The Influence of Green Surface Modification of Oil Palm Mesocarp Fiber by Superheated Steam on the Mechanical Properties and Dimensional Stability of Oil Palm Mesocarp Fiber/Poly(butylene succinate) Biocomposite

Abstract

:1. Introduction

2. Results and Discussion

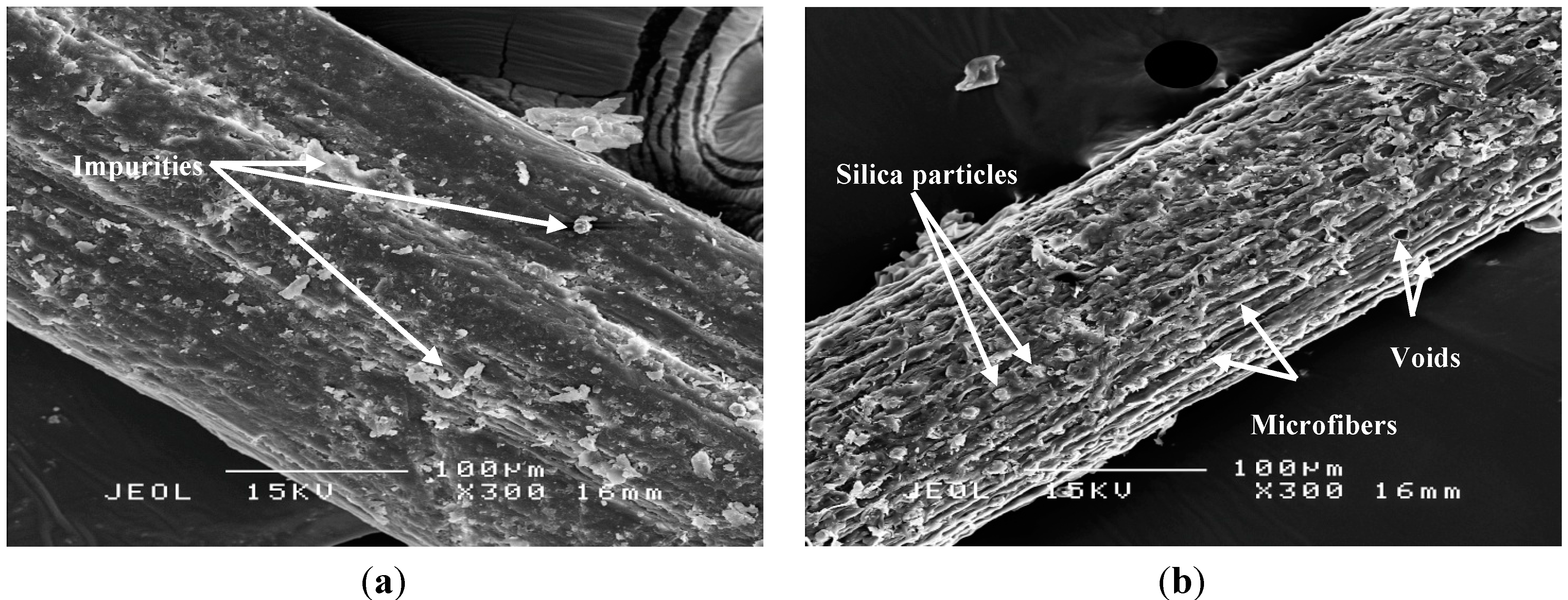

2.1. Characterizations of Untreated OPMF and SHSOPMF

2.1.1. FTIR Spectroscopy

2.1.2. Surface Morphology

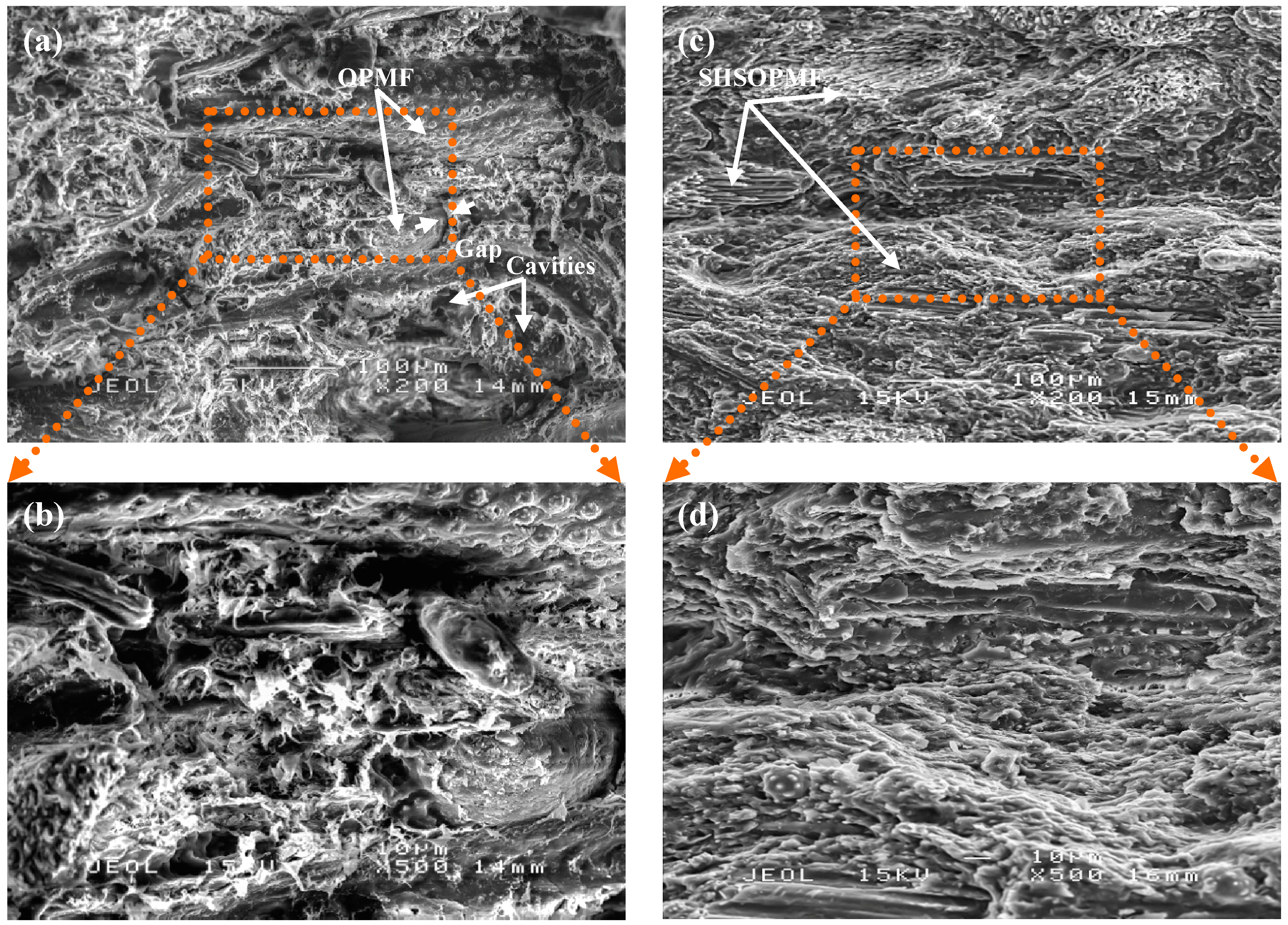

2.2. Characterizations of Untreated OPMF/PBS and SHS Treated OPMF/PBS Biocomposites

2.2.1. Tensile Properties

| Biocomposite | Temperature (°C) | Time (min) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| OPMF/PBS | - | - | 13.86 ± * 0.73 | 94.80 ± 7.60 | 2.50 ± 0.29 |

| SHS treated OPMF/PBS | 200 | 60 | 16.06 ± 0.58 | 111.82 ± 8.51 | 2.28 ± 0.29 |

| 210 | 60 | 17.72 ± 0.60 | 122.30 ± 3.21 | 2.65 ± 0.31 | |

| 220 | 30 | 16.26 ±1.00 | 128.00 ± 15.85 | 2.68 ± 0.25 | |

| 60 | 19.42 ± 0.45 | 552.50 ± 42.27 | 3.15 ± 0.35 | ||

| 90 | 19.64 ± 1.27 | 261.60 ± 41.30 | 2.87 ± 0.22 | ||

| 120 | 20.57 ± 1.26 | 122.67 ± 16.17 | 3.06 ± 0.28 | ||

| 230 | 60 | 17.46 ± 0.45 | 571.43 ± 19.27 | 2.90 ± 0.42 |

2.2.2. Surface Morphology

2.2.3. Flexural and Impact Properties

| Biocomposite | Flexural Strength, (MPa) | Flexural Modulus, (MPa) | Impact Strength, (J/m) |

|---|---|---|---|

| OPMF/PBS | 27.26 ± * 0.99 | 2191.00 ± 96.00 | 65.75 ± 3.08 |

| SHSOPMF/PBS | 32.56 ± 0.48 | 3180.00 ± 50.00 | 74.70 ± 0.54 |

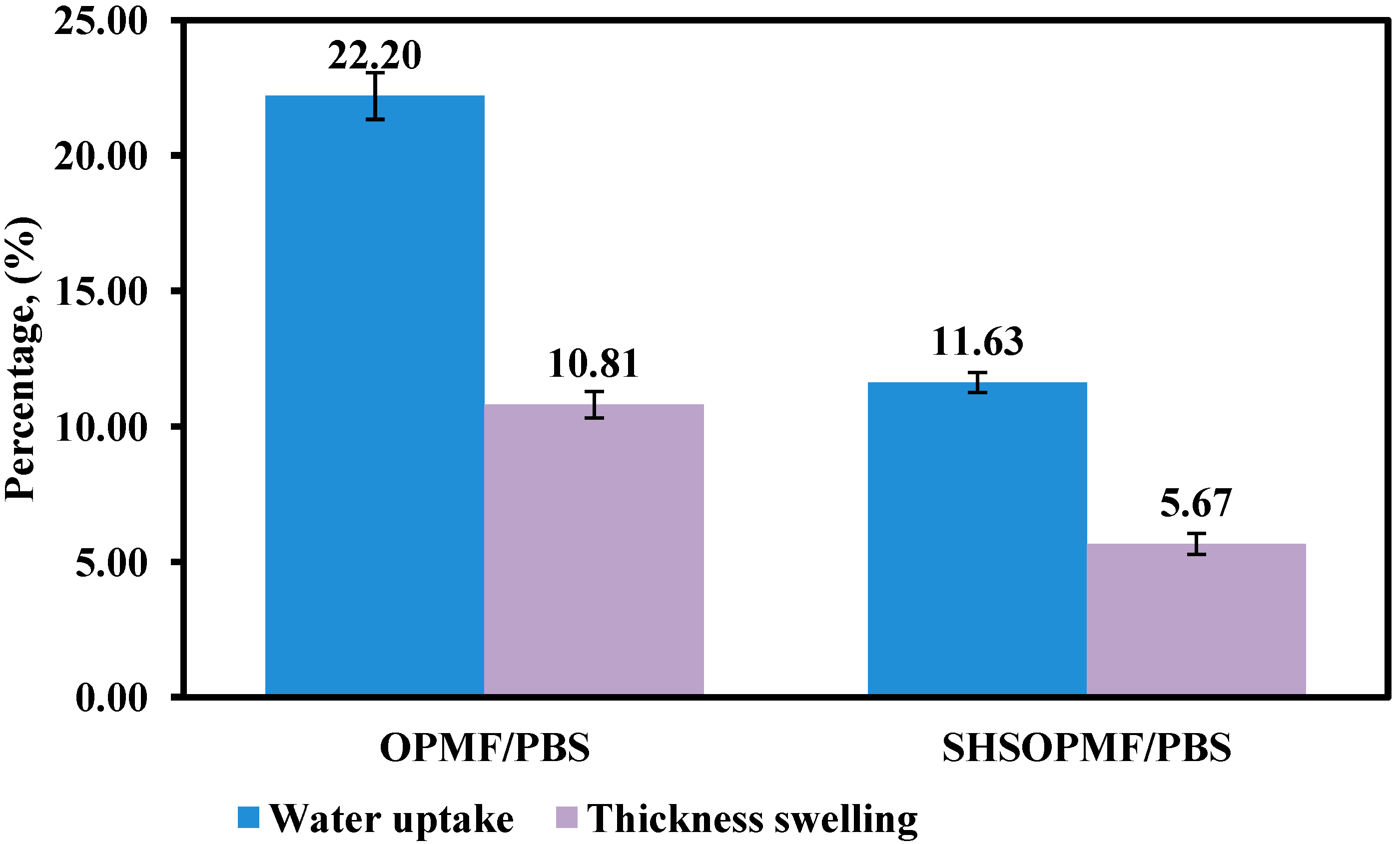

2.2.4. Dimensional Stability

3. Experimental Section

3.1. Materials

3.2. Modification of OPMF by SHS Treatment

3.3. Fabrication of Biocomposites

3.4. FTIR Spectroscopy

3.5. Mechanical Properties Measurement

3.6. Scanning Electron Microscopy

3.7. Dimensional Stability Measurement

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef]

- Sarikanat, M.; Seki, Y.; Sever, K.; Durmuskahya, C. Determination of properties of Althaea officinalis L. (Marshmallow) fibres as a potential plant fibre in polymeric composite materials. Compos. B Eng. 2014, 57, 180–186. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Bella, G.D. Artichoke (Cynara cardunculus L.) fibres as potential reinforcement of composite structures. Compos. Sci. Technol. 2011, 71, 1138–1144. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Lee, S.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Song, J.I.; Rajulu, A.V. Tensile and structural characterization of alkali treated Borassus fruit fine fibers. Compos. B Eng. 2013, 44, 433–438. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos. B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Zaman, H.U.; Beg, M.D.H. Preparation, structure, and properties of the coir fiber/polypropylene composites. J. Compos. Mater. 2013. [Google Scholar] [CrossRef]

- Islam, M.N.; Rahman, M.R.; Haque, M.M.; Huque, M.M. Physico-mechanical properties of chemically treated coir reinforced polypropylene composites. Compos. A Appl. Sci. Manuf. 2010, 41, 192–198. [Google Scholar] [CrossRef]

- Araujo, J.R.; Mano, B.; Teixeira, G.M.; Spinace, M.A.S.; de Paoli, M.A. Biomicrofibrilar compositesof high density polyethylene reinforced with curaua fibers: Mechanical, interfacial and morphological properties. Compos. Sci. Technol. 2010, 70, 1637–1644. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Durmuskahya, C. Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos. B Eng. 2013, 44, 517–523. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and thermal properties and water absorption of jute fiber reinforced poly(butylene succinate) biodegradable composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Razera, I.A.T.; Frollini, E. Composites based on jute fibers and phenolic matrices: Properties of fibers and composites. J. Appl. Polym. Sci. 2004, 91, 1077–1085. [Google Scholar] [CrossRef]

- Ahmad Thirmizir, M.Z.; Mohd Ishak, Z.A.; Taib, R.M.; Mohamad Jani, S. Kenaf-Bast-fiber-filled biodegradable poly(butylene succinate) composites: Effects of fiber loading, fiber length, and maleated poly(butylene succinate) on the flexural and impact properties. J. Appl. Polym. Sci. 2011, 122, 3055–3063. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Hadithon, K.A.; Abdan, K. Effect of fibre treatment on mechanical properties of kenaf-Ecoflex composites. J. Reinf. Plast. Compos. 2010, 29, 2192–2198. [Google Scholar] [CrossRef]

- Abdul Razak, N.I.; Ibrahim, N.A.; Zainuddin, N.; Rayung, M.; Saad, W.Z. The influence of chemical surface modification of kenaf fiber using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly(lactic acid) composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef]

- Nik Mahmud, N.A.; Baharuddin, A.S.; Bahrin, E.K.; Sulaiman, A.; Naim, M.Z.; Zakaria, R.; Hassan, M.A.; Nishida, H.; Shirai, Y. Enzymatic saccharification of oil palm mesocarp fiber (OPMF) treated with superheated steam. Bioresources 2013, 8, 1320–1331. [Google Scholar]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Lau, H.L.N.; Choo, Y.M.; Ma, A.N.; Chuah, C.H. Selective extraction of palm carotene and vitamin E from fresh palm-press mesocarp fiber (Elaeis guineensis) using supercritical CO2. J. Food Eng. 2008, 84, 289–296. [Google Scholar] [CrossRef]

- Teh, C.C.; Ibrahim, N.A.; Wan Yunus, W.M.Z. Response surface methodology for the optimization and characterization of oil palm mesocarp fiber-graft-poly(butyl acrylate). BioResources 2013, 8, 5244–5260. [Google Scholar]

- Then, Y.Y.; Ibrahim, N.A.; Zainuddin, N.; Ariffin, H.; Wan Yunus, W.M.Z. Oil palm mesocarp fiber as new lignocellulosic material for fabrication of polymer/fiber biocomposites. Int. J. Polym. Sci. 2013, 2013. [Google Scholar] [CrossRef]

- Eng, C.C.; Ibrahim, N.A.; Zainuddin, N.; Ariffin, H.; Wan Yunus, W.M.Z.; Then, Y.Y. Effect of hydrophilic nanoclay on morphology, thermal and mechanical properties of polylactic acid/polycaprolactone/oil palm mesocarp fiber biocomposites. Int. J. Inst. Mater. Malays. 2014, 1, 51–70. [Google Scholar]

- Bahrin, E.K.; Baharuddin, A.S.; Ibrahim, M.F.; Razak, M.N.A.; Sulaiman, A.; Abd-Aziz, S.; Hassan, M.A.; Shirai, Y.; Nishida, H. Physicochemical properties changes and enzymatic hydrolysis enhancement of oil palm empty fruit bunches treated with superheated steam. Bioresources 2012, 7, 1784–1801. [Google Scholar]

- Ahamad Nordin, N.I.A.; Ariffin, H.; Andou, Y.; Hassan, M.A.; Shirai, Y.; Nishida, H.; Wan Yunus, W.M.Z.; Karuppuchamy, S.; Ibrahim, N.A. Modification of oil palm mesocarp fiber characteristic using superheated steam treatment. Molecules 2013, 18, 9132–9146. [Google Scholar] [CrossRef]

- Sathishkumara, T.P.; Navaneethakrishnana, P.; Shankarb, S.; Rajasekara, R. Characterization of new cellulose sansevieria ehrenbergii fibers for polymer composites. Compos. Interfaces 2013, 20, 575–593. [Google Scholar] [CrossRef]

- Fujimaki, T. Processability and properties of aliphatic polyester BIONOLLE synthesized by polycondensation reaction. Polym. Degrad. Stab. 1998, 59, 209–214. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.H. Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Enayati, A.A.; Rials, T.G. Effects of hemicellulose extraction on properties of wood flour and wood-plastic composites. Compos. A Appl. Sci. Manuf. 2012, 43, 686–694. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Long-term moisture absorption and thickness swelling behavior of recycled thermoplastics reinforced with Pinus radiata sawdust. Chem. Eng. J. 2008, 142, 190–198. [Google Scholar] [CrossRef]

- Head, D.S.; Cenkowski, S.; Arntfield, S.; Henderson, K. Superheated steam processing of oat groats. LWT-Food Sci. Technol. 2010, 43, 690–694. [Google Scholar] [CrossRef]

- Sagehshi, M.; Miyasaka, N.; Shishido, H.; Sakoda, A. Superheated steam pyrolysis of biomass elemental components and Sugi (Japanese cedar) for fuels and chemicals. Bioresour. Technol. 2006, 97, 1272–1283. [Google Scholar] [CrossRef]

- Wang, K.B.; Jiang, J.X.; Xu, F.; Sun, R.C. Influence on steaming pressure on steam explosion pretreatment of Lespedza stalks (Lespedzacryobotrya): Part 1. Characteristic of degraded cellulose. Polym. Degrad. Stab. 2009, 94, 1379–1388. [Google Scholar] [CrossRef]

- Yang, H.P.; Yan, R.; Chen, H.P.; Zheng, C.G.; Lee, D.H.; Liang, D.T. In depth investigation of biomass pyrolysis based on three major components: Hemicellulose, cellulose and lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Brodin, I.; Sjoholm, E.; Gellerstedt, G. Kraft lignin as feedstock for chemical products: The effects of membrane filtration. Holzforschung 2009, 63, 290–297. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Then, Y.Y.; Ibrahim, N.A.; Zainuddin, N.; Ariffin, H.; Yunus, W.M.Z.W.; Chieng, B.W. The Influence of Green Surface Modification of Oil Palm Mesocarp Fiber by Superheated Steam on the Mechanical Properties and Dimensional Stability of Oil Palm Mesocarp Fiber/Poly(butylene succinate) Biocomposite. Int. J. Mol. Sci. 2014, 15, 15344-15357. https://doi.org/10.3390/ijms150915344

Then YY, Ibrahim NA, Zainuddin N, Ariffin H, Yunus WMZW, Chieng BW. The Influence of Green Surface Modification of Oil Palm Mesocarp Fiber by Superheated Steam on the Mechanical Properties and Dimensional Stability of Oil Palm Mesocarp Fiber/Poly(butylene succinate) Biocomposite. International Journal of Molecular Sciences. 2014; 15(9):15344-15357. https://doi.org/10.3390/ijms150915344

Chicago/Turabian StyleThen, Yoon Yee, Nor Azowa Ibrahim, Norhazlin Zainuddin, Hidayah Ariffin, Wan Md Zin Wan Yunus, and Buong Woei Chieng. 2014. "The Influence of Green Surface Modification of Oil Palm Mesocarp Fiber by Superheated Steam on the Mechanical Properties and Dimensional Stability of Oil Palm Mesocarp Fiber/Poly(butylene succinate) Biocomposite" International Journal of Molecular Sciences 15, no. 9: 15344-15357. https://doi.org/10.3390/ijms150915344

APA StyleThen, Y. Y., Ibrahim, N. A., Zainuddin, N., Ariffin, H., Yunus, W. M. Z. W., & Chieng, B. W. (2014). The Influence of Green Surface Modification of Oil Palm Mesocarp Fiber by Superheated Steam on the Mechanical Properties and Dimensional Stability of Oil Palm Mesocarp Fiber/Poly(butylene succinate) Biocomposite. International Journal of Molecular Sciences, 15(9), 15344-15357. https://doi.org/10.3390/ijms150915344