2.1. Ideal Response Model of the Two-Electrode EMF

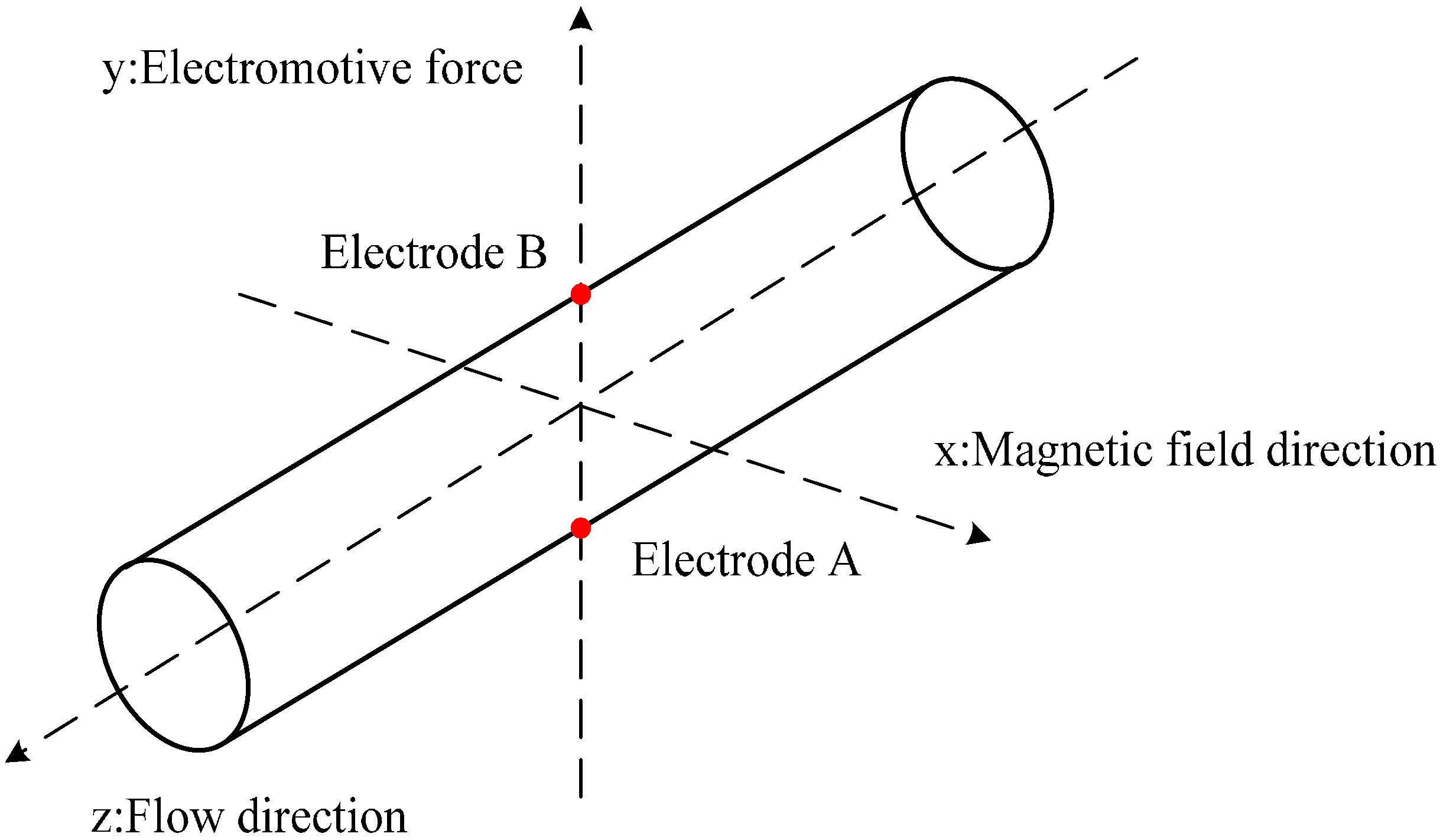

Based on the assumption of a uniform magnetic field and a rectilinear flow, the conventional form of the EMF is shown in

Figure 1. The distribution of the potential

U inside the flowtube of the EMF is described by the following basic equation:

where

v and

B are the velocity vector and the magnetic flux density vector, respectively.

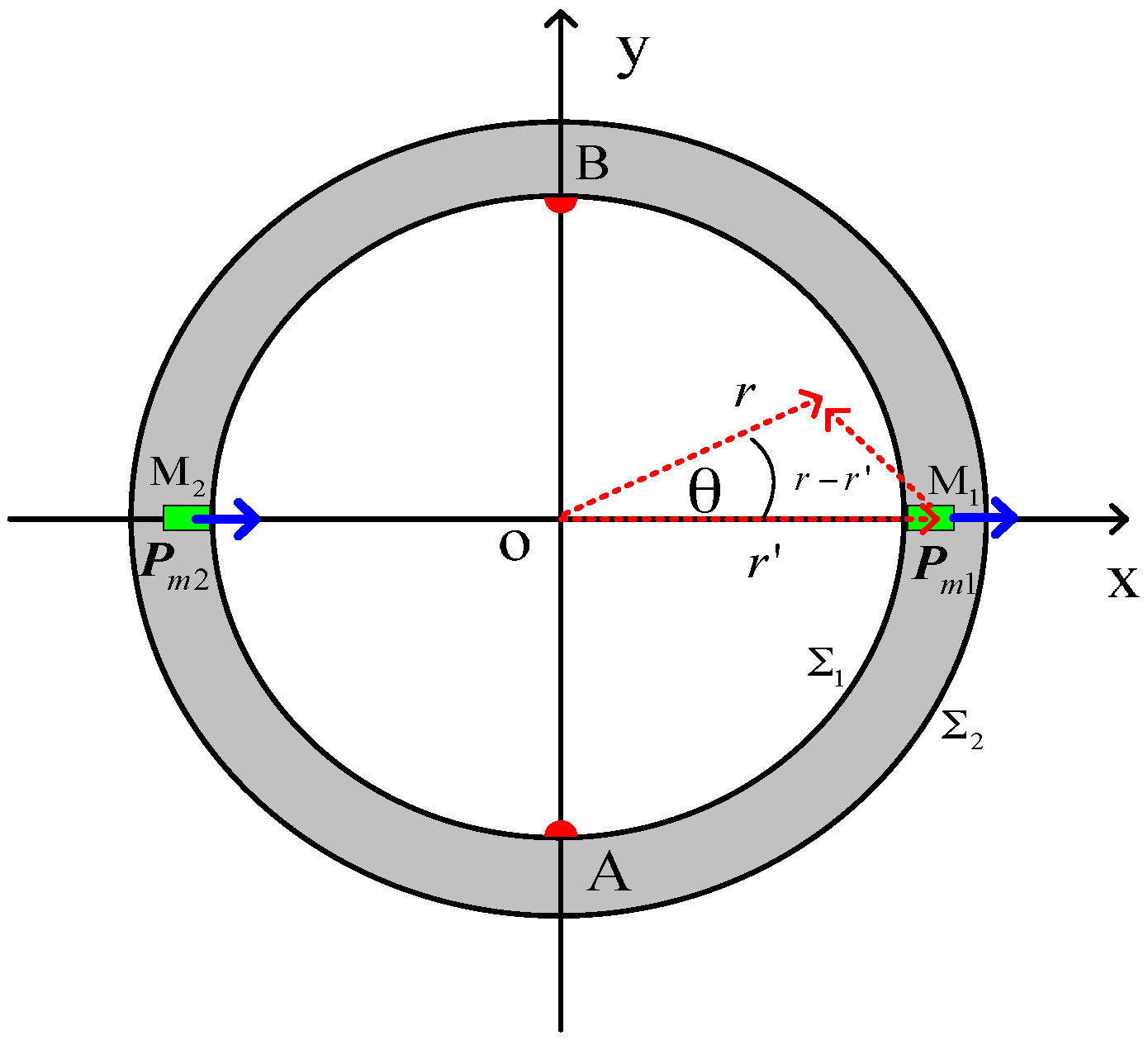

Figure 2 shows a schematic diagram of the downhole inserted two-electrode EMF, A and B represent two electrodes placed on the inner wall at intervals of 180° inside the flowtube,

M1 and

M2 represent two magnetic dipoles inlaid on the wall of the flowtube at intervals of 180°, and

and

represent the inner and outer surfaces of the EMF, respectively.

To simplify the mathematical expressions, we start with the extreme case of a two-dimensional model, for which we give detailed expressions for the solution and discuss the results.

The response equation of the downhole inserted two-electrode EMF can be obtained by solving partial differential Equation (1). Using the Green function

G to solve Equation (1), where

G satisfies Laplace’s equation on the inner surface of the flowmeter:

where

is the gradient operator, and

is the Laplace operator.

The boundary condition on the inner surface of the flowmeter in this situation is given by:

where

n is the normal of the boundary.

That is,

where

S0 is the area of the electrode,

a is the inner radius, and

L is the half-length of the flowmeter.

The identity

is used to solve the internal volume integral of the flowtube, and the volume integral can be transformed into a surface integral using Gauss’ theorem by applying the following equation:

where

F is the arbitrary vector function, d

V is the volume element, dΣ is the boundary area element, and

is the surface integral around the entire boundary.

Substituting Equation (5) into Equation (6) yields

By substituting Equations (1)–(4) into Equation (7), the induced potential difference can be given by:

where

B is the magnetic induction intensity, and

is referred to as the weight function that can be simplified as

W.

Equation (8) is the general formula used to determine the induced potential difference of the downhole inserted two-electrode EMF. In the two-dimensional situation, the induced potential difference can be expressed in polar coordinates as follows:

where

a represents the inner radius of the EMF.

2.2. Weight Function of the Two-Electrode EMF

The weight function W represents the contribution of the fluid velocity to the induced potential difference. In fact, even under the same velocity and magnetic field conditions, given that the distances and orientations between fluid units and electrodes are different in the measurement area, the contribution of the fluid units to the induced potential difference remains different, i.e., W has larger values near the electrodes and vice versa.

To solve the expression of the weight function in the cylindrical coordinate system, we suppose that the electrodes are linear, have the same length as the flowmeter, and possess central angles

, as shown in

Figure 2. For the linear electrodes, suppose

, such that

in Equation (4) can be written as follows:

By using the segregation variable method,

G can be expressed as:

We can easily verify that the formula satisfies Laplace’s equation by substituting Equation (11) into Equation (2). Furthermore, to determine the coefficients , , , and in Equation (11), we employ the solution below.

Suppose

when

and

,

. We derive the special solution of

G:

where the values of

and

are different from those in Equation (11).

The surface

shown in

Figure 2 is the inner surface of the flowmeter that satisfies the following boundary condition:

which can be written as follows:

Multiplying Equation (14) by

and solving the integral in the interval of

:

hence,

Similarly, multiplying Equation (14) by

and solving the integral in the interval of

:

For

, Equation (16) can be simplified as

Substituting Equations (16) and (17) into Equation (13),

G can be written as:

The weight function of the downhole inserted two-electrode EMF in the cylindrical coordinate system can be expressed as follows:

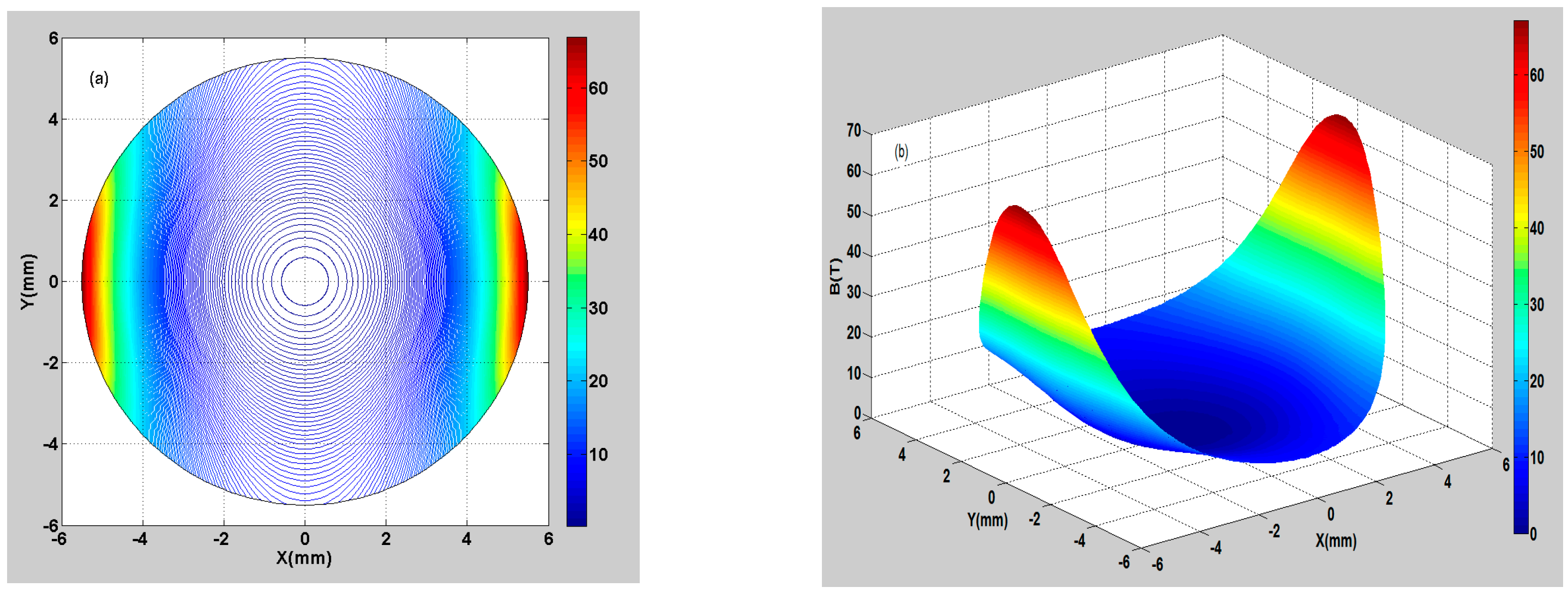

To study the weight function distribution inside the flowtube, this work conducted a numerical calculation on Equation (19), and the results of the numerical calculation were visualized graphically.

Suppose , a = 5.5 mm (a represents the inner radius of the EMF); the calculating step is . Suppose , the calculating step is .

Figure 3a shows the 2D contour plot of the numerical calculation results of the weight function.

Figure 3b shows the 3D surface plot of the numerical calculation results of the weight function. It is found that the maximum value of the weight function is 55.68 from the electrode positions, whereas the minimum value is 0.25 from the magnetic pole positions (the weight function is dimensionless). The color map changes from red to blue, representing a decrease in the weight function. On the whole, the weight function is relatively larger near the electrodes, indicating that the fluid elements in these regions have a great contribution to the potential difference. The weight function is relatively smaller in other regions, indicating that the fluid elements in these regions have a lower contribution to the potential difference.

2.3. Magnetic Field of the Two-Electrode EMF

The magnetic field of the downhole inserted two-electrode EMF is formed by two current-carrying coils. Giving a direct and strict analytical formula of the magnetic induction intensity for the actual coil structure is difficult. Alternatively, the two current-carrying coils are equivalent to two magnetic dipoles, and according to the assumption of column symmetry, the magnetic induction intensity of the magnetic dipoles that is perpendicular to the axial direction can be simplified as a plane distribution.

The magnetic vector potential

A is the superposition generated by the two magnetic dipoles—i.e.,

where

A1 and

A2 are the magnetic vector potentials of the two magnetic dipoles. The magnetic induction of the magnetic dipoles can be expressed as:

To solve the magnetic vector potential distribution of magnetic dipoles in the cylindrical coordinate systems, as shown in

Figure 4, we assume that the two magnetic dipoles are marked as

Pm1 and

Pm2, whereas their coordinates are

and

in the polar coordinate systems, respectively.

Pm1 point in the

r direction, whereas

Pm2 points opposite to the

r direction.

The magnetic vector potential distribution of

Pm1 in space can be written as follows:

where

, and

,

I, and

s represent the coil magnetic permeability, the current intensity, and the coil area, respectively.

can be expressed as:

where

, and

d is the radial position of the magnetic dipole.

Pm1 is in the same direction as

, such that

By substituting Equations (23)–(25) into Equation (22), the magnetic vector potential

A1 can be simplified as:

Similarly,

A2 can be expressed as:

By substituting Equations (26) and (27) into Equation (20) and, finally, into Equation (21), we derive

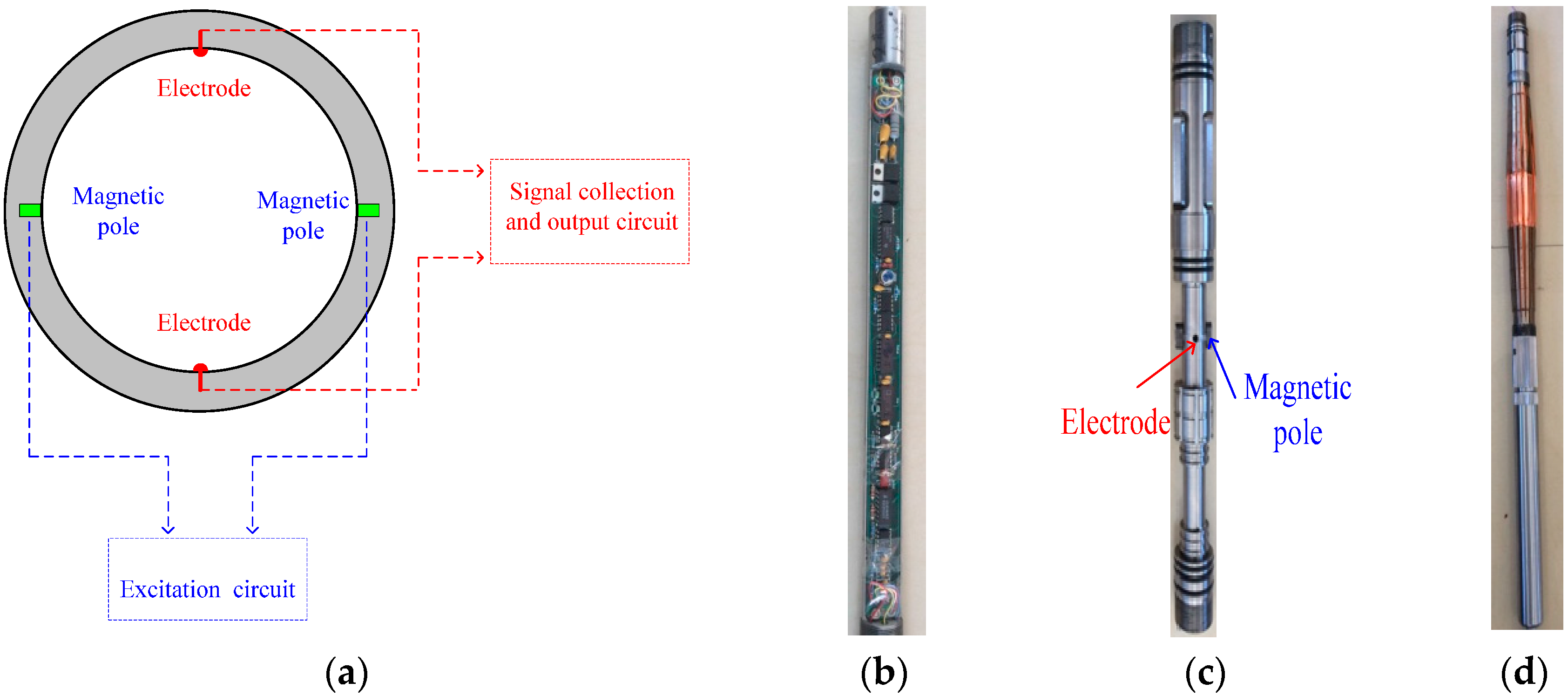

In addition, to study the magnetic field distribution inside the flowtube, this work conducted a numerical calculation on Equation (28), and the results of the numerical calculation were visualized graphically.

The ranges of variables r, θ, and the calculating step are the same as in Equation (19). Suppose d = 9.5 mm (d represents the distance between the center of the flowmeter and the magnetic dipole), and pm = 0.01 H·A·m (pm is an intermediate variable).

Figure 5a displays the 2D contour plot of the numerical calculation results of the magnetic field.

Figure 5b is the 3D surface plot of the numerical calculation results of the magnetic field. It is seen that the maximum value of the magnetic field is 65.36 from the magnetic pole positions, whereas the minimum value is 0.06 from the electrode positions. The color map changes from red to blue, representing the decrease in the magnetic field. In general, the magnetic field inside the flowtube is relatively larger close to the magnetic poles, indicating that the magnetic field in these regions makes a larger contribution to the potential difference. The values of the magnetic field are relatively smaller in the other positions, indicating that the magnetic field in these regions has a smaller contribution to the potential difference. It can be concluded that the feature of the magnetic field distribution can improve the measurement sensitivity of the sensor and is beneficial for the two-electrode EMF to measure the flowrate.