1995, 29, 1525–1536. [Google Scholar] [CrossRef] [PubMed]

- Bayer, I.S.; Tiwari, M.K.; Megaridis, C.M. Biocompatible poly(vinylidene fluoride)/cyanoacrylate composite coatings with tunable hydrophobicity and bonding strength. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Ahirrao, R.; Gupta, R.; Luthra, R.P.; Chadda, A.J.S.; Sharma, V.; Sarin, S. Silicone auricular prosthesis for a patient with unilateral congenital microtia: A case report. Int. J. Sci. Stud. 2015, 2, 19–21. [Google Scholar]

- Lee, J.S.; Hong, J.M.; Jung, J.W.; Shim, J.H.; Oh, J.H.; Cho, D.W. 3D printing of composite tissue with complex shape applied to ear regeneration. Biofabrication 2014, 6. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X. Patterned piezo-, pyro-, and ferroelectricity of poled polymer electrets. J. Appl. Phys. 2010, 108. [Google Scholar] [CrossRef]

- Klinge, U.; Klosterhalfen, B.; Ottinger, A.P.; Junge, K.; Schumpelick, V. PVDF as a new polymer for the construction of surgical meshes. Biomaterials 2002, 23, 3487–3493. [Google Scholar] [CrossRef]

| Extruder Temperature | 170 °C |

|---|---|

| Raft temperature | 190 °C |

| Printing speed | 15 mm3/s |

| Infill | 40% |

| Number of shells | 3 |

| Material | Properties |

|---|---|

| PVDF | Fairly flexible Not toxic Withstands temperatures up to 90 °C Used as a temperature sensor Used as a pressure sensor Humidity resistant If adjustments are necessary, they are performed only by software |

| Silicon | Totally flexible Not toxic Withstands temperatures up to 250 °C It is not a sensor Humidity resistant If adjustments are necessary, you have to make a new mold |

| Composite Tissue | Not flexible Not toxic Withstands temperatures up to 80 °C It is not a sensor If adjustments are necessary, they are performed only by software |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suaste-Gómez, E.; Rodríguez-Roldán, G.; Reyes-Cruz, H.; Terán-Jiménez, O. Developing an Ear Prosthesis Fabricated in Polyvinylidene Fluoride by a 3D Printer with Sensory Intrinsic Properties of Pressure and Temperature. Sensors 2016, 16, 332. https://doi.org/10.3390/s16030332

Suaste-Gómez E, Rodríguez-Roldán G, Reyes-Cruz H, Terán-Jiménez O. Developing an Ear Prosthesis Fabricated in Polyvinylidene Fluoride by a 3D Printer with Sensory Intrinsic Properties of Pressure and Temperature. Sensors. 2016; 16(3):332. https://doi.org/10.3390/s16030332

Chicago/Turabian StyleSuaste-Gómez, Ernesto, Grissel Rodríguez-Roldán, Héctor Reyes-Cruz, and Omar Terán-Jiménez. 2016. "Developing an Ear Prosthesis Fabricated in Polyvinylidene Fluoride by a 3D Printer with Sensory Intrinsic Properties of Pressure and Temperature" Sensors 16, no. 3: 332. https://doi.org/10.3390/s16030332

APA StyleSuaste-Gómez, E., Rodríguez-Roldán, G., Reyes-Cruz, H., & Terán-Jiménez, O. (2016). Developing an Ear Prosthesis Fabricated in Polyvinylidene Fluoride by a 3D Printer with Sensory Intrinsic Properties of Pressure and Temperature. Sensors, 16(3), 332. https://doi.org/10.3390/s16030332