Design and Sensitivity Analysis Simulation of a Novel 3D Force Sensor Based on a Parallel Mechanism

Abstract

:1. Introduction

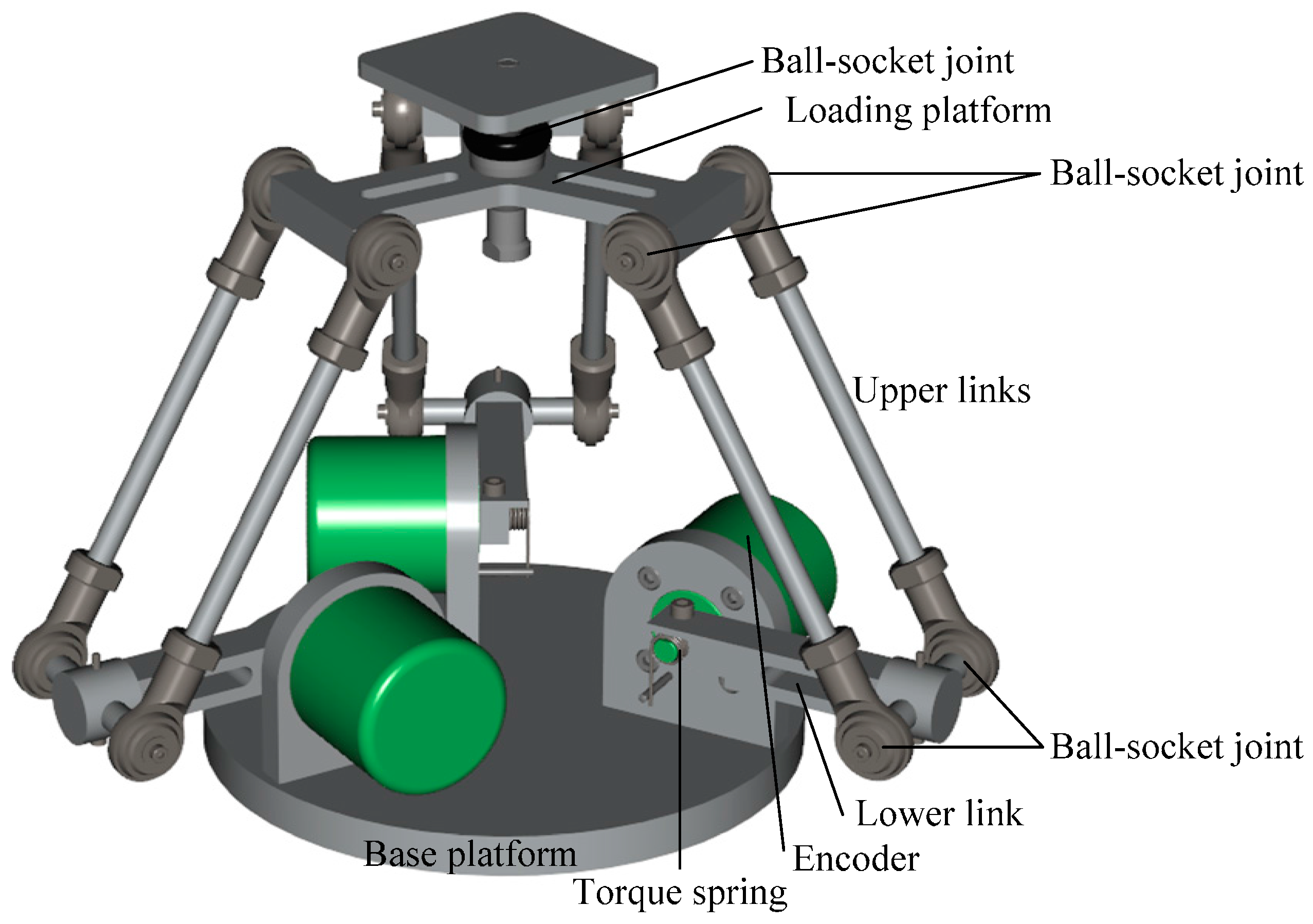

2. Mechanism of 3D Force Sensor

3. Transformation Function and Sensitivity Index

4. Simulation Results and Discussion

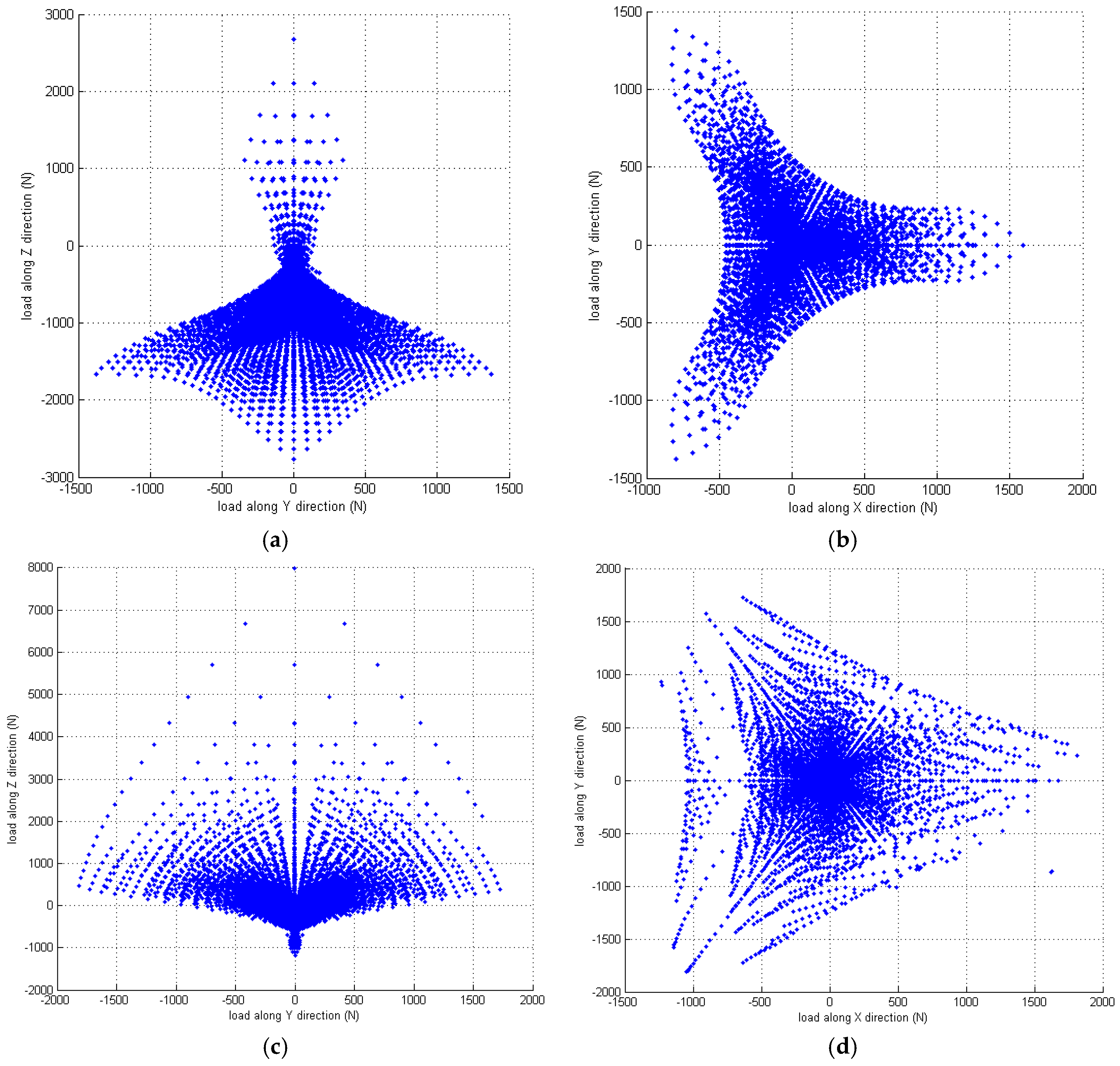

4.1. Effective Measuring Capability

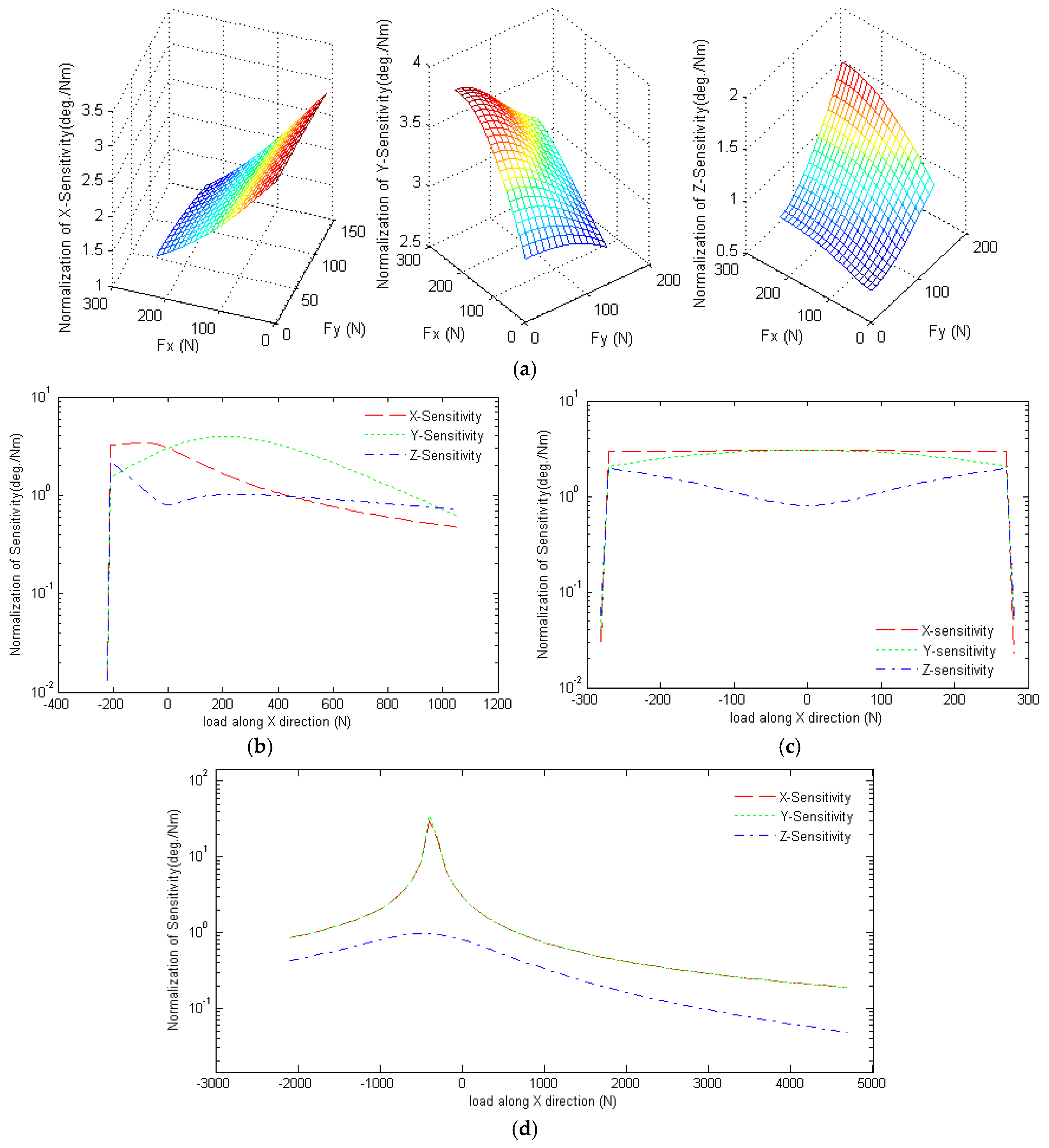

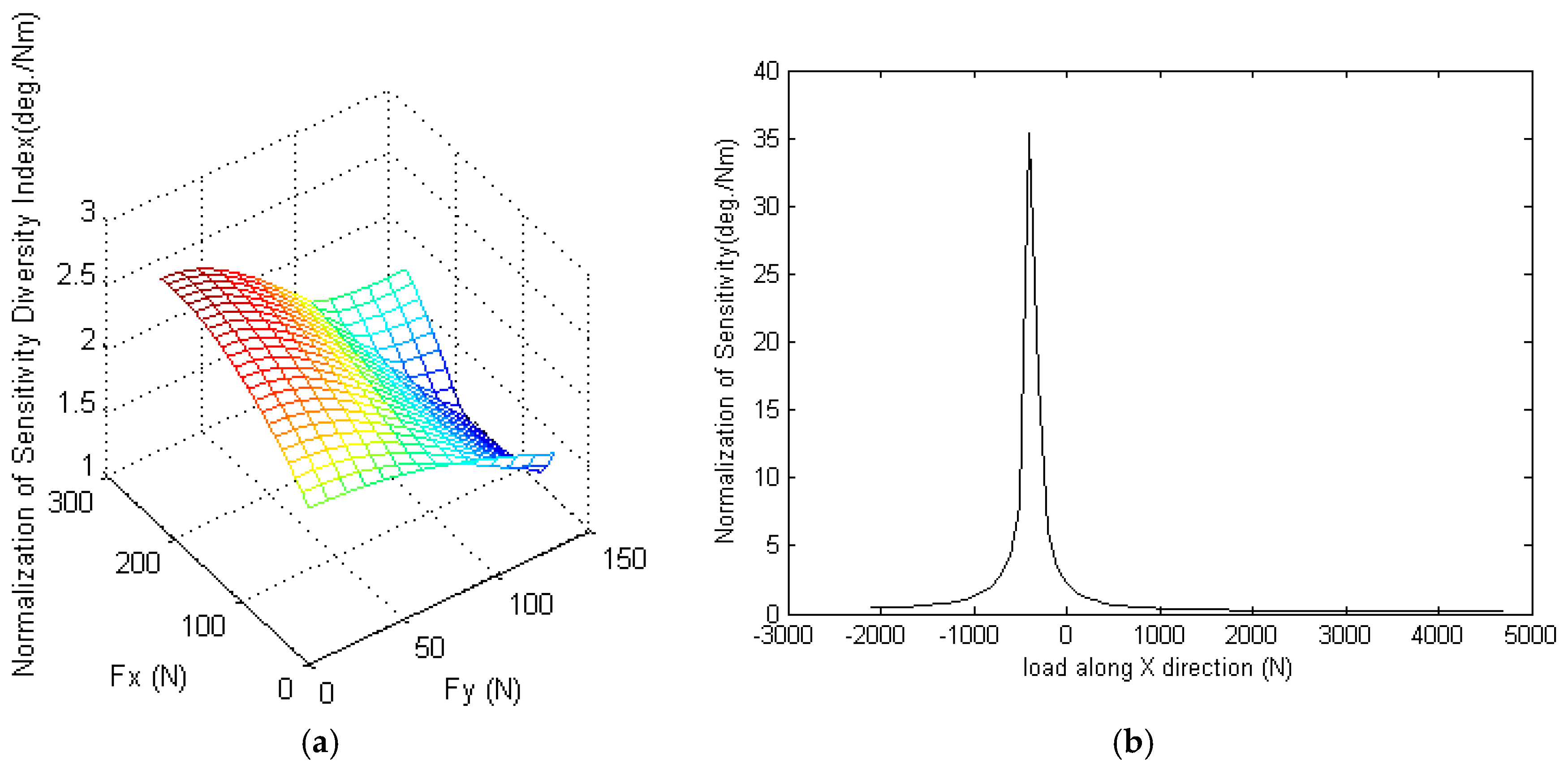

4.2. Sensitivity and Sensitivity Diversity Index

4.3. Design Variable Analysis

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Wei, Y.; Xu, Q. An overview of micro-force sensing techniques. Sens. Actuators A Phys. 2015, 234, 359–374. [Google Scholar] [CrossRef]

- Li, Y.-J.; Zhang, J.; Jia, Z.-Y.; Qian, M.; Li, H. Research on force-sensing element’s spatial arrangement of piezoelectric six-component force/torque sensor. Mech. Syst. Signal Process. 2009, 23, 2687–2698. [Google Scholar] [CrossRef]

- Noda, K.; Matsumoto, K.; Shimoyama, I. Stretchable tri-axis force sensor using conductive liquid. Sens. Actuators A Phys. 2014, 215, 123–129. [Google Scholar] [CrossRef]

- Vázsonyi, É.; Ádám, M.; Dücső, Cs.; Vízváry, Z.; Tóth, A.L.; Bársony, I. Three-dimensional force sensor by novel alkaline etching technique. Sens. Actuators A Phys. 2005, 123, 620–626. [Google Scholar] [CrossRef]

- Sieber, A.; Valdastri, P.; Houston, K.; Eder, C.; Tonet, O.; Menciassi, A.; Dario, P. A novel haptic platform for real time bilateral biomanipulation with a MEMS sensor for triaxial force feedback. Sens. Actuators A Phys. 2008, 142, 19–27. [Google Scholar] [CrossRef]

- Cappelleri, D.J.; Pizaaz, G.; Kumar, V. A two dimensional vision-based force sensor for microrobotic applications. Sens. Actuators A Phys. 2011, 171, 340–351. [Google Scholar] [CrossRef]

- Kim, G.-S. Development of a three-axis gripper force sensor and the intelligent gripper using it. Sens. Actuators A Phys. 2007, 137, 213–222. [Google Scholar] [CrossRef]

- Gaillet, C.R. An isostatic six componenet force and torque sensor. In Proceedings of the 13th International Symposium on Industrial Robots, Chicago, IL, USA, 17–21 April 1983.

- Kerr, D.R. Analysis, properties and design of a Stewart-platform transducer. J. Mech. Transm. Autom. Des. 1989, 111, 25–28. [Google Scholar] [CrossRef]

- Nguyen, C.C.; Antrazi, S.S.; Zhou, Z.L.; Campbell, C.E. Analysis and experimentation of a Stewart platform-based force/torque sensor. Int. J. Robot. Autom. 1992, 7, 133–140. [Google Scholar]

- Ferraresi, C.; Pastorelli, S.; Sorli, N.; Zhmud, M. State and dynamic behavior of a high stiffness Stewart platform-based force/torque sensor. J. Robot. Syst. 1995, 12, 883–893. [Google Scholar] [CrossRef]

- Sorli, M.; Pastorelli, S. Six-axis reticulated structure force/torque sensor with adaptable performances. Mechatronics 1995, 5, 585–601. [Google Scholar] [CrossRef]

- Dai, J.S.; Kerr, D.R. A six-component contact force measurement device based on the Stewart platform. J. Mech. Eng. Sci. 2000, 214, 687–697. [Google Scholar] [CrossRef]

- Dwarakanath, T.A.; Dasgupta, B.; Mruthyunjaya, T.S. Design and development of a Stewart platform based force-torque sensor. Mechatronics 2001, 11, 793–809. [Google Scholar] [CrossRef]

- Kang, C.-G. Closed-form force sensing of a 6-axis force transducer based on the Stewart platform. Sens. Actuators A Phys. 2001, 90, 31–37. [Google Scholar] [CrossRef]

- Jia, Z.-Y.; Lin, S.; Liu, W. Measurement method of six-axis load sharing based on the Stewart platform. Measurement 2010, 43, 329–335. [Google Scholar] [CrossRef]

- Dwarakanath, T.A.; Venkatesh, D. Simply supported, ‘Joint less’ parallel mechanism based force-torque sensor. Mechatronics 2006, 16, 565–575. [Google Scholar] [CrossRef]

- Ranganath, R.; Nair, P.S.; Mruthyunjaya, T.S.; Ghosal, A. A force-torque sensor based on a Stewart platform in a near-singular configuration. Mech. Mach. Theory 2004, 39, 971–998. [Google Scholar] [CrossRef]

- Liu, S.A.; Tzo, H.L. A novel six-component force sensor of good measurement isotropy and sensitivities. Sens. Actuators A Phys. 2002, 100, 223–230. [Google Scholar] [CrossRef]

- Yao, J.T.; Hou, Y.L.; Chen, J.; Lu, L.; Zhao, Y.S. Theoretical analysis and experiment research of a statically indeterminate pre-stressed six-axis force sensor. Sens. Actuators A Phys. 2009, 150, 1–11. [Google Scholar] [CrossRef]

- Yao, J.T.; Hou, Y.L.; Wang, H.; Zhou, T.L.; Zhao, Y.S. Spatially isotropic configuration of Stewart platform-based force sensor. Mech. Mach. Theory 2011, 46, 142–155. [Google Scholar] [CrossRef]

- Yao, J.T.; Cai, D.; Zhang, H.; Wang, H.; Wu, D.; Zhao, Y.S. Task-oriented design method and research on force compliant experiment of six-axis wrist force sensor. Mechatronics 2016, 35, 109–121. [Google Scholar] [CrossRef]

- Liang, Q.; Wang, Y. Flexible ankle based on PKM with force/torque sensor for humanoid robot. IJE Trans. B Appl. 2011, 24, 377–385. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y.; Ye, N.; Chen, L. Development of a novel sensor for hybrid hand with three fingers and analysis of its measure performances. Mech. Syst. Signal Process. 2017, 83, 116–129. [Google Scholar] [CrossRef]

- Yang, E.C.-Y. A novel measurement of intersegmental forces exerted on human lower limbs during forward falling and regaining balance motions. Measurement 2015, 60, 114–120. [Google Scholar] [CrossRef]

- González-Madruga, D.; Cuesta, E.; Barreiro, J.; Fernandez-Abia, A.I. Application of a force sensor to improve the reliability of measurement with articulated arm coordinate measuring machines. Sensors 2013, 13, 10430–10448. [Google Scholar] [CrossRef] [PubMed]

- Cuesta, E.; Telenti, A.; Patiño, H.; Gonzalez-Madruga, D.; Martinez-Pellitero, S. Sensor prototype to evaluate the contact force in measuring with coordinate Arms. Sensors 2015, 15, 13242–13257. [Google Scholar] [CrossRef] [PubMed]

- Miller, K. Maximization of Workspace Volume of 3-DOF Spatial Parallel Manipulators. J. Mech. Des. 2002, 124, 347–357. [Google Scholar] [CrossRef]

- Yang, E.C.-Y.; Yen, M.-H. Loading Deflection of a Delta-Type Parallel Robot Considered Link Flexibility and Joint Clearance. In Proceedings of the Annual Conference on Engineering & Information Technology (ACEAIT 2014), Tokyo, Japan, 28–30 March 2014.

- Huang, Z.-J.; Chou, M.-T.; Yang, E.C.-Y. Loading Deflection Optimization of Delta Robot. In Proceedings of the 10th International Symposium on Advanced Science and Technology in Experimental Mechanics, Matsue, Japan, 1–3 November 2015.

- Tannous, M.; Caro, S.; Goldsztejn, A. Sensitivity analysis of parallel manipulators using an interval linearization method. Mech. Mach. Theory 2014, 71, 93–114. [Google Scholar] [CrossRef] [Green Version]

| Stiffness Coefficient | Horizontal Force | Vertical Force | ||||

|---|---|---|---|---|---|---|

| νx, max | νy, max | νz, max | νx, max | νy, max | νz, max | |

| 0.3 (Nm/deg) | 0.426 | 0.427 | 0.274 | 1.559 | 1.614 | 0.136 |

| 0.7 (Nm/deg) | 0.181 | 0.182 | 0.120 | 1.809 | 2.132 | 0.058 |

| 1.5 (Nm/deg) | 0.080 | 0.084 | 0.057 | 2.501 | 3.720 | 0.027 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, E.C.-Y. Design and Sensitivity Analysis Simulation of a Novel 3D Force Sensor Based on a Parallel Mechanism. Sensors 2016, 16, 2147. https://doi.org/10.3390/s16122147

Yang EC-Y. Design and Sensitivity Analysis Simulation of a Novel 3D Force Sensor Based on a Parallel Mechanism. Sensors. 2016; 16(12):2147. https://doi.org/10.3390/s16122147

Chicago/Turabian StyleYang, Eileen Chih-Ying. 2016. "Design and Sensitivity Analysis Simulation of a Novel 3D Force Sensor Based on a Parallel Mechanism" Sensors 16, no. 12: 2147. https://doi.org/10.3390/s16122147