Preparation of Mesoporous and/or Macroporous SnO2-Based Powders and Their Gas-Sensing Properties as Thick Film Sensors

Abstract

: Mesoporous and/or macroporous SnO2-based powders have been prepared and their gas-sensing properties as thick film sensors towards H2 and NO2 have been investigated. The mesopores and macropores of various SnO2-based powders were controlled by self-assembly of sodium bis(2-ethylhexyl)sulfosuccinate and polymethyl-methacrylate (PMMA) microspheres (ca. 800 nm in diameter), respectively. The introduction of mesopores and macropores into SnO2-based sensors increased their sensor resistance in air significantly. The additions of SiO2 and Sb2O5 into mesoporous and/or macroporous SnO2 were found to improve the sensing properties of the sensors. The addition of SiO2 into mesoporous and/or macroporous SnO2 was found to increase the sensor resistance in air, whereas doping of Sb2O5 into mesoporous and/or macroporous SnO2 was found to markedly reduce the sensor resistance in air, and to increase the response to 1,000 ppm H2 as well as 1 ppm NO2 in air. Among all the sensors tested, meso-macroporous SnO2 added with 1 wt% SiO2 and 5 wt% Sb2O5, which were prepared with the above two templates simultaneously, exhibited the largest H2 and NO2 responses.1. Introduction

In recent years, the development for porous materials is been an essential objective of materials science research. This interest is the result of the progress in all fields of industry and technology [1–5]. According to the IUPAC definition, microporous materials are those with pore diameters less than 2 nm, mesoporous materials are those that have pore diameters between 2 and 50 nm, and macroporous materials are those with pores bigger than 50 nm [6]. Among them, macroporous and mesoporous silica with sufficient thermal stability has been applied to catalysts [7,8] membranes [9], adsorbents [10], chemical sensors [11] and templates for nanowires [12]. On the contrary, the poor thermal stability of non-silica mesoporous materials limits their applications. Over the past 50 years, semiconductor metal oxides such as SnO2, ZnO and In2O3 have been extensively studied as gas sensing materials due to their various advantages such as the facile fabrication process of thin and thick films, low cost and high thermal stability [13,14]. Among the various metal oxides, SnO2 is one of the most attractive materials for semiconductor gas sensors [13–23] operated at elevated temperatures (200–600 °C). The gas sensing property of semiconductor gas sensors is largely dependent on various factors such as shape and size of the oxide particles [24–30]. In addition, strict control of nanostructure of the oxide powders is also quite effective in improving the gas sensing properties [31–34]. Thus, our group’s efforts have so far been directed to preparing thermally stable mesoporous (m-) [15–17] and macroporous (mp-) [18,21] oxide films. However, the H2 sensing properties of the m-SnO2 sensors were relatively lower than expected from their large specific surface area and mp-SnO2 showed rather excellent sensing properties to H2. Moreover, our recent studies have demonstrated the successful preparation of thermally stable meso-macroporous (m·mp-) SnO2 and the improvement of gas sensing properties by employing pellet-type sensor structures [19]. However, the mechanical strength of the m·mp-SnO2 pellets was not enough for long-term operation and this then became a subject for further investigation.

The present study is thus directed to developing m-, mp- and m·mp-SnO2 thick film sensors. The sensors were fabricated by screen-printing of their as-prepared powders, which were produced by employing sodium bis(2-ethylhexyl)sulfosuccinate (aerosol-OT, AOT) as a mesopore template and PMMA microspheres with an average diameter of 800 nm as a macropore template, and then subsequent calcination at 600 °C for 5 h. The effects of the addition of SiO2 and Sb2O5 to m-, mp- and m·mp-SnO2 powders on their H2 and NO2 sensing properties were also examined.

2. Experimental Section

2.1. Preparation of Mesoporous and/or Macroporous SnO2-Based Powders

Various SnO2-based powders with well-developed mesopores and/or macropores were prepared by a sol-gel method using SnCl4·5H2O (Kishida Chem. Co., Ltd.) as a Sn source, AOT (Kishida Chem. Co., Ltd.) as a mesopore template and PMMA microspheres with an average diameter of 800 nm (MP-1600, Soken Chem. & Eng. Co., Ltd.) as a macropore template. A given amount of SnCl4·5H2O (1.75 g) was mixed in 400 mL of ultra pure water together with an appropriate amount of AOT and/or PMMA microspheres. In some cases, appropriate amounts of tetraethoxysilane (TEOS, Kishida Chem. Co., Ltd.) and/or SbCl3 (Kishida Chem. Co., Ltd.) were also added to the solution, in order to prepare SnO2 powders added with the given amounts of SiO2 and/or Sb2O5. Then the pH value of the resulting mixture was adjusted to 8.5 by adding an aqueous solution of NH3. The solid product obtained was aged in the solution at 20 °C for 3 days, then the resulting product was separated from the solution by centrifugation. After drying the product in an oven at 80 °C overnight, the resulting powder product was treated with a 0.1 mol L−1 phosphoric acid solution for about 2 h, and the resulting product was dried in an oven at 80 °C overnight. The powder product resulting after pulverization is referred to as-prepared powder. The as-prepared powders were used for fabricating thick film sensors, but for the characterization tests, as-prepared powders were subjected to calcination at 600 °C for 5 h in air, which are the same conditions adopted for the thick film sensors after the screen-printing of a paste of as-prepared powders. The preparation conditions and compositions of all SnO2-based powders obtained in this study and their abbreviations are summarized in Table 1.

In our study, the SnO2-based powders prepared using AOT or PMMA microspheres as a template are identified by using abbreviations such as m-TxSy or mp-TxSy, respectively, and the SnO2-based powder prepared using both AOT and PMMA microspheres as templates is indicated as m·mp-TxSy, as shown in Table 1. Here, T and S mean the addition of TEOS and SbCl3 in the precursor solution, respectively, and x (x = 0, 1, 5) and y (y = 0, 1, 5) represent the added amounts of SiO2 and Sb2O5 (wt%) with respect to the weight of SnO2, respectively, on the basis of the expected weight of constituent oxides after calcination.

Crystal phase and crystallite size of SnO2-based powders were characterized with X-ray diffraction (XRD, CuKα, Shimadzu Corp., RINT-2200). The crystallite size was calculated by using Scherrer’s formula:

2.2. Fabrication of Mesoporous and/or Macroporous SnO2-Based Thick Film Sensors

The as-prepared SnO2-based powder was mixed with a printing oil which is composed of an alkyl ester of methacrylic acid as a binder, a toluene-based solvent, and an ammonium salt of polyacrylic acid as a plasticizer, and the resulting paste was screen printed on an alumina substrate, on which a pair of interdigitated Pt electrodes (gap between electrodes: 130 μm) had been printed (the thickness of the film was controlled to be about 20 μm after calcination for all the sensors fabricated). Then the printed film was subjected to heat treatment at 600 °C for 5 h in air prior to response measurements. The gas-sensing properties of the thick film sensors to 1,000 ppm H2 and 1 ppm NO2 balanced with air were measured in the temperature range of 350–500 °C. The magnitude of the gas response was defined as the ratio (Ra/Rg) of the sensor resistance in air (Ra) to that in a target gas (Rg) for H2, but the reverse ratio (Rg/Ra) was used for NO2.

3. Results and Discussion

3.1. Characterization of Mesoporous and/or Macroporous SnO2-Based Powders

Pore size distribution and specific surface area (SSA) of representative m-SnO2, mp-SnO2 and m·mp-SnO2 powders after calcination are shown in Figure 1. As shown in Figures 1(a-i), m-T0S0 powder, which was prepared only with the addition of AOT, showed a SSA of 150.9 m2 g−1 and a larger pore volume of 0.153 cm3 g−1 with a pore diameter of ca. 3.1 nm at the maximum pore volume (hereafter, it will be referred to as the maximum pore diameter). The characterization data of representative SnO2-based powders is summarized in Table 2. The addition of 1 wt% SiO2 to m-T0S0 induced a slight increase in SSA (162.3 m2 g−1) and reduced the maximum pore diameter to ca. 2.7 nm (see m-T1S0). This result implies the repression of growth of SnO2 crystallites and/or grains by the added SiO2, as was reported by Fukuoka et al. [12]. Simultaneous addition of 1 wt% SiO2 and 5 wt% Sb2O5 to m-T0S0 resulted in further increase in SSA slightly to a value of 176.5 m2 g−1 (see m-T1S5). Thus, the addition of Sb2O5 was suggested to be also effective in controlling grain growth, which will be confirmed by the change in SnO2 crystallite size discussed later.

It was revealed that the introduction of macropores into m-T1S5 was very effective for increasing SSA to a value of 262.7 m2 g−1 (see m·mp-T1S5, Figures 1(c-ii)). This arises undoubtedly from the decrease in the maximum pore diameter and the increase in pore volume, as summarized in Table 2. On the other hand, the introduction of macropores only (mp-T1S5), instead of mesopores (m-T1S5), into SnO2-based powder reduced SSA to a value of 112.0 m2 g−1 (compare Figure 2(b-ii) with Figure 2(a-iii)) and then decreased pore volume (see Table 2). From these results, it is confirmed that the introduction of mesopores is essential for obtaining both large specific surface and large pore volume of SnO2-based powders.

Figure 2 shows variations in SSA of representative SnO2-based powders with amount of Sb2O5 added. The effect of the Sb2O5 on SSA can be seen more clearly from this figure. As for the cases of m-T1Sy and mp-T1Sy series, SSA values increased slightly with increasing amounts of Sb2O5 added, but only for the m·mp-T1Sy series, it is obvious that SSA increased markedly with an increase in the additive amount of Sb2O5 reaching the largest value of 262.7 m2 g−1 obtained in the present study. The reason for this preferable effect for sensor application observed only the m·mp-T1Sy series is not yet clarified and is a subject for future work.

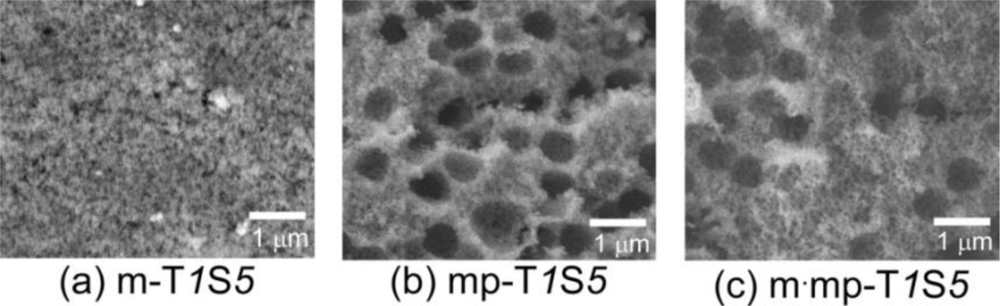

Figure 3 shows the SEM images of the fracture surface of m-T1S5, mp-T1S5 and m·mp-T1S5 thick film sensors. No formation of macropores in m-T1S5 is reasonable, since no PMMA microspheres were added, as shown in Figure 3(a). But, Figure 3(b,c) confirm the formation of many spherical macropores originating from the morphology of PMMA microspheres as a template in the mp-T1S5 and m·mp-T1S5 thick film sensors. However, the diameter of macropores observed was in the 400–750 nm range, which was smaller than that of the diameter of raw PMMA microspheres, due to shrinkage of resulting voids during the growth of SnO2 crystallites.

As shown in Figure 1 and Table 1, mp-SnO2 powder prepared in the present study showed relatively larger SSA than the conventional SnO2 powder (8.4 m2 g−1, [35]), indicating the formation of a certain amount of mesopores, irrespective of the addition or not of AOT as a mesoporous structure template. This result implies penetration or diffusion of PMMA fragments into the dried SnO2 precursor material during the calcination and such fragments may act as a mesoporous template at the interface between the PMMA microsphere and surrounding dried SnO2 precursor. Thus, after the calcination at 600 °C for 5 h of the mp-SnO2 thick film, a thin mesoporous layer may be formed at the interface between the pores and SnO2 particles, as shown schematically in Figure 4(a) [36]. As for m·mp-SnO2, it is considered that mesopores are formed uniformly inside all the SnO2 particles and the whole thick film structure, as shown in Figure 4(b).

Another notable finding in Figure 3 is a relatively longer distance of the macropores in m·mp-T1S5 than that in mp-T1S5. Since AOT was used as a mesoporous template in fabricating m·mp-SnO2 powder, thermal decomposition and subsequent firing along with generation of combustion gases may induce sponge and/or bulky structure with mesopores, leading to a longer distance of the macropores, as also shown schematically in Figure 4(b).

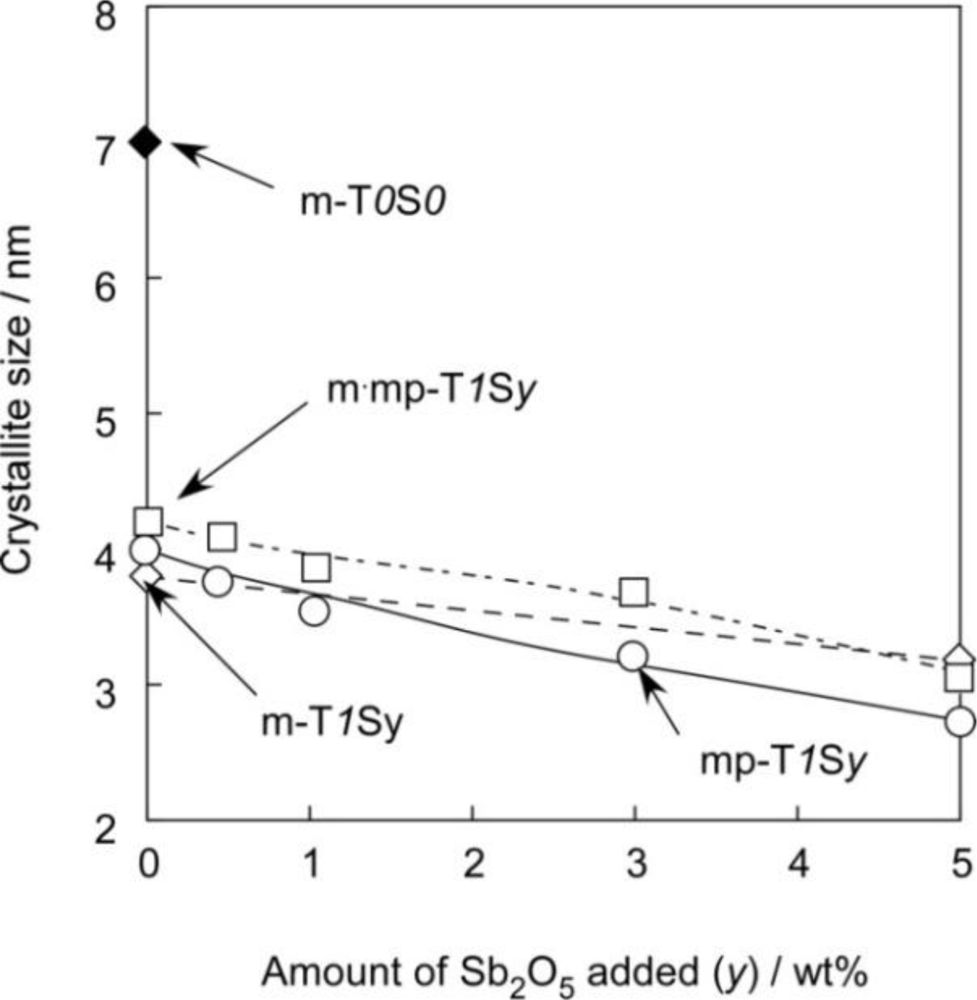

Figure 5 shows XRD patterns of representative m-SnO2, mp-SnO2 and m·mp-SnO2 powders. Diffraction peaks of all powders were rather broad, indicating low crystallinity, but all peaks could be ascribed to those of tetragonal SnO2. The CS value which was calculated for each powder using Scherrer’s formula is summarized in Table 2. Variations in CS of representative SnO2-based powders are shown Figure 6. On the whole, the CS values were small and were in a range of 2.7–7 nm in diameter, due to the limitation of crystallite growth induced by the phosphoric acid treatment before the calcination [15,16]. Exceptionally, m-T0S0 showed the largest CS value of 7 nm. The CS value was decreased drastically to 3.8 nm by the addition of 1 wt% SiO2 to m-T0S0 (see m-T1S0 in Table 2 and Figure 6). Thus, the repression of the growth of SnO2 crystallites by the added SiO2 could be confirmed from these results [37]. As for the powders containing 1 wt% SiO2, CS values were almost comparable, whereas they tended to decrease slightly with increasing amounts of the Sb2O5 additive in each series. In addition, the kind of porous structure, i.e., mesopore, macropore, and mesopore plus macropore, was found to have only a little effect on controlling the CS values. Thus, we can confirm again that the addition of 1 wt% SiO2 was the most powerful method in reducing the CS value among several factors. The CS values decreased slightly by the Sb2O5 addition in each series, but no diffraction peaks other than SnO2 were observed in XRD patterns even for the cases of 5 wt% Sb2O5 addition (Figure 5). This implies that Sb ions added were sufficiently incorporated into the SnO2 crystal lattice and this solid-solution is also effective for the repression of the crystal growth among SnO2-based crystallites [23,38,39]. These results demonstrate that the pore size distribution, SSA and CS values of SnO2-based powders can be controlled by selecting the kinds of templates, the kind of additives and their additive amounts.

3.2. H2 and NO2 Sensing Properties of Mesoporous and/or Macroporous SnO2-Based Sensors

Variations in sensor resistance of SnO2-based thick film sensors in air at 450 °C with amounts of Sb2O5 added are shown in Figure 7. The m-T0S0 sensor showed the lowest resistance in air, but the addition of 1 wt% SiO2 to m-T0S0 increased the sensor resistance in air (see m-T1S0). The sensor resistance of other two series sensors, i.e., mp-T1S0 and m·mp-T1S0, in air was also very high. Even if Si4+ ions would be substituted for Sn4+ ion sites, no valency control effect could be expected. Therefore, SiO2 added was anticipated to be segregated among SnO2 crystallites and/or grains and then to reduce electronic conduction of SnO2-based thick film sensors, although the segregation of SiO2 was not confirmed by the XRD measurements due to its small amount added.

Introduction of macropores into SnO2 by using PMMA microspheres (see mp-T1Sy series), instead of the introduction of mesopores, and/or the simultaneous introduction of macropores (see m·mp-T1Sy series) also resulted in an increase in sensor resistance. This phenomenon can be considered to arise mainly from the introduction of air voids, which are electrical insulators, via various pores in the thick film sensors, but the mp-T1Sy sensor with macropores showed the largest resistance in air, irrespective of the smallest pore volume, among three series of sensors. This fact implies the existence of another factor, besides the pore volume, in determining the sensor resistance in air, such as the manner of distribution of pores in the thick film and so on, though the details are not clear at present.

In each sensor series, the sensor resistance in air decreased with increasing amounts of Sb2O5 additive. This behavior can be explained by the valency control, i.e., partial substitution of Sn4+ sites with Sb5+ ions, producing free electrons, as described in Equation (2) [38–40]:

These results also confirm the existence of substituted Sb5+ ions, i.e., the solid-solution of between Sb2O5 and SnO2 and then little amount of segregated Sb2O5 among SnO2-based particles.

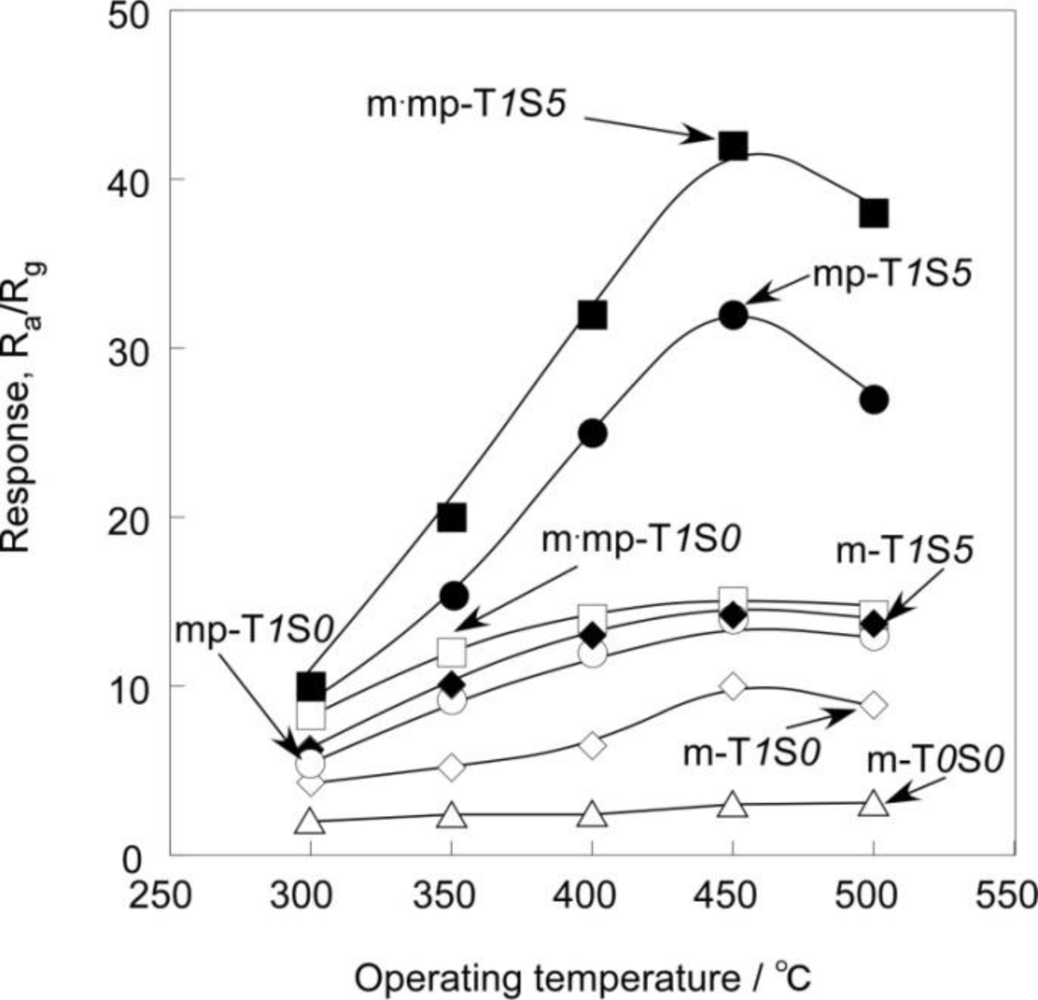

Figures 8 and 9 show temperature dependence of response of SnO2-based thick film sensors to 1,000 ppm H2 balanced with air and 1 ppm NO2 balanced with air. Almost all sensors showed the maximum response to 1,000 ppm H2 at a temperature of 450 °C. In contrast, the response to 1 ppm NO2 of all sensors tended to increase as the operating temperature decreased, and showed the largest response in the temperature range studied at 350 °C.

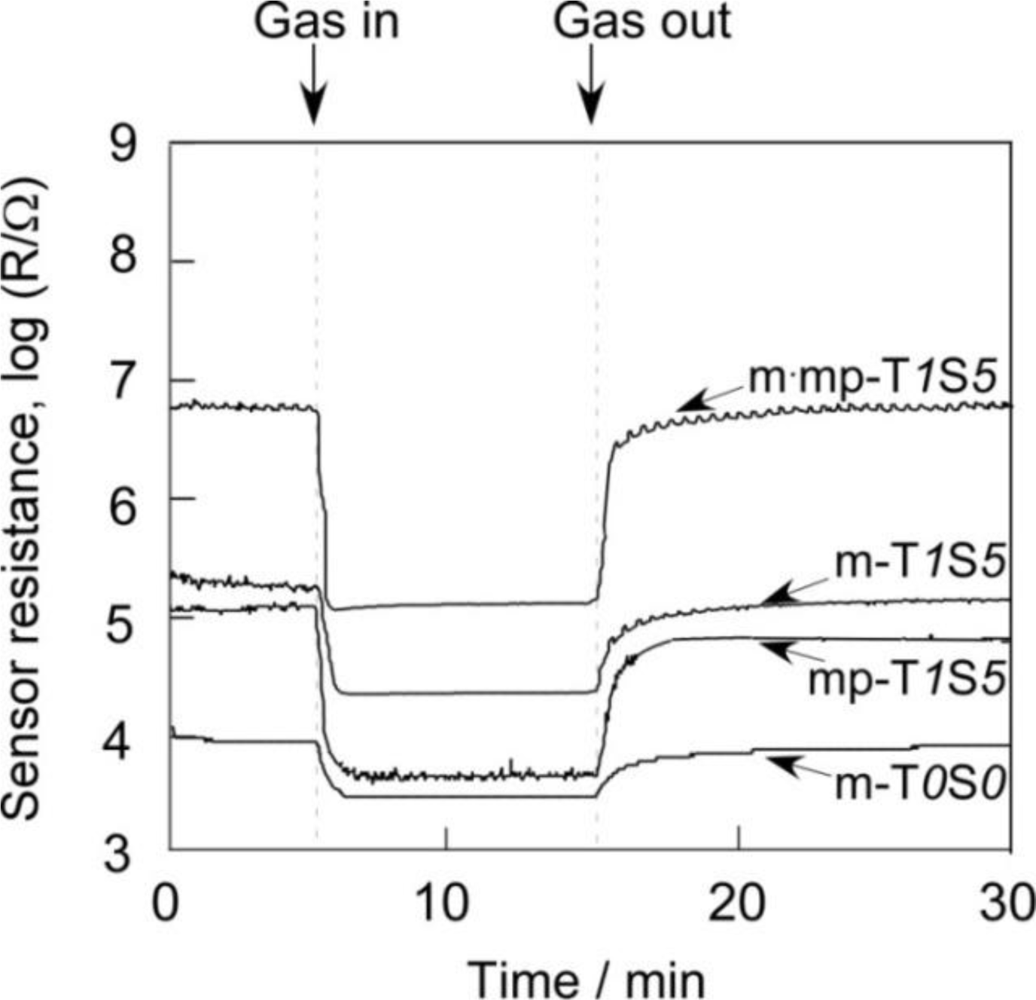

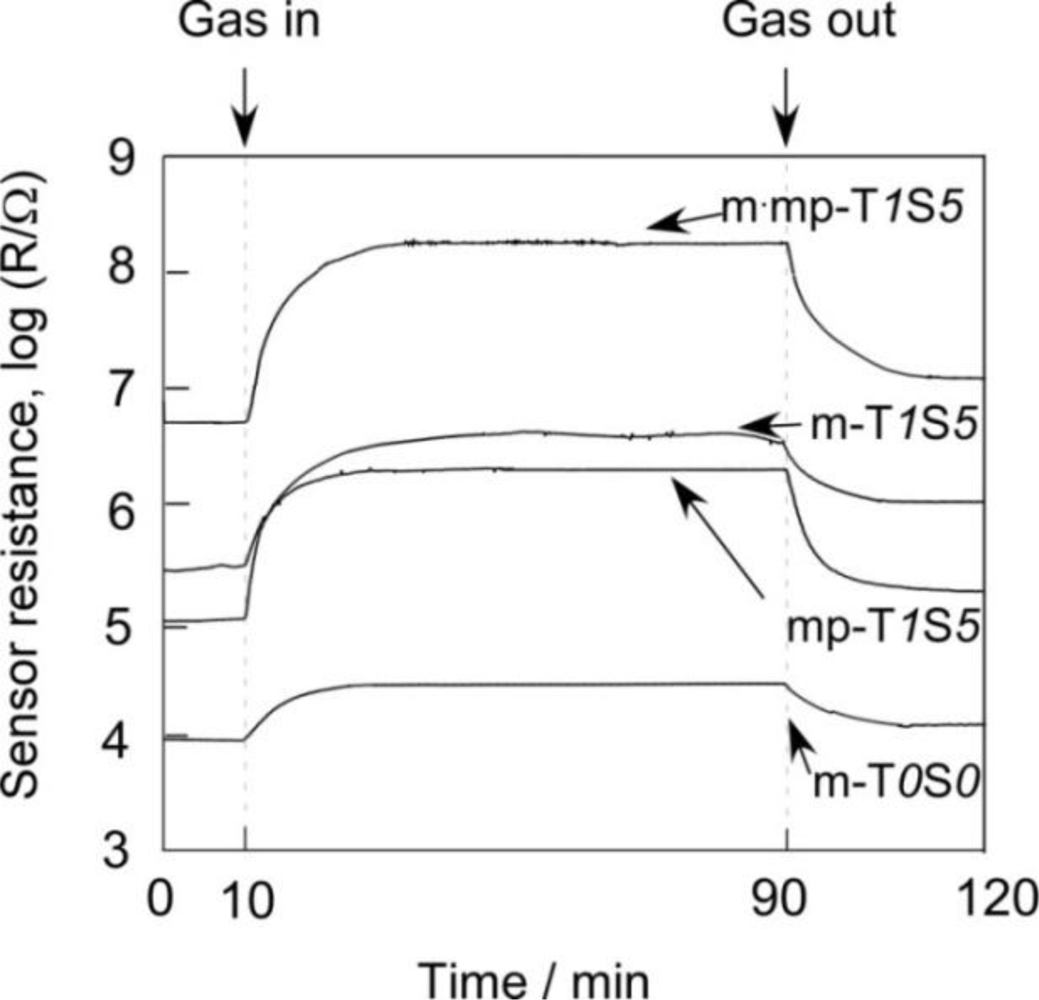

Response transients of SnO2-based thick film sensors to 1,000 ppm H2 at 450 °C and 1 ppm NO2 at 350 °C balanced with air are shown in Figures 10 and 11, respectively. In this study, 50% response time is defined as a period necessary to achieve 50% of resistance value of Ra − Rg, while 50% recovery time is defined as that necessary to achieve 50% of resistance value of Rg − Ra for H2. The 50% response and recovery times to NO2 are also defined in the similar manner, but by using Rg − Ra for response time and Ra − Rg for recovery time. Hereafter, they are simply expressed as response time and recovery time, respectively. Response and recovery times of SnO2-based thick film sensors to 1,000 ppm H2 at 450 °C and 1 ppm NO2 at 350 °C were summarized in Table 3. The m-T0S0 sensor showed the longest response and recovery times to H2 among the sensors listed in Table 3. The simultaneous addition of 1 wt% SiO2 and 5 wt% Sb2O5 to m-T0S0 was found to shorten slightly response and recovery times to H2 (see m-T1S5).

However, the m-T1S5 sensor showed longer response and recovery times to 1 ppm NO2 than m-T0S0. Thus, the effect of additive on the response and recovery times varied with the kind of target gas. The introduction of macropores into m-T1S5 shortens the response and recovery times to H2. More remarkable shortening of the recovery time to H2 as well as response and recovery times to NO2 were observed with m·mp-T1S5. It is reasonable to consider that the response time to H2 is closely related to the diffusivity of H2, while the recovery time is controlled by the diffusivity of O2 which has a larger molecular size than H2. As for NO2, on the other hand, both the response and recovery times are considered to affected by the diffusivity of NO2 itself, which has a larger molecular size than H2, from its gas sensing mechanism. Such considerations predict a shorter recovery time to H2 as well as shorter response and recovery times to NO2 by the introduction of macropores into the sensor materials. The results obtained with m·mp-T1S5 were in good agreement with this prediction. Thus, the mp-T1S5 sensor, which was fabricated only by the introduction of macropores, showed the fastest response to H2 as well as the fastest response and recovery times to NO2 among the sensors tested. But, the reason for the longer recovery time to H2 of mp-T1S5 than m·mp-T1S5 is not clear at present. Anyway, such behavior undoubtedly arises from more easy diffusion of a target gas as well as oxygen through mesopores rather than macropores. On the other hand, all of the response and recovery times to NO2 are much longer than those to H2. This may arise not only from slow diffusivity of NO2 in comparison to H2, but also from slow adsorption rate and strong interaction of NO2− species on the oxide surface.

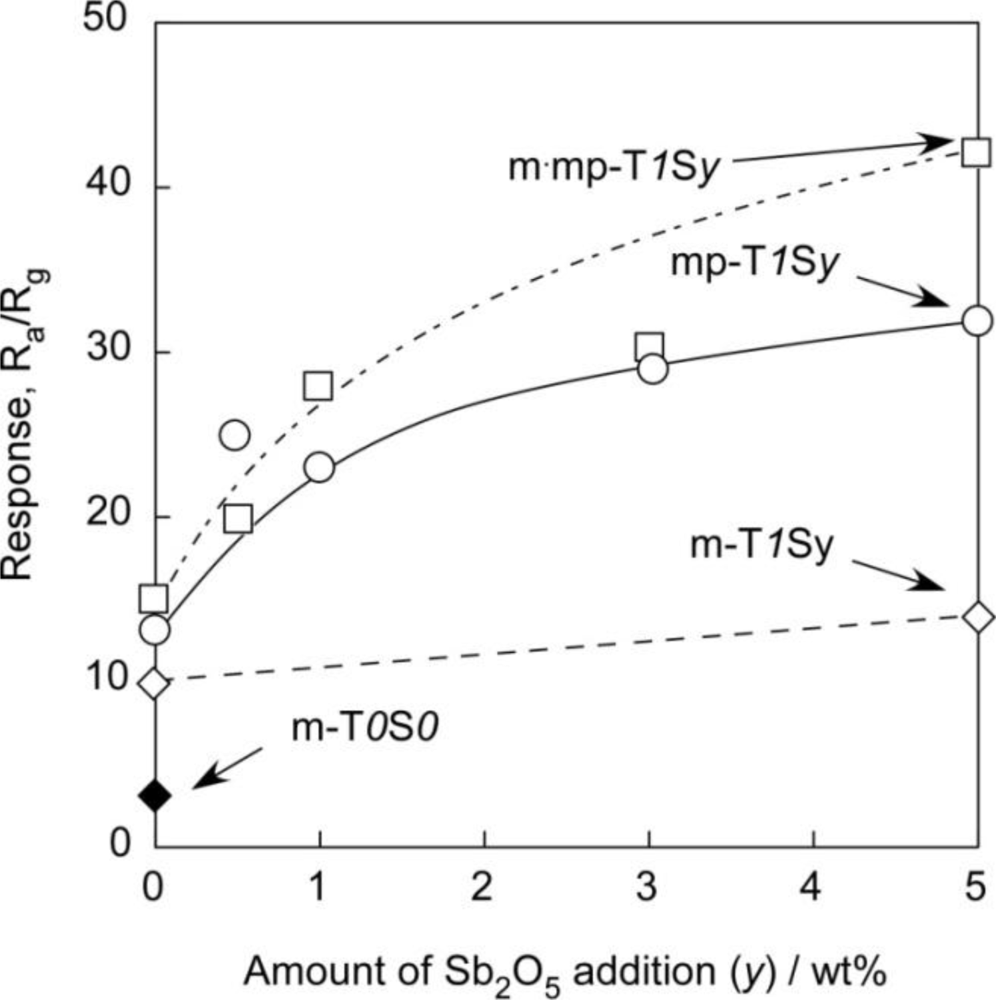

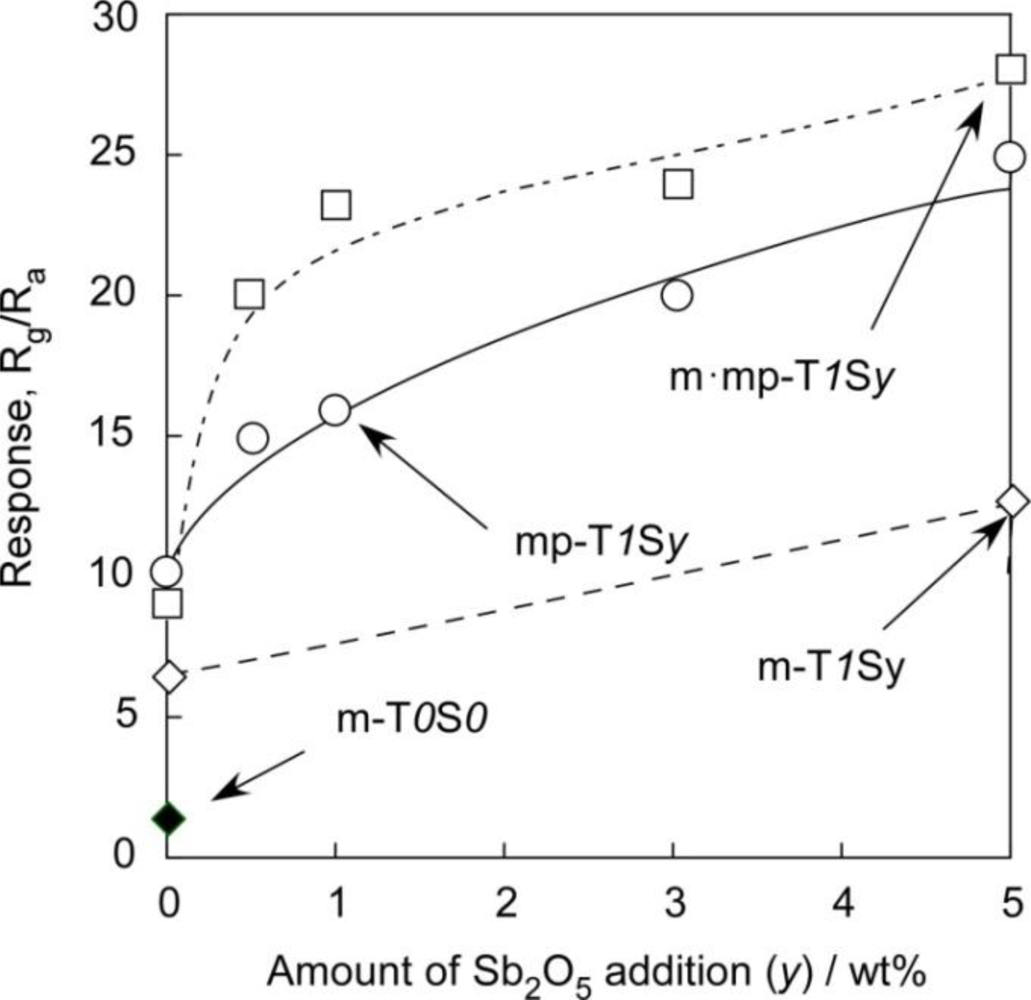

Figures 12 and 13 show variations in responses of SnO2-based sensors to 1,000 ppm H2 at 450 °C and to 1 ppm NO2 at 350 °C in air with amounts of Sb2O5 added, respectively. From these figures, it is also apparent that the m-T0S0 sensor showed the smallest responses to both H2 and NO2 among the sensors studied. The addition of 1 wt% SiO2 to m-T0S0 enhanced responses to both H2 and NO2 to a certain level for every series of sensors. In addition, H2 and NO2 responses increased with increasing amounts of Sb2O5 additive in each series of sensors. On the whole, the magnitude of the response was in the order of m·mp-T1Sy > mp-T1Sy > m-T1Sy, when the comparison was made at the same additive amount of Sb2O5, with only one exception observed for the NO2 response of the m·mp-T1S0 sensor. It is worth noting that the mp-T1Sy series sensors showed higher H2 and NO2 responses than those of m-T1Sy series sensors, irrespective of their smaller surface area. This implies that all the surface of sensor materials including the inner surface of mesopores is not utilized effectively for gas detection, and that easy diffusion of a target gas as well as oxygen to the active surface, i.e., the existence of certain amounts of macropores inside the thick film sensors, is more important for improving gas response. The highest H2 and NO2 responses observed with the m·mp-T1Sy sensors may be a result of good combination of mesopore and macropores in the thick film sensors. From these results, it was revealed that the strict control of microstructure having well-developed mesoporous and macroporous is indispensable to enhancing gas reactivity and diffusivity and thus to improving responses to H2 and NO2 in air.

4. Conclusions

Mesoporous and/or macroporous SnO2-based powders have been prepared by a sol-gel method by employing SnCl4·5H2O, ATO as a mesopore template, PMMA microspheres as a macropore template, and their gas-sensing properties as thick film sensors towards 1 ppm NO2 as well as 1,000 ppm H2 in air have been investigated. The addition of SiO2 into mesoporous and/or macroporous SnO2 was found to increase SSA of mesoporous SnO2. However, the SSA of all samples increased and their CS tended to decrease slightly with the addition of the Sb2O5. The additions of SiO2 and Sb2O5 into mesoporous and/or macroporous SnO2 were found to improve the sensing properties of the resulting sensors. The addition of SiO2 into mesoporous and/or macroporous SnO2 was found to increase the sensor resistance in air. However, the doping of Sb2O5 into mesoporous and/or macroporous SnO2 was found to markedly reduce the sensor resistance in air, and to increase the response to 1,000 ppm H2 as well as 1 ppm NO2 in air. Among all the sensors tested, meso-macroporous SnO2 mixed with 1 wt% SiO2 and 5 wt% Sb2O5, which were prepared with above two templates simultaneously, exhibited the largest H2 and NO2 responses.

References and Notes

- Soler-Illia, G.J.A.A.; Sanchez, C.; Lebeau, B.; Patarin, J. Chemical strategies to design textured materials: From microporous and mesoporous oxides to nano networks and hierarchical structures. Chem. Rev 2002, 102, 4093–4138. [Google Scholar]

- Havancsak, K. Materials science: Testing and informatics I. Materi. Sci. Forum 2003, 85, 414–415. [Google Scholar]

- Wolf, E.L. Nanophysics and Nanotechnology: An Introduction to Modern Concepts in Nanoscience; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Yamazoe, N. New approaches for improving semiconductor gas sensors. Sens. Actuat. B 1991, 5, 7–19. [Google Scholar]

- Borisenko, V.E.; Ossicini, S. What is What in the Nanoworld: A Handbook on Nanoscience and Nanotechnology; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Szostak, R. Handbook of Molecular Sieves; Van Nostrand Reinhold: New York, NY, USA, 1992. [Google Scholar]

- Nguyen, S.V.; Szabo, V.; Trong On, D.; Kaliaguine, S. Mesoporous silica supported LaCoO3 perovskites as catalysts for methane oxidation. Microporous Mesoporous Mater 2002, 54, 51–61. [Google Scholar]

- Umbarkar, S.B.; Kotbagi, T.V.; Biradar, A.V.; Pasricha, R.; Chanale, J.; Dongare, M.K.; Mamede, A.S.; Lancelot, C.; Payen, E. Acetalization of glycerol using mesoporous MoO3/SiO2 solid acid catalyst. J. Mol. Catal. A Chem 2009, 310, 150–158. [Google Scholar]

- Zhong, S.H.; Li, C.F.; Li, Q.; Xiao, X.F. Supported mesoporous SiO2 membrane synthesized by sol-gel-template technology. Sep. Purif. Technol 2003, 32, 17–22. [Google Scholar]

- Li, J.; Zhang, Y.; Hao, Y.; Zhao, J.; Sun, X.; Wang, L. Synthesis of ordered mesoporous silica membrane on inorganic hollow fiber. J. Colloid Interface Sci 2008, 326, 439–444. [Google Scholar]

- Liu, J.; Cai, Y.; Deng, Y.H.; Sun, Z.K.; Gu, D.; Tu, B.; Zhao, D. Magnetic 3-D ordered macroporous silica templated from binary colloidal crystals and its application for effective removal of microcystin. Microporous Mesoporous Mater 2010, 130, 26–31. [Google Scholar]

- Fukuoka, A.; Araki, H.; Sakamoto, Y.; Inagaki, S.; Fukushima, Y.; Ichikawa, M. Palladium nanowires and nanoparticles in mesoporous silica templates. Inorg. Chim. Acta 2003, 350, 371–378. [Google Scholar]

- Choe, Y.S. New gas sensing mechanism for SnO2 thin-film gas sensors fabricated by using dual ion beam sputtering. Sens. Actuat. B 2001, 77, 200–208. [Google Scholar]

- Kim, D.; Yoon, J.; Park, H.; Kim, K. CO2-sensing characteristics of SnO2 thick film by coating lanthanum oxide. Sens. Actuat. B 2000, 62, 61–66. [Google Scholar]

- Hyodo, T.; Shimizu, Y.; Egashira, M. Design of mesoporous oxides as semiconductor gas sensor materials. Electrochemistry 2003, 71, 387–392. [Google Scholar]

- Hyodo, T.; Nishida, N.; Shimizu, Y.; Egashira, M. Preparation and gas-sensing properties of thermally stable mesoporous SnO2. Sens. Actuat. B 2002, 83, 209–215. [Google Scholar]

- Sasahara, K.; Hyodo, T.; Shimizu, Y.; Egashira, M. Macroporous and nanosized ceramic films prepared by modified sol-gel method with PMMA microsphere templates. J. Eur. Ceram. Soc 2004, 24, 1961–1967. [Google Scholar]

- Hyodo, T.; Sasahara, K.; Shimizu, Y.; Egashira, M. Preparation of macroporous SnO2 films using PMMA microspheres and their sensing properties to NOx and H2. Sens. Actuat. B 2005, 106, 580–590. [Google Scholar]

- Yuan, L.; Hyodo, T.; Shimizu, Y.; Egashira, M. Preparation of mesoporous and meso-macroporous SnO2 powders and their application to H2 gas sensor. Sens. Mater 2009, 21, 241–250. [Google Scholar]

- Supothina, S. Gas sensing properties of nanocrystalline SnO2 thin films prepared by liquid flow deposition. Sens. Actuat. B 2003, 93, 526–530. [Google Scholar]

- Firooz, A.A.; Hyodo, T.; Mahjoub, A.R.; Khodadadi, A.A.; Shimizu, Y.; Egashira, M. Synthesis and gas-sensing properties of nano- and mesoporous MoO3-doped SnO2. Sens. Actuat. B 2010, 147, 554–560. [Google Scholar]

- Hyodo, T.; Abe, S.; Shimizu, Y.; Egashira, M. Gas-sensing properties of ordered mesoporous SnO2 and effects of coatings thereof. Sens. Actuat. B 2003, 93, 590–600. [Google Scholar]

- Szczuko, D.; Werner, J.; Oswald, S.; Behr, G.; Wetzig, K. Surface-related investigations to characterize different preparation techniques of Sb-doped SnO2 powders. Appl. Surf. Sci 2001, 79, 484–491. [Google Scholar]

- Horrillo, M.C.; Serventi, A.; Rickerby, D.; Gutierrez, J. Influence of tin oxide microstructure on the sensitivity to redactor gases. Sens. Actuat. B 1999, 58, 474–477. [Google Scholar]

- Jones, A.; Jones, T.A.; Mann, B.; Firth, J.G. The effect of the physical form of the oxide on the conductivity changes produced by CH4, CO and H2O on ZnO. Sens. Actuat 1984, 5, 75–88. [Google Scholar]

- Xu, C.N.; Tamaki, J.; Miura, N.; Yamazoe, N. Grain size effects on gas sensitivity of porous SnO2-based elements. Sens. Actuat. B 1991, 3, 147–155. [Google Scholar]

- Ahn, J.P.; Kim, S.H.; Park, J.K.; Huh, M.Y. Effect of orthorhombic phase on hydrogen gas sensing property of thick film sensors fabricated by nanophase tin dioxide. Sens. Actuat. B 2003, 7106, 1–7. [Google Scholar]

- Clifford, P.K.; Tuma, D.T. Characteristics of semiconductor gas sensors. II. Transient response to temperature change. Sens. Actuat 1982, 3, 255–265. [Google Scholar]

- Yamazoe, N.; Sakai, G.; Shimanoe, K. Oxide semiconductor gas sensors. Catal. Surv. Asia 2003, 7, 63–75. [Google Scholar]

- Ahna, J.P.; Kim, J.H.; Park, J.K.; Huh, M.Y. Microstructure and gas-sensing properties of thick film sensor using nanophase SnO2 powder. Sens. Actuat. B 2004, 99, 18–24. [Google Scholar]

- Williams, G.; Coles, G.S.V. Gas-sensing potential of nanocrystalline tin dioxide produced by a laser ablation technique. MRS Bull 1999, 24, 25–29. [Google Scholar]

- Tholen, A.R. Formation land observation of ultrafine particles. Mater. Sci. Eng 1993, A168, 131–135. [Google Scholar]

- Herrmann, J.M.; Disdier, J.; Fernandez, A.; Jimenez, V.M.; Sanchez-Lopez, J.C. Oxygen gas sensing behavior of nanocrystalline tin oxide prepared by the gas phase condensation method. Nano Struct. Mater 1997, 6, 675–686. [Google Scholar]

- Li, G.J.; Kawi, S. High-surface area SnO2: A novel semiconductor oxide gas sensor. Mater. Lett 1998, 34, 99–102. [Google Scholar]

- Shimizu, Y.; Hyodo, T.; Egashira, M. Mesoporous semiconducting oxides for gas sensor application. J. Eur. Ceram. Soc 2004, 34, 1389–1398. [Google Scholar]

- Hieda, K.; Hyodo, T.; Shimizu, Y.; Egashira, M. Preparation of porous tin dioxide powder by ultrasonic spray pyrolysis and their application to sensor materials. Sens. Actuat. B 2008, 133, 144–150. [Google Scholar]

- Hyodo, T.; Baba, Y.; Wada, K.; Shimizu, Y.; Egashira, M. Hydrogen sensing properties of SnO2 varistors loaded with SiO2 by surface chemical modification with diethoxydimethylsilane. Sens. Actuat. B 2000, 64, 175–181. [Google Scholar]

- Li, L.L.; Mao, L.; Duan, X.C. Solvothermal synthesis and characterization of Sb-doped SnO2 nanoparticles used as transparent conductive films. Mater. Res. Bull 2006, 41, 541–546. [Google Scholar]

- Wang, Y.D.; Chen, T. Nonaqueous and template-free synthesis of Sb doped SnO2 microspheres and their application to lithium-ion battery anode. Electrochim. Acta 2009, 54, 3510–3515. [Google Scholar]

- Kong, J.; Deng, H.; Yang, P.; Chu, J. Properties of pure and antimony-doped tin dioxide thin films fabricated by sol-gel technique on silicon wafer. Mater. Chem. Phys 2009, 114, 854–859. [Google Scholar]

| Sensors | Mesopore template (AOT) /g* | Macropore template (PMMA) /g* | Amount of MO added to SnO2 (x or y)/wt% | ||

|---|---|---|---|---|---|

| Kind of powder | Abbreviation | MO: Sb2O5 (using NbCl5) | MO: SiO2 (using TEOS) | ||

| Mesoporous (m-) SnO2 | m-T0S0 | 1.75 | none | none | none |

| m-T1S0 | 1.0 | ||||

| m-T1S5 | 5.0 | ||||

| Meso-macroporous (m·mp-) SnO2 | m·mp-T1S0 | 1.75 | 0.35 | none | 1.0 |

| m·mp-T1S0.5 | 0.5 | ||||

| m·mp-T1S1 | 1.0 | ||||

| m·mp-T1S3 | 3.0 | ||||

| m·mp-T1S5 | 5.0 | ||||

| Macroporous (mp-) SnO2 | mp-T1S0 | none | 0.35 | none | 1.0 |

| mp-T1S0.5 | 0.5 | ||||

| mp-T1S1 | 1.0 | ||||

| mp-T1S3 | 3.0 | ||||

| mp-T1S5 | 5.0 | ||||

*In 400 mL aqueous solution.

| Sensors | Specific surface area (SSA) /m2 g−1 | Pore volume/cm3 g−1 | Maximum pore diameter */nm | Crystallite size (CS)/nm | |

|---|---|---|---|---|---|

| Kind of powder | Abbreviation | ||||

| m-SnO2 | m-T0S0 | 150.9 | 0.153 | 3.1 | 7.0 |

| m-T1S0 | 162.3 | 0.160 | 2.7 | 3.8 | |

| m-T1S5 | 176.5 | 0.155 | 2.5 | 3.2 | |

| m·mp-SnO2 | m·mp-T1S0 | 178.2 | 0.184 | 2.5 | 4.2 |

| m·mp-T1S5 | 262.7 | 0.191 | 2.3 | 3.2 | |

| mp-SnO2 | mp-T1S0 | 101.8 | 0.090 | 2.9 | 3.9 |

| mp-T1S5 | 112.0 | 0.079 | 2.0 | 2.7 | |

*Pore diameter at the maximum pore volume in the pore size distribution curve.

| Sensors | 1,000 ppm H2 (450 °C) | 1 ppm NO2 (350 °C) | |||

|---|---|---|---|---|---|

| Kind of powder | Abbreviation | 50% response time/s | 50% recovery time/s | 50% response time/s | 50% recovery time/s |

| m-SnO2 | m-T0S0 m-T1S5 | 25 22 | 35 29 | 182 195 | 330 600 |

| m·mp-SnO2 | m·mp-T1S5 | 20 | 17 | 154 | 325 |

| mp-SnO2 | mp-T1S5 | 16 | 22 | 110 | 220 |

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Yuan, L.; Hyodo, T.; Shimizu, Y.; Egashira, M. Preparation of Mesoporous and/or Macroporous SnO2-Based Powders and Their Gas-Sensing Properties as Thick Film Sensors. Sensors 2011, 11, 1261-1276. https://doi.org/10.3390/s110201261

Yuan L, Hyodo T, Shimizu Y, Egashira M. Preparation of Mesoporous and/or Macroporous SnO2-Based Powders and Their Gas-Sensing Properties as Thick Film Sensors. Sensors. 2011; 11(2):1261-1276. https://doi.org/10.3390/s110201261

Chicago/Turabian StyleYuan, Luyang, Takeo Hyodo, Yasuhiro Shimizu, and Makoto Egashira. 2011. "Preparation of Mesoporous and/or Macroporous SnO2-Based Powders and Their Gas-Sensing Properties as Thick Film Sensors" Sensors 11, no. 2: 1261-1276. https://doi.org/10.3390/s110201261

APA StyleYuan, L., Hyodo, T., Shimizu, Y., & Egashira, M. (2011). Preparation of Mesoporous and/or Macroporous SnO2-Based Powders and Their Gas-Sensing Properties as Thick Film Sensors. Sensors, 11(2), 1261-1276. https://doi.org/10.3390/s110201261