Concentration of Rutin Model Solutions from Their Mixtures with Glucose Using Ultrafiltration

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Feed Solution

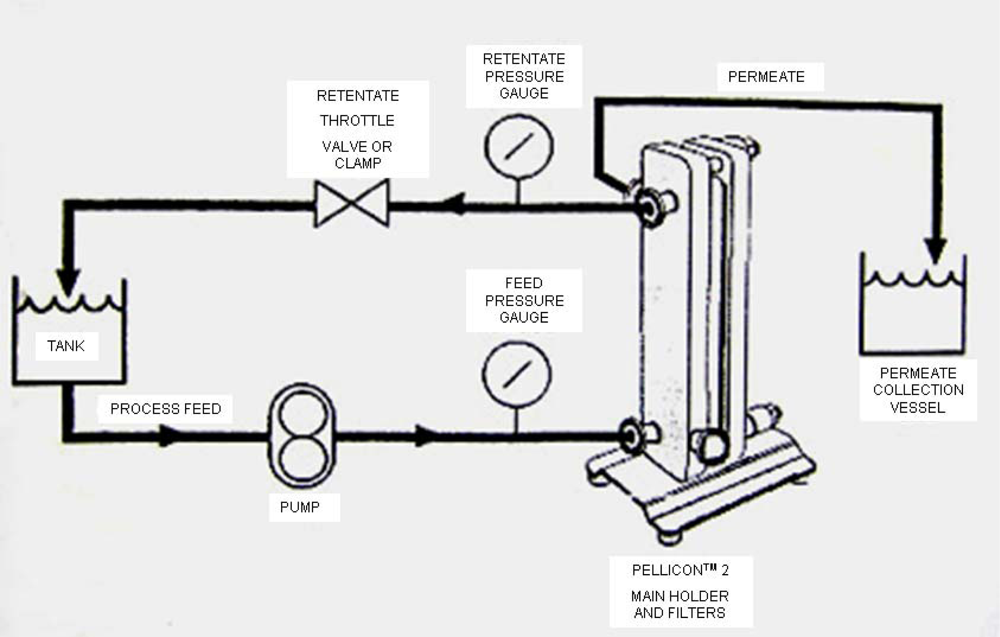

2.2. Experimental Procedures

2.3. Analysis of Membrane Performance

3. Results and Discussions

3.1. Pure Water Flux

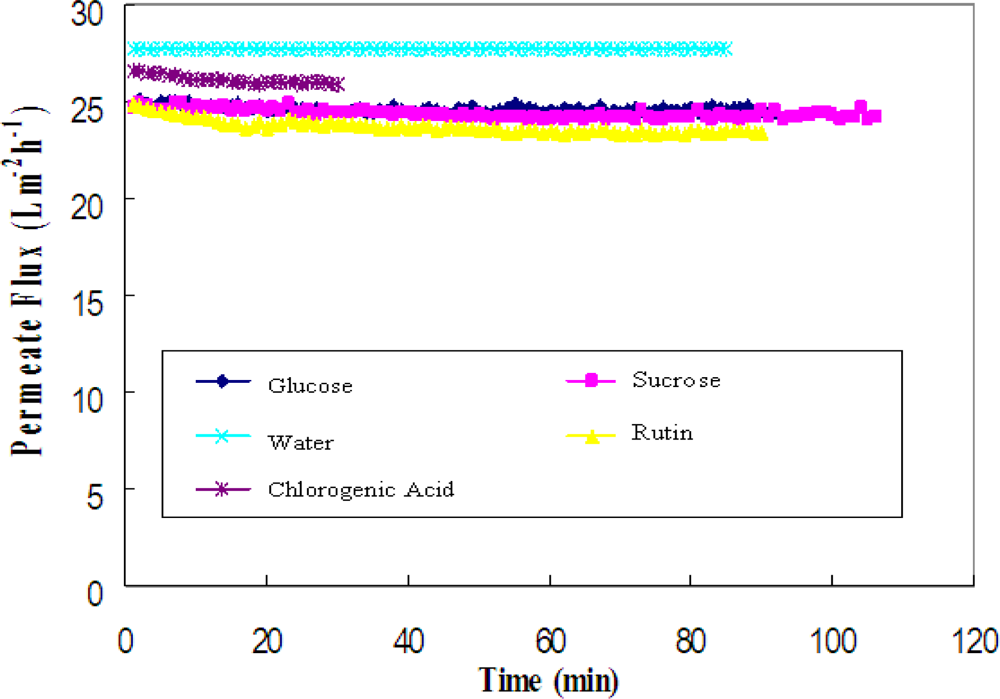

3.2. Single Component Ultrafiltration

3.3. Ultrafiltration of Two-component Solutions

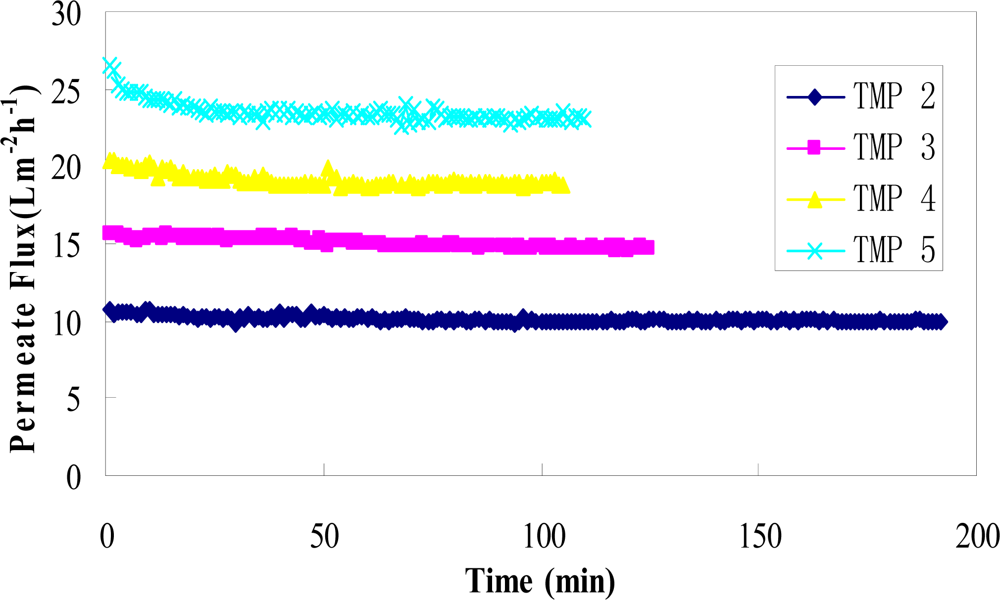

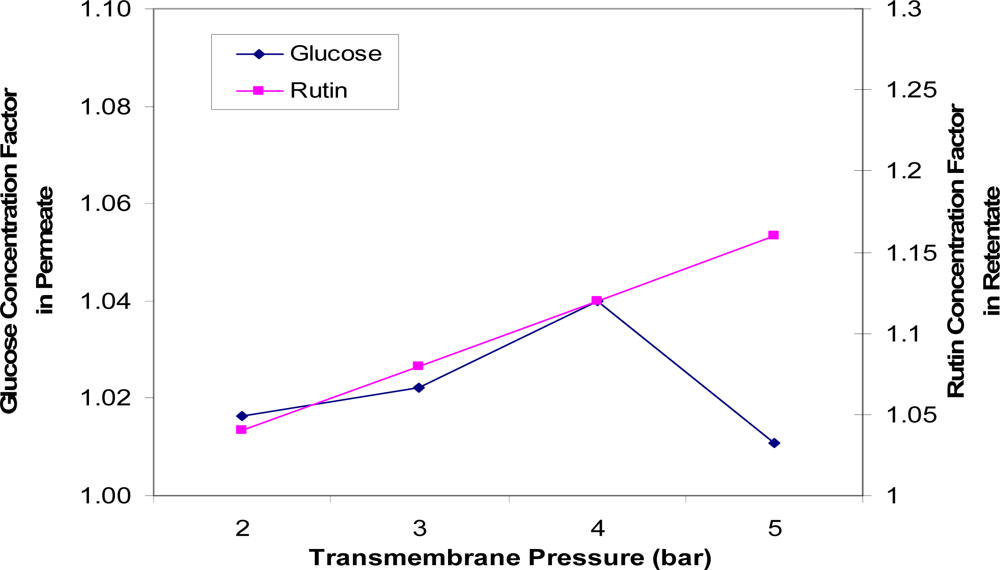

3.3.1. Effect of transmembrane pressure

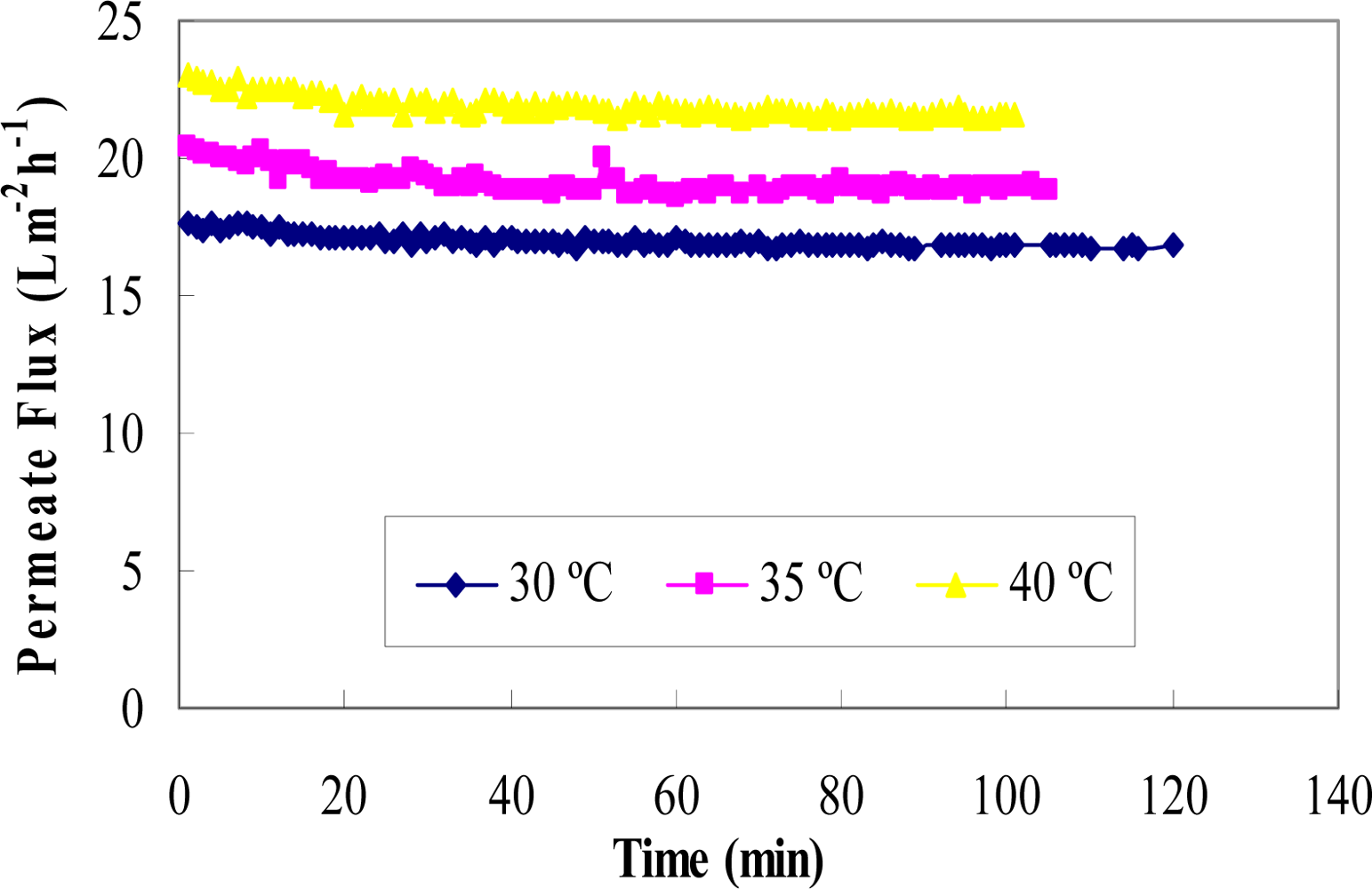

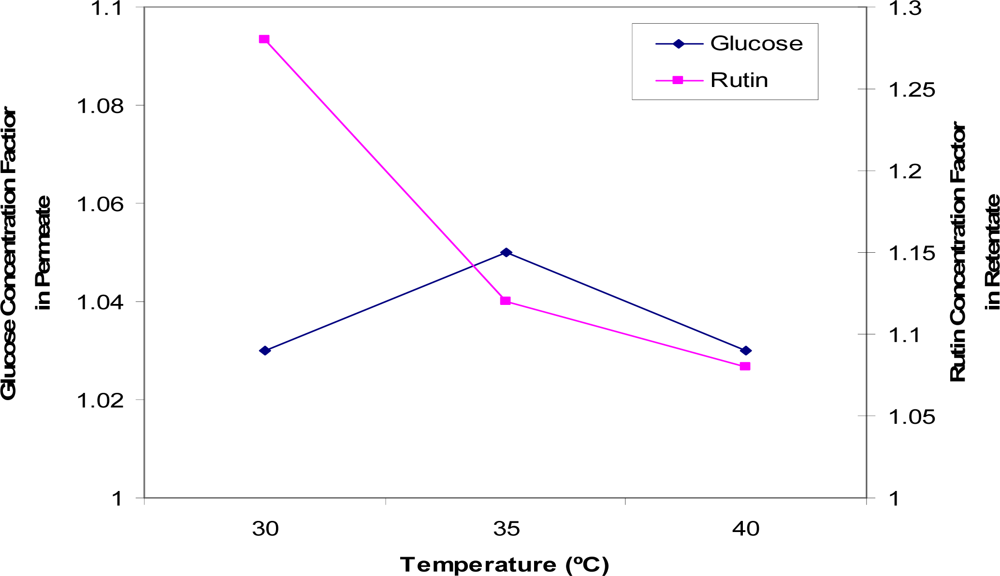

3.3.2. Effect of temperature

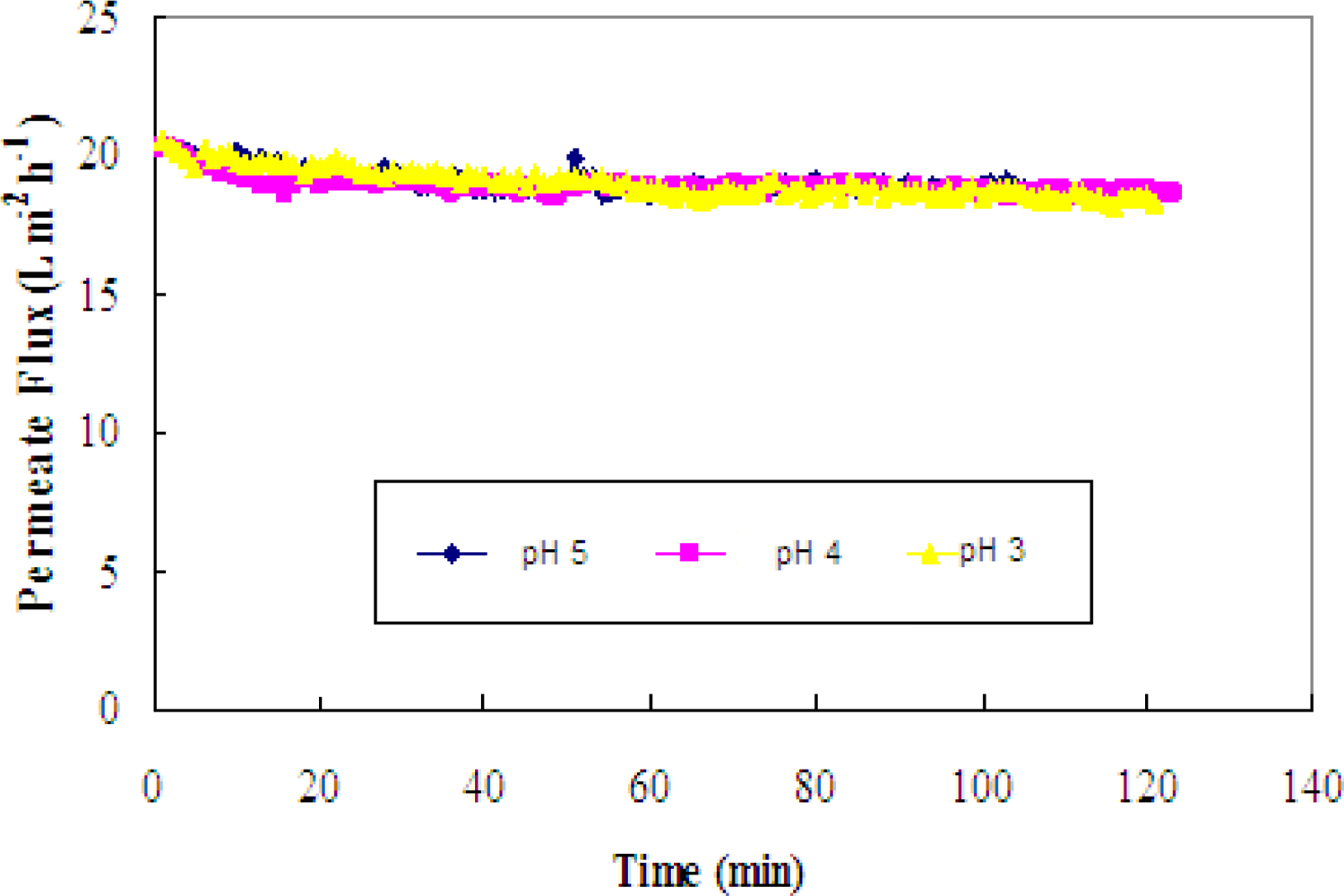

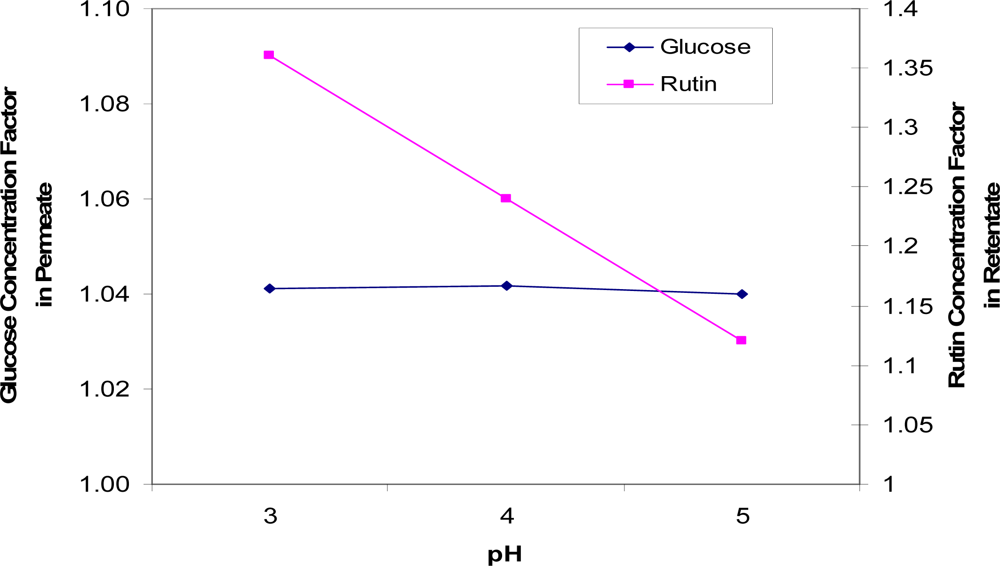

3.3.3. Effect of pH

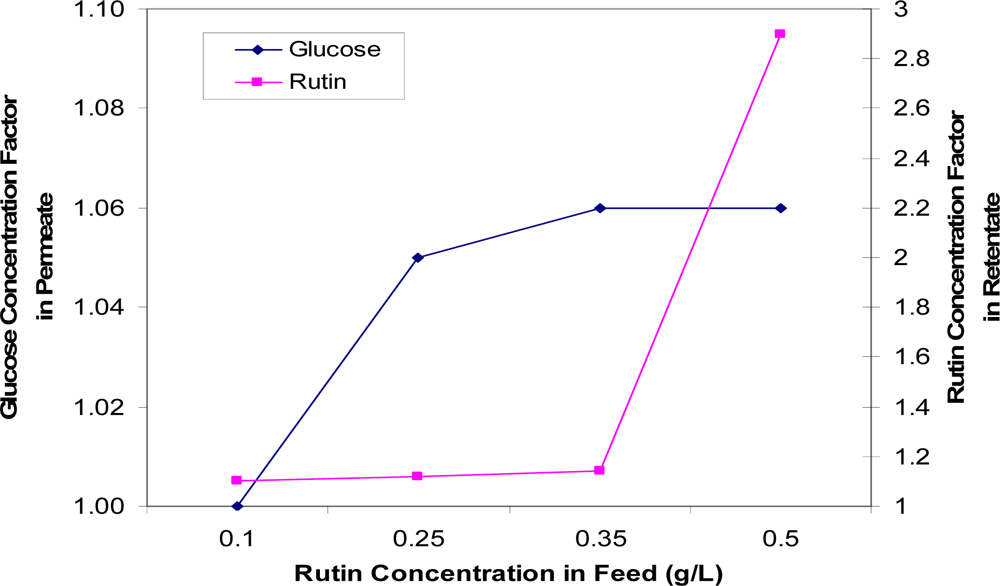

3.3.4. Effect of feed rutin concentration

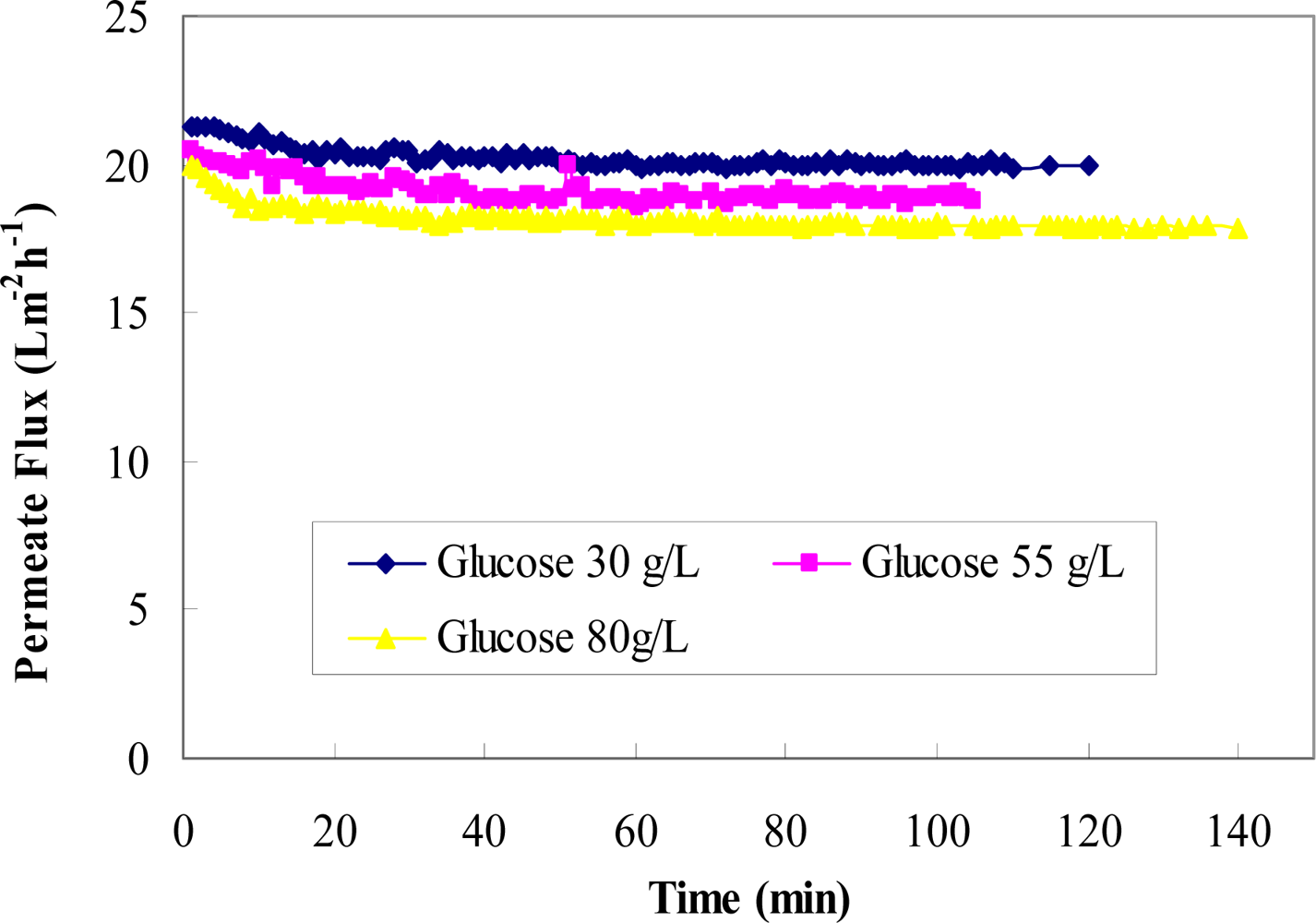

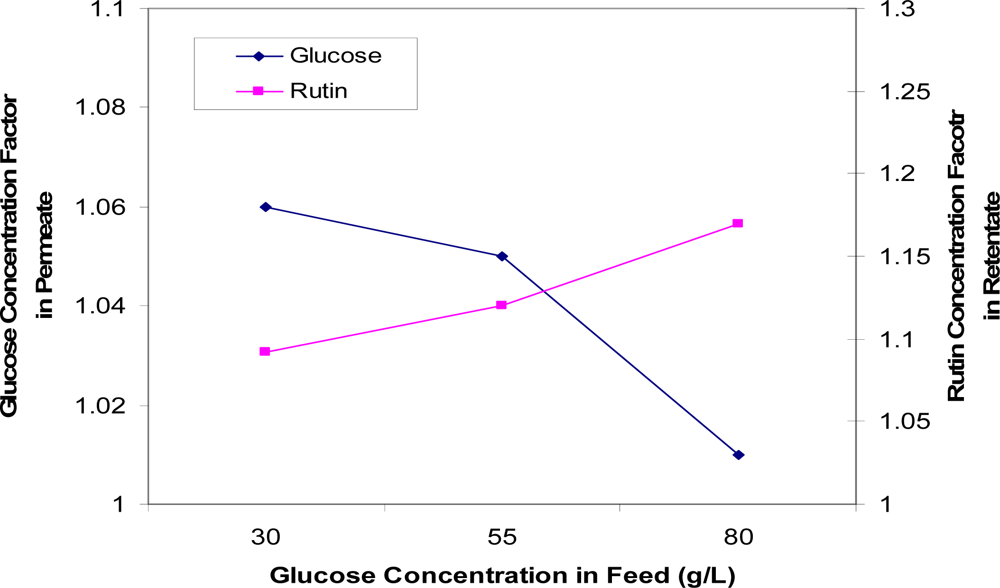

3.3.5. Effect of feed glucose concentration

3.3.6. Effect of feed flowrate

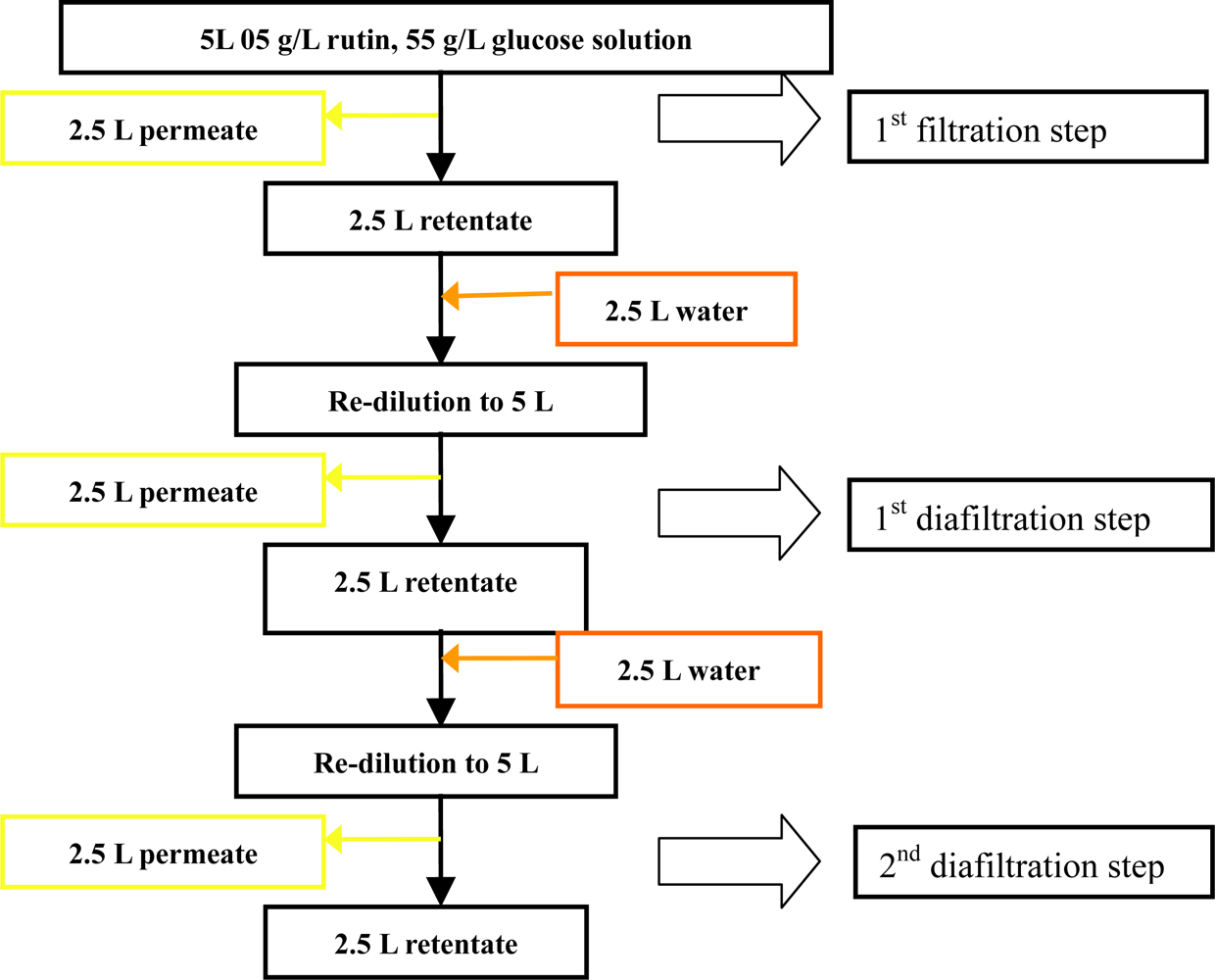

3.4. Diafiltration of Binary Feed

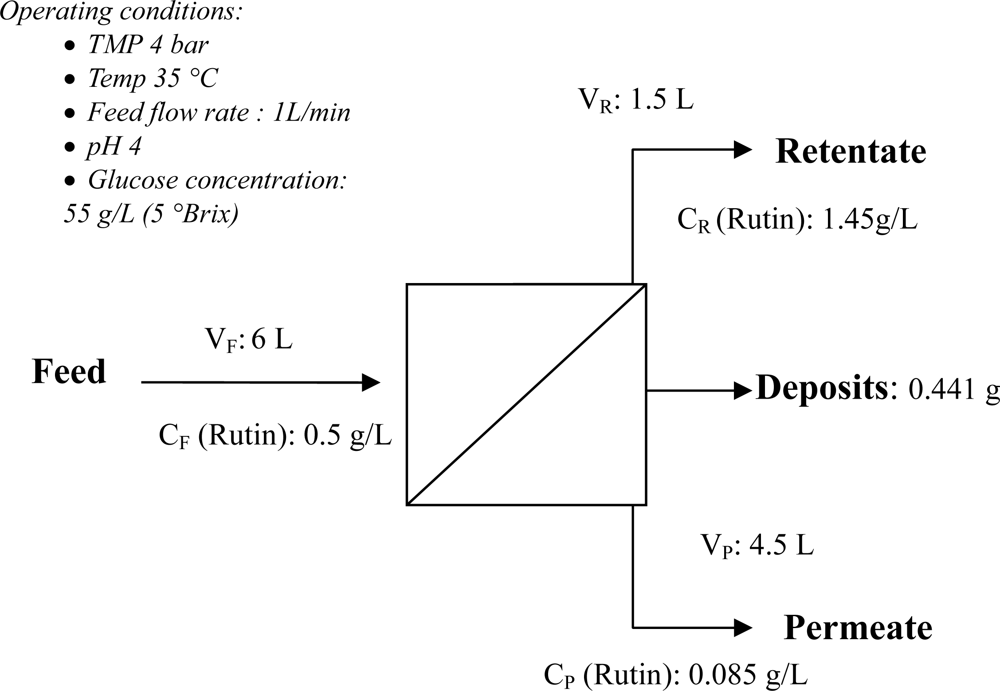

3.5. Mass Balance

- - No leakage in the system

- - Samples were an accurate representation of the actual situation.

4. Conclusions

- Flux increases with increasing transmembrane pressure. However, after a certain pressure limit, permeate flux gradually levels off. An increase in transmembrane pressure increases the accumulation of polyphenolics and potentially causes the formation of fouling layers. The optimum transmembrane pressure can be suggested to be approx. 4 bar where the fouling is minimal.

- Flux increases with increasing feed solution temperature because of lower feed viscosity, and better solubility of rutin at higher temperatures.

- Separation and concentration of rutin are favored at lower temperatures (30 °C).

- Lowering pH can increase the retention of polyphenolics. The optimum pH was suggested to be approx. 3.

- Flux declines with the increase in concentration of rutin in the feed. However, the rutin concentration in the retentate increased simultaneously with that in the feed, suggesting that membrane fouling was severe and that the deposits formed prevented most of the rutin molecules from passing through the membrane pores.

- Higher cross flow rates can reduce membrane fouling by providing a shear force to sweep away deposited materials. At high feed flow rates, more polyphenolics were retained by the membrane with less sugar permeating through. The optimum feed flow rate was 1.5 L/min.

- The best performance of the process for the concentration of polyphenolics from sugar was judged to be when the rutin concentration factor and recovery in retentate were 2.9 and 72.5%, respectively; and the glucose concentration factor and recovery in permeate were 1.06 and 76.3% respectively.

- Diafiltration improved the membrane performance: it maintained the flux at higher levels and reduced the concentration of glucose in the retentate, with only approx. 11% of glucose being retained in the retentate after diafiltration.

Acknowledgments

References

- Nawaz, H; Shi, J; Mittal, GS; Y. Kakuda, Y. Extraction of polyphenols from grape seeds and concentration by ultrafiltration. Sep. Purific. Technol 2006, 48, 176–181. [Google Scholar]

- Shahidi, F. Phenolics in Food and Nutraceuticals; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Alonso-Salces, RM; Barranco, A; Abad, B; Berrueta, LA; Gallo, B; Vicente, F. Polyphenolic profiles of basque cider apple cultivars and their technological properties. J. Agric. Food Chem 2004, 52, 2938–2952. [Google Scholar]

- Alper, N; Acar, J. Removal of phenolic compounds in pomegranate juice using ultrafiltration and laccase-ultrafiltration combinations. Nahrung 2004, 48, 184–187. [Google Scholar]

- Borneman, ZV; Gökmen, V; Nijhuis, HH. Selective removal of polyphenols and brown colour in apple juices using PES/PVP membranes in a single ultrafiltration process. Sep Purific Technol 2001, 22–23, 53–61. [Google Scholar]

- Schieber, A; Stintzing, FC; Carle, R. By-products of plant food processing as a source of functional compounds–recent developments. Trends Food Sci. Technol 2002, 12, 401–413. [Google Scholar]

- Kammerer, DR; Schieber, A; Carle, R. Characterization and recovery of phenolic compounds from grape pomace: A review. J. Appl. Bot. Food Qual 2005, 79, 189–196. [Google Scholar]

- Shi, J; Nawaz, H; Mittal, G; Pohorly, J; Kakuda, Y; Jiang, Y. Extraction of polyphenolics from plant material for functional foods–Engineering and technology. Food Rev. Intl 2005, 21, 139–166. [Google Scholar]

- Schieber, A; Hilt, P; Streker, P; Endreß, H-U; Rentschler, C; Carle, R. A new process for the combined recovery of pectin and phenolic compounds from apple pomace. Innov. Food Sci. Emerg. Technol 2003, 4, 99–107. [Google Scholar]

- Johnson, RL; Chandler, BV. Adsorptive removal of bitter principles and titratable acid from fruit juices. Food Technol 1988, 42, 130–137. [Google Scholar]

- Kimball, DA; Norman, SI. Processing effects during commercial debittering of California Navel orange juice. J. Agric. Food Chem 1990, 38, 1396–1400. [Google Scholar]

- Lyndon, R. Kommerzialisierung der adsorbertechnologie in der fruchtsaftindustrie. Flüssiges Obst 1996, 63, 499–503. [Google Scholar]

- Stevens, RR. Process for decolorizing aqueous sugar solution. US Patent 4871397 1989. [Google Scholar]

- Scordino, M; Di Mauro, A; Passerini, A; Maccarone, E. Selective recovery of anthocyanins and hydroxycinnamates from a byproduct of citrus processing. J. Agric. Food Chem 2005, 53, 651–658. [Google Scholar]

- Di Mauro, A; Fallico, B; Passerini, A; Rapisarda, P; Maccarone, E. Recovery of hesperidin from orange peel by concentration of extracts on styrene-divinylbenzene resin. J. Agric. Food Chem 1999, 47, 4391–4397. [Google Scholar]

- Di Mauro, A; Fallico, B; Passerini, A; Maccarone, E. Waste water from citrus processing as a source of hesperidin by concentration on styrene-divinylbenzene resin. J. Agric. Food Chem 2000, 48, 2291–2295. [Google Scholar]

- Di Mauro, A; Arena, E; Fallico, B; Passerini, A; Maccarone, E. Recovery of anthocyanins from pulp wash of pigmented oranges by concentration on resins. J. Agric. Food Chem 2002, 50, 5968–5974. [Google Scholar]

- Kammerer, DR; Saleh, ZS; Carle, R; Stanley, RA. Adsorptive recovery of phenolic compounds from apple juice. Eur. Food Res. Technol 2007, 224, 605–613. [Google Scholar]

- Scordino, M; Di Mauro, A; Passerini, A; Maccarone, E. Adsorption of flavonoids on resins: hesperidin. J. Agric. Food Chem 2003, 51, 6998–7004. [Google Scholar]

- Scordino, M; Di Mauro, A; Passerini, A; Maccarone, E. Adsorption of flavonoids on resins: cyanidin 3-glucoside. J. Agric. Food Chem 2004, 52, 1965–1972. [Google Scholar]

- Bretag, J; Kammerer, DR; Jensen, U; Carle, R. Adsorption of rutin onto a food-grade styrene-divinylbenzene copolymer in a model system. Food Chem 2009, 114, 151–160. [Google Scholar]

- Bretag, J; Kammerer, DR; Jensen, U; Carle, R. Evaluation of the adsorption behavior of flavonoide and phenolic acids onto a food-grade resin using a D-optimal design. Eur. Food Res. Technol 2009, 228, 985–999. [Google Scholar]

- Mondor, M; Girard, B; Moresoli, C. Modeling flux behavior for membrane filtration of apple juice. Food Res. Intl 2000, 33, 539–548. [Google Scholar]

- de Bruijn, JPF; Venegas, A; Martínez, JA; Bórquez, R. Ultrafiltration performance of Carbosep membranes for the clarification of apple juice. Food Sci. Technol 2003, 36, 397–406. [Google Scholar]

- De Bruijn, J; Venegas, A; Bórquez, R. Influence of crossflow ultrafiltration on membrane fouling and apple juice quality. Desalination 2002, 148, 131–136. [Google Scholar]

- Laan, SV. Membrane processing of fruit extracts; HortResearch/ENZAFOODS: Hastings: New Zealand, 2004. [Google Scholar]

- Lowe, J. Removal of Humic Acid Using Ultrafiltration, . Thesis, The University of Auckland: Auckland, New Zealand, 2005.

- Kumar, KNS; Yea, MK; Cheryan, M. Ultrafiltration of soy protein concentrate: performance and modeling of spiral and tubular polymeric modules. J. Membr. Sci 2004, 244, 235–242. [Google Scholar]

- Nomura, T; Nakao, S; Kimura, S. Influence of the temperature of feed on ultrafiltration. Int. Chem. Eng 1989, 29, 707–714. [Google Scholar]

- Acero, JL; Benez, FJ; Leal, AI; Real, FJ. Removal of phenolic compounds in water by ultrafiltration membrane treatments. J. Envir. Sci. Health 2005, 40, 1585–1603. [Google Scholar]

- Abbas, H. . Anhydrous Milk Fat Fractionation Using Membrane. Thesis, The University of Auckland: Auckland, New Zealand, 2004.

- Lahoussine-Turcaud, V; Wiesner, MR; Bottero, JY. Fouling in tangential -flow ultrafiltration: the effect of colloid size and coagulation pretreatment. J. Membr. Sci 1990, 52, 173–190. [Google Scholar]

- Bhattacharjee, C; Datta, S. A mass transfer model for the prediction of rejection and flux during ultrafiltration of PEG-6000. J. Membr. Sci 1997, 125, 303–310. [Google Scholar]

- Makardij, AA. . Impact of Operating Parameters on Flux Decline in Microfiltration and Ultrafiltration. Thesis, The University of Auckland: Auckland, New Zealand, 2002.

- Kallioinen, M; Pekkarinen, M; Manttari, M; Nystrom, M; Nuortila-Jokinen, J. Stability of two different regenerated cellulose ultrafiltration membrane under varying solution temperature. Desalination 2006, 199, 204–206. [Google Scholar]

- Saleh, Z; Stanley, R; Nigam, M. Extraction of polyphenolics from apple juice by foam fractionation. Int. J. Food Eng 2006, 2, 1–15. [Google Scholar]

- Kabsch-Korbutowicz, M; Majewska-Nowak, K; Winnicki, T. Analysis of membrane fouling in the treatment of water solutions containing humic acids and mineral salts. Desalination 1999, 126, 179–185. [Google Scholar]

- Nakatsuka, S; Nakate, I; Miyano, T. Drinking water treatment by using ultrafiltration hollow fiber membranes. Desalination 1996, 106, 55–61. [Google Scholar]

- Vladisavljevic, GT; Vukosavljevic, P; Bukvic, B. Permeate flux and fouling resistance in ultrafiltration of depectinizad apple juice using ceramic membranes. J. Food Eng 2003, 60, 241–247. [Google Scholar]

| Glucose | Sucrose | Rutin | Chlorogenic acid | |

|---|---|---|---|---|

| Feed concentration(g/L) | 55 | 55 | 0.25 | 0.075 |

| Retentate concentration (g/L) | 57.8 | 60 | 0.33 | 0.077 |

| Concentration factor | 1.05 | 1.09 | 1.32 | 1.03 |

| Process condition | Rutin content (g/L) | Glucose content(g/L) | Fouling deposits (gm−2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Run | pH | TMP (bar) | Feed flowrate (L/min) | Temp (°C) | F | Ret | Per | F | Ret | Per | |

| 1 | 5 | 4 | 1 | 35 | 0.5 | 1.45 | 0.084 | 55 | 44.96 | 58.34 | 4.41 |

| 2 | 3 | 4 | 1 | 35 | 0.25 | 0.31 | 0.15 | 55 | 49.29 | 57.26 | 3.28 |

| 3 | 4 | 4 | 1 | 35 | 0.25 | 0.31 | 0.2 | 55 | 49.83 | 57.3 | 2.75 |

| 4 | 5 | 4 | 1 | 35 | 0.25 | 0.28 | 0.16 | 55 | 50.67 | 57.2 | 2.59 |

| 5 | 5 | 5 | 1 | 35 | 0.25 | 0.29 | 0.15 | 55 | 53.7 | 55.6 | 3.02 |

| 6 | 5 | 3 | 1 | 35 | 0.25 | 0.27 | 0.18 | 55 | 52.33 | 56.22 | 2.2 |

| 7 | 5 | 2 | 1 | 35 | 0.25 | 0.26 | 0.2 | 55 | 53.91 | 55.9 | 1.1 |

| 8 | 5 | 4 | 1 | 35 | 0.1 | 0.11 | 0.08 | 55 | 54.78 | 55.1 | 0.67 |

| 9 | 5 | 4 | 1 | 35 | 0.35 | 0.4 | 0.24 | 55 | 47.42 | 58.44 | 3.21 |

| 10 | 5 | 4 | 1 | 30 | 0.25 | 0.32 | 0.12 | 55 | 50.28 | 56.8 | 3.22 |

| 11 | 5 | 4 | 1 | 40 | 0.25 | 0.27 | 0.2 | 55 | 50.28 | 56.9 | 1.35 |

| 12 | 5 | 4 | 1 | 35 | 0.25 | 0.273 | 0.172 | 30 | 26.66 | 31.68 | 2.02 |

| 13 | 5 | 4 | 1 | 35 | 0.25 | 0.293 | 0.148 | 80 | 77.16 | 81.17 | 2.76 |

| 14 | 5 | 4 | 1.5 | 35 | 0.25 | 0.285 | 0.162 | 55 | 49.8 | 57.4 | 2.34 |

| 15 | 5 | 4 | 1.8 | 35 | 0.25 | 0.289 | 0.161 | 55 | 50.91 | 56.98 | 2.17 |

| Component | Concentration (g/L) | Concentration Factor (in retentate) | Recovery% (in retentate) | |

|---|---|---|---|---|

| Feed | Retentate | |||

| Rutin | 0.50 | 0.682 | 1.36 | 69.00 |

| Glucose | 55.00 | 11.99 | 0.22 | 11.00 |

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wei, S.; Hossain, M.M.; Saleh, Z.S. Concentration of Rutin Model Solutions from Their Mixtures with Glucose Using Ultrafiltration. Int. J. Mol. Sci. 2010, 11, 672-690. https://doi.org/10.3390/ijms11020672

Wei S, Hossain MM, Saleh ZS. Concentration of Rutin Model Solutions from Their Mixtures with Glucose Using Ultrafiltration. International Journal of Molecular Sciences. 2010; 11(2):672-690. https://doi.org/10.3390/ijms11020672

Chicago/Turabian StyleWei, Swallow, Md. M. Hossain, and Zaid S. Saleh. 2010. "Concentration of Rutin Model Solutions from Their Mixtures with Glucose Using Ultrafiltration" International Journal of Molecular Sciences 11, no. 2: 672-690. https://doi.org/10.3390/ijms11020672