Fructose Production by Inulinase Covalently Immobilized on Sepabeads in Batch and Fluidized Bed Bioreactor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Enzyme Immobilization

Immobilization procedure

Inulinase activity

Protein Determination

Determination of Water Content

2.3. Batch Experiments

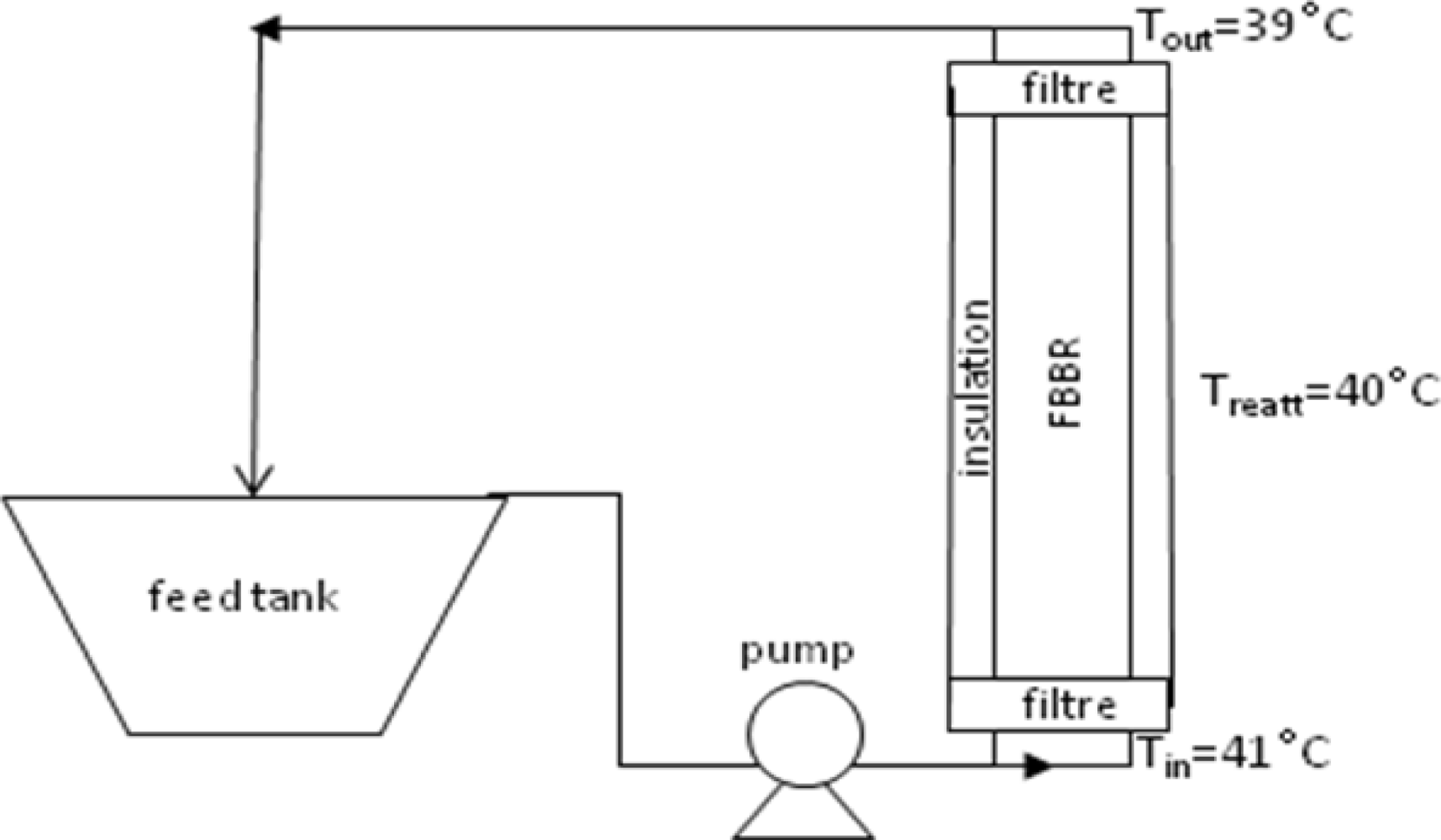

2.4. FBBR Continuous Operation

2.5. Analysis of Reaction Products

3. Results and Discussion

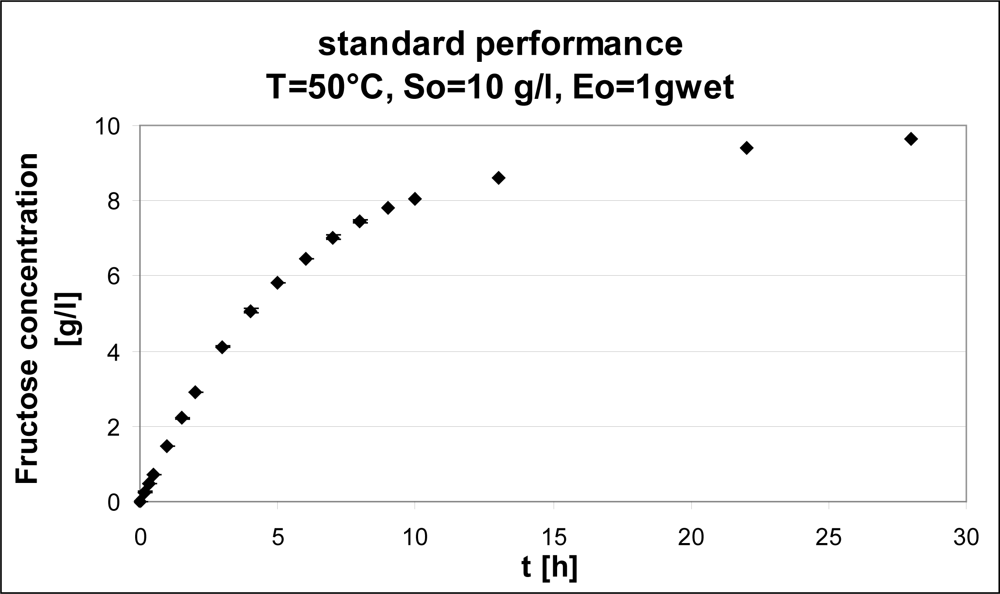

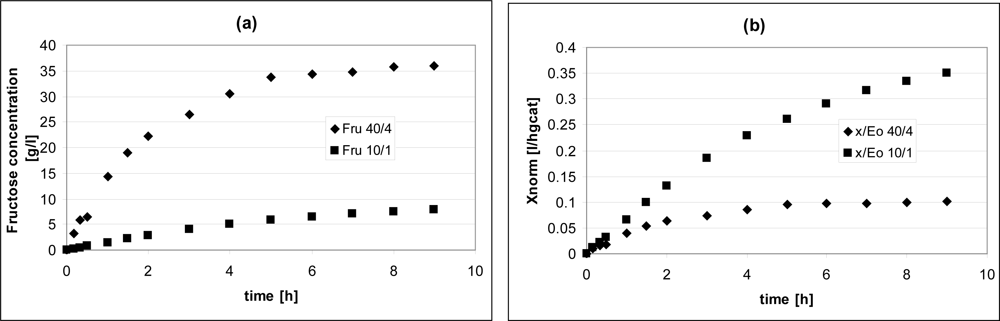

3.1. Batch Tests

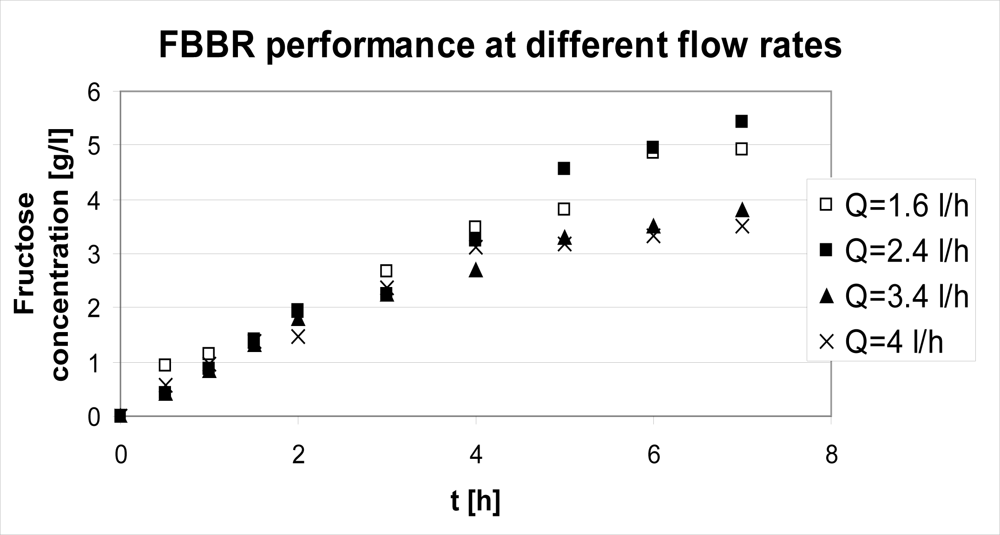

3.2. FBBR Tests

4. Conclusions

References and Notes

- Kochhar, A; Gupta, AK; Kaur, N. Purification and immobilisation of inulinase from Aspergillus candidus for producing fructose. J. Sc. Food Agric 1999, 79, 549–554. [Google Scholar]

- Vandamme, EJ; Derycke, DG. Microbial inulinases: Fermentation process, properties and applications. Adv. Appl. Microbiol 1983, 29, 139–176. [Google Scholar]

- Ricca, E; Calabrò, V; Curcio, S; Iorio, G. The state of the art in the production of fructose from inulin enzymatic hydrolysis. Crit. Rev. Biotechnol 2007, 27, 129–145. [Google Scholar]

- Franck, A; De Leenheer, L. Inulin. In Polysaccharides II: Polysaccharides from Eukaryotes; De Baets, S, Vandamme, E, Steinbüchel, A, Steinbüchel, A, Eds.; Wiley-VHC: Weinheim, Germany, 2000. [Google Scholar]

- van Loo, J; Coussement, P; de Leenheer, L; Hoebregs, H; Smits, G. On the presence of inulin and oligofructose as natural ingredients in the western diet. Crit. Rev. Food Sci. Nutr 1995, 35, 525–552. [Google Scholar]

- Monti, A; Pritoni, G; Amaducci, MT. Evaluation of chicory varieties in north Italy: Inulin production and photosynthesis. Presented at 9th Seminar on Inulin, Budapest, Hungary, 18th–19th April 2002.

- Rhee, SK; Kim, CH. Fructose production from Jerusalem artichoke by inulinase immobilized on chitin. Biotechnol. Lett 1989, 11, 201–206. [Google Scholar]

- Toneli, JTCL; Murr, FEX; Martinelli, P; Dal Fabbro, IM; Park, KJ. Optimization of a physical concentration process for inulin. J. Food Eng 2007, 80, 832–838. [Google Scholar]

- Wenling, W; Huiying, WWL; Shiyuan, W. Continuous preparation of fructose syrups from Jerusalem artichoke tuber using immobilized intracellular inulinase from Kluyveromyces sp. Y-85. Proc. Biochem 1999, 34, 643–646. [Google Scholar]

- Pandey, A; Soccol, CR; Selvakumar, P; Soccol, VT; Krieger, N; Fontana, JD. Recent developments in microbial inulinases. Appl. Biochem. Biotechnol 1999, 81, 35–52. [Google Scholar]

- Diaz, EG; Catana, R; Ferriera, BF; Luque, S; Fernandes, P; Cabral, JMS. Towards the development of a membrane reactor for enzymatic inulin hydrolysis. J. Mem. Sci 2006, 273, 152–158. [Google Scholar]

- Gupta, AK; Kaur, M; Kaur, N; Singh, R. A comparison of properties of inulinases of Fusarium oxysporum immobilized on various supports. J. Chem. Technol. Biotechnol 1992, 53, 293–296. [Google Scholar]

- Nakamura, T; Ogata, Y; Shitara, A; Nakamura, A; Ohta, K. Continuous production of fructose syrups from inulin by immobilized inulinase from Aspergillus niger Mutant 817. J. Ferment. Bioeng 1995, 80, 164–169. [Google Scholar]

- Gill, PK; Manhas, RK; Singh, P. Hydrolysis of inulin by immobilized thermostable extracellular exoinulinase from Aspergillus fumigatus. J. Food Eng 2006, 76, 369–375. [Google Scholar]

- Mateo, C; Abian, O; Fernandez-Lorente, G; Pedroche, J; Fernandez-Lafuente, R; Guisan, JM; Tam, A; Daminati, M. Epoxy Sepabeads: A Novel Epoxy Support for Stabilization of Industrial Enzymes via Very Intense Multipoint Covalent Attachment. Biotechnol. Prog 2002, 18, 629–634. [Google Scholar]

- Ghazi, I; De Segura, AG; Fernandez-Arrojo, L; Alcalde, M; Yates, M; Rojas-Cervantes, ML; Plou, FJ; Ballesteros, A. Immobilisation of fructosyltransferase from Aspergillus aculeatus on epoxy-activated Sepabeads EC for the synthesis of fructo-oligosaccharides. J. Mol. Cat. B: Enzymatic 2005, 35, 19–27. [Google Scholar]

- Alonso, N; Lopez-Gallego, F; Betancor, L; Hidalgo, A; Mateo, C; Guisan, JM; Fernandez-Lafuente, R. Immobilization and stabilization of glutaryl acylase on aminated sepabeads supports by the glutaraldehyde crosslinking method. J. Mol. Cat. B: Enzymatic 2005, 35, 57–61. [Google Scholar]

- Basso, A; Braiuca, P; Cantone, S; Ebert, C; Linda, P; Spizzo, P; Caimi, P; Hanefeld, U; Degrassi, G. In silico analysis of enzyme surface and glycosylation effect as a tool for efficient covalent immobilisation of CalB and PGA on Sepabeads. Adv. Syn. Cat 2007, 349, 877–886. [Google Scholar]

- Basso, A; Spizzo, P; Ferrario, V; Knapic, L; Savko, N; Braiuca, P; Ebert, C; Ricca, E; Calabrò, V; Gardossi, L. Endo- and exo-inulinases: Enzyme-substrate interaction and rational immobilization. Biotechnol. Progr. Article online in advance of print. DOI: 10.1002/btpr.334. http://www3.interscience.wiley.com/journal/123191700/abstract. (accessed on 18 of March, 2010).

- Ricca, E; Calabrò, V; Curcio, S; Iorio, G. Fructose production by chicory inulin enzyme hydrolysis: Kinetic study and reaction mechanism. Proc. Biochem 2009, 44, 466–471. [Google Scholar]

- Giacobini, C; Villarino, A; Franco-Fraguas, L; Batista-Viera, F. Immobilization of β-galactosidase from Kluyveromyces lactis on silica and agarose: comparison of different methods. J. Mol. Cat. B: Enzymatic 1998, 4, 313. [Google Scholar]

- Roy, I; Gupta, M. Lactose hydrolysis by Lactozym™ immobilized on cellulose beads in batch and fluidized bed modes. Proc. Biochem 2003, 39, 325–332. [Google Scholar]

| Enzyme loading [gcat] | Initial velocity [g/Lh] | Specific initial velocity [g/gcath] |

|---|---|---|

| 1 | 1.46 | 0.72 |

| 4 | 5.32 | 0.66 |

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ricca, E.; Calabrò, V.; Curcio, S.; Basso, A.; Gardossi, L.; Iorio, G. Fructose Production by Inulinase Covalently Immobilized on Sepabeads in Batch and Fluidized Bed Bioreactor. Int. J. Mol. Sci. 2010, 11, 1180-1189. https://doi.org/10.3390/ijms11031180

Ricca E, Calabrò V, Curcio S, Basso A, Gardossi L, Iorio G. Fructose Production by Inulinase Covalently Immobilized on Sepabeads in Batch and Fluidized Bed Bioreactor. International Journal of Molecular Sciences. 2010; 11(3):1180-1189. https://doi.org/10.3390/ijms11031180

Chicago/Turabian StyleRicca, Emanuele, Vincenza Calabrò, Stefano Curcio, Alessandra Basso, Lucia Gardossi, and Gabriele Iorio. 2010. "Fructose Production by Inulinase Covalently Immobilized on Sepabeads in Batch and Fluidized Bed Bioreactor" International Journal of Molecular Sciences 11, no. 3: 1180-1189. https://doi.org/10.3390/ijms11031180