A Laser-Based Measuring System for Online Quality Control of Car Engine Block

Abstract

:1. Introduction

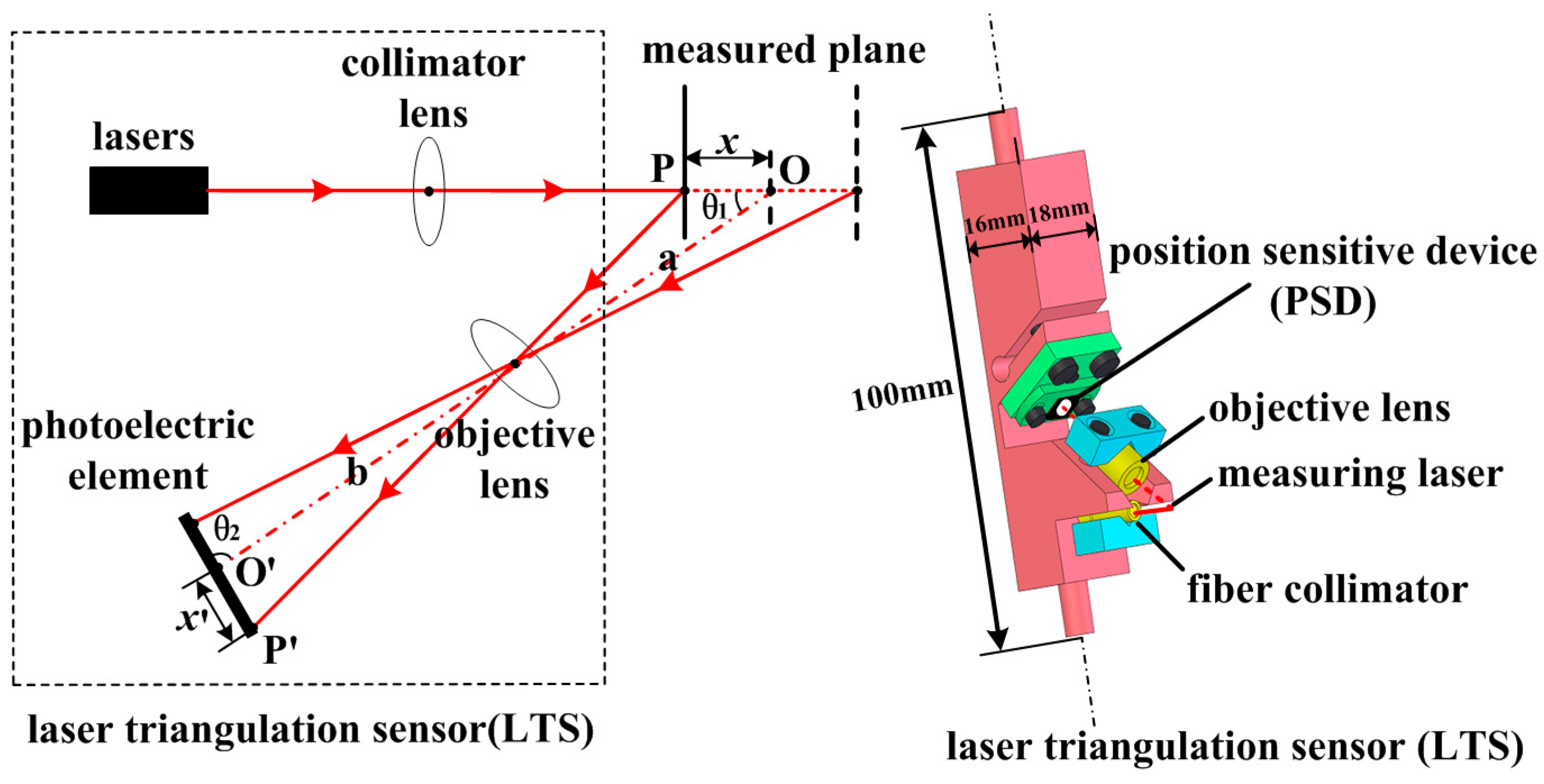

2. Measuring Principle of Laser Triangulation Sensor

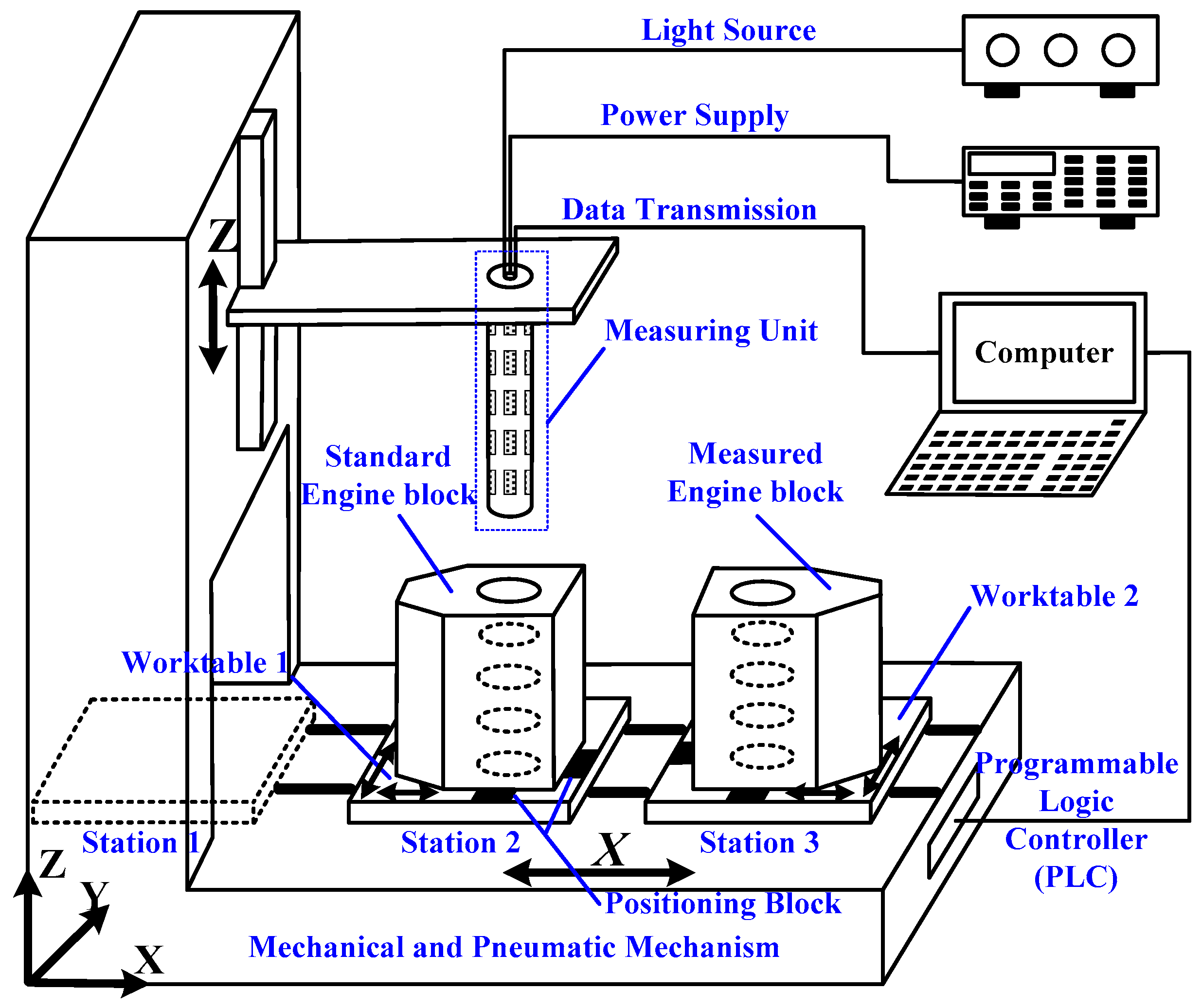

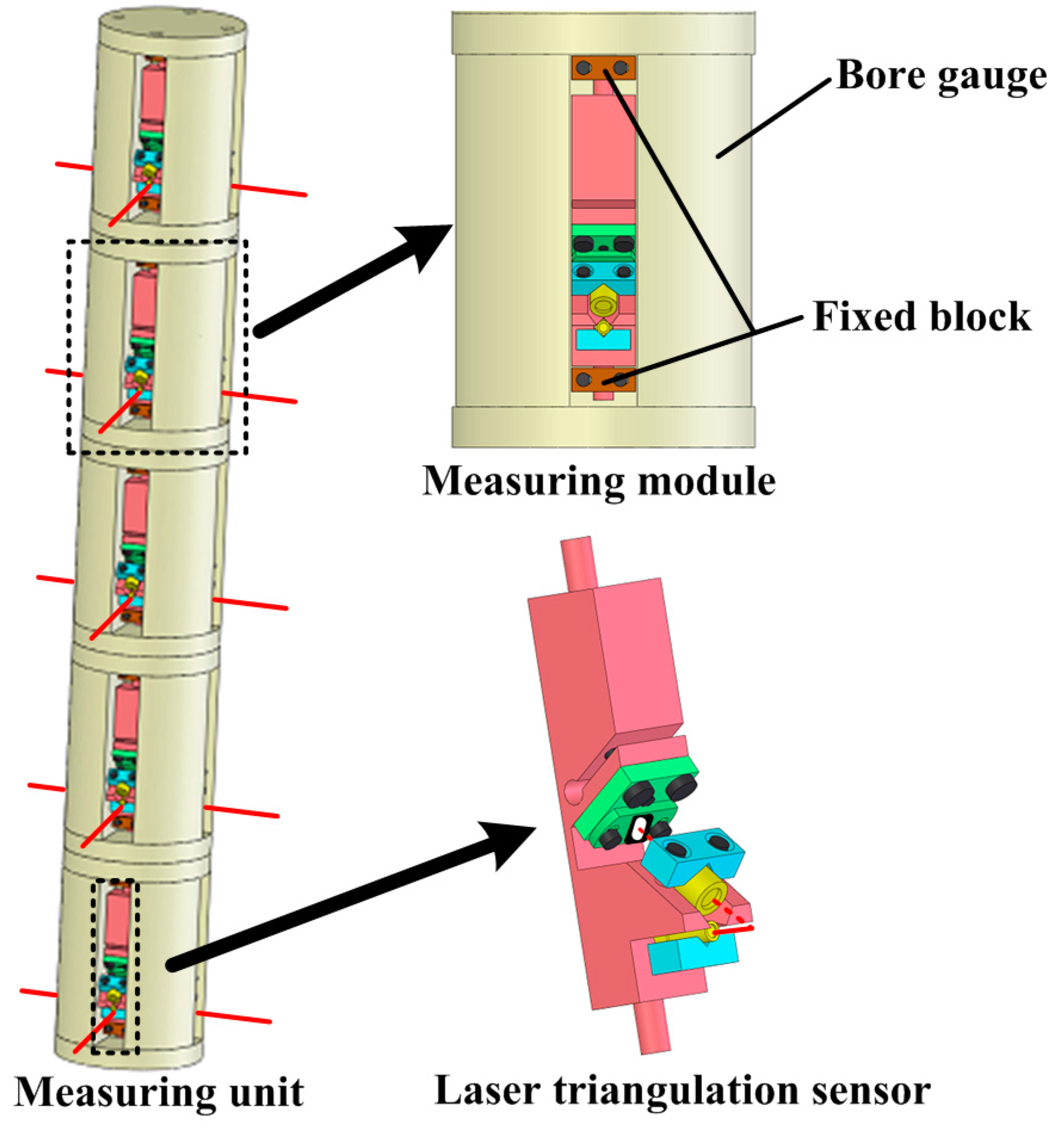

3. System Configuration

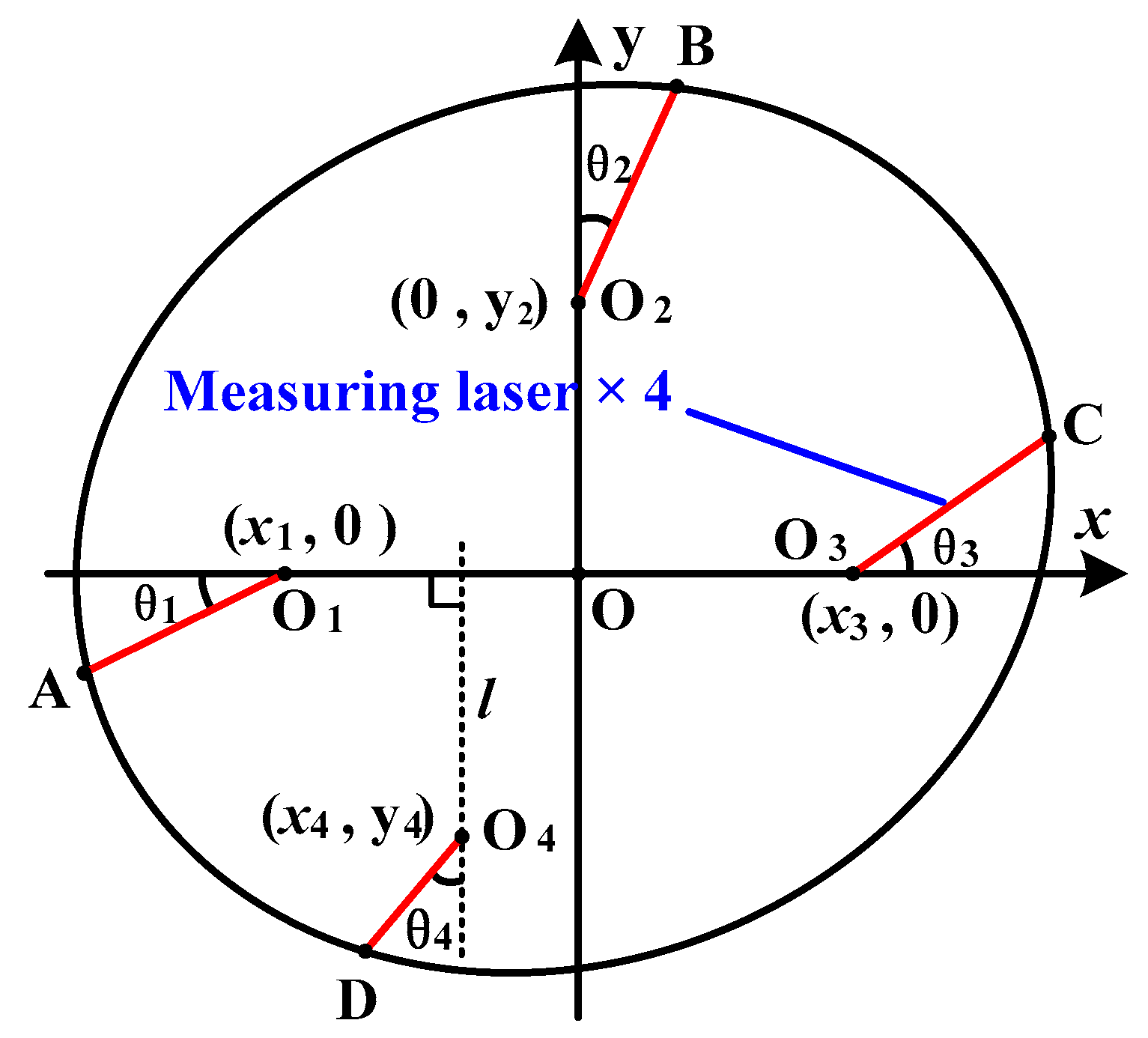

4. Mathematical Model and Data Processing Algorithm

4.1. Mathematical Model

4.2. Data Processing Algorithm

- (1)

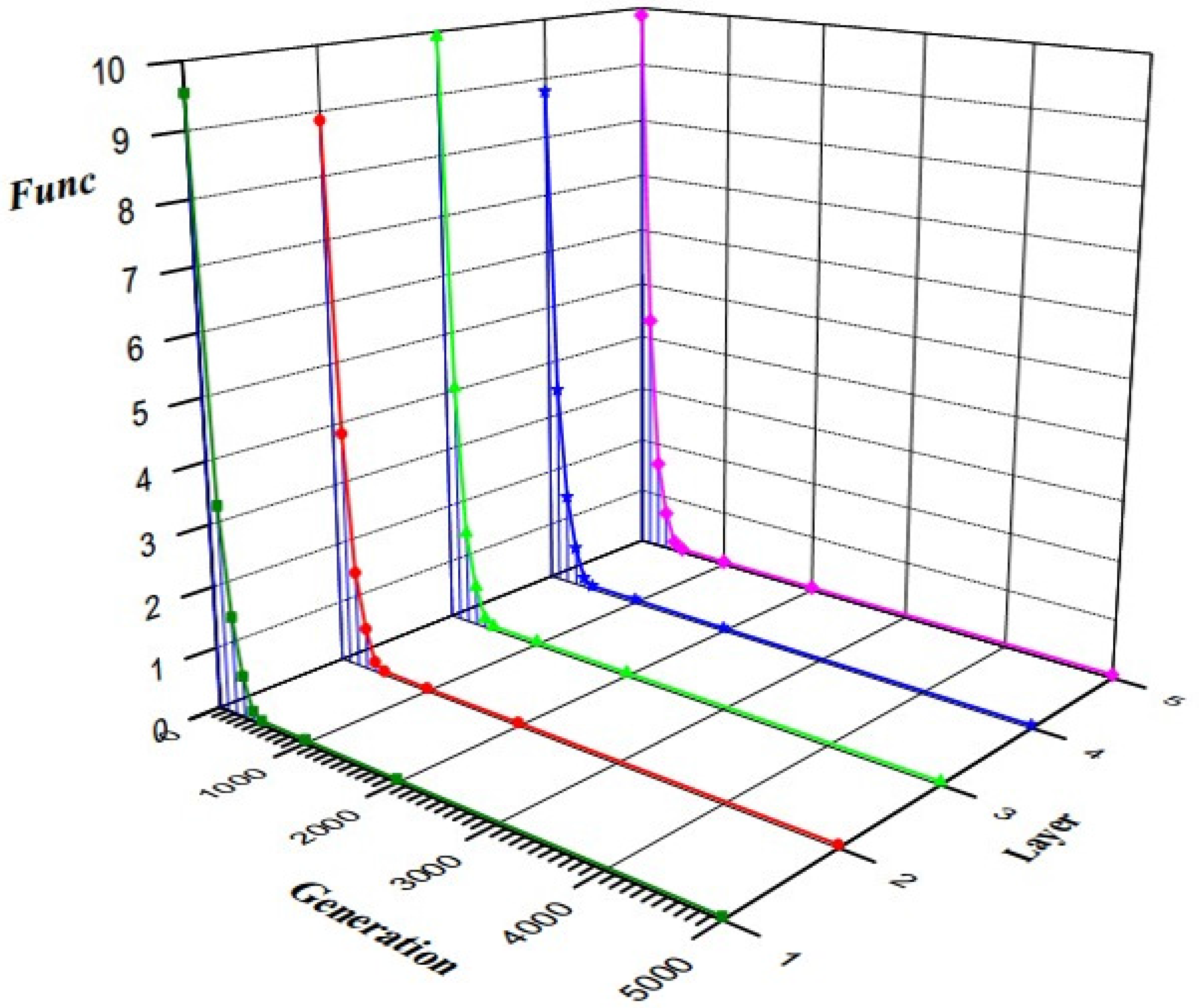

- Initializationxi,G is an D-dimensional individual, which is defined as:where G represents the number of generations, and Np is the number of individuals. The initial value of G is given as 0. The initial population which contains Np D-dimensional individuals, is generated through Equation (15):where and are, respectively, the lower and upper limits of the jth variable of the individual, rand(0, 1) is a random number, which ranges from 0 to 1, under uniform distribution. In this paper, the value of D is 10. {,…,}, respectively, correspond to the intrinsic parameters {x1, y2, x3, x4, y4, θ1, θ2, θ3, θ4, γ}. Considering the system design and the actual errors caused by machining and installation, the intrinsic parameters follows the constraint in Equation (16). The population size Np is usually defined as 10·D. To further improve the accuracy of parameter estimation, the population size Np is given as 1000 here.

- (2)

- MutationThe mutation vector vi,G is generated through Equation (17):where xpbest,G represents one of the top 100·p% individuals in current population, Fi denotes the mutation factor that varies with the make-up of population, and r1 and r2 are random numbers chosen from 1 to Np. The value of p is given as 0.1. Fi is determined by the following equation:where Fi is generated in accordance with Cauchy distribution, meanL(∙) is the Lehmer mean, and SF is the set of all successful mutation factors in current population. The initial value of μF is given as 0.5, and the value of c is given as 0.1 here.

- (3)

- CrossoverThe exponential crossover operation is selected as the crossover strategy because this strategy usually has a good performance in nonlinear optimization. The trial vector is defined as:where jrand is a random number within the range [1, D], and Rj is a uniform random number in the range of [0, 1]. Cri is expressed as the equation below:where Cri is generated according to the normal distribution, meanA(∙) is the usual arithmetic mean, and SCr is the set of all successful crossover factors in current population. The initial value of μCr is given as 0.5.

- (4)

- SelectionThe offspring is defined as below:

- (5)

- Termination conditionG = G + 1. (The generation number G increases by one.)Repeat Steps 2–5 until the value of Func no longer decreases in the last 100 generations.

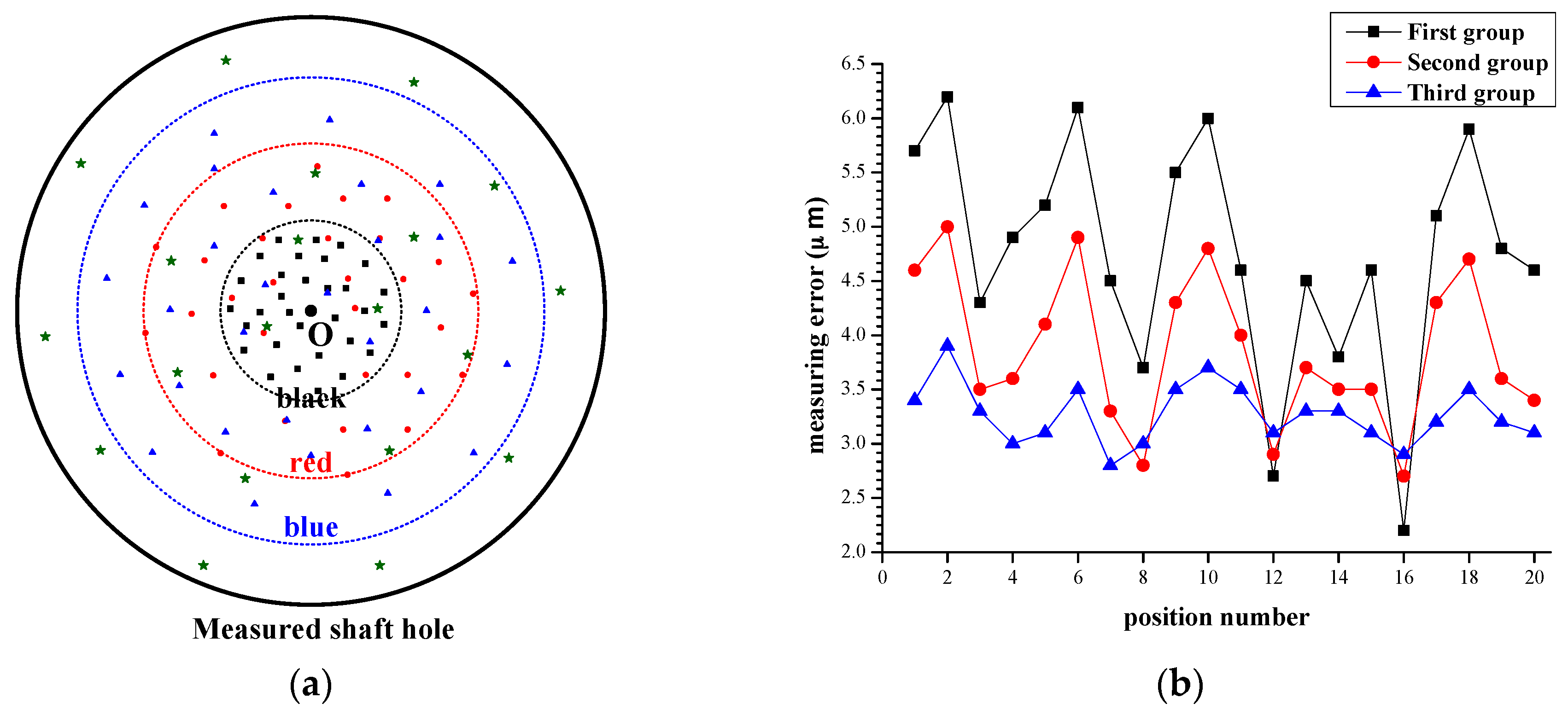

5. Experiments and Discussion

- (1)

- The measured engine block on production line is transported to proposed measuring system and finally located at Station 3.

- (2)

- Measured engine block is transported from Station 3 to Station 2 by double-acting cylinders.

- (3)

- The measuring unit moves down through the measured shaft holes. Data samples collected by the measuring unit are then transmitted to data processing system on RS-485 bus.

- (4)

- The measuring results are finally computed by data processing system.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shi, Y.; Sun, C.; Wang, P.; Wang, Z.; Duan, H. High-Speed measurement algorithm for the position of holes in a large plane. Opt. Laser Eng. 2012, 50, 1828–1835. [Google Scholar] [CrossRef]

- Gromczak, K.; Gąska, A.; Ostrowska, K.; Sładek, J.; Harmatys, W.; Gaska, P.; Gruza, M.; Kowalski, M. Validation model for coordinate measuring methods based on the concept of statistical consistency control. Precis. Eng. 2012, 45, 414–422. [Google Scholar] [CrossRef]

- Cuesta, E.; Telenti, A.; Patiño, H.; González-Madruga, D.; Martínez-Pellitero, S. Sensor prototype to evaluate the contact force in measuring with coordinate measuring arms. Sensors 2015, 15, 13242–13257. [Google Scholar] [CrossRef] [PubMed]

- Mansour, G. A developed algorithm for simulation of blades to reduce the measurement points and time on coordinate measuring machine (CMM). Measurement 2014, 54, 51–57. [Google Scholar] [CrossRef]

- Marposs, “Hand Held Gauges”. Available online: http://www.marposs.com/product_line.php/eng/hand_held_gauges (accessed on 30 April 2000).

- Dell’Era, G.; Mersinligil, M.; Brouckaert, J.F. Assessment of Unsteady Pressure Measurement Uncertainty—Part I: Single Sensor Probe. ASME J. Eng. Gas. Turbines Power 2016, 138, 041601. [Google Scholar] [CrossRef]

- Dell’Era, G.; Mersinligil, M.; Brouckaert, J.F. Assessment of Unsteady Pressure Measurement Uncertainty—Part II: Virtual Three-Hole Probe. ASME J. Eng. Gas. Turbines Power 2016, 138, 041602. [Google Scholar] [CrossRef]

- Peiner, E.; Balke, M.; Doering, L. Slender tactile sensor for contour and roughness measurements within deep and narrow holes. IEEE Sens. J. 2008, 8, 1960–1967. [Google Scholar] [CrossRef]

- Alblalaihid, K.; Kinnell, P.; Lawes, S.; Desgaches, D.; Leach, R. Performance assessment of a new variable stiffness probing system for micro-CMMs. Sensors 2016, 16, 492. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, J.; Feng, K.; Hu, Y.; Li, J.; Tan, J. A twin fiber Bragg grating probe for the dimensional measurement of microholes. IEEE Photonics Technol. Lett. 2014, 26, 1778–1781. [Google Scholar]

- Kulkarni, O.P.; Islam, M.N.; Terry, F.L. Optical probe for porosity defect detection on inner diameter surfaces of machined bores. Opt. Eng. 2010, 49, 123606. [Google Scholar] [CrossRef]

- Tong, Q.B.; Jiao, C.Q.; Huang, H.; Li, G.B.; Ding, Z.L.; Yuan, F. An automatic measuring method and system using laser triangulation scanning for the parameters of a screw thread. Meas. Sci. Technol. 2014, 25, 035202. [Google Scholar] [CrossRef]

- Schwenke, H.; Schmitt, R.; Jatzkowski, P.; Warmann, C. On-the-fly calibration of linear and rotary axes of machine tools and CMMs using a tracking interferometer. CIRP Ann. Manuf. Technol. 2009, 58, 477–480. [Google Scholar] [CrossRef]

- Lee, J.; Gao, W.; Shimizu, Y.; Hwang, J.; Oh, J.S.; Park, C.H. Spindle error motion measurement of a large precision roll lathe. Int. J. Precis. Eng. Manuf. 2012, 13, 861–867. [Google Scholar] [CrossRef]

- Zavyalov, P. 3D Hole Inspection Using Lens with High Field Curvature. Meas. Sci. Rev. 2015, 15, 52–57. [Google Scholar] [CrossRef]

- Kondo, Y.; Hasegawa, K.; Kawamata, H.; Morishita, T.; Naito, F. On-Machine non-contact dimension-measurement system with laser displacement sensor for vane-tip machining of RFQs. Nucl. Instrum. Methods Phys. Res. Sect. A 2012, 667, 5–10. [Google Scholar] [CrossRef]

- Jeong, H.J.; Yoo, H.; Gweon, D. High-Speed 3-D measurement with a large field of view based on direct-view confocal microscope with an electrically tunable lens. Opt. Express 2016, 24, 3806–3816. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, F.; Qu, X.; Liang, B. Fast measurement and reconstruction of large workpieces with freeform surfaces by combining local scanning and global position data. Sensors 2015, 15, 14328–14344. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Qu, X.; Ouyang, J. An automated inner dimensional measurement system based on a laser displacement sensor for long-stepped pipes. Sensors 2012, 12, 5824–5834. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.N.; Zareie, S.; Alam, M.S.; Seethaler, R.J. Novel Method for Interstory Drift Measurement of Building Frames Using Laser-Displacement Sensors. J. Struc. Eng. 2016, 142, 06016001. [Google Scholar] [CrossRef]

- Boltryk, P.J.; Hill, M.; McBride, J.W.; Nasce, A. A comparison of precision optical displacement sensors for the 3D measurement of complex surface profiles. Sens. Actuators A 2008, 142, 2–11. [Google Scholar] [CrossRef]

- Bae, Y. An Improved Measurement Method for the Strength of Radiation of Reflective Beam in an Industrial Optical Sensor Based on Laser Displacement Meter. Sensors 2016, 16, 752. [Google Scholar] [CrossRef] [PubMed]

- Miks, A.; Novak, J.; Novak, P. Analysis of imaging for laser triangulation sensors under Scheimpflug rule. Opt. Express 2013, 21, 18225–18235. [Google Scholar] [CrossRef] [PubMed]

- Martinez, S.; Cuesta, E.; Barreiro, J.; Alvarez, B. Analysis of laser scanning and strategies for dimensional and geometrical control. Int. J. Adv. Manuf. Technol. 2010, 46, 621–629. [Google Scholar] [CrossRef]

- Stewart, J. Parametric Equations and Polar Coordinates. In Calculus, 7th ed.; Covello, L., Neustaetter, L., Staller, J., Ross, M., Eds.; Brooks/Cole: Belmont, CA, USA, 2010; Volume 10, pp. 670–687. [Google Scholar]

- Zhang, J.; Sanderson, A.C. JADE: Adaptive differential evolution with optional external archive. IEEE Trans. Evol. Comput. 2009, 13, 945–958. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution—A simple and efficient adaptive scheme for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

| Layer | The Intrinsic Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| x1 | y2 | x3 | x4 | y4 | θ1 | θ2 | θ3 | θ4 | γ | |

| 1 | 44.5671 | 44.5723 | 44.5713 | −0.1327 | −44.6198 | 0.1337 | 0.6959 | 1.2318 | 0.5715 | 0.3753 |

| 2 | 44.7193 | 44.6717 | 44.9979 | 0.3336 | −44.2274 | 1.2836 | 0.9078 | 1.1764 | 0.3842 | 0.3755 |

| 3 | 44.6228 | 44.6034 | 44.6315 | 0.2098 | −44.3536 | 0.7832 | 0.7344 | 1.3335 | 1.7318 | 0.3751 |

| 4 | 44.5234 | 44.5171 | 44.5297 | −0.1373 | −44.5475 | 0.0595 | 0.5375 | 1.5518 | 1.6273 | 0.3751 |

| 5 | 44.6866 | 44.6255 | 44.9436 | 0.3091 | −44.8171 | 0.9061 | 0.8224 | 0.5942 | 0.8619 | 0.3753 |

| Layer | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Average Value | Standard Deviation | Standard Value |

|---|---|---|---|---|---|---|---|---|

| 1 | 91.9972 | 92.0010 | 91.9969 | 91.9993 | 91.9966 | 91.9982 | 0.0019 | 91.9997 |

| 2 | 91.9989 | 91.9989 | 92.0002 | 91.9997 | 92.0018 | 91.9999 | 0.0012 | 92.0011 |

| 3 | 91.9972 | 92.0013 | 91.9979 | 91.9981 | 91.9970 | 91.9983 | 0.0017 | 91.9999 |

| 4 | 91.9921 | 91.9946 | 91.9928 | 91.9959 | 91.9921 | 91.9935 | 0.0017 | 91.9947 |

| 5 | 92.0002 | 92.0009 | 92.0011 | 92.0028 | 92.0035 | 92.0017 | 0.0014 | 92.0026 |

| Layer | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Average Value | Standard Deviation | Standard Value |

|---|---|---|---|---|---|---|---|---|

| 1 | 91.9931 | 91.9952 | 91.9962 | 91.9934 | 91.9956 | 91.9947 | 0.0014 | 91.9959 |

| 2 | 92.0048 | 92.0057 | 92.0061 | 92.0049 | 92.0075 | 92.0058 | 0.0011 | 92.0070 |

| 3 | 91.9975 | 91.9991 | 92.0018 | 91.9985 | 92.0006 | 91.9995 | 0.0017 | 91.9984 |

| 4 | 91.9962 | 91.9966 | 91.9976 | 91.9983 | 91.9983 | 91.9974 | 0.0010 | 91.9960 |

| 5 | 91.9993 | 91.9985 | 92.0004 | 91.9986 | 92.0012 | 91.9996 | 0.0012 | 91.9984 |

| Layer | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Average Value | Standard Deviation | Standard Value |

|---|---|---|---|---|---|---|---|---|

| 1 | 91.9956 | 91.9964 | 91.9977 | 91.9982 | 91.9956 | 91.9967 | 0.0012 | 91.9973 |

| 2 | 92.0035 | 92.0038 | 92.0047 | 92.0048 | 92.0037 | 92.0041 | 0.0006 | 92.0053 |

| 3 | 91.9958 | 91.9985 | 91.9961 | 91.9965 | 91.9971 | 91.9968 | 0.0011 | 91.9981 |

| 4 | 91.9948 | 91.9948 | 91.9972 | 91.9976 | 91.9966 | 91.9962 | 0.0013 | 91.9958 |

| 5 | 91.9978 | 92.0013 | 91.9982 | 91.9999 | 92.0008 | 91.9996 | 0.0016 | 92.0007 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.-Q.; Wang, Z.; Fu, L.-H. A Laser-Based Measuring System for Online Quality Control of Car Engine Block. Sensors 2016, 16, 1877. https://doi.org/10.3390/s16111877

Li X-Q, Wang Z, Fu L-H. A Laser-Based Measuring System for Online Quality Control of Car Engine Block. Sensors. 2016; 16(11):1877. https://doi.org/10.3390/s16111877

Chicago/Turabian StyleLi, Xing-Qiang, Zhong Wang, and Lu-Hua Fu. 2016. "A Laser-Based Measuring System for Online Quality Control of Car Engine Block" Sensors 16, no. 11: 1877. https://doi.org/10.3390/s16111877