1. Introduction

Due to rapid development of the national economy and society, requirement for transportation capability has been increased considerably. As one of the most important means of transportation, the railway is extremely important because of its high speed and strong transportation capability. However, unexpected breakdowns may lead to serious accidents and damages to the train transportation system, which would result in large economic losses [

1]. In this circumstance, it is urgently required to guarantee the stability, security and continuous operation of train transportation for passengers and freight. Bearing defect is one of the most dominant fault types that cause the trains’ breakdown [

2]. A slight defect on the rolling bearing may force the train to stop, and a serious fault may lead to major accidents and bring about substantial damage [

3]. Therefore, it is profoundly important to develop the techniques of train bearing condition monitoring and fault diagnosis [

4].

There exists two common kinds of train bearing condition monitoring systems nowadays, one is the on train detection system (OTDS) and the other is the wayside acoustic defective bearing detector system (ADBD) [

2,

5]. Since its advent, several diagnostic strategies have been proposed for OTDS, such as oil monitoring [

6], temperature detecting [

7,

8], vibration signal analysis [

9,

10,

11], and acoustic emission diagnosis [

12,

13,

14] methods. However, the oil monitoring strategy is only suitable for lubrication bearing in low velocity situations [

15]. The temperature detecting method can only detect serious faults of the train bearing, as only serious faults happen in the bearing, the bearing temperature raises. That would bring about a tremendous threat to the train transportation. Meanwhile, for the acoustic emission diagnosis technique, because of signal attenuation and the difficulty in signal processing and classification, there still exist some problems for application. Moreover, for all the techniques taken in the OTDS, they all suffer from the drawbacks of value and size. Hundreds of sensors should be fabricated on the train as hundreds of bearings must be monitored and the situation of each monitored bearing is comparatively complex [

16]. Besides, a set of OTDS can only monitor one train, which makes the system uneconomic.

Subsequently, when it comes to the ADBD, the acoustic signal analysis method [

17,

18] is included in the system as this method can detect the incipient defect of the train bearing. While comparing with the OTDS, the ADBD requires less sensors and thousands of bearings can be detected when trains pass by the system each day, as all of the hardware devices are placed by the trackside [

19]. Furthermore, the diagnosis result of ADBD is more reliable than that of OTDS [

3]. In addition, the ADBD can detect the incipient defect of the bearing degradation process to prevent a grave accident happening [

20]. However, as the trains move at a high relative speed to the microphones that are placed by the wayside, the Doppler effect is introduced in the acquired signal [

21]. Especially, frequency shift and frequency band expansion would appear in the spectrum of the acquired acoustic signal. Besides, the amplitude of the origin signal would be modulated according to the Morse acoustic theory. As a consequence, the performance of the diagnosis system would be brought down greatly, especially when the train is passing by at a high speed.

To overcome the aforementioned problem in the ADBD system, He

et al. [

22] proposed a method which is a combination of signal resampling and information enhancement. The Doppler distorted acoustic signal is first reduced by the new resampling method according to a frequency variation curve extracted from the time-frequency domain. Dybała [

21] put forward a disturbance-oriented dynamic signal resampling method based on the Hilbert transform (HT) to remove the Doppler effect. Liu

et al. [

23,

24] presented a time-domain interpolation resampling (TIR) method to eliminate the Doppler distortion and Shen

et al. [

25] proposed a Doppler transient model based on the Laplace wavelet and spectrum correlation assessment for the Doppler distorted signal. Nevertheless, most of the proposed strategies eliminate the Doppler distortion by processing the acquired signal off-line, including the methods aforementioned. However, the diagnosis speed is vital for the ADBD. The less time the ADBD consumed, the higher probability that grave casualty is avoided and immeasurable economic benefit is added. So, it is meaningful to investigate an online Doppler effect elimination method for the ADBD to reduce time latency of fault diagnosis. To the authors’ knowledge, such a method has not been studied yet.

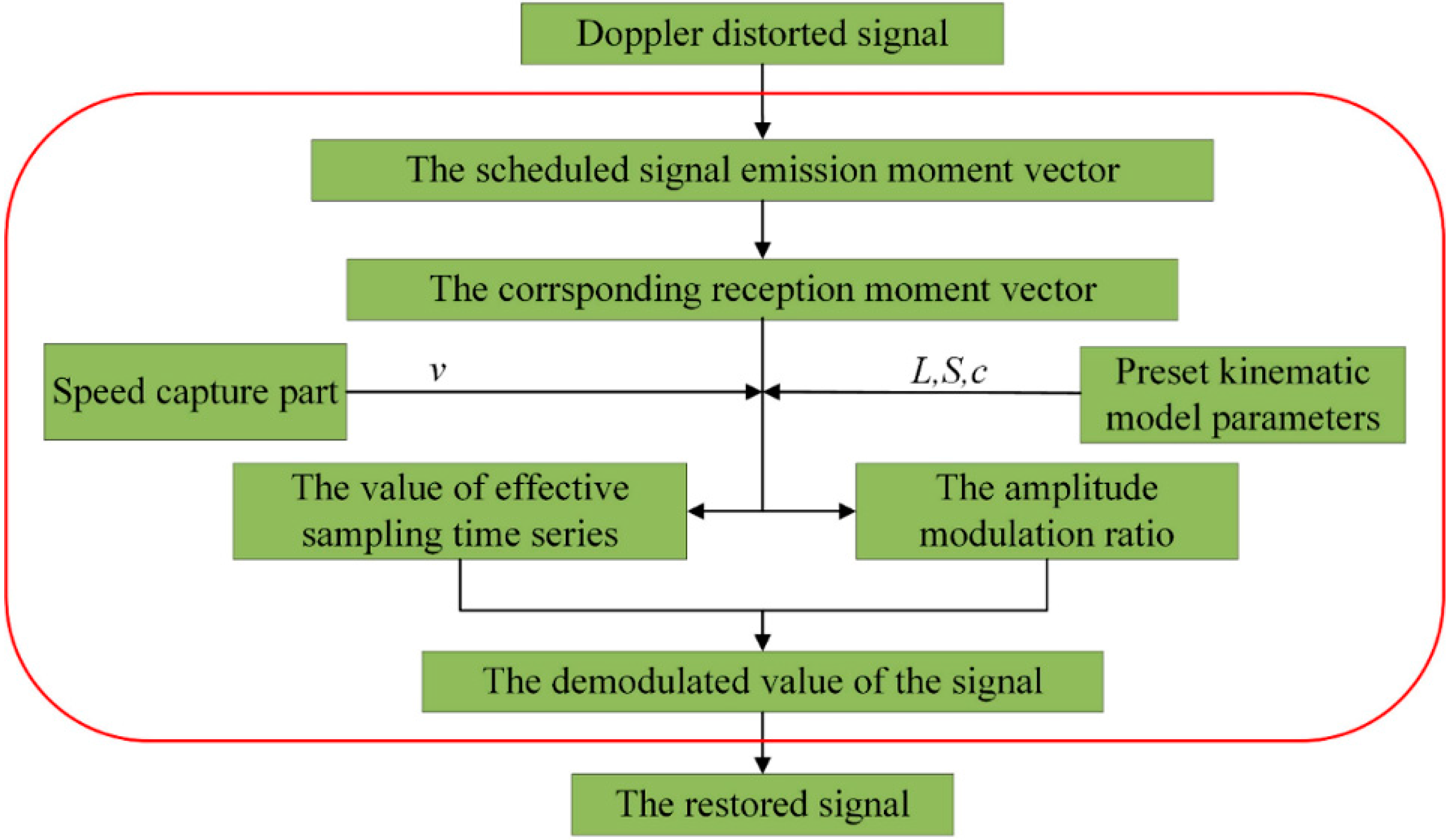

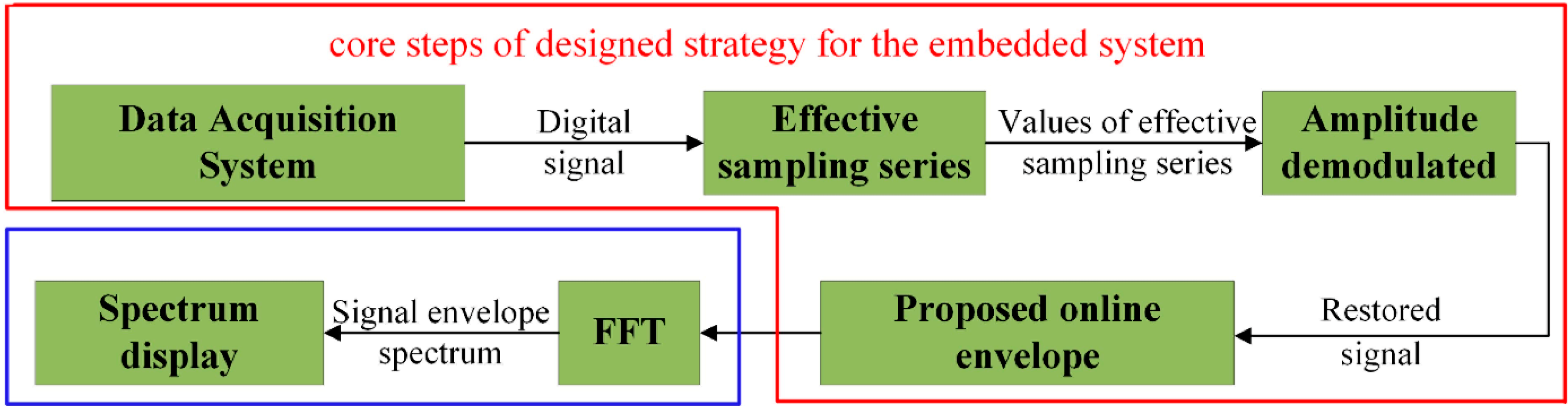

Motivated by the above analysis, an online fault diagnosis strategy called online Doppler effect elimination (ODEE) based on acoustic signal analysis technique is proposed in this paper for the ADBD. The analysis process of the proposed ODEE strategy is illustrated as follows: (1) the spatial and temporal parameters of the constructed kinematic model for the train movement is obtained in advance; (2) the proposed simplified unequal time interval strategy is taken and the distorted amplitude of the signal is demodulated as well; (3) the Doppler-free acoustic signal is restored and the characteristic frequency of the defective signal can be detected through the envelop spectrum of the restored Doppler-free signal. The procedure of the proposed ODEE strategy can be achieved online, which means the time consumption is less than that of the traditional offline strategy. Both simulation study and real train defective bearing signal process demonstrate that a remarkable performance is achieved by using the proposed ODEE method in the restoration of the Doppler distortion signal. Ultimately, the ODEE is implemented in a designed embedded system in bearing fault diagnosis and condition detection. The effectiveness of the proposed method is further verified. In summary, compared to the off-line strategy, the proposed ODEE strategy has the following properties: (1) the simplified unequal time interval strategy can be applied for online sampling to eliminate the Doppler effect; (2) The algorithms are designed for online running, e.g., the online envelope strategy; (3) A low-cost, low-powered, and high-efficiency embedded system is designed for the ODEE method, so the proposed ODEE technique is of low resource consumption and high efficiency when comparing to the traditional offline methods.

The rest of the paper is outlined as follows:

Section 2 presents the principle of the proposed ODEE method. The simulation verification of the ODEE method is presented in

Section 3. Afterwards, experimental verification of the ODEE method in the self-designed embedded system and discussions are presented in

Section 4. Finally, conclusions are drawn in

Section 5.

3. Simulation Verification of the ODEE Method

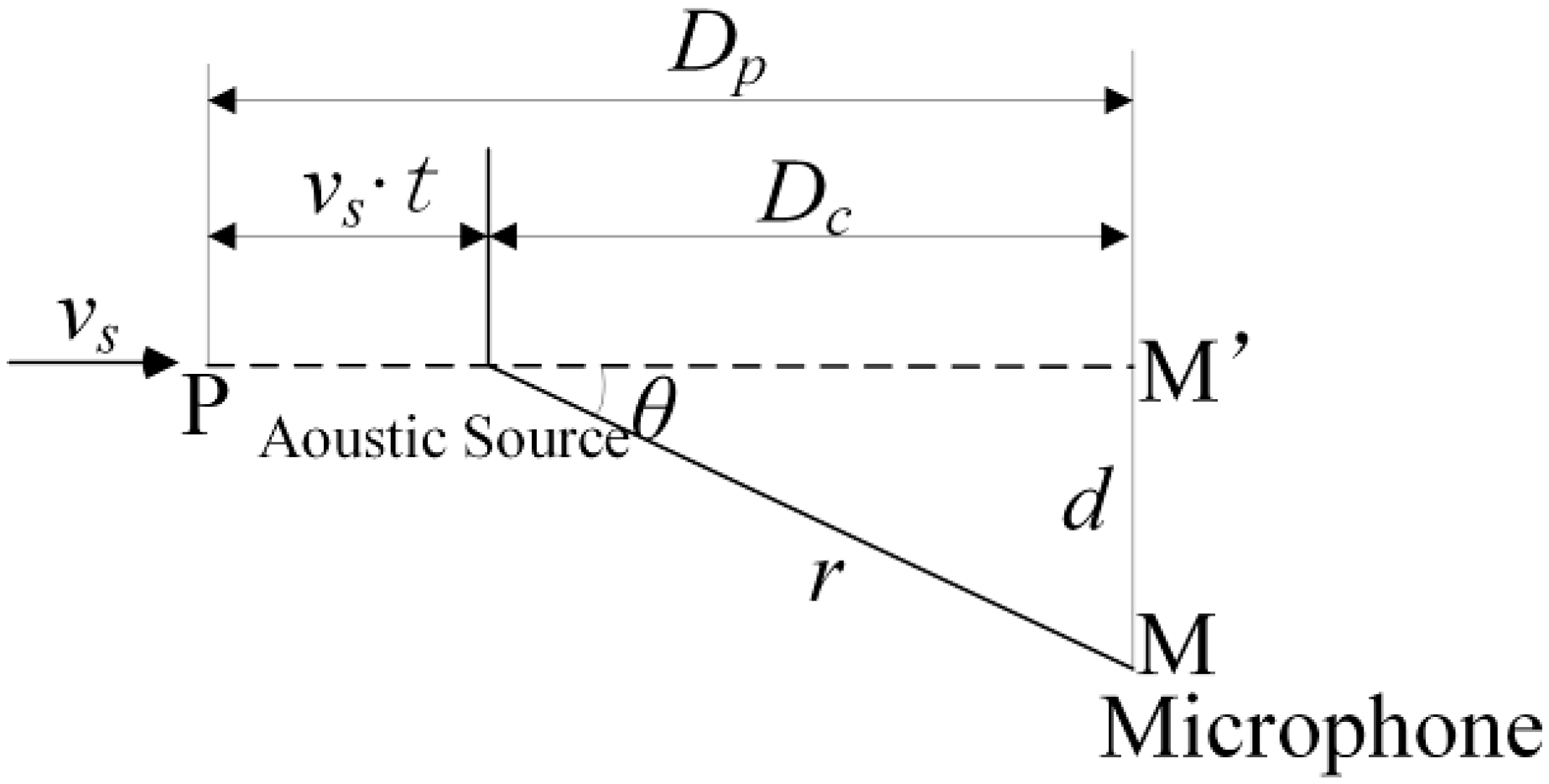

Subsequently, the effectiveness of the proposed ODEE method is verified according to the simulation analysis. Considering the aforementioned schematic diagram in detail in

Figure 1, the relevant kinematic parameters are set as listed in

Table 1. Besides, the actual sampling frequency

frs is set as 50 kHz and the frequency amplification factor is set as 5. The original signal can be composed as follows:

Therefore, on the basis of the derived formula, the simulative Doppler distortion fault signal corrupted by the stochastic noise can be obtained as:

where

f1~

f5 denote the five different frequency components in the simulated signal. With the purpose of verifying the effectiveness of proposed ODEE method in both high- and low-frequency, the frequencies are selected as listed in

Table 2.

f3 is adjacent to

f4 to evaluate the effectiveness of correcting the Doppler distortion signal with frequency band confusion. Furthermore, the parameters of 2π

qi fi/4π is set to be 1 for simplicity.

noise(

t) denotes an additive Gaussian white noise, and the signal-to-noise ratio (SNR) of the signal is set as 10 dB.

Table 1.

Parameters of the simulation Doppler distorted signal.

Table 1.

Parameters of the simulation Doppler distorted signal.

| Parameter | c | L | v | S |

|---|

| Value | 340 m/s | 2 m | 30 m/s | 10 m |

Table 2.

Parameters of the selected characteristic frequency.

Table 2.

Parameters of the selected characteristic frequency.

| Parameter | f1 | f2 | f3 | f4 | f5 |

|---|

| Value | 200 Hz | 800 Hz | 1500 Hz | 1550 Hz | 2800 Hz |

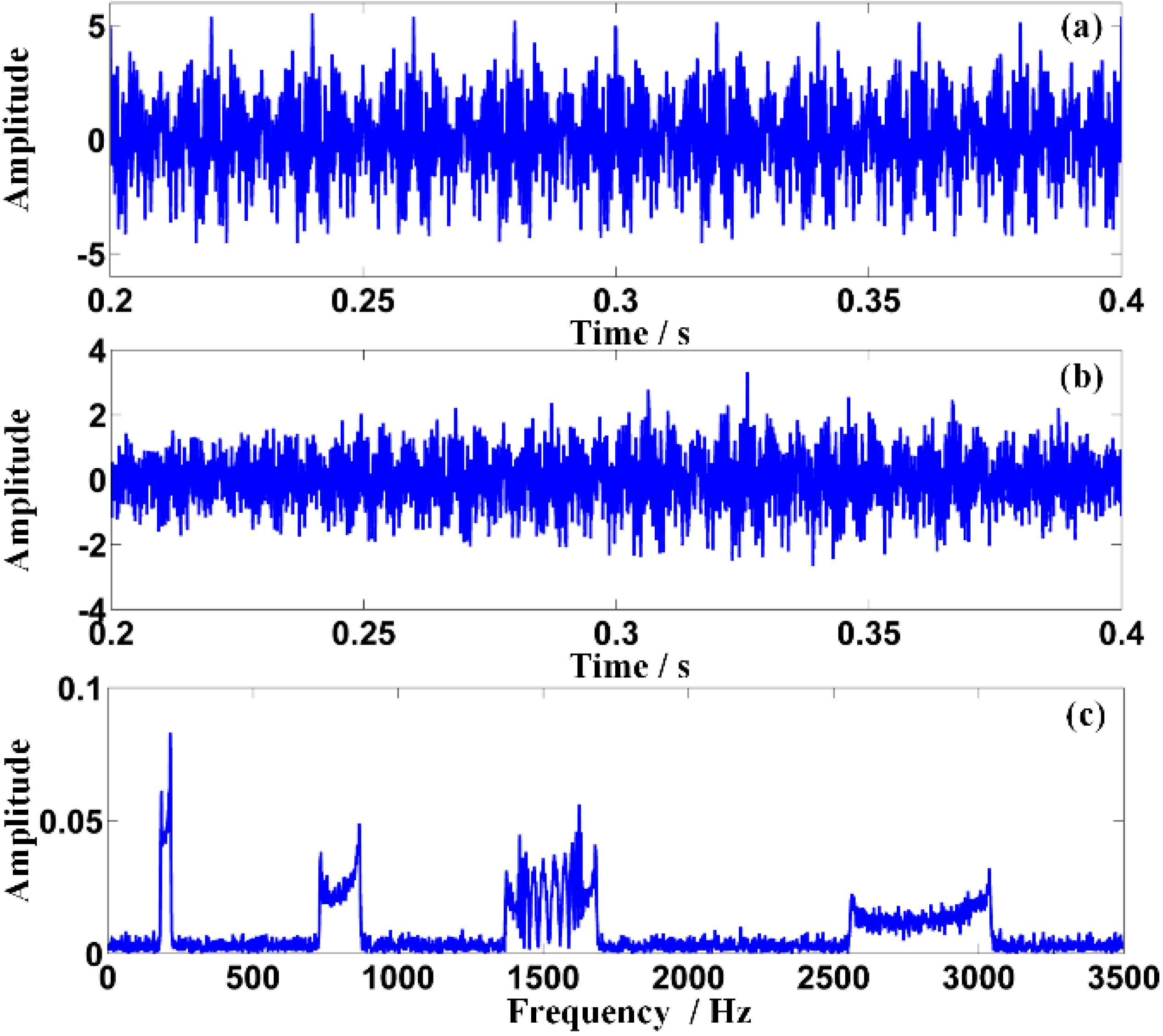

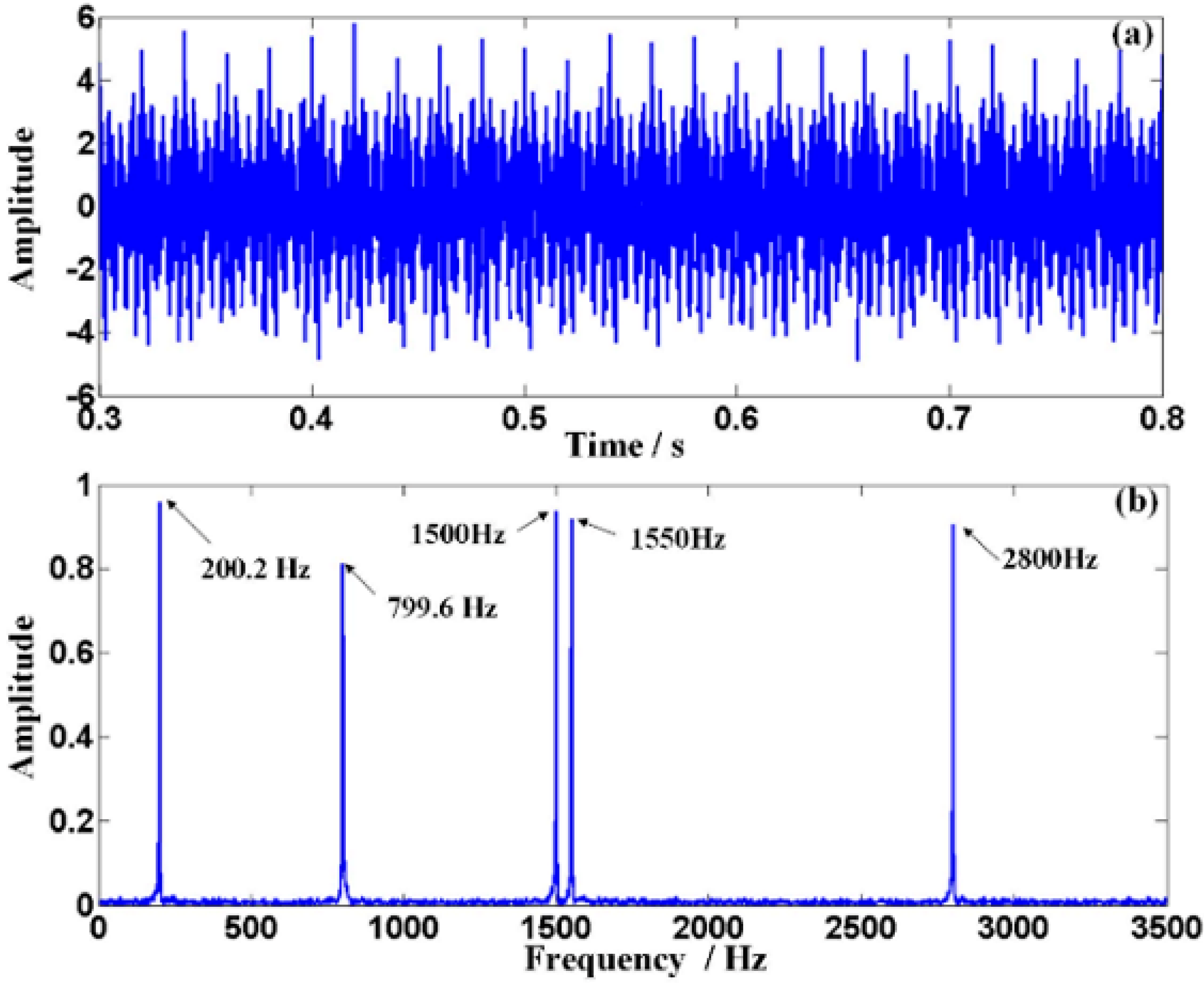

The waveforms of the origin signal and the distorted signal are shown in

Figure 6a,b, respectively. The amplitude modulation can be observed clearly in

Figure 6b. The frequency spectrum of the Doppler distorted signal shown in

Figure 6c demonstrates the frequency shift and the frequency band extension. Besides, the higher the characteristic frequency is, the larger the frequency band extension is. Moreover, serious frequency band confusion appears between the scheduled adjacent characteristic frequencies

f3 and

f4. Therefore, the detected frequencies of the signal are not clear enough for recognition.

To tackle the problem aforementioned and realize the proposed ODEE method, the proposed strategy is used to process the simulated Doppler distortion signal to validate the effectiveness. Firstly, a reasonable

fs that equals to

frs/k is selected. Thus,

tr is obtained according to the selected

fs and the pre-obtained parameters of the kinematic model. Meanwhile, comparison between the selected

te and calculated

tr is shown in

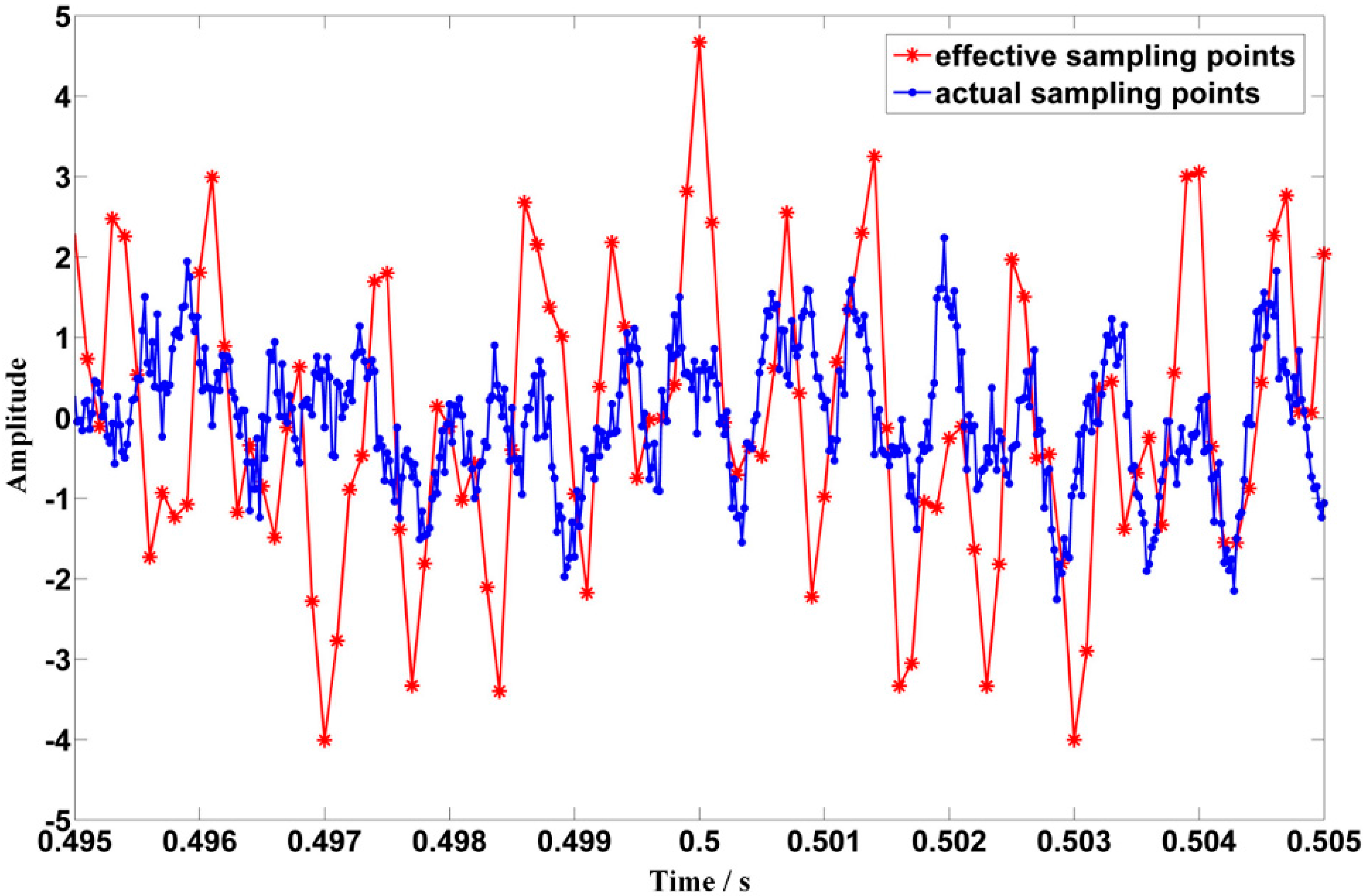

Figure 7a. Afterwards, as the approximation relationship between the actual sampling moment series and the theoretical reception moment series mentioned above is established, the values of effective sampling time series are correspondingly obtained to reveal the frequency domain of the Doppler distorted signal. At the same time, with the corresponding amplitude demodulation ratios shown in

Figure 7b, the amplitude distortions are demodulated. Afterwards, a comparison between the actual sampling series and the demodulated effective sampling series is conducted, which is employed to explicitly illustrate the processing procedure of the proposed strategy. The result is shown in detail in

Figure 8. Finally, the Doppler effect elimination of the distorted signal is realized successfully and the result is shown in

Figure 9, where the waveform and the spectrum of the restored signal are shown in

Figure 9a,b, respectively. It is obvious that the frequency shift, the frequency band extension and confusion are all eliminated, and a satisfactory restoration of the Doppler distortion signal is achieved.

Figure 6.

The Doppler effect of the simulated signal: (a) the waveform of the origin signal with SNR of 10 dB; (b) the waveform of the Doppler distorted signal; (c) the frequency spectrum of the Doppler distorted signal.

Figure 6.

The Doppler effect of the simulated signal: (a) the waveform of the origin signal with SNR of 10 dB; (b) the waveform of the Doppler distorted signal; (c) the frequency spectrum of the Doppler distorted signal.

Figure 7.

(a) Comparison between the scheduled emission time vector and the scheduled reception time vector with the scheduled frequency fs of 10 kHz; (b) the amplitude modulation ratio of the effective sampling series with the scheduled frequency fs of 10 kHz.

Figure 7.

(a) Comparison between the scheduled emission time vector and the scheduled reception time vector with the scheduled frequency fs of 10 kHz; (b) the amplitude modulation ratio of the effective sampling series with the scheduled frequency fs of 10 kHz.

Figure 8.

Comparison between the actual sampling series and the demodulated effective sampling series when the actual sampling frequency is 50 kHz.

Figure 8.

Comparison between the actual sampling series and the demodulated effective sampling series when the actual sampling frequency is 50 kHz.

Figure 9.

(a) The waveform of the restored signal via the ODEE method; (b) the spectrum of the restored signal.

Figure 9.

(a) The waveform of the restored signal via the ODEE method; (b) the spectrum of the restored signal.

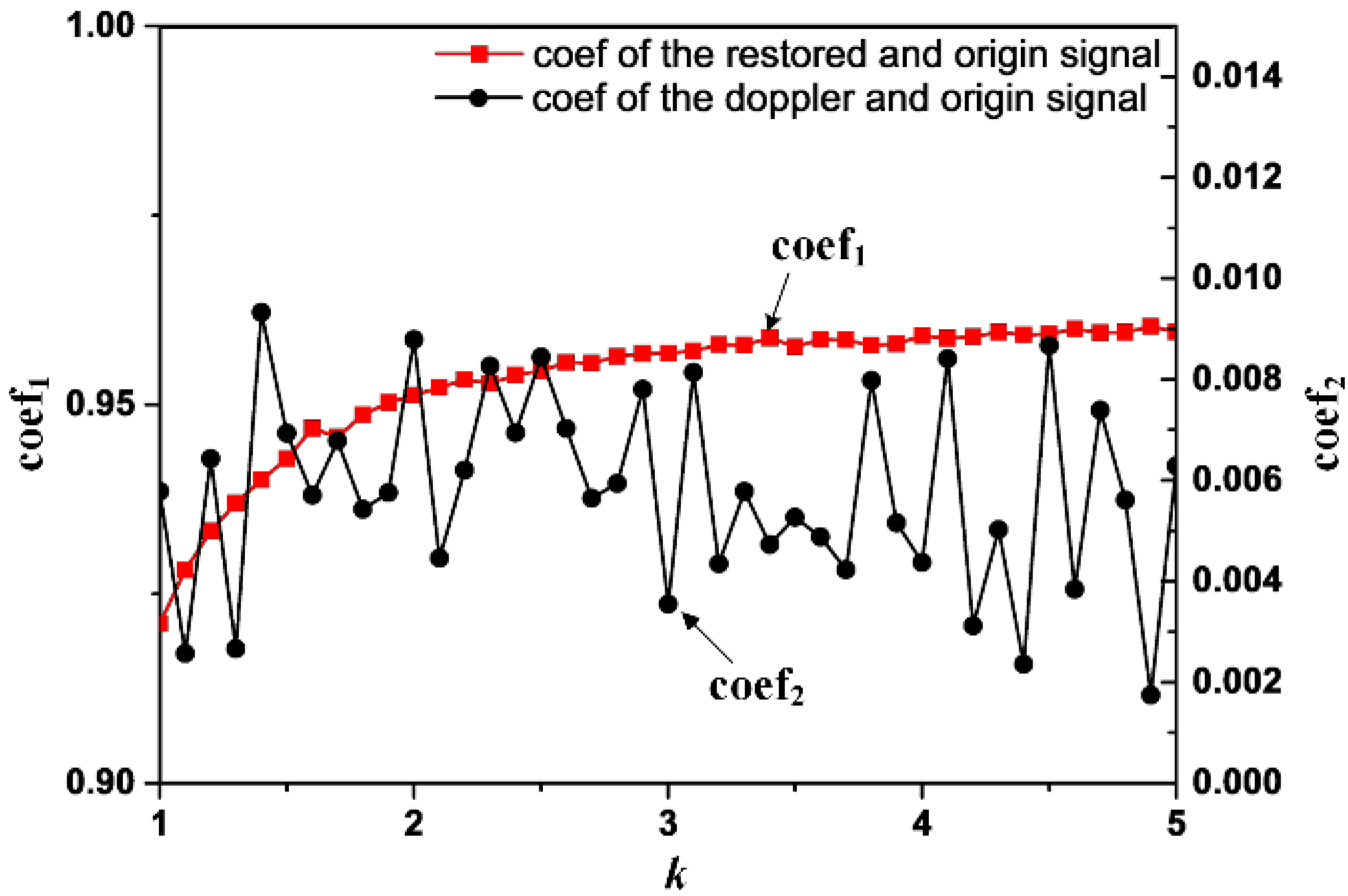

Moreover, correlation analysis is carried out between the origin signal and the restored signal to validate the effectiveness of the strategy proposed, where the correlative relationship between the selected

k and

ηx(n),y(n) of the origin signal and the restored signal is constructed. With the obtained analysis result and removal result of the Doppler distortion signal, it is convenient to select a reasonable

k for the proposed processing procedure. As the stochastic noise would reduce the effectiveness of the analysis procedure significantly, in the following experiments, the SNR of the chosen signal

xo is selected to be 10 dB. For each

k, once the Doppler effect of the distorted signal is eliminated with the ODEE method mentioned above, the corresponding correlation coefficients can be calculated. The desired result of the correlative relationship is shown in

Figure 10. The correlation coefficient of the origin signal and the obtained restored signal (coef

1) increases with the growth of

k and tends to be stabilized. While the correlation coefficient of the origin signal and the Doppler distortion signal (coef

2) is of random distribution. Besides, coef

1 is much higher than coef

2, which verifies the effectiveness of the proposed ODEE method. Moreover, when

k comes around 4.3, the correlation coefficient between the origin signal and the restored signal comes to 0.9596, which indicates that the restored signal is quite similar to the origin signal. The comparison result of the simulation verification implies the fairly good performance of the constructed ODEE method.

Besides, the implementation of the proposed ODEE method would become difficult to realize with the growth of

k. Considering both accuracy and facilitation implementation, the value of

k is chosen to be 5 during the simulation verification, which is high enough for the restoration procedure according to the correlation analysis. The results shown in details in

Figure 9 also verified that the appropriate value of

k has been chosen. Meanwhile, the same value of

k has been selected in the following experimental verification procedure.

Figure 10.

The relationships between k and coef1, coef2, respectively.

Figure 10.

The relationships between k and coef1, coef2, respectively.

4. Experimental Verification of the ODEE Method in Embedded System

4.1. Experimental Setups for Signal Acquisition

As far as concerned, when there exists defect on the train bearing, periodic impulses will appear in the train bearing acoustic signal with the balls passing over the defect. Hence, the type of the bearing defect can be determined if the frequency of the periodic impulses generated by the defective bearing is obtained [

28,

29]. Besides, the defective characteristic frequency

fO of the bearing with outer-race defect can be calculated by the formula as follows:

where

Z stands for the number of rollers,

d, D represents the diameter of roller and pitch diameter, respectively.

fr stands for the rotating speed. Similarly, the defective characteristic frequency

fI of the bearing with inner-race defect can be calculated by the equation as:

Therefore, once the parameters of the used bearing and the rotating speed are given, the characteristic frequency of the defective bearing is determined. The type of train bearing defect can be classified according to the comparison.

After the effectiveness of the ODEE method has been verified in the simulation analysis, the proposed strategy is about to be employed in the embedded system to eliminate the Doppler effect of a real defective train bearing signal for further verification of the applicability and performance.

First of all, to make the designed system repeatable, the Doppler distortion signal should be obtained with the experimental setups for signal acquisition with Doppler effect described in the previous work [

22,

23]. The specifications of the tested bearing are listed in

Table 3.

Table 4 presents the parameters of the experiment to acquire the static signal without Doppler effect, including the radial direction load of the tested bearing, the rotation speed of the motor, and the sampling frequency. Thus, the defective characteristic frequencies

fO and

fI are calculated to be 138.7 Hz and 194.9 Hz, respectively. Besides, the necessary parameters of the dynamic experiment to obtain the Doppler distorted signal are shown in detail in

Table 5.

Table 3.

Specifications of the experiment bearing with the type of NJ(P)3226.

Table 3.

Specifications of the experiment bearing with the type of NJ(P)3226.

| Pitch Diameter (D) | Roller Diameter(d) | Rollers Number(Z) |

|---|

| 190 mm | 32 mm | 14 |

Table 4.

Parameters of the first experiment.

Table 4.

Parameters of the first experiment.

| Parameter | Radial Direction Load | Rotation Speed of the Motor | Sampling Frequency |

|---|

| Value | 3 tons | 1430 rpm | 50 kHz |

Table 5.

Actual parameters of the Second constructed experiment.

Table 5.

Actual parameters of the Second constructed experiment.

| Parameter | c | L | v | S |

|---|

| Value | 340 m/s | 2 m | 30 m/s | 6 m |

Once the defective characteristic frequency of the acquired Doppler distortion signal is revealed, the type of train bearing defect can be determined via comparison with the aforementioned theoretical values. In the following analysis, the acquired Doppler distorted signal is used as the input acoustic signal of the designed embedded system to verify the effectiveness of the proposed ODEE method.

4.2. Experimental Setups of the Proposed Embedded System

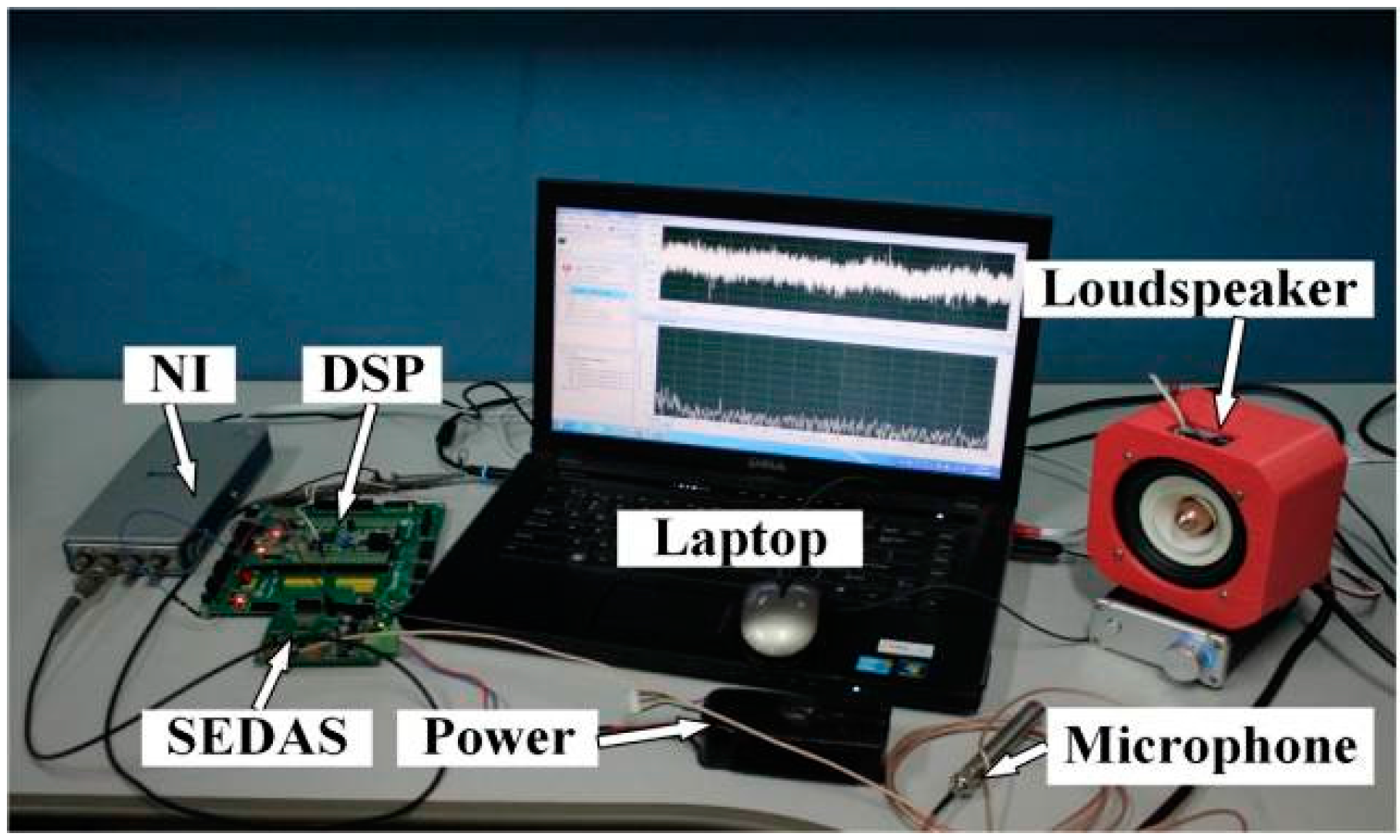

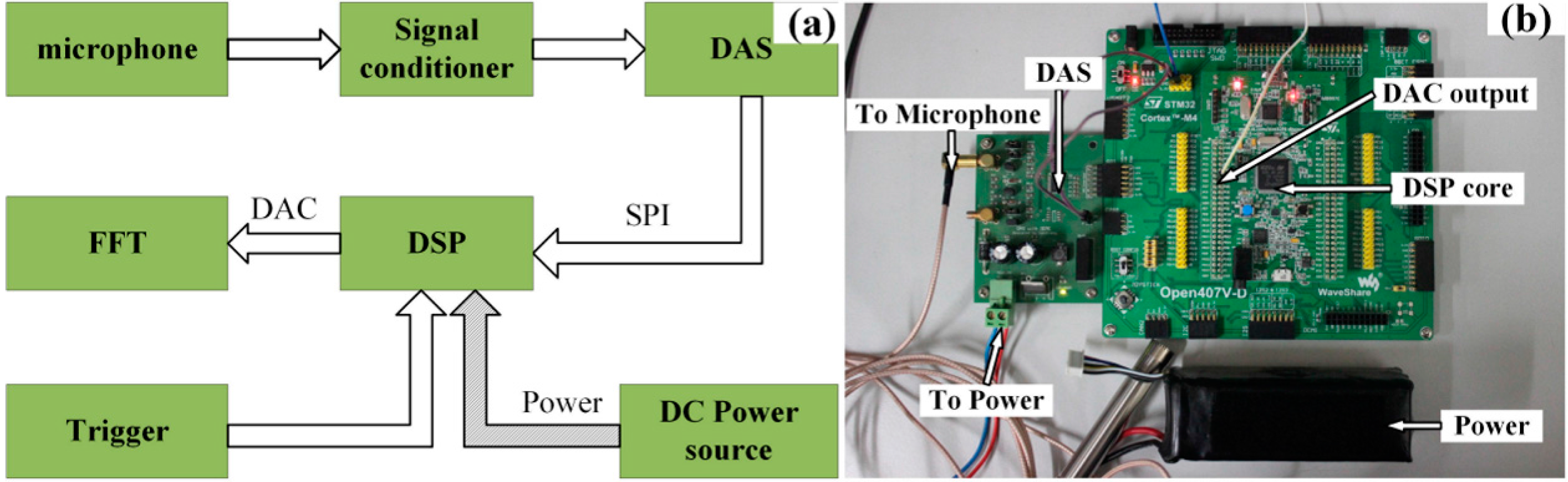

As mentioned above, the input acoustic signal of the proposed embedded system are obtained according the designed experimental setups aforementioned. To realize the ODEE strategy by trackside for the train bearing fault diagnosis and condition monitoring, experiments are conducted to collect and process the Doppler distortion acoustic signals via the constructed embedded system. As shown in

Figure 11, a loudspeaker is used to play the acquired actual Doppler distorted signals. A microphone is employed as the acoustic sensor for the signal acquisition of the embedded system. To accomplish the ODEE strategy, an embedded system composed by a self-designed embedded data acquisition system (SEDAS) and a digital signal processing (DSP) system is designed. The restored signal is processed via the system and the output can be observed on the laptop via the NI DAS to verify the effectiveness of the ODEE method. The module diagram of the designed hardware system is shown in

Figure 12a, where the arrows represent the data flow direction. As a matter of fact, the constructed system is a signal reconstruction analyzer and modulator-demodulator that can realize the online Doppler effect elimination strategy.

Figure 11.

Experimental setups to validate the effectiveness of the ODEE method in the embedded system.

Figure 11.

Experimental setups to validate the effectiveness of the ODEE method in the embedded system.

Figure 12.

(a) The module diagram of the designed embedded system; (b) the hardware details of the embedded system.

Figure 12.

(a) The module diagram of the designed embedded system; (b) the hardware details of the embedded system.

The details of the designed hardware system are shown in

Figure 12b. The maximal sampling rate of the SEDAS that is based on an analog-to-digital converter MAX1300 (Maxim Inc. Roanoke, VA, USA) is 115 ksps. The signal conditioner is composed of an operational amplifier MAX9632 (Maxim Inc. Roanoke, VA, USA) and the power supply for microphone is provided by an LM334 (STMicroelectronics Inc. Geneva, Switzerland). First of all, STM32F407VGT6 (STMicroelectronics Inc. Geneva, Switzerland) is based on the high-performance ARM Cortex-M4 platform. Besides, the floating-point processing unit (FPU) of the Cortex-M4 core supports all ARM single-precision data processing instructions and data types, which is essential for the restoration procedure of the proposed ODEE method such as the online envelope procedure, analog to digital transform. Additionally, it is a reduced instruction set computing (RISC) processor with a full set of DSP instructions to make the programming procedure easier. The designed application security can be enhanced by the memory protection unit (MPU) as well. Meanwhile, the incorporated high-speed embedded memories and the standard and advanced communication interfaces make it adaptive to complex situations. Furthermore, with the help of its DAC, the output can be transformed into analog signal and transmitted to other equipment for further analysis. The maximal frequency of the processor unit is up to 168 MHz, 210 DIPS. Moreover, the price is fairly low and the power consumption control is excellent. Thus, STM32F407VGT6 is chosen as the DSP core of the designed embedded system. With the help of the digital-to-analog converter embedded in the DSP, the restored Doppler-free signal can be collected with NI DAS and transmitted to the laptop that connected to NI DAS for further analysis.

Besides, a satisfactory restoration of the Doppler distortion signal could be achieved when the value of k is selected to be 5 according to the aforementioned simulation verification. Meanwhile, the complexity of implementation would be appropriate as well. Hence, the value of k has been selected to be 5 for the following experimental verification.

4.3. Case Study: Bearing with Outer-Race Defects

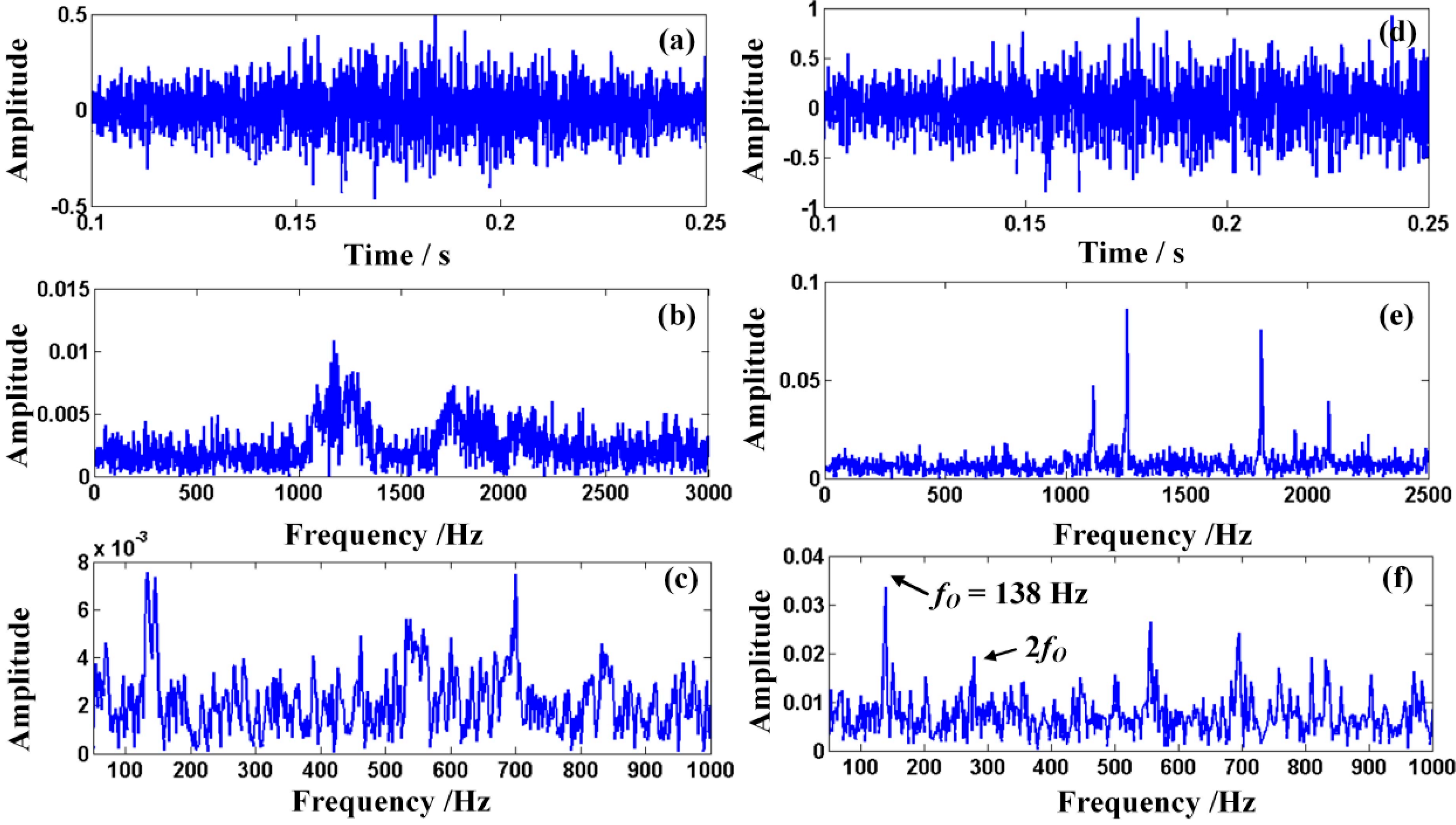

After obtaining the Doppler signal of the bearing with the outer-race defect by using the aforementioned experimental setups, the waveform and the power spectrum of the acquired Doppler distortion signal are described in detail in

Figure 13a,b, respectively, and the envelope spectrum of the Doppler-shifted signal is drawn in

Figure 13c. It is obvious that in the frequency domain there exists the frequency shift and the frequency band extension because of the Doppler distortion. Obvious amplitude modulation can also be found in

Figure 13a. The characteristic frequency cannot be easily read from the current analysis. Hence, the defect cannot be easily detected from the envelope spectrum of the Doppler distorted signal. Afterwards, the distorted fault signal is first processed via the ODEE method on the laptop and the results are shown in detail in

Figure 13d–f. The waveform of the restored signal is shown in

Figure 13d, where the demodulated amplitude of the Doppler-free signal is displayed. The frequency spectrum and the envelope spectrum are drawn in

Figure 13e,f, respectively. From

Figure 13f, the characteristic frequency of the restored signal and its harmonic can be obtained. The characteristic frequency can be detected as 138 Hz, which is rather close to the theoretical value

fO calculated with the given parameters. From the comparison between the theoretical value and the calculated value, the proposed ODEE method correctly reveals the characteristic frequency of the defective bearing and the result validates the effectiveness of the proposed ODEE method running on the laptop.

Figure 13.

(a–c) The waveform, the spectrum and the envelope spectrum of the Doppler distorted signal emitted by the fault bearing with a outer-race defect; (d–f) the waveform, the spectrum and the envelope spectrum of the restored signal.

Figure 13.

(a–c) The waveform, the spectrum and the envelope spectrum of the Doppler distorted signal emitted by the fault bearing with a outer-race defect; (d–f) the waveform, the spectrum and the envelope spectrum of the restored signal.

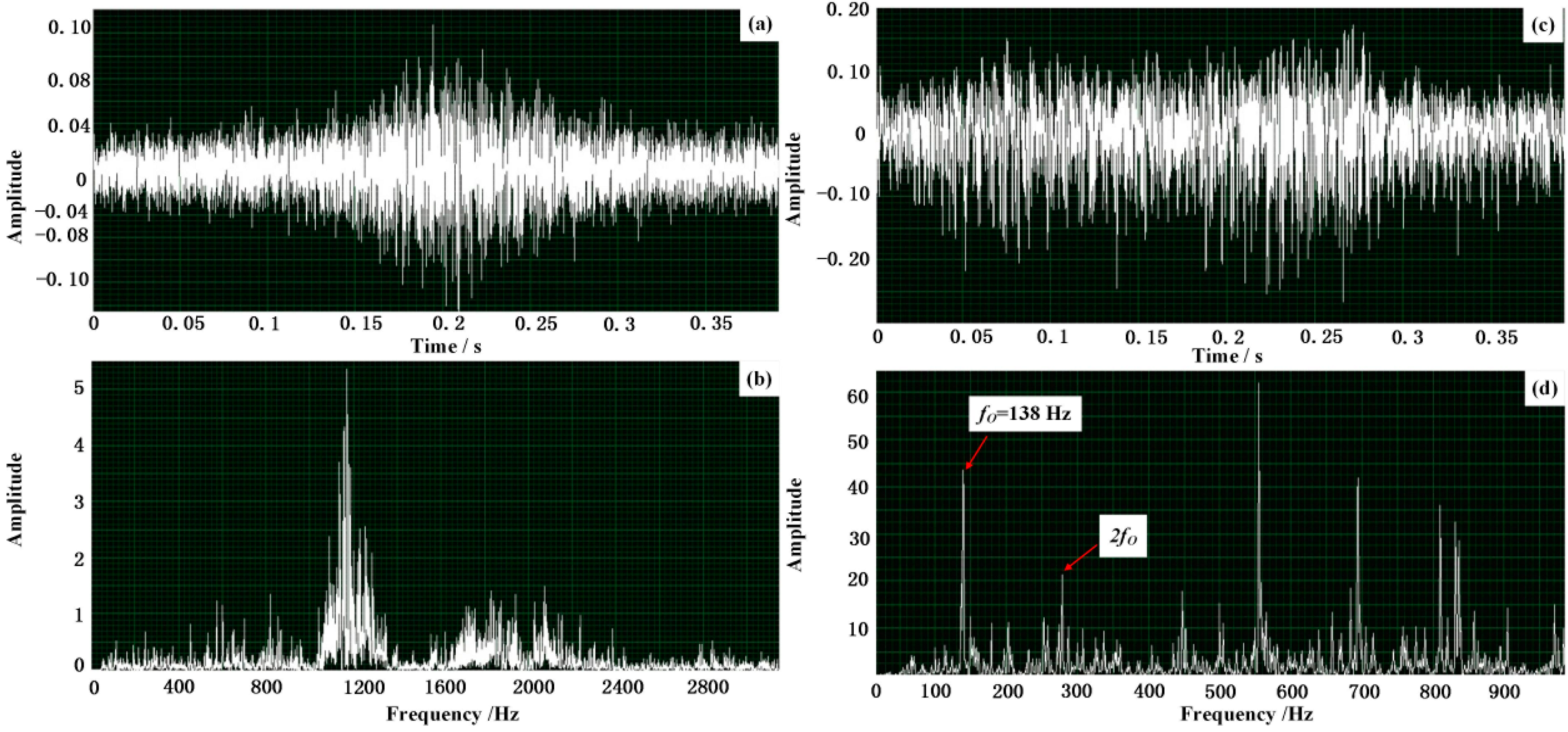

Subsequently, the acquired Doppler acoustic signal of the bearing with outer-race defect is taken in the designed system to validate the effectiveness of the algorithm implementation and hardware design. Firstly, the acoustic signal of the fault bearing with outer-race defect acquired by the aforementioned experiments is used as the input signal of the embedded system and its waveform and spectrum are displayed in

Figure 14a,b, respectively. It is clear that the amplitude of the obtained signal is modulated according to

Figure 14a and the frequency shift and frequency band extension can be observed according to

Figure 14b. After the processing of the designed embedded system, the waveform and the frequency spectrum of the output restored envelope signal are drawn in

Figure 14c,d, respectively, where the frequency shift and the frequency band extension shown in

Figure 14b are successfully eliminated and the amplitude modulation shown in

Figure 14a is demodulated. That implies the frequency domain of the acquired acoustic signal is restored and correctly reveals the feature frequency of the defective train bearing. The feature frequency of the defective train bearing can be clearly observed as 138 Hz, which is approximately equal to the calculated characteristic frequency

fO aforementioned. The effectiveness of the designed hardware embedded system has been verified.

Figure 14.

Effectiveness verification via the designed embedded system: (a,b) the waveform and the spectrum of the input Doppler distorted signal of the defective train bearing with a defect on the outer-race; (c,d) the waveform and the spectrum of the output restored envelope signal via the designed embedded system.

Figure 14.

Effectiveness verification via the designed embedded system: (a,b) the waveform and the spectrum of the input Doppler distorted signal of the defective train bearing with a defect on the outer-race; (c,d) the waveform and the spectrum of the output restored envelope signal via the designed embedded system.

4.4. Case Study: Bearing with Inner-Race Defect

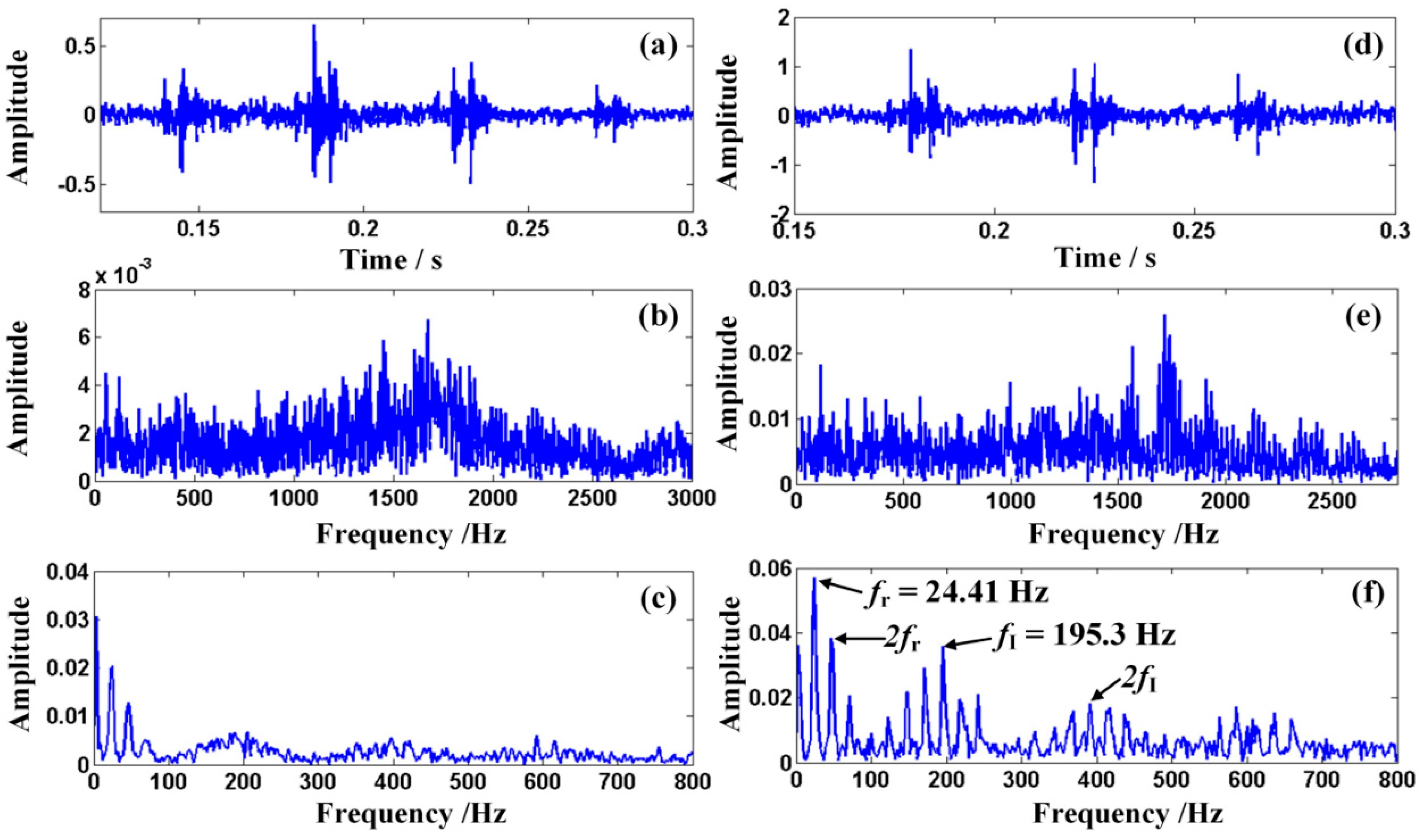

Subsequently, similarly to procedure of bearing with the outer-race defect, the obtained Doppler signal of the bearing with inner-race defect is analyzed on the laptop as well. The waveform of the measured signal is shown in detail in

Figure 15a, where obvious amplitude modulation can be observed. The frequency spectrum is shown in

Figure 15b and the envelope spectrum is drawn in

Figure 15c, where serious frequency shift and frequency band extension are observable. Hence, it is not easy to detect the type of bearing fault from the envelope of the obtained signal directly. The results of the analysis via the ODEE method are shown in detail in

Figure 15d–f, where the demodulated amplitude, the frequency spectrum and the envelope spectrum of the Doppler-free signal are observable. The characteristic frequency of the restored signal can be detected as 195.3 Hz. It indicates a rather similar result to the theoretical value. Thus, it displays the characteristic frequency of the defective bearing signal correctly and the type of the fault bearing can be distinguished, which verifies the effectiveness of the ODEE method running on the laptop as well.

Subsequently, the input signal of the embedded system turns into the corresponding signal of the fault bearing with inner-race defect to verify the effectiveness of the designed embedded system. The waveform and spectrum of the Doppler distorted signal are displayed in

Figure 16a,b, respectively. It is observable that the amplitude of the obtained signal is modulated and the frequency shift and frequency band extension take place in the frequency domain. Afterwards, the output of the constructed embedded system is shown in

Figure 16c,d, which display the waveform and the spectrum of the output restored envelope signal, respectively. It is obvious that the frequency domain of the distorted signal has been restored and the feature frequency can be observed as 195 Hz, which is rather close to the aforementioned theoretical value

fI calculated with the given parameters. Thus, the characteristic frequency of the fault train bearing is displayed correctly, which again demonstrates the effectiveness of the constructed embedded system.

Figure 15.

(a–c) The waveform, the spectrum and the envelope of the Doppler distorted signal emitted by the fault bearing with inner-race defect; (d–f) the waveform, the spectrum and the envelope spectrum of the restored signal.

Figure 15.

(a–c) The waveform, the spectrum and the envelope of the Doppler distorted signal emitted by the fault bearing with inner-race defect; (d–f) the waveform, the spectrum and the envelope spectrum of the restored signal.

Figure 16.

Effectiveness verification via the designed embedded system: (a,b) the waveform and the spectrum of the input Doppler distorted signal of the defective train bearing with a defect on the inner-race; (c,d) the waveform and the spectrum of the output restored envelope signal via the designed embedded system.

Figure 16.

Effectiveness verification via the designed embedded system: (a,b) the waveform and the spectrum of the input Doppler distorted signal of the defective train bearing with a defect on the inner-race; (c,d) the waveform and the spectrum of the output restored envelope signal via the designed embedded system.

As a result, the above experiments verify the effectiveness of the designed hardware system in train bearing fault diagnosis and condition detection. The results show a potential application in analyzing the acoustic signal of the train bearings for fault diagnosis and condition detection by the trackside.

Besides, the proposed hardware system including the DSP, the DAS and the DC power is a low-cost implementation that costs less than $70. The current consumption of the designed system is 120 mA at 22 V DC, which means that the proposed hardware system is a low-powered system. In summary, the designed platform for real-time data acquisition and the Doppler effect elimination procedure is a low-cost, low-powered, and high-efficiency embedded system.

4.5. Discussions

The following presents some discussions for the proposed ODEE strategy.

- (1)

As known in this paper, the speed is regarded as a constant to simplify the dynamical model. In practice, the speed of the moving acoustic source may vary during the motion. In this regard, a more accurate instantaneous speed needs to be obtained for accurate diagnosis results. In further study, a more accurate dynamic model including the accelerated speed would be considered to improve the performance of the ODEE method.

- (2)

In this paper, a simplified unequal time interval sampling strategy is taken for the proposed ODEE method, which would bring in approximation error. An actual unequal time interval sampling strategy will be taken and implemented in the new embedded system for a more accurate diagnosis result.

- (3)

In the paper, the chosen speed is fairly high for a train bearing monitoring system. It might not be practical to listen to the train at this speed due to aerodynamic forces. In our further study, more reliable choices on the speed would be considered for application.