A High Performance Sensor for Triaxial Cutting Force Measurement in Turning

Abstract

:1. Introduction

2. Experimental Section

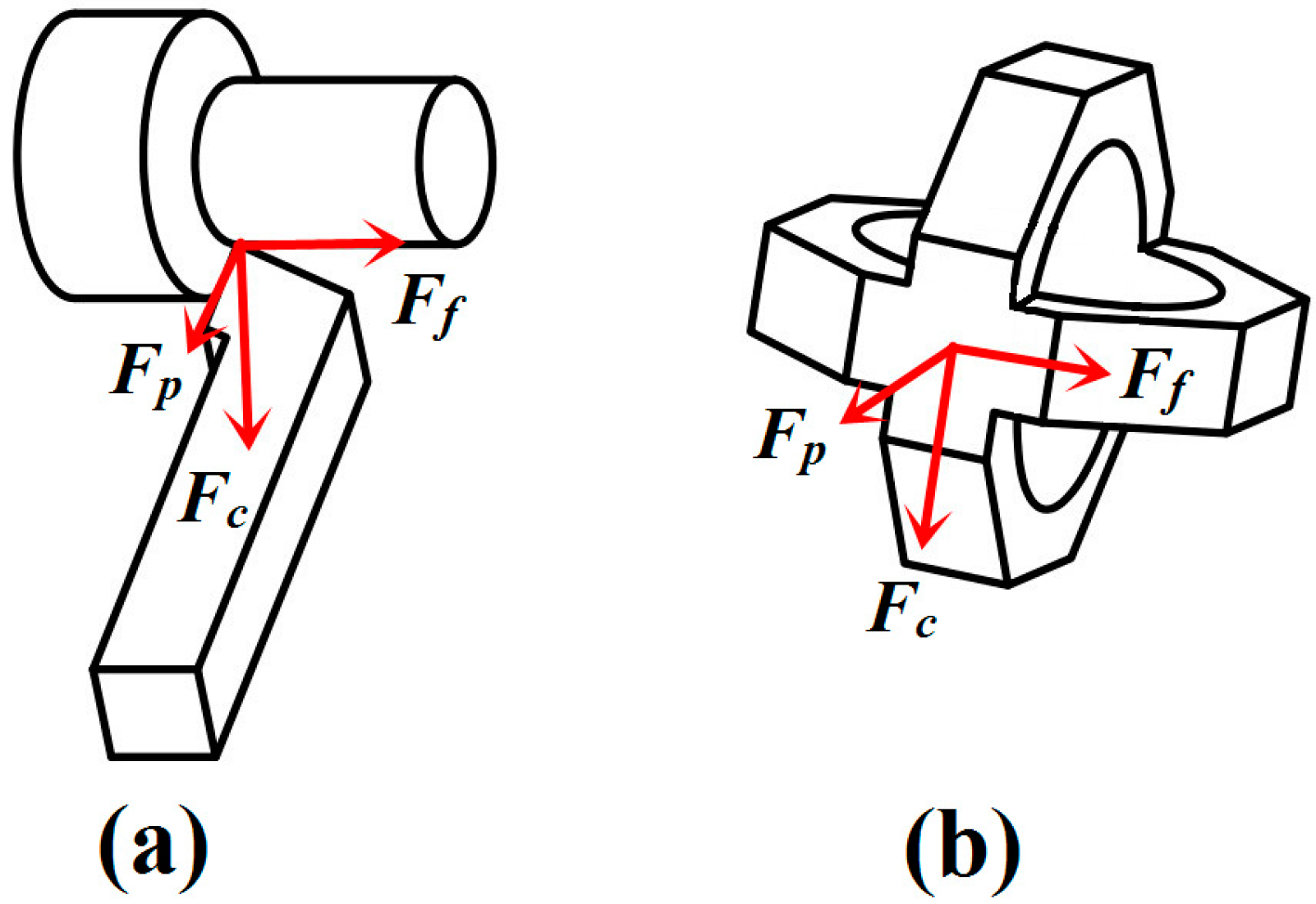

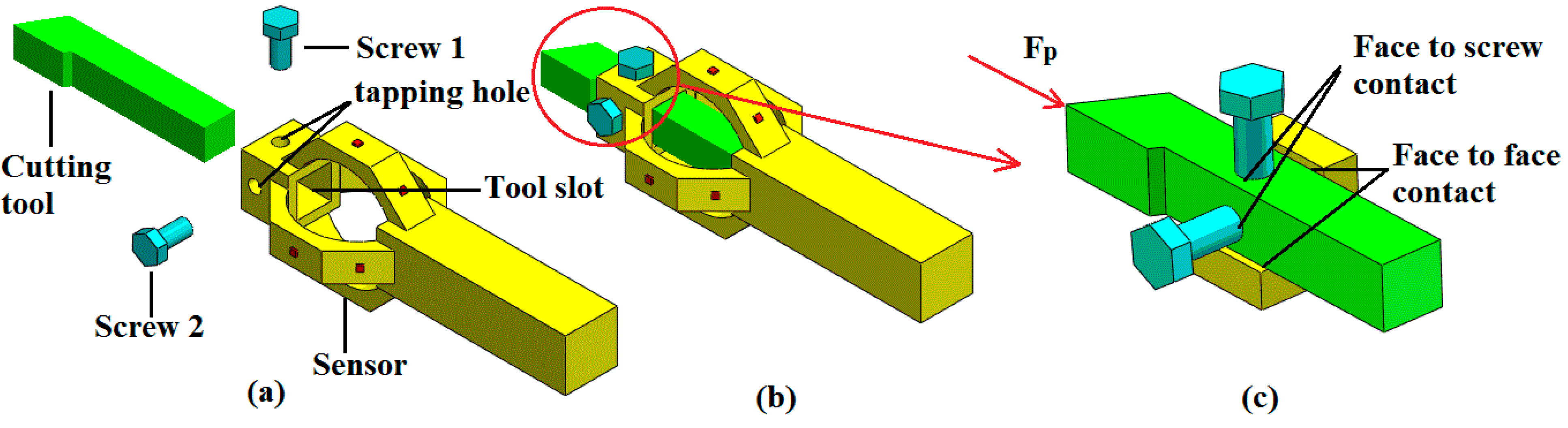

2.1. Design Principle

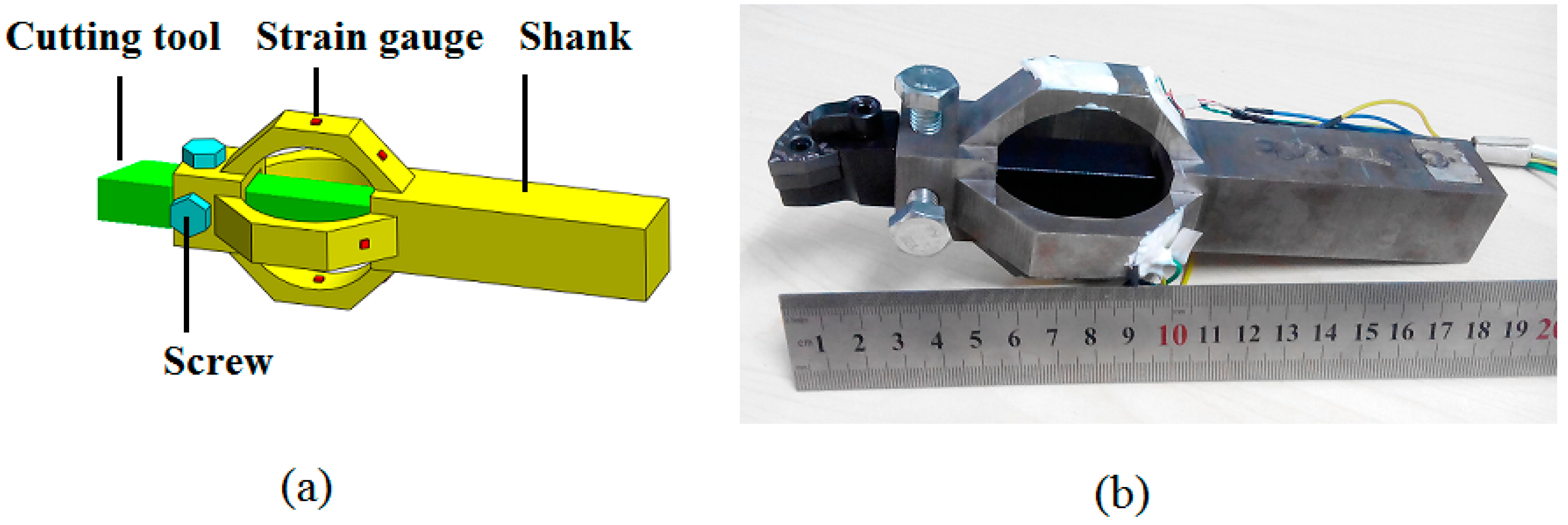

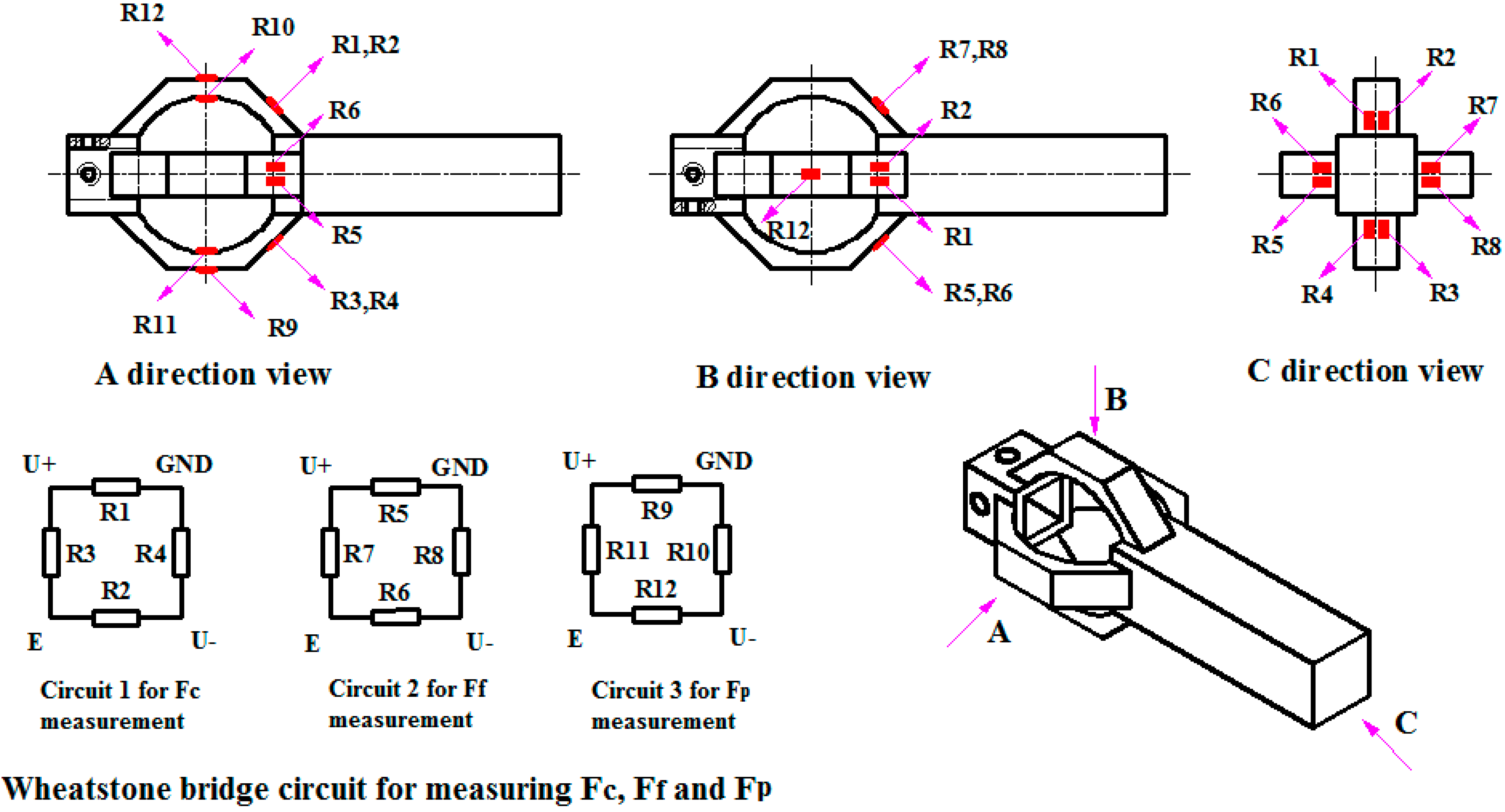

2.2. Sensor Design and Fabrication

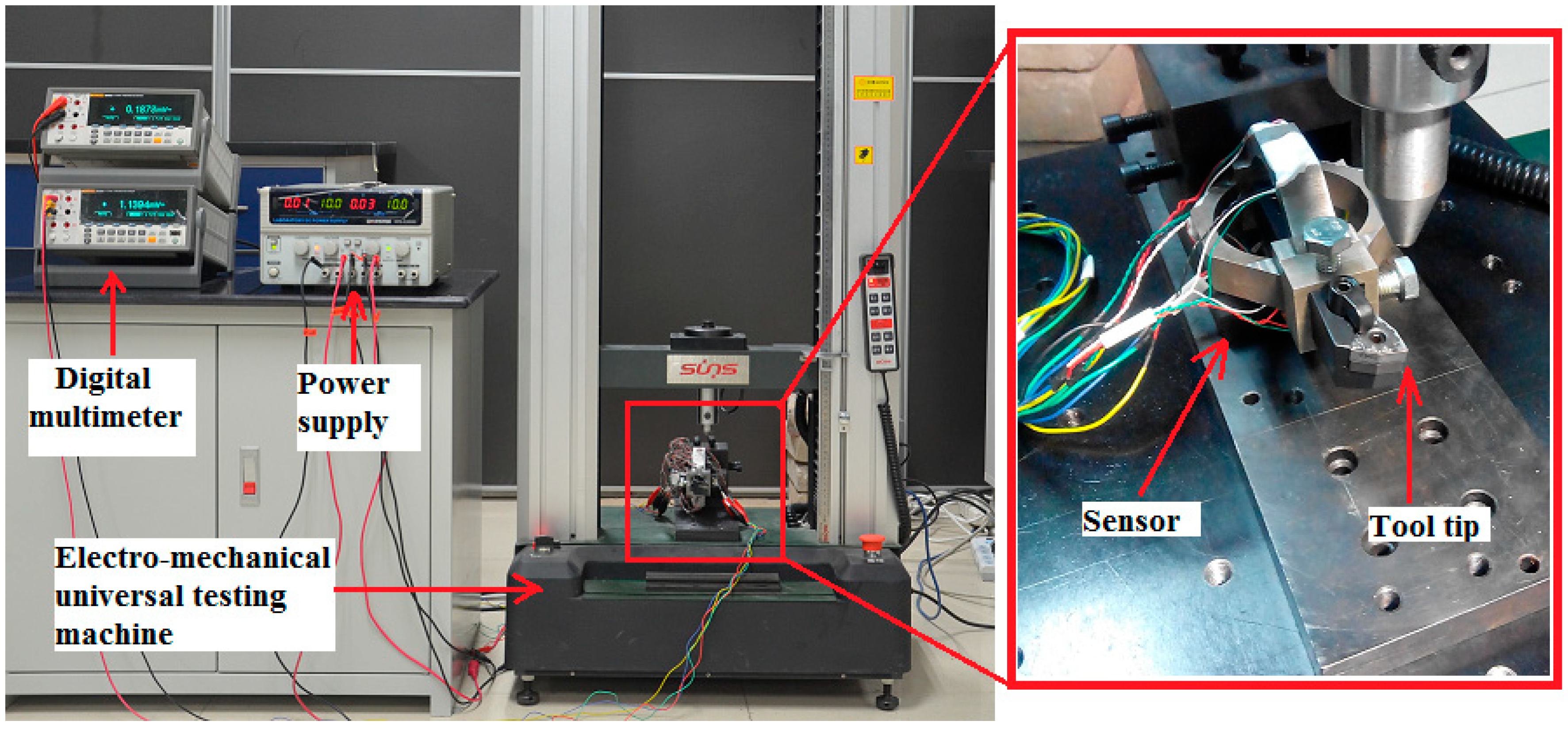

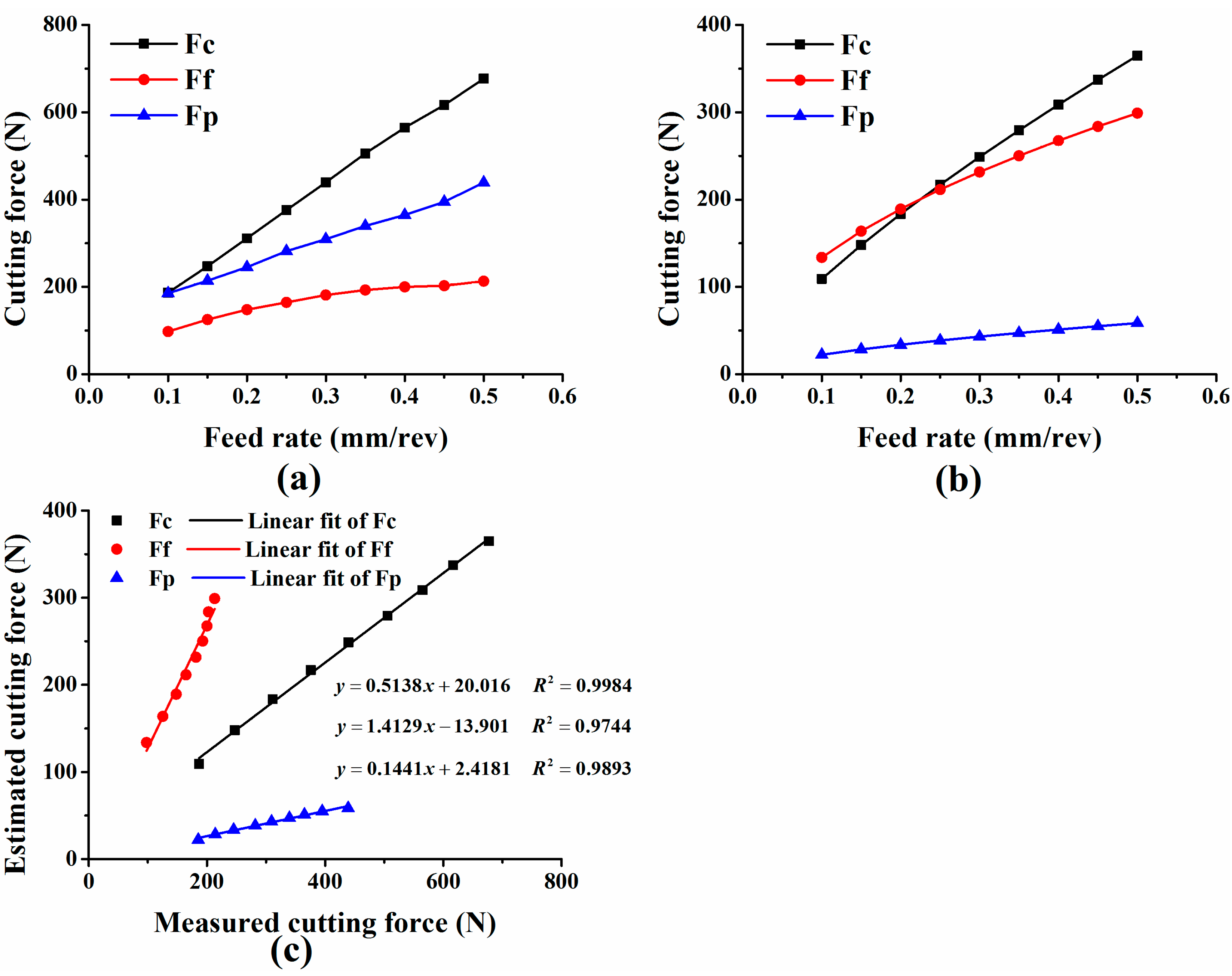

2.3. Static Calibration

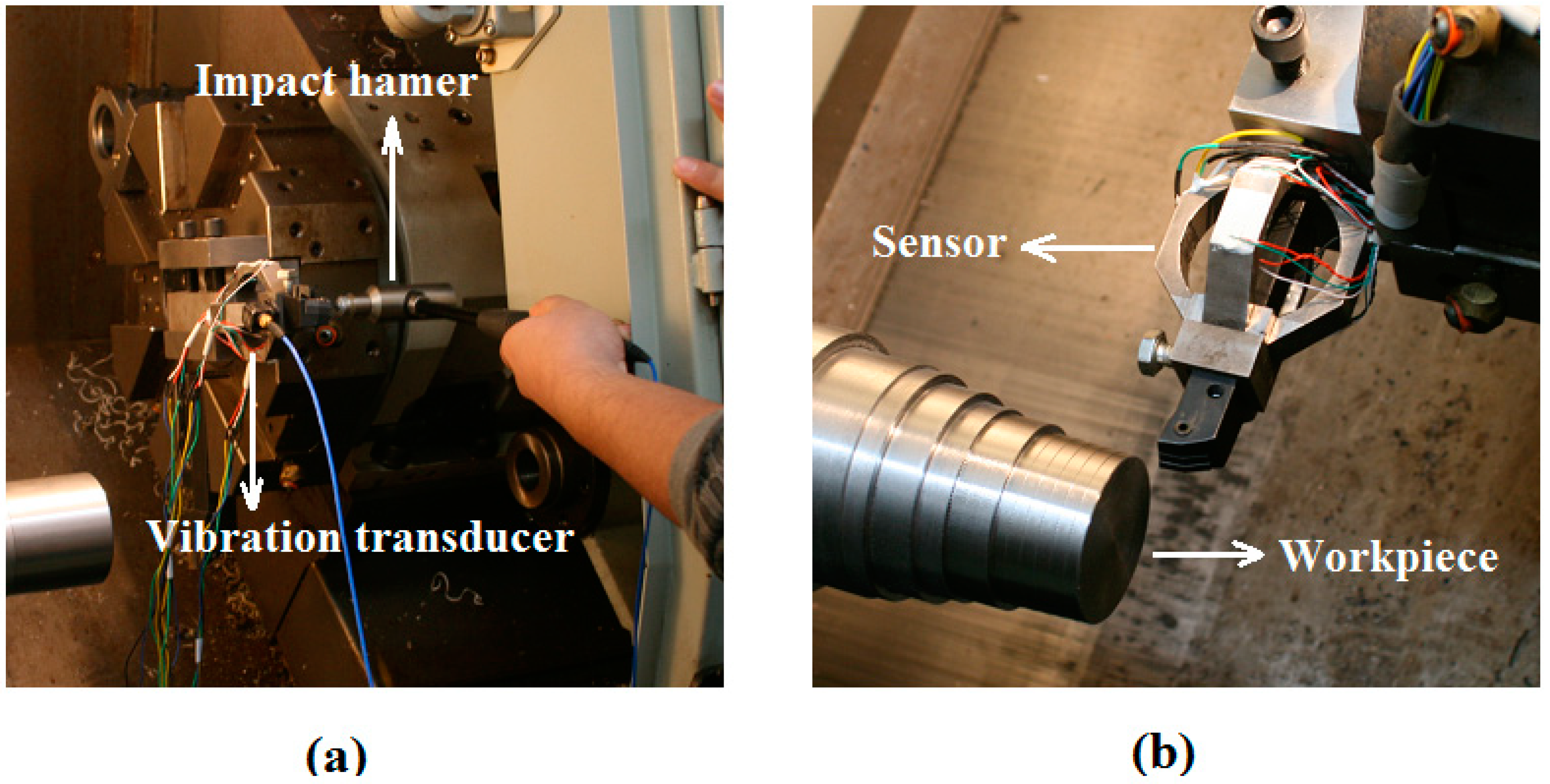

2.4. Natural Frequency Identification

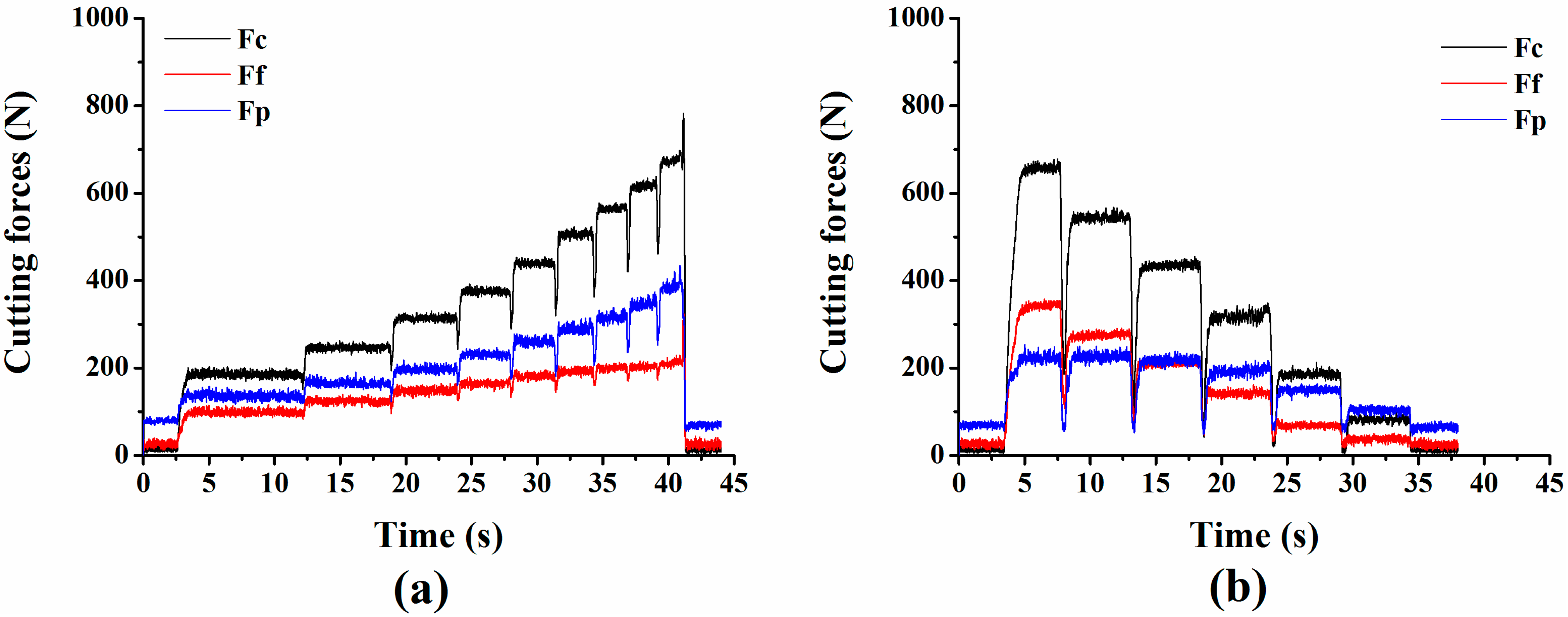

2.5. Sensor Application in Dynamic Cutting Test

| Group One | |||

|---|---|---|---|

| Spindle speed (rev/min) | Diameter of the metal bar (mm) | Depth of cut (mm) | Feed rate (mm/rev) |

| 300 | 63.0 | 0.5 | 0.10,0.15,0.20,0.25,0.30,0.35,0.40,0.45,0.50 |

| Group Two | |||

| Spindle speed (rev/min) | Diameter of the metal bar (mm) | Feed rate (mm/rev) | Depth of cut (mm) |

| 300 | 62.0 | 0.2 | 1.1,0.9,0.7,0.5,0.3,0.1 |

| Equipment | Type | Maker | Country |

|---|---|---|---|

| Strain gauge | BF1000-1.5-90/BA | SAISUO Electronic Technology Co. Ltd | Baoji, Shaanxi, China |

| Silicon rubber | GD-414 | Bluestar New Chemical Material Co. Ltd | Chengdu, Sichuan, China |

| Electro-mechanical universal testing machine | UTM6104 | Shenzhen Suns Technology Stock Co. Ltd | Shenzhen, Guangdong, China |

| Power supply | GPS-3303C | GWINSTEK Electronic Technology Co. Ltd | Suzhou, Jiangsu, China |

| Digital multimeter | 8846A | FLUKE CORPORATION | USA |

| Mobile data acquisition system | SCADAS305 | LMS Company | Belgium |

| NC lathe | FTC-20 | Fair Friend Group | Taiwan, China |

| ANSYS software | ANSYS 12.1 | ANSYS, Inc. | USA |

| Cutting tool | MWLNR1616H08 | Birinai precision CNC group Limited | Taiwan, China |

| CFi | XFi | YFi | ZFi | KmFi | KrFi | KλFi | KγFi | |

|---|---|---|---|---|---|---|---|---|

| Fc (i = c) | 270 | 1.0 | 0.75 | −0.15 | 0.75 | 0.86 | 1.0 | 1.04 |

| Ff (i = f) | 294 | 1.0 | 0.5 | −0.4 | 1.0 | 1.25 | 1.10 | 1.19 |

| Fp (i = p) | 199 | 0.9 | 0.6 | −0.3 | 1.35 | 0.38 | 0.71 | 1.19 |

3. Results and Discussion

3.1. Static Calibration

3.2. Natural Frequency Identification

| Sensor Type | Linearity (%) | Cross-Axis Interference (%) | Natural Frequency (Hz) | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fc | Ff | Ft | Fc→Ff Ft | Ff→Fc Ft | Ft→Fc Ff | Fc | Ff | Ft | ||

| Triaxial | 1.4 | 1.3 | 1.2 | 9.2, 1.7 | 0.7, 1.8 | 0.5, 3.3 | / | / | / | [17,23] |

| Monoaxial | 4.6 | 5.97 | / | [15] | ||||||

| Triaxial | 3.05 | 5.32 | 5.91 | ≤1.81 | ≤2.94 | ≤1.43 | 1000 | / | / | [14] |

| Monoaxial | 1.2 | ≤3 | 950 | [9] | ||||||

| Triaxial | / | / | / | 0.05% | 192 | [21] | ||||

| Triaxial | 0.83 | 0.38 | 0.71 | 4.73, 4.09 | 2.58, 5.38 | 7.33, 10.51 | 1147 | 1122 | 2035 | This work |

3.3. Sensor Application in Dynamic Cutting Test

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. Manuf. Technol. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Dimla, E.; Dimla, S. Sensor signals for tool-wear monitoring in metal cutting operations—A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Abellan-Nebot, J.V.; Subirón, F.R. A review of machining monitoring systems based on artificial intelligence process models. Int. J. Adv. Manuf. Technol. 2010, 47, 237–257. [Google Scholar] [CrossRef]

- Murthy, K.S.; Rajendran, I. Design and development of strain gauge based milling tool dynamometer. Int. J. Mach. Mach. Mater. 2010, 7, 286–298. [Google Scholar]

- Rehorn, A.G.; Jiang, J.; Orban, P.E. State-of-the-art methods and results in tool condition monitoring: A review. Int. J. Adv. Manuf. Technol. 2005, 26, 693–710. [Google Scholar] [CrossRef]

- Audy, J. An appraisal of techniques and equipment for cutting force measurement. J. Zhejiang Univ. Sci. A 2006, 7, 1781–1789. [Google Scholar] [CrossRef]

- Li, X.L. Development of current sensor for cutting force measurement in turning. IEEE Trans. Instrum. Meas. 2005, 54, 289–296. [Google Scholar] [CrossRef]

- Spiewak, S.A. Acceleration based indirect force measurement in metal cutting processes. Int. J. Mach. Tools Manuf. 1995, 35, 1–17. [Google Scholar] [CrossRef]

- Jin, W.L.; Venuvinod, P.K.; Wang, X. An optical fiber sensor based cutting force measuring device. Int. J. Mach. Tools Manuf. 1995, 35, 877–883. [Google Scholar] [CrossRef]

- Liu, M.Y.; Zhou, Z.D.; Tao, X.L.; Tan, Y.G. A dynamometer design and analysis for measurement the cutting forces on turning based on optical fiber Bragg Grating sensor. In Proceedings of the World Congress on Intelligent Control and Automation WCICA, Beijing, China, 6–8 July 2012; pp. 4287–4290.

- Ates, E.; Aztekin, K. Design, manufacturing, and calibration process of one piece lathe dynamometer for measurement in two axes. J. Manuf. Sci. Eng. Trans. ASME 2013, 135, 044501:1–044501:5. [Google Scholar] [CrossRef]

- Panzera, T.H.; Souza, P.R.; Campos Rubio, J.C.; Abrăo, A.M.; Mansur, T.R. Development of a three-component dynamometer to measure turning force. Int. J. Adv. Manuf. Technol. 2012, 62, 913–922. [Google Scholar] [CrossRef]

- Yaldiz, S.; Ȕnsacar, F. Design, development and testing of a turning dynamometer for cutting force measurement. Mater. Des. 2006, 27, 839–846. [Google Scholar] [CrossRef]

- Totis, G.; Sortino, M. Development of a modular dynamometer for triaxial cutting force measurement in turning. Int. J. Mach. Tools Manuf. 2011, 51, 34–42. [Google Scholar] [CrossRef]

- Wang, C.; Rakowski, R.; Cheng, K. Design and analysis of a piezoelectric film embedded smart cutting tool. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 254–260. [Google Scholar] [CrossRef]

- Zhao, Z.M.; Xie, X.J. Study of dynamometer for surface grinding. J. Southeast Univ. 1981, 2, 69–84. [Google Scholar]

- Yaldiz, S.; Ȕnsacar, F. A dynamometer design for measurement the cutting forces on turning. Meas. J. Int. Meas. Confed. 2006, 39, 80–89. [Google Scholar] [CrossRef]

- Karabay, S. Design criteria for electro-mechanical transducers and arrangement for measurement of strains due to metal cutting forces acting on dynamometers. Mater. Des. 2007, 28, 496–506. [Google Scholar] [CrossRef]

- O’Dogherty, M.J. The design of octagonal ring dynamometers. J. Agric. Eng. Res. 1996, 63, 9–18. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Korkut, I. A dynamometer design and its construction for milling operation. Mater. Des. 2003, 24, 631–637. [Google Scholar] [CrossRef]

- Chen, X.Q.; Peng, X.N. Metal Cutting Principles and Tools, 1st ed.; Peking University Press: Beijing, China, 2006; pp. 49–52. [Google Scholar]

- Yaldiz, S.; Ȕnsacar, F.; Sağlam, H.; Isik, H. Design, development and testing of a four-component milling dynamometer for the measurement of cutting force and torque. Mech. Syst. Signal Process. 2007, 21, 1499–1511. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhao, Y.; Liang, S.; Zhou, G. A High Performance Sensor for Triaxial Cutting Force Measurement in Turning. Sensors 2015, 15, 7969-7984. https://doi.org/10.3390/s150407969

Zhao Y, Zhao Y, Liang S, Zhou G. A High Performance Sensor for Triaxial Cutting Force Measurement in Turning. Sensors. 2015; 15(4):7969-7984. https://doi.org/10.3390/s150407969

Chicago/Turabian StyleZhao, You, Yulong Zhao, Songbo Liang, and Guanwu Zhou. 2015. "A High Performance Sensor for Triaxial Cutting Force Measurement in Turning" Sensors 15, no. 4: 7969-7984. https://doi.org/10.3390/s150407969