Applicability of Vacuum Impregnation to Modify Physico-Chemical, Sensory and Nutritive Characteristics of Plant Origin Products—A Review

Abstract

:1. Introduction

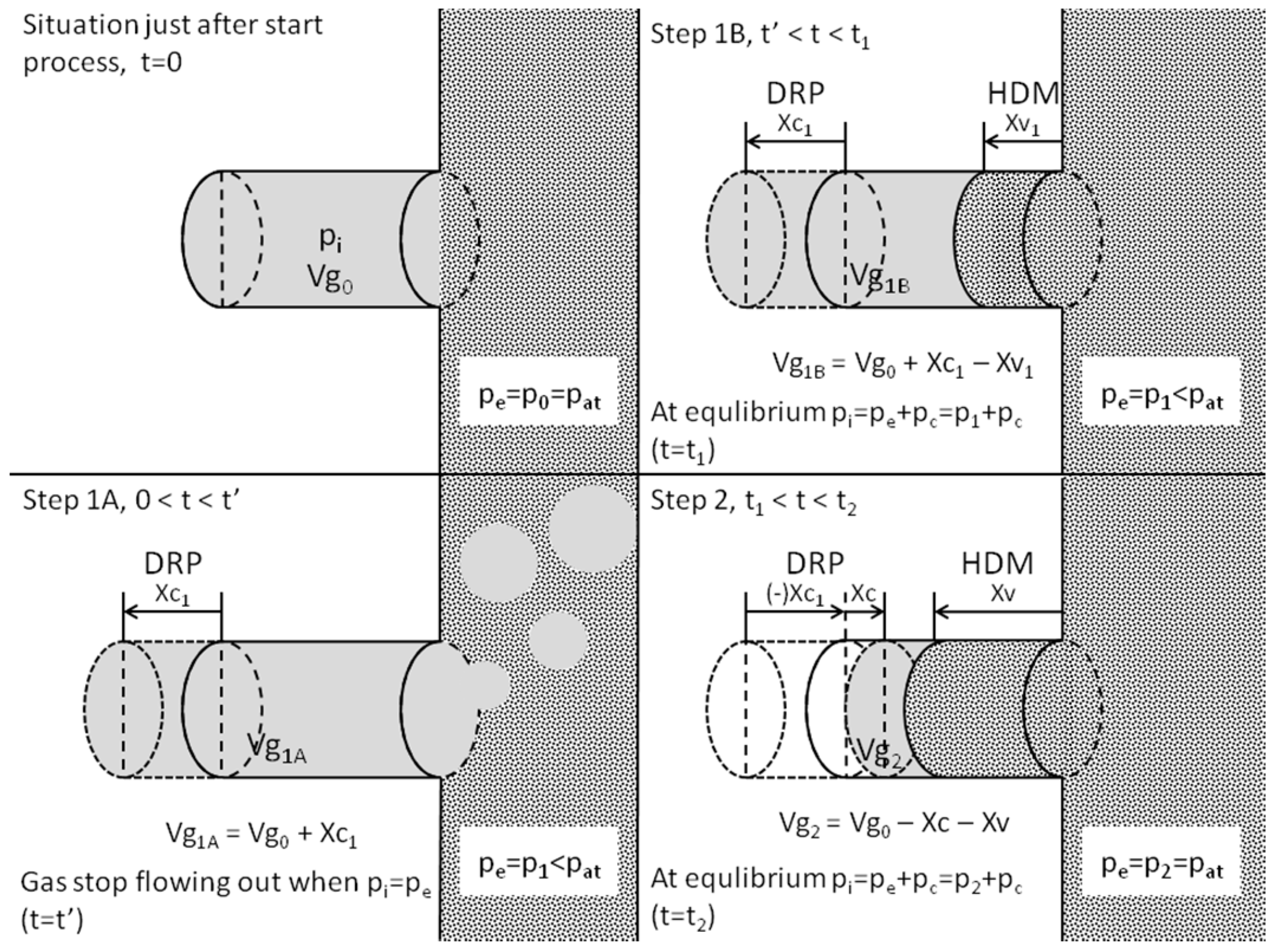

2. The Course of the Vacuum Impregnation Process

3. The Application of Vacuum Impregnation to Modify Physico–Chemical Properties and Sensory Attributes of the Product

| Raw Material | Composition of Vacuum Impregnation Solutions | Process Parameters | Effect | References |

|---|---|---|---|---|

| peppers (slices of 15 cm in length and 1 cm in width) | lactic acid solution (pH 2.70) | solution:sample mass ratio of 5:1; | increase of the acidification degree in peppers | [10] |

| p1 20 or 40 kPa | ||||

| t1 2 or 5 min | ||||

| t2 10, 15 and 30 min | ||||

| mushrooms (Agaricus bisporus) (cut in half) | lactic acid solution (pH 3.05) | solution:product ratio of 8:1; | increase of the acidification degree in mushrooms | [14] |

| p1 20 and 40 kPa | ||||

| t1 2 min | ||||

| t2 20, 40, 60, 120, 240, 300, 360 and 720 min | ||||

| zucchini (slices of 1.5 cm in thickness and a diameter of 2.0 cm; the average weight of each slice was 5 g) | lactic acid solution (pH 2.70) | solution:product mass ratio of 8:1; | increase of the acidification degree in zucchini slices | [15] |

| p1 20 and 40 kPa | ||||

| t1 2 min | ||||

| t2 20, 40, 60, 120, 240, 300, 360 and 720 min | ||||

| papayas (cut into 4 × 2.5 × 0.5 cm pieces (length × width × thickness)) | 55% and 65% (w/w) sucrose solution | p1 5 kPa | decrease of aw | [16] |

| t1 10 min at 30 °C | ||||

| strawberry | 65% (w/w) sucrose solution | steam blanching or microwave and osmotic dehydration at atmospheric pressure or pulsed vacuum treatments | decrease of aw | [17] |

| p1 5 kPa | ||||

| t1 5 min at 30 °C | ||||

| rabbiteye blueberries | aqueous sucrose solutions (600 g/kg) | solution:product ratio of 1:1; | shortenning of dehydratation time in comparison with soaking at atmospheric pressure | [18] |

| p1 88 kPa | ||||

| plum (cut in slices of 4 × 1 × 1 cm, weighting approximately 10 g) | 40°, 50° and 60° Brix sucrose solution | solution:product ratio of 10:1; | new product with good visual quality and satisfactory shrinkage | [19] |

| t1 10 min | ||||

| apples cv. (cultivar). Granny Smith (cylindrical samples (2 cm height and diameter)) | rectified grape must (hypertonic solutions: 65°, 50° and 30° Brix) and 3% (w/w) high methoxyl pectin solutions | p1 5 kPa | improvement of mechanical and structural properties of tissue, notable reduction of freezable water which could improve fruit resistance to freezing damage | [13] |

| t1 5 min | ||||

| t2 25 min in higher solution viscosity | ||||

| t2 55 min | ||||

| strawberry (10 mm slices) | 50% (w/w) high fructose corn syrup or 3% (w/w) high methoxyl pectin solution containing calcium and/or zinc | p1 7 kPa | improvement of textural quality and reduced drip loss of frozen-thawed strawberries | [20] |

| t1 15 min | ||||

| t2 30 min | ||||

| spinach (rectangular 3.0 cm long, 0.5 cm wide and 0.06 cm thick) | 40% (w/w) trehalose solution | pulsed electric fields (580 V/cm) in combination with vacuum impregnation | improvement of freezing tolerance of spinach leaves | [21] |

| p1 86 kPa | ||||

| t1 20 min | ||||

| t2 150 min | ||||

| apple samples cv. Granny Smith (cylindrical samples (8 cm height and 2 cm diameter)) | sucrose isotonic solution | p1 50 kPa | increase of thermal conductivity | [22] |

| t1 10 min | ||||

| t2 20 min | ||||

| zucchini (slices 0.5-cm thick) | maltodextrine solution (7.5%–9%, 10%), NaCl (0%–5%) and CaCl2 (0–1000 mM) | product:solution ratio of 1:3.3; | improvement of solute and water gain and limitation of textural and microstructural changes | [23] |

| p1 2.5 kPa | ||||

| t1 10 min | ||||

| t2 30 min | ||||

| eggplant, carrot, oyster mushroom | 33 g sucrose and 20 g calcium lactate solution in isotonic solution | p1 5 kPa | notable impact on mechanical behaviour of eggplant and carrot, no effects in oyster mushroom | [1] |

| t1 10 min | ||||

| t2 10 min | ||||

| apple samples cv. Granny Smith | CaCl2 solution (0.6%, 2.0% or 4.0% (w/w)) | p1 9.3 and 59.9 kPa | improvement of texture | [24] |

| t1 4 min | ||||

| t2 5 min | ||||

| apple cv. Jonagold (cut into 1 cm thick slices) | 10 mg/L ascorbic acid, 0.05 mg/L 4-hexylresorcinol, 5 mg/L calcium chloride and 200 mg/L sucrose | p1 8 kPa | the same effect of dipping and vacuum impregnation regarding hardness | [25] |

| t1 5 min | ||||

| t2 5 min | ||||

| apples cv. Granny Smith (1 cm cubes) strawberries (cut in halves) and raspberries | high methylated pectin solution preparation up to 3% (w/w) and/or CaCl2, up to 6.5% (w/w) | p1 6.6 kPa | limitation of loss in fruit firmness following pasteurization | [26] |

| t1 2 min | ||||

| strawberries (cv. Elsanta and Darselect) (cut in halves) | high methylated pectin (from Aspergillus aceleatus) containing 100 U/mL, 0.5% (w/w) CaCl2·2H2O 1% and 3% (w/w) of apple pectin | p1 1 kPa | limitation of structural damage during subsequent rapid freezing processes | [27] |

| t1 5 min | ||||

| peaches (cut in halves) | pectin methylesterase together with CaCl2 (100 mg/L) | p1 85 kPa t1 30, 60, 90, 120 min | increase of firmness in canned peaches | [28] |

| eggplants (slices of 1 cm trick) | pectinmethyl-esterase derived from Aspergillus niger and extracted from orange and grapefruit and 4000 ppm CaCl2·2H2O | 1st method: | increase of firmness in impregnated eggplants | [29] |

| p1 68 kPa | ||||

| t1 15 min at 30 °C | ||||

| 2nd method: pulsed vacuum impregnation | ||||

| p1 85 kPa | ||||

| t1 5 min | ||||

| release vacuum to atmospheric pressure for 1 min reapply vacuum for 5 min and release for 5 min | ||||

| watercress (leaves were selected diameter 1.4 cm) | winter flounder antifreeze protein type I solution (1 mg/100 mL AFP-I ultra pure water) | p1 51, 58, 68, 85 and 101 kPa | smaller ice crystals in AFP-I impregnated (58 kPa, for 5 min) frozen samples | [30] |

| t1 5 min | ||||

| strawberry | 12 g/100 g trehalose solution; 0.2 g/100 g solution unpasteurized cold acclimated winter wheat grass extract as a source of AFP and 12 g/100 g trehalose and 0.2 g/100 g unpasteurized cold acclimated winter wheat grass extract | p1 86 kPa | improvement of freezing tolerance of strawberry | [31] |

| t1 5 min | ||||

| strawberry slices | CaCl2 solution (1, 10, 100 mM); spermine solution (1, 10, 100 mM); spermidine (1, 10, 100 mM); putrescine (1, 10, 100 mM); | p1 16.9 kPa | effect of spermine and spermidine on the increase of firmness, whereas putrescine was not as effective | [32] |

| t1 8 min | ||||

| carrots (cv. Nantesa) slices (20-mm diameter, 10 mm thick) | chitosan (1%, w/v) dispersed in aqueous solution of glacial acetic acid (1%, w/v), at 40 °C | p1 5 kPa | improvement of sample resistance to water vapor transmission, better preservation of color and mechanical response during cold storage | [33] |

| t1 4 min | ||||

| t2 2 min | ||||

| pineapple (slices 1 cm thickness) | chitosan- or casinate-based film-forming emulsions | ratio of the weight of coating solution:sample: 20:1; | extension of shelf-life in pineapple-cereal system for caseinate based coating | [34] |

| p1 5 kPa | ||||

| t1 3 min | ||||

| t2 2 min | ||||

| pear (Pirus communis cv. Blanquilla) (cylinders 2 cm height, 2 cm diameter) | isotonic sucrose solution (14° Brix) containing trisodium citrate 2-hydrate, sodium l-ascorbate, ethylenediamine tetraacetic acid 2-hydrate disodium salt and calcium lactate 5-hydrate and 4-hexylresorcinol | solution: fruit ratio of 20:1; | ascorbate and calcium lactate in impregnated solution were the most effective for extending the shelf life of pear | [35] |

| p1 5 kPa | ||||

| t1 5 min | ||||

| t2 10 min | ||||

| apple cv. Jonagold (1-cm thick slices) | ascorbic acid, citric acid, 4-hexylresorcinol, sodium chloride, calcium chloride, sodium lactate, calcium lactate and sucrose solutions | p1 7 kPa | effective inhibition of browning and softening of apple slices during storage by 1% ascorbic acid, 0.005% 4-hexylresorcinol, 0.5% calcium chloride, 20% sucrose in impregnated solution | [36] |

| t1 5 min | ||||

| t2 5 min | ||||

| button mushrooms (slice thickness was 6.5 mm with a 3 to 5 mm cap length) | 2 g/100 g ascorbic acid + 1 g/100 g calcium lactate solution; 2 g/100 g citric acid + 1 g/100 g calcium lactate; 1 g/100 g chitosan + 1 g/100 g calcium lactate solution; and 1 g/100 g calcium lactate solution | p1 6.7, 10.0, 13.3, 16.7 kPa | vacuum impregnation with ascorbic acid and calcium lactate at 6.7 kPa for 5 min and atmospheric restoration time of 5 min was the most effective to limit adverse changes of color in sliced button mushrooms | [37] |

| t1 5 and 10 min | ||||

| t2 5 and 10 min | ||||

| litchi cv. Rose | 502 g/kg sucrose solution containing 4.9 g/kg cysteine + 20 g/kg ascorbic acid + 0.134 g/kg 4-hexyl resorcinol and 502 g/kg sucrose solutions also contained 20 g/kg calcium lactate and 1 g/kg potassium sorbate | p1 76 kPa | samples were sensory acceptable up to 24 days | [38] |

| t1 10 min | ||||

| t2 10 min | ||||

| apple sticks | mass ratio of fruit:syrup was 1:17; fructose isotonic solution (14.0°–15° Brix) containing ascorbic acid (0.5% wt/wt) and dry, food-grade green apple flavoring (0.5% wt/wt) | p1 28 kPa | aroma enrichment | [39] |

| t1 5 min | ||||

| t2 2.5, 5, 12.5 min | ||||

| olive fruits cv. Domat | NaCl (3%), NaOH (1.5%) and NaOH (1.5%) + NaCl (3%) solutions | p1 68 kPa | shortening the duration of debittering process | [40] |

| apples cv. Granny Smith and Stark Delicious | higher values of hardness, crispness, juiciness and sourness in vacuum impregnated Granny Smith apples | the solution:fruit ratio was 11:1; | higher values of hardness, crispness, juiciness and sourness in vacuum impregnated Granny Smith apples | [41] |

| p1 10 kPa | ||||

| t1 30 min | ||||

| t2 5 min |

3.1. Reduction of pH

3.2. Reduction of Water Activity (aw)

3.3. Changes in Thermal Properties

3.4. Improvement in the Structure of Fruit and Vegetables

3.5. Improvement of Color, Aroma and Taste

4. Vacuum Impregnation as a Tool to Modify Health-Promoting Properties of Fruit and Vegetable Products

| Raw Material | Vacuum Impregnation Solutions Composition | Process Parameters | Effect | References | |

|---|---|---|---|---|---|

| apple cylinders | apple juice with an addition of microorganisms Saccharomyces cerevisiae, milk with an addition of Saccharomyces cerevisiae and Lactobacillus casei | p1 5 kPa t1 10 min t2 10 min | over 106 CFU/g Lactobacillus casei in air dried (40 °C) product | [4] | |

| pieces of guava and papaya | papaya and guava fruit juices (1—Extracted by blending with water, ratio 1:1; 2, 3—Extracted fruit juices containing 15° and 30° Brix, respectively) with an addition of Lactobacillus casei microorganisms | p1 5 kPa t1 5, 10, 15 min t2 10 min | after impregnation: 108 to 109 CFU/g Lactobacillus casei, after drying at 40 °C for 36 h: 107 CFU/g Lactobacillus casei in impregnated fruits | [69] | |

| apple | isotonic sucrose solution containing 108 CFU/g Bifidobacterium ssp. | p1 14, 17, 30, 43, 57 kPa | greater incorporation at pressures of 14 and 17 kPa, levels of microorganisms over 107 CFU/g | [70] | |

| apple cylinders cv. Granny Smith | sucrose isotonic solution containing microorganisms Saccharomyces cerevisiae, Lactobacillus acidophilus and Phoma glomerata | p1 10, 17, 30, 43, 57 kPa (one vacuum pulse of 2 min) | increase by 0.36 log for Saccharomyces cerevisiae, 0.73 log for Lactobacillus acidophilus and 1.07 log for Phoma glomerata for vacuum impregnated sample in comparison to soaking sample | [71] | |

| apple slices (cv. Fuji) | apple juice diluted with pre-sterilized distilled water (1:1, v/v, pH 5–5.2) with an addition of Lactobacillus rhamnosus (ATCC 7469, in 1:1 (v/v) glycerol frozen cultures) | p1 20 kPa t1 15 min t2 15 min apple slices were dried by air drying, freeze drying, and a combination of air drying + REV drying | after vacuum impregnation: 109 CFU/gof tissue | [72] | |

| apples cv. Granny Smith (disk-shaped samples) | mandarin juice (pH 5, 8–6, 0) with an addition of Lactobacillus salivarius (Salivarius spp.) | p1 5 kPa t1 10 min t2 10 min | after vacuum impregnation: 1.51·108 CFU/g Lactobacillus salivarius spp. Salivarius; the highest microbial content: after 24 h incubation period, pH 6 | [73] | |

| apples cv. Granny Smith (disk-shaped samples) | mandarin juice inoculated with Lactobacillus salivarius spp. salivarius at pH 6 and after 24 h incubation | p1 5 kPa t1 10 min t2 10 min | concentration of microorganisms in the final product: 107 CFU/g | [74] | |

| eggplant fruits and orange peel | isotonic solution of sucrose, iron gluconate and calcium lactate | p1 5 kPa t1 15 min t2 15 min | a mathematical model to determine the concentration of active components in impregnation solution was established in order to formulate functional food with different calcium and iron salts levels | [9] | |

| iceberg lettuce leaves | sucrose aqueous solution of the same aw as lettuce leaves used vaccum impregnation reference solution and isotonic solution with an addition of Ca lactogluconate (5.4 g Ca/L of water) | p1 50 kPa t1 10 min t2 10 min | total content of 169 mg Ca per 250 g of impregnated iceberg lettuce leaves | [75] | |

| apple slices cv. Granny Smith | sucrose isotonic solutions with an addition of calcium lactate (44.2 g/L) or ferrous gluconate (1.13 g/L) | p1 5 kPa t1 10 min t2 10 min | after vacuum impregnation: fruits enriched with Ca2+ and Fe2+ ions respectively | [76] | |

| apple slices cv. Granny Smith | isotonic aqueous solution containing sucrose (aw 0.986) and calcium lactate OD in osmotic solution with an addition of 1% calcium salt | p1 5 kPa t1 10 min t2 10 min | an increase in calcium content from 0% to 40% of the recommended daily intake for an adult per 200 g of apples | [77] | |

| fresh-cut apples cv. Fuji | 20% diluted high fructose corn syrup (HFCS) or 1% calcium caseinate (CC) aqueous solution with an addition of 0.4% α-tocopherol acetate, 7.5% Gluconal Cal® (GC), and 0.04% zinc lactate (ZL) | p1 13.3 kPa t1 15 min t2 30 min | in 100 g fresh-cut apples the vitamin E content increased more than 100 times, and calcium and zinc contents increased about 20 times compared with unfortified apples | [78] | |

| fresh-cut pears cv. D’Anjou | 20% diluted wildflower honey solution with 0.4% to 0.8% α-tocopherol from 3 different sources: α-tocopherol-acetate (VE-acetate), free α-tocopherol (V-OH), or water-soluble α-tocopherol-acetate (VE-H2O) | p1 10 kPa t1 15 min t2 30 min | vitamin E content of impregnated pears increased 80 to 100 times and 65% to 80% VE activities were retained during 2 week of storage | [79] | |

| whole potatoes | 10% ascorbic acid solution | p1 9.33 kPa t1 0–60 min t2 3 h | after vacuum impregnation the ascorbic acid content of whole potatoes increased ten times (150 mg/100 g fresh weight) | [80] | |

| endive, cauliflower, broccoli, carrots | vacuum impregnation reference solution—aqueous sucrose solutions of the same aw as each of the four raw materials; Aloe vera aqueous solution with an addition of 5 and 30 g/L of aloe vera powder (powder dispersed in water), respectively | p1 50 kPa t1 10 min t2 10 min | after vacuum impregnation: incorporation of up to 7 g of Aloe vera in 100 g (dry matter) in broccoli, about 4 g in cauliflower and endive, and about 3 g in carrots | [81] | |

| apples cv. Granny Smith (disk-shaped samples) | mandarin low pulp juice | p1 5 kPa t1 10 min t2 10 min | forty grams of the final product (apple snack) made using mandarin juice provide the same quantity of hesperidin as 250 mL of fresh mandarin juice | [82] | |

| 13 apple cultivars (6 mm apple slices) | commercial apple juice (11.1° ± 0.1° Brix) enriched with 0.3% hfv (high in flavonoids) apple peel extract | p1 10–80 kPa t1 5 min t2 10 min | after vacuum impregnation of 13 apple cultivars: quercetin content ranged between 368 and 604 μg/g dry matter | [83] | |

| green apples cv. Orin (apple cubes) | sugar solution (total soluble solids of 50° Brix ) mixed with blackcurrant syrup (47.4°–47.8° Brix). Total soluble solids of the mixture of sugar syrup/blackcurrant syrup of 80%/20%, 70%/30% and 60%/40% were 49.1°, 49.3° and 49.5° Brix, respectively | p1 40, 60, 80 kPa t1 15, 30, 45 min (following a Box–Behnken response surface methodology design) t2 2.5 min | optimized conditions for vacuum impregnation of apple cubes were 18%–20% blackcurrant concentrate level, 77–80 kPa vacuum pressure and 38–45 min vacuum time | [84] | |

| fresh-cut apple cv. Granny Smith (wedges, each ca. 10 g) | 50% (v/v) Mexican or 50% (v/v) Argentinean honeys, distilled water (control sample) | p1 70 kPa t1 10 min t2 10 min | less acceptable in terms of sensory qualities than their fresh-cut counterparts, total polyphenol content and antioxidant activity values in vacuum impregnated products were lower than in fresh-cut samples | [85] |

4.1. Probiotics Introduced to the Fruit and Vegetable Matrix

4.2. Enrichment with Minerals and Vitamins

4.3. Other Applications of Vacuum Impregnation to Enrich the Fruit and Vegetable Matrix

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gras, M.L.; Vidal, D.; Betoret, N.; Chiralt, A.; Fito, P. Calcium fortification of vegetables by vacuum impregnation: Interactions with cellular matrix. J. Food Eng. 2003, 56, 279–284. [Google Scholar] [CrossRef]

- Allali, H.; Marchal, L.; Vorobiev, E. Effects of vacuum impregnation and ohmic heating with citric acid on the behaviour of osmotic dehydration and structural changes of apple fruit. Biosyst. Eng. 2010, 106, 6–13. [Google Scholar]

- Derossi, A.; Pilli, T.; Severini, C. Application of vacuum impregnation techniques to improve the pH reduction of vegetables: Study on carrots and eggplants. Food Bioprocess Technol. 2013, 6, 3217–3226. [Google Scholar] [CrossRef]

- Betoret, N.; Puente, L.; Dı́az, M.J.; Pagán, M.J.; Garcı́a, M.J.; Gras, M.L.; Martı́nez-Monzó, J.; Fito, P. Development of probiotic-enriched dried fruits by vacuum impregnation. J. Food Eng. 2003, 56, 273–277. [Google Scholar] [CrossRef]

- Zhao, Y.; Xie, J. Practical applications of vacuum impregnation in fruit and vegetable processing. Trends Food Sci. Technol. 2004, 15, 434–451. [Google Scholar] [CrossRef]

- Fito, P.; Andrés, A.; Chiralt, A.; Pardo, P. Coupling of hydrodynamic mechanism and deformation-relaxation phenomena during vacuum treatments in solid porous food-liquid systems. J. Food Eng. 1996, 27, 229–240. [Google Scholar] [CrossRef]

- Salvatori, D.; Andrés, A.; Chiralt, A.; Fito, P. Osmotic dehydration progression in apple tissue I: Spatial distribution of solutes and moisture content. J. Food Eng. 1999, 42, 125–132. [Google Scholar] [CrossRef]

- Fito, P.; Chiraldt, A.; Betoret, N.; Gras, M.; Chafer, M.; Martínez-Monzó, J.; Andres, A.; Vidal, D. Vacuum impregnation and osmotic dehydratation in matrix engineering application in functional fresh food development. J. Food Eng. 2001, 49, 175–183. [Google Scholar] [CrossRef]

- Fito, P.; Chiralt, A.; Barat, J.M.; Andres, A.; Martínez-Monzó, J.; Martinez-Navarrete, N. Vacuum impregnation for development of new dehydrated products. J. Food Eng. 2001, 49, 297–302. [Google Scholar] [CrossRef]

- Derossi, A.; de Pilli, T.; Severini, C. Reduction in the pH of vegetables by vacuum impregnation: A study on pepper. J. Food Eng. 2010, 99, 9–15. [Google Scholar] [CrossRef]

- Sapers, G.M.; Garzarella, L.; Pilizota, V. Application of browning inhibitors to cut apple and potato by vacuum and pressure infiltration. J. Food Sci. 1990, 55, 1049–1053. [Google Scholar] [CrossRef]

- Sapers, G.M.; Douglas, F.W., Jr.; Ziolkowski, M.A.; Miller, R.L.; Hicks, K.B. Determination of ascorbic acid, dehydroascorbic acid and ascorbic acid-2-phosphate in infiltrated apple and potato tissue by high-performance liquid chromatography. J. Chromatogr. A 1990, 503, 431–436. [Google Scholar] [CrossRef]

- Martínez-Monzó, J.; Martínez-Navarrete, N.; Chiralt, A.; Fito, P. Mechanical and structural changes in apple (var. Granny Smith) due to vacuum impregnation with cryoprotectants. J. Food Sci. 1998, 63, 499–503. [Google Scholar]

- Derossi, A.; de Pilli, T.; Severini, C. Application of pulsed vacuum acidification for the pH reduction of mushrooms. LWT Food Sci. Technol. 2013, 54, 585–591. [Google Scholar] [CrossRef]

- Derossi, A.; de Pilli, T.; la Penna, M.P.; Severini, C. pH reduction and vegetable tissue structure changes of zucchini slices during pulsed vacuum acidification. LWT Food Sci. Technol. 2011, 44, 1901–1907. [Google Scholar] [CrossRef]

- Moreno, J.; Bugueño, G.; Velasco, V.; Petzold, G.; Tabilo-Munizaga, G. Osmotic dehydration and vacuum impregnation on physicochemical properties of Chilean papaya (Carica candamarcensis). J. Food Sci. 2004, 69, FEP102–FEP106. [Google Scholar]

- Moreno, J.; Chiralt, A.; Escriche, I.; Serra, J.A. Effect of blanching/osmotic dehydration combined methods on quality and stability of minimally processed strawberries. Food Res. Int. 2000, 33, 609–616. [Google Scholar] [CrossRef]

- Pallas, L.A.; Pegg, R.B.; Kerr, W.L. Quality factors, antioxidant activity, and sensory properties of jet-tube dried rabbiteye blueberries. J. Sci. Food Agric. 2013, 93, 1887–1897. [Google Scholar] [CrossRef] [PubMed]

- Fante, C.; Corrêa, J.; Natividade, M.; Lima, J.; Lima, L. Drying of plums (Prunus sp., cv. Gulfblaze) treated with KCl in the field and subjected to pulsed vacuum osmotic dehydration. Int. J. Food Sci. Technol. 2011, 46, 1080–1085. [Google Scholar]

- Xie, J.; Zhao, Y. Use of vacuum impregnation to develop high quality and nutritionally fortified frozen strawberries. J. Food Process. Preserv. 2004, 28, 117–132. [Google Scholar] [CrossRef]

- Phoon, P.Y.; Galindo, F.G.; Vicente, A.; Dejmek, P. Pulsed electric field in combination with vacuum impregnation with trehalose improves the freezing tolerance of spinach leaves. J. Food Eng. 2008, 88, 144–148. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Monzó, J.; Barat, J.M.; Gonzalez-Martinez, C.; Chiralt, A.; Fito, P. Changes in thermal properties of apple due to vacuum impregnation. J. Food Eng. 2000, 43, 213–218. [Google Scholar] [CrossRef]

- Occhino, E.; Hernando, I.; Liorca, E.; Neri, L.; Pittia, P. Effect of vacuum impregnation treatments to improve quality and texture of zucchini (Cucurbita pepo, L). Procedia Food Sci. 2011, 1, 829–835. [Google Scholar] [CrossRef]

- Del Valle, J.M.; Aranguiz, V.; León, H. Effects of blanching and calcium infiltration on PPO activity, texture, microstructure and kinetics of osmotic dehydration of apple tissue. Food Res. Int. 1998, 31, 557–569. [Google Scholar] [CrossRef]

- Biegańska-Marecik, R.; Czapski, J. Effect of minimal processing on changes in the texture of vacuum-packaged apple slices. Pol. J. Food Nutr. Sci. 2007, 57, 161–166. [Google Scholar]

- Degraeve, P.; Saurel, R.; Coutel, Y. Vacuum-impregnation pre-treatment to improve firmness of pasteurized fruits. J. Food Sci. 2003, 68, 716–721. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Messagie, I.; Maes, V.; Duvetter, T.; van Loey, A.; Hendrickx, M. Minimizing texture loss of frozen strawberries: Effect of infusion with pectinmethylesterase and calcium combined with different freezing conditions and effect of subsequent storage/thawing conditions. Eur. Food Res. Technol. 2006, 223, 395–404. [Google Scholar] [CrossRef]

- Javeri, H.; Toledo, R.; Wicker, L. Vacuum infusion of citrus pectin methylesterase and calcium effects on firmness of peaches. J. Food Sci. 1991, 56, 739–742. [Google Scholar] [CrossRef]

- Banjongsinsiri, P.; Shield, J.; Wicker, L. Vacuum infusion of plant or fungal pectinmethylesterase and calcium affects the texture and structure of eggplant. J. Agric. Food Chem. 2004, 52, 8214–8223. [Google Scholar] [CrossRef] [PubMed]

- Cruz, R.; Vieira, M.C.; Silva, C.L. The response of watercress (Nasturtium officinale) to vacuum impregnation: Effect of an antifreeze protein type I. J. Food Eng. 2009, 95, 339–345. [Google Scholar] [CrossRef]

- Velickova, E.; Tylewicz, U.; Dalla Rosa, M.; Winkelhausen, E.; Kuzmanova, S.; Gómez Galindo, F. Effect of vacuum infused cryoprotectants on the freezing tolerance of strawberry tissues. LWT Food Sci. Technol. 2013, 52, 146–150. [Google Scholar] [CrossRef]

- Ponappa, T.; Scheerens, J.C.; Miller, A.R. Vacuum infiltration of polyamines increases firmness of strawberry slices under various storage conditions. J. Food Sci. 1993, 58, 361–364. [Google Scholar] [CrossRef]

- Vargas, M.; Chiralt, A.; Albors, A.; González-Martínez, C. Effect of chitosan-based edible coatings applied by vacuum impregnation on quality preservation of fresh-cut carrot. Postharvest Biol. Technol. 2009, 51, 263–271. [Google Scholar] [CrossRef]

- Talens, P.; Pérez-Masía, R.; Fabra, M.J.; Vargas, M.; Chiralt, A. Application of edible coatings to partially dehydrated pineapple for use in fruit-cereal products. J. Food Eng. 2012, 112, 86–93. [Google Scholar] [CrossRef]

- Perez-Cabrera, L.; Chafer, M.; Chiralt, A.; Gonzalez-Martinez, C. Effectiveness of antibrowning agents applied by vacuum impregnation on minimally processed pear. LWT Food Sci. Technol. 2011, 44, 2273–2280. [Google Scholar] [CrossRef]

- Biegańska-Marecik, R.; Czapski, J. The effect of selected compounds as inhibitors of enzymatic browning and softening of minimally processed apples. Acta Sci. Pol. Technol. Aliment. 2007, 6, 37–49. [Google Scholar]

- Yurttas, Z.S.; Moreira, R.G.; Castell-Perez, E. Combined vacuum impregnation and electron-beam irradiation treatment to extend the storage life of sliced white button mushrooms (Agaricus bisporus). J. Food Sci. 2014, 79, E39–E46. [Google Scholar] [CrossRef] [PubMed]

- Shah, N.S.; Nath, N. Changes in qualities of minimally processed litchis: Effect of antibrowning agents, osmo-vacuum drying and moderate vacuum packaging. LWT Food Sci. Technol. 2008, 41, 660–668. [Google Scholar] [CrossRef]

- Comandini, P.; Blanda, G.; Paz, H.M.; Fragoso, A.V.; Toschi, T.G. Impregnation techniques for aroma enrichment of apple sticks: A preliminary study. Food Bioprocess Technol. 2010, 3, 861–866. [Google Scholar] [CrossRef]

- Tamer, C.E.; İncedayı, B.; Yıldız, B.; Çopur, Ö.U. The use of vacuum impregnation for debittering green olives. Food Bioprocess Technol. 2013, 6, 3604–3612. [Google Scholar]

- Blanda, G.; Cerretani, L.; Bendini, A.; Cardinali, A.; Scarpellini, A.; Lercker, G. Effect of vacuum impregnation on the phenolic content of Granny Smith and Stark Delicious frozen apple cvv. Eur. Food Res. Technol. 2008, 226, 1229–1237. [Google Scholar] [CrossRef]

- Montville, T.J.; Matthews, K.R. Food Microbiology An Introduction, 1st ed.; American Society for Microbiology (ASM) Press: Washington, DC, USA, 2005; pp. 19–20. [Google Scholar]

- Roa, V.; Tapia, M.S.; Millán, F. Mass balances in porous foods impregnation. J. Food Sci. 2001, 66, 1332–1336. [Google Scholar] [CrossRef]

- Salvatori, D.; Andres, A.; Chiralt, A.; Fito, P. The response of some properties of fruits to vacuum impregnation. J. Food Process Eng. 1998, 21, 59–73. [Google Scholar] [CrossRef]

- Mújica-Paz, H.; Valdez-Fragoso, A.; Lopez-Malom, A.; Palou, E.; Welti-Chanes, J. Impregnation properties of some frutis at vacuum pressure. J. Food Eng. 2003, 56, 307–314. [Google Scholar] [CrossRef]

- Andreas, I.; Salvatori, D.; Chiralt, A.; Fito, P. Vacuum impregnation viability of some fruits and vegetables. In Osmotic Dehydration and Vacuum Impregnation: Applications in Food Industries, 1st ed.; Fito, P., Chiralt, A., Barat, J.M., Spiess, W.E.L., Behsnilian, D., Barat, J.M., Spiess, W.E.L., Behsnilian, D., Eds.; Technomic Publishers: Lancaster, PA, USA, 2001. [Google Scholar]

- Mújica-Paz, H.; Valdez-Fragoso, A.; Lopez-Malo, A.; Palou, E.; Welti-Chanes, J. Impregnation and osmotic dehydration of some fruits: Effect of the vacuum pressure and syrup concentration. J. Food Eng. 2003, 57, 305–314. [Google Scholar] [CrossRef]

- Fito, P. Modelling of vacuum osmotic dehydration of food. J. Food Eng. 1994, 22, 313–328. [Google Scholar] [CrossRef]

- Paes, S.S.; Stringari, G.B.; Laurindo, J.B. Effect of vacuum and relaxation periods and solution concentration on the osmotic dehydration of apples. Int. J. Food Sci. Technol. 2007, 42, 441–447. [Google Scholar] [CrossRef]

- Danyluk, J.; Perron, A.; Houde, M.; Limin, A.; Fowler, B.; Benhamou, N.; Sarhan, F. Accumulation of an acidic dehydrin in the vicinity of the plasma membrane during cold acclimation of wheat. Plant Cell Online 1998, 10, 623–638. [Google Scholar] [CrossRef]

- Fito, P.; Chiralt, A. Vacuum impregnation of plant tissues. In Minimally Processed Fruits and Vegetables: Fundamental Aspects and Applications, 1st ed.; Alzamora, S.M., Tapia, M.S., Lopez-Malo, A., Eds.; Aspen Publication: Gaithersburg, MD, USA, 2000; pp. 189–204. [Google Scholar]

- Main, G.L.; Morris, J.R.; Wehunt, E.J. Effects of pre-processing treatments on the firmness and quality characteristics of whole and sliced strawberries after freezing and thermal processing. J. Food Sci. 1986, 51, 391–394. [Google Scholar] [CrossRef]

- French, D.A.; Kader, A.A.; Labavitch, J.M. Softening of canned apricots: A chelation hypothesis. J. Food Sci. 1989, 54, 86–89. [Google Scholar] [CrossRef]

- Suutarinen, J.; Honkapää, K.; Heiniö, R. L.; Autio, K.; Mokkila, M. The effect of different prefreezing treatments on the structure of strawberries before and after jam making. LWT Food Sci. Technol. 2000, 33, 188–201. [Google Scholar] [CrossRef]

- Anino, S.V.; Salvatori, D.M.; Alzamora, S.M. Changes in calcium level and mechanical properties of apple tissue due to impregnation with calcium salts. Food Res. Int. 2006, 39, 154–164. [Google Scholar] [CrossRef]

- Guillemin, A.; Degraeve, P.; Guillon, F.; Lahaye, M.; Saurel, R. Incorporation of pectin methylesterase in apple tissue either by soaking or by vacuum-impregnation. Enzym. Microb. Technol. 2006, 38, 610–616. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Grauwet, T.; van Loey, A.; Hendrickx, M. Use of pectinmethylesterase and calcium in osmotic dehydration and osmodehydrofreezing of strawberries. Eur. Food Res. Technol. 2008, 226, 1145–1154. [Google Scholar] [CrossRef]

- Yang, C.; Sharp, K.A. The mechanism of the type III antifreeze protein action: A computational study. Biophys. Chem. 2004, 109, 137–148. [Google Scholar] [CrossRef] [PubMed]

- Griffith, M.; Ewart, K.V. Antifreeze proteins and their potential use in frozen foods. Biotechnol. Adv. 1995, 13, 375–402. [Google Scholar] [CrossRef] [PubMed]

- Kramer, G.F.; Wang, C.Y.; Conway, W.S. Inhibition of softening by polyamine application in Golden Delicious and McIntosh Apples. J. Am. Soc. Hortic. Sci. 1991, 116, 813–817. [Google Scholar]

- Kramer, G.F.; Wang, C.Y.; Conway, W.S. Correlation of reduced softening and increased polyamine levels during low-oxygen storage of McIntosh apples. J. Am. Soc. Hortic. Sci. 1989, 114, 942–946. [Google Scholar]

- Radziejewska-Kubzdela, E.; Czapski, J.; Czaczyk, K. The effect of pretreatment of shredded celeriac using solutions of enzymatic browning inhibitors on the quality of minimally processed product. J. Food Qual. 2007, 30, 594–608. [Google Scholar]

- Blanda, G.; Cerretani, L.; Bendini, A.; Cardinali, A.; Lercker, G. Phenolic content and antioxidant capacity versus consumer acceptance of soaked and vacuum impregnated frozen nectarines. Eur. Food Res. Technol. 2008, 227, 191–197. [Google Scholar] [CrossRef]

- Pino, J.A.; Panadés, G.; Fito, P.; Chiralt, A.; Ortega, A. Influence of osmotic dehydration on the volatile profile of guava fruits. J. Food Qual. 2008, 31, 281–294. [Google Scholar] [CrossRef]

- Tapia, M.S.; Schulz, E.; Gómez, V.; López-Malo, A.; Welti-Chanes, J. A new approach to vacuum impregnation and functional foods: Melon impregnated with calcium and zinc. In Proceedings of the 2003 IFT Annual Meeting Technical Program Abstracts, Chicago, IL, USA, 13–16 July 2003. Paper No 60D-2.

- Barat, J.M.; Talens, P.; Barrera, C.; Chiralt, A.; Fito, P. Pineapple candying at mild temperature by applying vacuum impregnation. J. Food Sci. 2002, 67, 3046–3052. [Google Scholar] [CrossRef]

- Alzamora, S.M.; Salvatori, D.; Tapia, M.S.; Lopez-Malo, A.; Welti-Chanes, J.; Fito, P. Novel functional foods from vegetable matrices impregnated with biologically active compounds. J. Food Eng. 2005, 67, 205–2014. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Vidal, D.; Fito, P. Functional foods development: Trends and technologies. Trends Food Sci. Technol. 2011, 22, 498–508. [Google Scholar] [CrossRef]

- Krasaekoopt, W.; Suthanwong, B. Vacuum impregnation of probiotics in fruit pieces and their survival during refrigerated storage. Kasetsart J. 2008, 42, 723–731. [Google Scholar]

- Maguiña, G.; Tapia, M.S.; Briceño, A.G.; Rodriguez, C.; Sànchez, D.; Roa, V.; López-Malo, A. Incorporación of Bifidobacterium spp. en una Matriz Porosa de Fruta por el Mecanismo Hidrodinámico (PF-08). In Actas del 2 Congreso Español de Ingeniería de Alimentos; Lleida, España, 2002; p. PF-08. (In Spanish) [Google Scholar]

- Rodriguez, M.I. Estudio de la penetración de microorgasnismos en frutas mediante el modelo Hidrodinàmico (HDM). Ph.D. Thesis, Instituto de Ciencia y Tecnoloģia de Alimentos, Universidad Central de Venezuela, Caracas/Maracay, Venezuela, 1998. [Google Scholar]

- Noorbakhsh, R.; Yaghmaee, P.; Durance, T. Radiant energy under vacuum (REV) technology: A novel approach for producing probiotic enriched apple snacks. J. Funct. Foods 2013, 5, 1049–1056. [Google Scholar] [CrossRef]

- Betoret, E.; Bennar, M.; Betore, N.; Bojňanská, T.; Fito, P. Vacuum impregnation and hot air drying of apple (var. Granny smith) aimed at obtaining probiotic food with protective effect against the infection caused by Helicobacter pyroli. Acta fytotechnica et zootechnica—Mimoriadne číslo 2009, 37–46. (In Spanish) [Google Scholar]

- Betoret, E.; Betoret, N.; Arilla, A.; Bennár, M.; Barrera, C.; Codoñer, P. No invasive methodology to produce a probiotic low humid apple snack with potential effect against Helicobacter pylori. J. Food Eng. 2012, 110, 289–293. [Google Scholar] [CrossRef]

- Gras, M.L.; Vidal-Brotóns, D.; Vásquez-Forttes, F.A. Production of 4th range iceberg lettuce enriched with calcium. Evaluation of some quality parameters. Procedia Food Sci. 2011, 1, 1534–1539. [Google Scholar] [CrossRef]

- Barrera, C.; Betoret, N.; Fito, P. Ca2+ and Fe2+ influence on the osmotic dehydration kinetics of apple slices (var. Granny Smith). J. Food Eng. 2004, 6, 9–14. [Google Scholar]

- Barrera, C.; Betoret, N.; Corell, P.; Fito, P. Effect of osmotic dehydration on the stabilization of calcium-fortified apple slices (var. Granny Smith): Influence of operating variables on process kinetics and compositional changes. J. Food Eng. 2009, 92, 416–424. [Google Scholar]

- Park, S.; Kodihalli, I.; Zhaonutritional, Y. Sensory, and physicochemical properties of vitamin E- and mineral-fortified fresh-cut apples by use of vacuum impregnation. J. Food Sci. 2005, 70, 593–599. [Google Scholar] [CrossRef]

- Lin, D.S.; Leonard, S.W.; Lederer, C.; Traber, M.G.; Zhao, Y. Retention of fortified vitamin E and sensory quality of fresh-cut pears by vacuum impregnation with honey. J. Food Sci. 2006, 71, 553–559. [Google Scholar] [CrossRef]

- Hironaka, K.; Kikuchi, M.; Koaze, H.; Sato, T.; Kojima, M.; Yamamoto, K.; Yasuda., K.; Mori, M.; Tsuda, S. Ascorbic acid enrichment of whole potato tuber by vacuum-impregnation. Food Chem. 2011, 127, 1114–1118. [Google Scholar] [CrossRef] [PubMed]

- Sanzana, S.; Gras, M.L.; Vidal-Brotóns, D. Functional foods enriched in Aloe vera. Effects of vacuum impregnation and temperature on the respiration rate and the respiratory quotient of some vegetables. Procedia Food Sci. 2011, 1, 1528–1533. [Google Scholar]

- Betoret, E.E.; Sentandreu, E.; Betoret, N.; Codoñer-Franch, P.; Valls-Bellés, V.; Fito, P. Technological development and functional properties of an apple snack rich in flavonoid from mandarin juice. Innov. Food Sci. Emerg. Technol. 2012, 16, 298–304. [Google Scholar] [CrossRef]

- Schulze, B.; Peth, S.; Hubbermann, E.M.; Schwarz, K. The influence of vacuum impregnation on the fortification of apple parenchyma with quercetin derivatives in combination with pore structures X-ray analysis. J. Food Eng. 2012, 109, 380–387. [Google Scholar] [CrossRef]

- Diamante, L.M.; Hironaka, K.; Yamaguchi, Y.; Nademude, E. Optimisation of vacuum impregnation of blackcurrant-infused apple cubes: Application of response surface methodology. Int. J. Food Sci. Technol. 2014, 49, 689–695. [Google Scholar] [CrossRef]

- Roßle, C.; Brunton, N.; Gormley, T.R.; Butler, F. Quality and antioxidant capacity of fresh-cut apple wedges enriched with honey by vacuum impregnation. Int. J. Food Sci. Technol. 2011, 46, 626–634. [Google Scholar] [CrossRef]

- Bhupinder, S.S.; Saloni, J. Prebiotics, probiotics and synbiotics: An overview. J. Pharm. Educ. Res. 2010, 1, 13–36. [Google Scholar]

- Granato, D.; Branco, G.F.; Nazzaro, F.; Cruz, A.G.; Faria, J.A.F. Functional foods and non-dairy probiotic food development: Trends, concepts, and products. Compr. Rev. Food Sci. Food Saf. 2010, 9, 292–302. [Google Scholar] [CrossRef]

- Peres, C.M.; Peres, C.; Hernández-Mendoza, A.; Malcata, F.X. Review on fermented plant materials as carriers and sources of potentially probiotic lactic acid bacteria—With an emphasis on table olives. Trends Food Sci. Technol. 2012, 26, 31–42. [Google Scholar] [CrossRef]

- Martins, E.M.; Ramos, A.M.; Vanzela, E.S.L.; Stringheta, P.C.; de Oliveira Pinto, C.L.; Martins, J.M. Products of vegetable origin: A new alternative for the consumption of probiotic bacteria. Food Res. Int. 2013, 51, 764–770. [Google Scholar] [CrossRef]

- Matusek, A.; Czukor, B.; Merész, P. Comparison of diffusion of fructo-oligosaccharide components during vacuum impregnation and osmotic dehydration. Eur. Food Res. Technol. 2008, 227, 417–423. [Google Scholar] [CrossRef]

- Broadus, A.E. Physiologic functions of calcium, magnesium, and phosphorus. In Primer of the Metabolic Bone Diseases and Disorders of Mineral Metabolism, 1st ed.; Favus, M.J., Ed.; Lippincott Williams & Wilkins: Hagerstown, MD, USA, 1990; pp. 29–30. [Google Scholar]

- Graczyk, A.; Radomska, K.; Konarski, J. Magnez w fizjologii i patologii człowieka [Magnesium in human physiology and pathology]. Mag. Med. 1993, 8, 34–38. (In Polish) [Google Scholar]

- Olejniczak, T.; Opala, T.; Woźniak, J. Osteoporoza—Epidemiologia, patogeneza, diagnostyka i leczenie [Osteoporosis—Epidemiology, pathogenesis, diagnostics and treatment]. Przew. Lek. 2000, 9, 39–47. (In Polish) [Google Scholar]

- Berg, A.O. Screening for osteoporosis in postmenopausal women: Recommendations and rationale. Am. J. Nurs. 2003, 103, 73–80. [Google Scholar] [PubMed]

- Knypl, K. Znaczenie magnezu i wapnia w schorzeniach układu krążenia [The role of magnesium and calcium in cardiovascular diseases]. Przew. Lek. 2004, 11, 44–48. (In Polish) [Google Scholar]

- Goldberg, I. Functional Foods, Designer Foods, Pharmafoods, Nutraceuticals, 1st ed.; Chapman and Hall: New York, NY, USA, 1994. [Google Scholar]

- Leonard, S.W.; Good, C.K.; Gugger, E.T.; Traber, M.G. Vitamin E bioavailability from fortified breakfast cereal is greater than that from encapsulated supplements. Am J. Clin. Nutr. 2004, 79, 86–92. [Google Scholar] [PubMed]

- Han, C.; Zhao, Y.; Leonard, S.W.; Traber, M.G. Edible coatings to improve storability and enhance nutritional value of fresh and frozen strawberries (Fragaria ananasa) and raspberries (Rubus ideaus). Postharvest Biol. Technol. 2004, 33, 67–78. [Google Scholar] [CrossRef]

- Bruno, R.S; Leonard, S.W; Park, S.I; Zhao, Y; Traber, M.G. Human vitamin E requirements assessed using apples fortified with deuterium-labeled α-tocopheryl acetate. Am J. Clin. Nutr. 2006, 83, 299–304. [Google Scholar]

- Barnes, M.J.; Kodieck, K. Biological hydroxylations and ascorbic acid with special regard for collagen metabolism. Vitam. Horm. 1972, 30, 1–43. [Google Scholar] [PubMed]

- Levine, M. New concepts in the biology and biochemistry of ascorbic acid. N. Engl. J. Med. 1986, 314, 892–902. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, R.E.; Darias, M.J.; Diaz, R.C. Aloe vera as a functional ingredient in foods. Crit. Rev. Food Sci. Nutr. 2010, 50, 305–326. [Google Scholar] [CrossRef] [PubMed]

- Hanasaki, Y.; Ogawa, S.; Fukui, S. The correlation between active oxygens scavenging and antioxidative effects of flavonoids. Free Radic. Biol. Med. 1994, 16, 845–850. [Google Scholar] [PubMed]

- Yao, L.H.; Jiang, Y.M.; Shi, J. Flavonoids in food and their health benefits. Plant Foods Hum. Nutr. 2004, 59, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Codoñer-Franch, P.; Betoret, E.; Betoret, N.; López-Jaén, A.B.; Valls-Belles, V.; Fito, P. Dried apples enriched with mandarin juice by vacuum impregnation improve antioxidant capacity and decrease inflammation in obese children. Nutr. Hosp. 2013, 28, 1177–1183. [Google Scholar]

- Van Acker, F.A.; Schouten, O.; Haenen, G.R. Flavonoids can replace α-tocopherol as an antioxidant. FEBS Lett. 2000, 473, 145–148. [Google Scholar] [CrossRef] [PubMed]

- Schulze, B.; Hubbermann, E.M.; Schwarz, K. Stability of quercetin derivatives in vacuum impregnated apple slices after drying (microwave vacuum drying, air drying, freeze drying) and storage. LWT Food Sci. Technol. 2014, 57, 426–433. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Kidoń, M. Applicability of Vacuum Impregnation to Modify Physico-Chemical, Sensory and Nutritive Characteristics of Plant Origin Products—A Review. Int. J. Mol. Sci. 2014, 15, 16577-16610. https://doi.org/10.3390/ijms150916577

Radziejewska-Kubzdela E, Biegańska-Marecik R, Kidoń M. Applicability of Vacuum Impregnation to Modify Physico-Chemical, Sensory and Nutritive Characteristics of Plant Origin Products—A Review. International Journal of Molecular Sciences. 2014; 15(9):16577-16610. https://doi.org/10.3390/ijms150916577

Chicago/Turabian StyleRadziejewska-Kubzdela, Elżbieta, Róża Biegańska-Marecik, and Marcin Kidoń. 2014. "Applicability of Vacuum Impregnation to Modify Physico-Chemical, Sensory and Nutritive Characteristics of Plant Origin Products—A Review" International Journal of Molecular Sciences 15, no. 9: 16577-16610. https://doi.org/10.3390/ijms150916577