Stable Isolation of Phycocyanin from Spirulina platensis Associated with High-Pressure Extraction Process

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Yield of Phycocyanin Isolated Using the High-Pressure Process

2.2. The Purity of Phycocyanin Isolated Using the High-Pressure Process

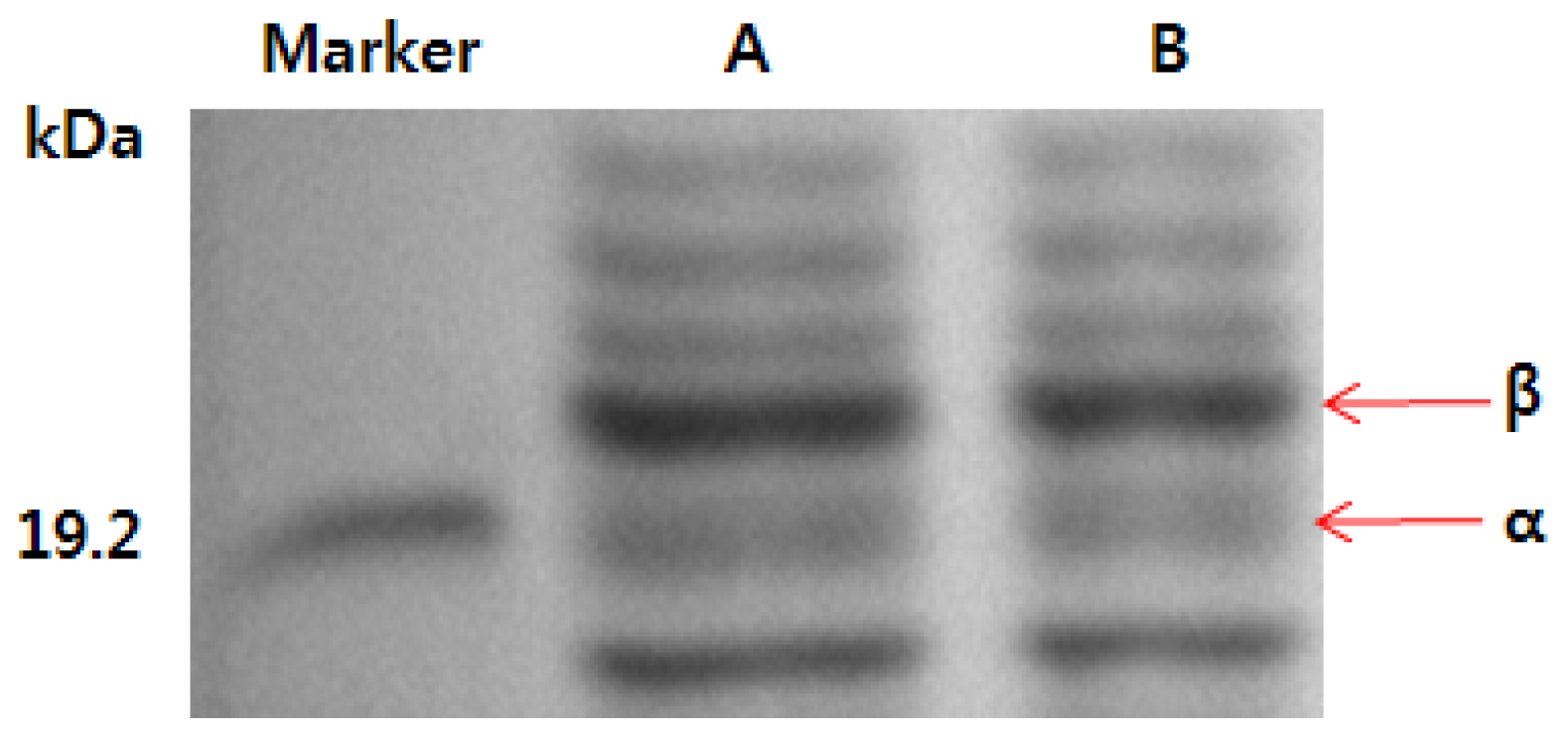

2.3. SDS-PAGE Analysis of Phycocyanin

2.4. Stability of Phycocyanin Extract

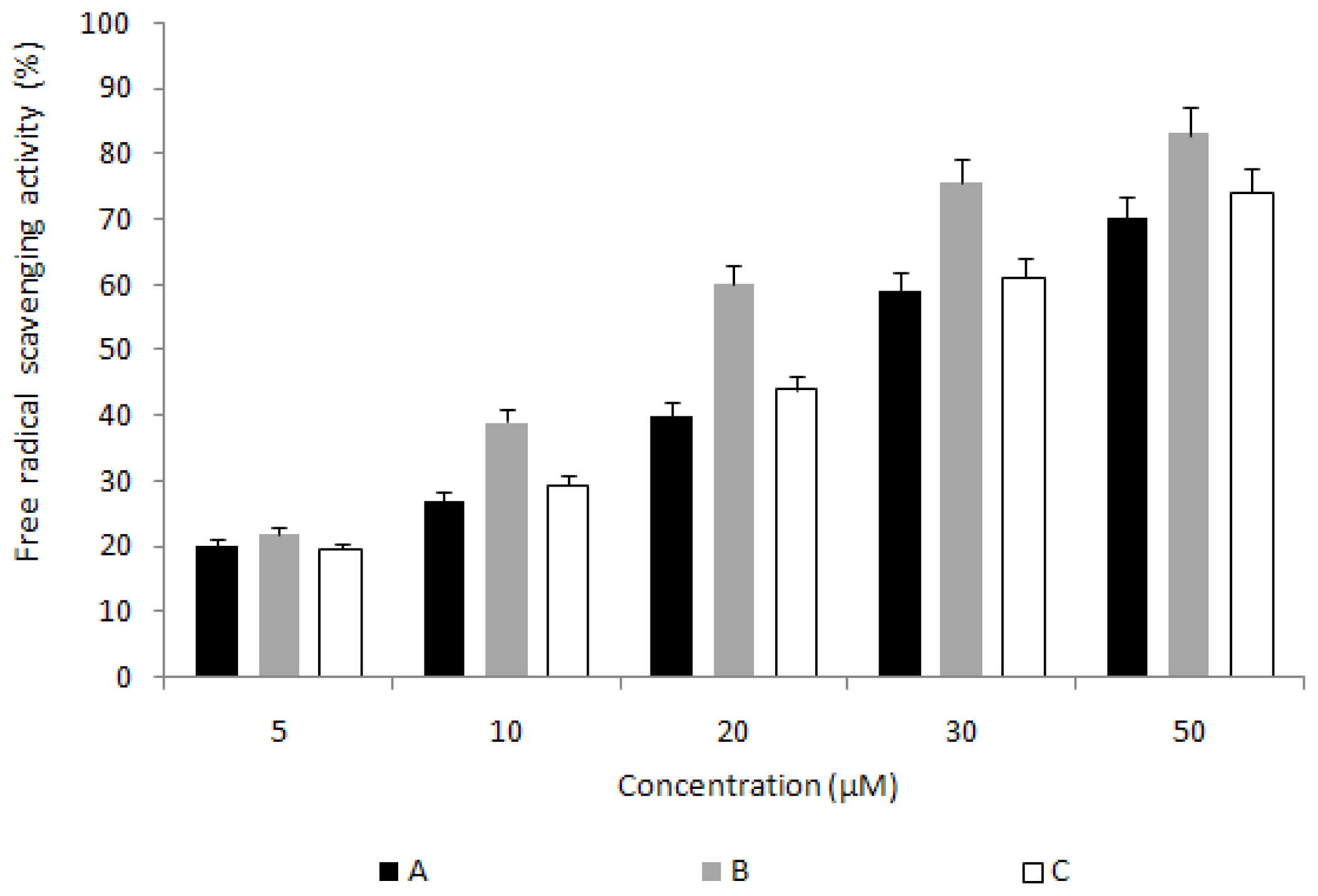

2.5. Measurement of DPPH (α,α-diphenyl-β-picrylhydrazyl) Scavenging Activity

2.6. Measurement of Reducing Power

3. Experimental Section

3.1. Extraction from Spirulina platensis

3.2. Isolation of Phycocyanin

3.3. Measurement of Extraction Yield and the Purity of Phycocyanin

3.4. SDS-PAGE Pattern of Phycocyanin

3.5. Stability of Phycocyanin

3.6. Measurement of DPPH (α,α-diphenyl-β-picrylhydrazyl) Scavenging Activity

3.7. Measurement of Reducing Power

3.8. Statistics

4. Conclusions

Acknowledgments

References

- Becker, E.W. Microalgae: Biotechnology and Microbiology; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Kay, R.A. Microalgae as food and supplement. Crit. Rev. Food Sci 1991, 30, 555–573. [Google Scholar]

- Glazer, A.N. Light harvesting by phycobilisomes. Ann. Rev. Biophys. Chem 1985, 14, 47–77. [Google Scholar]

- Sautier, C.; Tremolieres, J. Food value in Spirulina algae in humans. J. Ann. Nutr. Aliment 1975, 30, 517–522. [Google Scholar]

- Abalde, J.; Betancourt, L.; Torres, E.; Cid, A.; Barwell, C. Purification and characterization of phycocyanin from the marine cyanobacterium Synechococcus sp. IO9201. Plant Sci 1998, 136, 109–120. [Google Scholar]

- Diego, J.M.; Gomez, C.; Ibanez, E.; Ruperez, F.J.; Barbas, C. Tocopherol measurement in edible products of vegetable origin. J. Chromatogr. A 2004, 1054, 227–233. [Google Scholar]

- Grinstead, G.S.; Tokach, S.S.; Goodband, R.D.; Nelssen, J.L. Effects of Spirulina platensis in growth performance of weanling pigs. Anim. Feed Sci. Tech 2000, 83, 237–247. [Google Scholar]

- Kaji, T.; Fujiwara, Y.; Inomata, Y.; Hamada, C.; Yamamoto, C.; Shimada, S.; Lee, J.B.; Hayashi, T. Repair of wounded monolayers of cultured bovine aortic endothelial cells is inhibited by calcium spirulan, a novel sulfated polysaccharide isolated form Spirulina platensis. Life Sci 2002, 70, 1841–1848. [Google Scholar]

- Lee, H.S.; Lee, S.H.; Mun, H.C.; Lee, H.Y. Screening of the immuno-stimulatory activity of the marine alga Chlorella capsulate. Kor. J. Biotechnol. Bioeng 2003, 18, 19–24. [Google Scholar]

- Sarada, R.; Pillai, M.G.; Ravishankar, G.A. Phycocyanin from Spirulina sp: Influence of processing of biomass on phycocyanin yield, analysis of efficacy of extraction methods and stability studies on phycocyanin. Process Biochem 1999, 34, 795–801. [Google Scholar]

- Zhang, S.; Zhu, J.; Wang, C. Novel high pressure extraction technology. Int. J. Pharm 2004, 278, 471–474. [Google Scholar]

- Kim, Y.S.; Choi, J.M. Physiochemical properties and dyeability of safflower colorants extracted by ultrasonic treatment. J. Korean Soc. Cloth. Ind 2009, 11, 337–343. [Google Scholar]

- Antelo, F.S.; Anschau, A.; Costa, J.A.V.; Kalil, S.J. Extraction and purification of C-phycocyanin from Spirulina platensis in conventional and integrated aqueous two-phase systems. J. Braz. Chem. Soc 2010, 21, 921–926. [Google Scholar]

- Chaiklahan, R.; Chirasuwan, N.; Loha, V.; Tia, S.; Bunnag, B. Separation and purification of phycocyanin from Spirulina sp. using a membrane process. Bioresour. Technol 2011, 102, 7159–7164. [Google Scholar]

- Kim, S.S.; Jeong, M.H.; Seo, Y.C.; Kim, J.S.; Kim, N.S.; Woon, W.B.; Ahn, J.H.; Hwang, B.; Park, D.S.; Park, S.J.; Lee, H.Y. Comparison of antioxidation activities by high pressure extraction of Codonopsis lanceolata from different production Areas. Korean J. Med. Crop Sci 2010, 18, 248–254. [Google Scholar]

- Boussiba, S.; Richmond, A. Isolation and characterization of phycocyanins from the blue-green alga Spirulina platensis. Arch. Microbiol 1979, 120, 155–159. [Google Scholar]

- Binder, A.; Wilson, K.; Zuber, H. C-phycocyanin from the thermophilic blue-green alga Mastigocladus laminousus. FEBS Lett 1972, 20, 111–116. [Google Scholar]

- Liu, L.N.; Chen, X.L.; Zhang, X.Y.; Zhang, Y.Z.; Zhou, B.C. One-step chromatography method for efficient separation and purification of R-phycoerythrin from Polysiphonia urceolata. J. Biotechnol 2005, 116, 91–100. [Google Scholar]

- Joo, D.S.; Cho, S.Y. Stability of phycocyanin and spectral characteristic of phycobilins from Spirulina platensis. J. Korean Fish. Soc 2000, 33, 482–488. [Google Scholar]

- Kang, M.Y.; Lee, Y.R.; Koh, H.J.; Nam, S.H. Antioxidative and antimutagenic activity of ethanolic extracts from Glant embroynic rices. J. Korean Soc. Appl. Biol. Chem 2004, 47, 61–66. [Google Scholar]

- Oyaizu, M. Studies on products of browning reactions: Antioxidative activities of products of browning reaction prepared from glucosamine. Jpn. J. Nutr 1986, 44, 307–315. [Google Scholar]

| Sample | Yields (%) |

|---|---|

| A | 7.2 ± 0.5 |

| B | 10.2 ± 0.2 |

| C | 8.4 ± 0.4 |

| Sample | Absorbance ratios (nm) | ||

|---|---|---|---|

| 280 | 620 | 620/280 | |

| A | 2.114 ± 0.005 | 1.868 ± 0.012 | 0.884 ± 0.004 |

| B | 2.104 ± 0.007 | 1.912 ± 0.004 | 0.909 ± 0.003 |

| C | 2.125 ± 0.008 | 1.873 ± 0.009 | 0.882 ± 0.006 |

| D | 2.105 ± 0.006 | 1.903 ± 0.004 | 0.904 ± 0.005 |

| Reducing power (O.D.) | |||||

|---|---|---|---|---|---|

| Sample | Concentration (μM) | ||||

| 5 | 10 | 20 | 30 | 50 | |

| A | 0.07 ± 0.13 | 0.15 ± 0.12 | 0.15 ± 0.08 | 0.18 ± 0.04 | 0.19 ± 0.06 |

| B | 0.08 ± 0.04 | 0.16 ± 0.09 | 0.25 ± 0.13 | 0.31 ± 0.06 | 0.38 ± 0.05 |

| C | 0.09 ± 0.04 | 0.15 ± 0.18 | 0.18 ± 0.04 | 0.20 ± 0.06 | 0.21 ± 0.08 |

© 2013 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Seo, Y.C.; Choi, W.S.; Park, J.H.; Park, J.O.; Jung, K.-H.; Lee, H.Y. Stable Isolation of Phycocyanin from Spirulina platensis Associated with High-Pressure Extraction Process. Int. J. Mol. Sci. 2013, 14, 1778-1787. https://doi.org/10.3390/ijms14011778

Seo YC, Choi WS, Park JH, Park JO, Jung K-H, Lee HY. Stable Isolation of Phycocyanin from Spirulina platensis Associated with High-Pressure Extraction Process. International Journal of Molecular Sciences. 2013; 14(1):1778-1787. https://doi.org/10.3390/ijms14011778

Chicago/Turabian StyleSeo, Yong Chang, Woo Seok Choi, Jong Ho Park, Jin Oh Park, Kyung-Hwan Jung, and Hyeon Yong Lee. 2013. "Stable Isolation of Phycocyanin from Spirulina platensis Associated with High-Pressure Extraction Process" International Journal of Molecular Sciences 14, no. 1: 1778-1787. https://doi.org/10.3390/ijms14011778