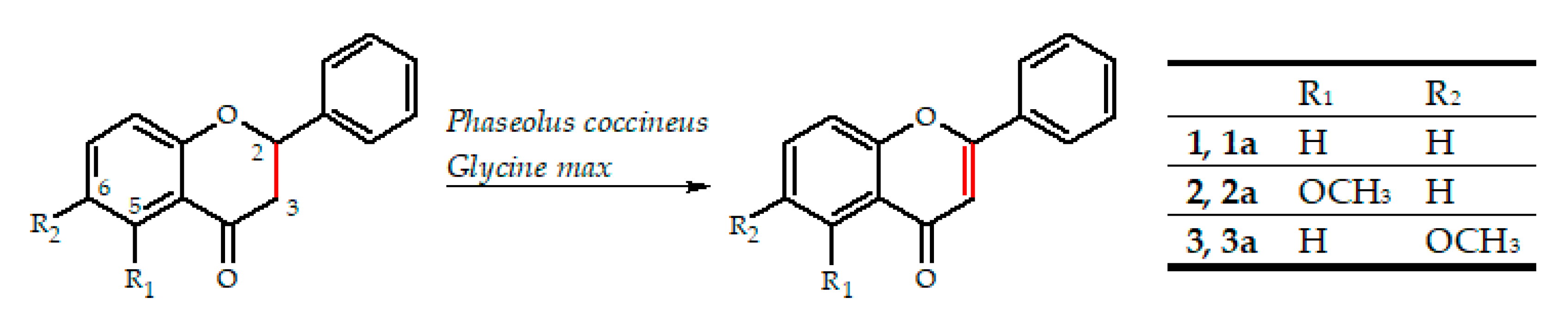

The Callus of Phaseolus coccineus and Glycine max Biotransform Flavanones into the Corresponding Flavones

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Chemicals

- Flavanone (1)C15H12O2, tR 19.53.

- 5-Methoxyflavanone (2)C16H14O3, tR 16.72.

- 6-Methoxyflavanone (3)C16H14O3, tR 20.17.

- Flavone (1a)C15H10O2, tR 17.55.

- 5-Methoxyflavone (2a)C16H12O3, tR 15.37.

- 6-Methoxyflavone (3a)C16H12O3, tR 18.41.

3.2. Plant Cultures

3.2.1. Seed Sterilization

3.2.2. Seed Ggermination Medium

3.2.3. Seed Germination and Callus Induction

3.3. Biotransformations

3.3.1. Biotransformations in Water

3.3.2. Biotransformations on Solid Medium

3.3.3. Extraction of Biotransformation Products

3.3.4. Assessment of Substrate Stability

3.4. Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ruiz-Cruz, S.; Chaparro-Hernández, S.; Hernández-Ruiz, K.L.; Cira-Chávez, L.A.; Estrada-Alvarado, M.I.; Ortega, L.E.G.; Ornelas-Paz, J.d.J.; Mata, M.A.L. Flavonoids: Important Biocompounds in Food. In Flavonoids—From Biosynthesis to Human Health; InTech: London, UK, 2017; Volume I, p. 13. [Google Scholar]

- Heim, K.E.; Tagliaferro, A.R.; Bobilya, D.J. Flavonoid antioxidants: Chemistry, metabolism and structure-activity relationships. J. Nutr. Biochem. 2002, 13, 572–584. [Google Scholar] [CrossRef]

- Ramawat, K.G.; Mérillon, J.M. Natural Products: Phytochemistry, Botany and Metabolism of Alkaloids, Phenolics and Terpenes; Ramawat, K.G., Mérillon, J.-M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Atmani, D.; Chaher, N.; Atmani, D.; Berboucha, M.; Debbache, N.; Boudaoud, H. Flavonoids in Human Health: From Structure to Biological Activity. Curr. Nutr. Food Sci. 2009, 5, 225–237. [Google Scholar] [CrossRef]

- Silva, M.M.; Santos, M.R.; Caroco, G.; Rocha, R.; Justino, G.; Mira, L. Structure-antioxidant Activity Relationships of Flavonoids: A Re-examination. Free Radic. Res. 2002, 36, 1209–1218. [Google Scholar] [CrossRef] [PubMed]

- Panche, A.N.; Diwan, A.D.; Chandra, S.R. Flavonoids: An overview. J. Nutr. Sci. 2016, 5, 1–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weidenbörner, M.; Jha, H.C. Antifungal spectrum of flavone and flavanone tested against 34 different fungi. Mycol. Res. 1997, 101, 733–736. [Google Scholar] [CrossRef]

- Jucá, M.M.; Cysne Filho, F.M.S.; de Almeida, J.C.; Mesquita, D.D.S.; Barriga, J.R.D.M.; Dias, K.C.F.; Barbosa, T.M.; Vasconcelos, L.C.; Leal, L.K.A.M.; Ribeiro, J.E.; et al. Flavonoids: Biological activities and therapeutic potential. Nat. Prod. Res. 2020, 34, 692–705. [Google Scholar] [CrossRef] [PubMed]

- Matkowski, A. Plant in vitro culture for the production of antioxidants—A review. Biotechnol. Adv. 2008, 26, 548–560. [Google Scholar] [CrossRef]

- Mora-Pale, M.; Sanchez-Rodriguez, S.P.; Linhardt, R.J.; Dordick, J.S.; Koffas, M.A.G. Biochemical strategies for enhancing the in vivo production of natural products with pharmaceutical potential. Curr. Opin. Biotechnol. 2014, 25, 86–94. [Google Scholar] [CrossRef]

- Sato, F.; Yamada, Y. Engineering Formation of Medicinal Compounds in Cell Cultures. In Advances in Plant Biochemistry and Molecular Biology; Pergamon Press (Elsevier): Oxford, UK, 2008; Volume 1, pp. 311–345. [Google Scholar]

- Ishihara, K.; Hamada, H.; Hirata, T.; Nakajima, N. Biotransformation using plant cultured cells. J. Mol. Catal. B Enzym. 2003, 23, 145–170. [Google Scholar] [CrossRef]

- Giri, A.; Dhingra, V.; Giri, C.C.; Singh, A.; Ward, O.P.; Narasu, M.L. Biotransformations using plant cells, organ cultures and enzyme systems: Current trends and future prospects. Biotechnol. Adv. 2001, 19, 175–199. [Google Scholar] [CrossRef]

- Efferth, T. Biotechnology Applications of Plant Callus Cultures. Engineering 2019, 5, 50–59. [Google Scholar] [CrossRef]

- Ochoa-Villarreal, M.; Howat, S.; Hong, S.; Jang, M.O.; Jin, Y.-W.; Lee, E.K.; Loake, G.J. Plant cell culture strategies for the production of natural products. BMB Rep. 2016, 49, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Yue, W.; Ming, Q.L.; Lin, B.; Rahman, K.; Zheng, C.J.; Han, T.; Qin, L.P. Medicinal plant cell suspension cultures: Pharmaceutical applications and high-yielding strategies for the desired secondary metabolites. Crit. Rev. Biotechnol. 2016, 36, 215–232. [Google Scholar] [CrossRef] [PubMed]

- Matos, I.L.; Nitschke, M.; Fonseca, L.J.P.; Porto, A.L.M. Biotransformation of Flavonoids by Terrestrial and Marine Microorganisms. In Encyclopedia of Marine Biotechnology; Wiley: Hoboken, NJ, USA, 2020; pp. 1979–2000. [Google Scholar]

- Krawczyk-Łebek, A.; Dymarska, M.; Janeczko, T.; Kostrzewa-Susłow, E. Entomopathogenic filamentous fungi as biocatalysts in glycosylation of methylflavonoids. Catalysts 2020, 10, 1148. [Google Scholar] [CrossRef]

- Dymarska, M.; Janeczko, T.; Kostrzewa-Susłow, E. Glycosylation of 3-Hydroxyflavone, 3-Methoxyflavone, Quercetin and Baicalein in Fungal Cultures of the Genus Isaria. Molecules 2018, 23, 2477. [Google Scholar] [CrossRef] [Green Version]

- Dymarska, M.; Grzeszczuk, J.; Urbaniak, M.; Janeczko, T.; Pląskowska, E.; Stępień, Ł.; Kostrzewa-Susłow, E. Glycosylation of 6-methylflavone by the strain Isaria fumosorosea KCH J2. PLoS ONE 2017, 12, e0184885. [Google Scholar] [CrossRef]

- Dymarska, M.; Janeczko, T.; Kostrzewa-Susłow, E. Glycosylation of Methoxylated Flavonoids in the Cultures of Isaria fumosorosea KCH J2. Molecules 2018, 23, 2578. [Google Scholar] [CrossRef] [Green Version]

- Dymarska, M.; Janeczko, T.; Kostrzewa-Susłow, E. Biotransformations of Flavones and an Isoflavone (Daidzein) in Cultures of Entomopathogenic Filamentous Fungi. Molecules 2018, 23, 1356. [Google Scholar] [CrossRef] [Green Version]

- Łużny, M.; Tronina, T.; Kozłowska, E.; Dymarska, M.; Popłoński, J.; Łyczko, J.; Kostrzewa-Susłow, E.; Janeczko, T. Biotransformation of methoxyflavones by selected entomopathogenic filamentous fungi. Int. J. Mol. Sci. 2020, 21, 6121. [Google Scholar] [CrossRef]

- Sharifian, S.; Homaei, A.; Kamrani, E.; Etzerodt, T.; Patel, S. New insights on the marine cytochrome P450 enzymes and their biotechnological importance. Int. J. Biol. Macromol. 2020, 142, 811–821. [Google Scholar] [CrossRef]

- Birolli, W.G.; Lima, R.N.; Porto, A.L.M. Applications of marine-derived microorganisms and their enzymes in biocatalysis and biotransformation, the underexplored potentials. Front. Microbiol. 2019, 10, 1453. [Google Scholar] [CrossRef] [PubMed]

- Janeczko, T.; Gładkowski, W.; Kostrzewa-Susłow, E. Microbial transformations of chalcones to produce food sweetener derivatives. J. Mol. Catal. B Enzym. 2013, 98, 55–61. [Google Scholar] [CrossRef]

- Łużny, M.; Krzywda, M.; Kozłowska, E.; Kostrzewa-Susłow, E.; Janeczko, T. Effective Hydrogenation of 3-(2”-furyl)- And 3-(2”-thienyl)-1-(2′-hydroxyphenyl)-prop-2-en-1-one in Selected Yeast Cultures. Molecules 2019, 24, 3185. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, A.; Feng, X.; Rasool, A.; Sun, W.; Li, C. Production of plant natural products through engineered Yarrowia lipolytica. Biotechnol. Adv. 2020, 43, 107555. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Nielsen, J. Recent trends in metabolic engineering of microbial chemical factories. Curr. Opin. Biotechnol. 2019, 60, 188–197. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-F.; Liu, S.-S.; Song, Z.-Q.; Xu, T.-C.; Liu, C.-S. Naturally Occurring Flavonoids and Isoflavonoids and Their Microbial Transformation: A Review. Molecules 2020, 25, 5112. [Google Scholar] [CrossRef]

- Yonekura-Sakakibara, K.; Higashi, Y.; Nakabayashi, R. The Origin and Evolution of Plant Flavonoid Metabolism. Front. Plant. Sci. 2019, 10, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, M.A.; Lajis, N.H.; Ali, A.M.; Marziah, M.; Sinskey, A.J.; Rha, C. Issues in plant cell culture engineering for enhancement of productivity. Dev. Chem. Eng. Miner. Process. 2005, 13, 573–587. [Google Scholar] [CrossRef]

- Cardoso, J.C.; de Oliveira, M.E.B.S.; Cardoso, F.D.C.I. Advances and challenges on the in vitro production of secondary metabolites from medicinal plants. Hortic. Bras. 2019, 37, 124–132. [Google Scholar] [CrossRef] [Green Version]

- Santos, R.B.; Abranches, R.; Fischer, R.; Sack, M.; Holland, T. Putting the spotlight back on plant suspension cultures. Front. Plant. Sci. 2016, 7, 297. [Google Scholar] [CrossRef] [Green Version]

- Sutter, A.; Poulton, J.; Grisebach, H. Oxidation of flavanone to flavone with cell-free extracts from young parsley leaves. Arch. Biochem. Biophys. 1975, 170, 547–556. [Google Scholar] [CrossRef]

- Yun, C.S.; Yamamoto, T.; Nozawa, A.; Tozawa, Y. Expression of parsley flavone synthase I establishes the flavone biosynthetic pathway in Arabidopsis thaliana. Biosci. Biotechnol. Biochem. 2008, 72, 968–973. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leonard, E.; Yan, Y.; Lim, K.H.; Koffas, M.A.G. Investigation of Two Distinct Flavone Synthases for Plant-Specific Flavone Biosynthesis in Saccharomyces cerevisiae. Appl. Environ. Microbiol. 2005, 71, 8241–8248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, J.; Wang, X.C.; Liu, Y.; Du, H.; Shu, Q.Y.; Su, S.; Wang, L.J.; Li, S.S.; Wang, L.S. Flavone synthases from Lonicera japonica and L. macranthoides reveal differential flavone accumulation. Sci. Rep. 2016, 6, 19245. [Google Scholar] [CrossRef]

- Akashi, T.; Fukuchi-Mizutani, M.; Aoki, T.; Ueyama, Y.; Yonekura-Sakakibara, K.; Tanaka, Y.; Kusumi, T.; Ayabe, S.I. Molecular cloning and biochemical characterization of a novel cytochrome P450, flavone synthase II, that catalyzes direct conversion of flavanones to flavones. Plant. Cell Physiol. 1999, 40, 1182–1186. [Google Scholar] [CrossRef] [Green Version]

- Kostrzewa-Susłow, E.; Dymarska, M.; Białońska, A.; Janeczko, T. Enantioselective conversion of certain derivatives of 6-hydroxyflavanone. J. Mol. Catal. B Enzym. 2014, 102, 59–65. [Google Scholar] [CrossRef]

- Kostrzewa-Susłow, E.; Dmochowska-Gładysz, J.; Białońska, A.; Ciunik, Z.; Rymowicz, W. Microbial transformations of flavanone and 6-hydroxyflavanone by Aspergillus niger strains. J. Mol. Catal. B Enzym. 2006, 39, 18–23. [Google Scholar] [CrossRef]

- Kostrzewa-Susłow, E.; Janeczko, T. Microbial transformations of 7-hydroxyflavanone. Sci. World J. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Jiang, N.; Doseff, A.I.; Grotewold, E. Flavones: From biosynthesis to health benefits. Plants 2016, 5, 27. [Google Scholar] [CrossRef]

- Zhang, J.; Subramanian, S.; Zhang, Y.; Yu, O. Flavone synthases from Medicago truncatula are flavanone-2-hydroxylases and are important for nodulation. Plant. Physiol. 2007, 144, 741–751. [Google Scholar] [CrossRef] [Green Version]

- Noland, D.; Drisko, J.A.; Wagner, L. (Eds.) Integrative and Functional Medical Nutrition Therapy; Humana Press: Totowa, NJ, USA, 2020. [Google Scholar]

- The, E.; Aglycones, F.; Activity, C.E. The Effect of Flavonoid Aglycones on the CYP1A2, CYP2A6, CYP2C8 and CYP2D6 Enzymes Activity. Molecules 2019, 24, 3174. [Google Scholar]

- Fan, H.X.; Zhou, Z.Q.; Peng, J.; Wu, B.J.; Chen, H.R.; Bao, X.F.; Mu, Z.Q.; Jiao, W.H.; Yao, X.S.; Gao, H. A microbial model of mammalian metabolism: Biotransformation of 4,5-dimethoxyl-canthin-6-one using Cunninghamella blakesleeana CGMCC 3.970. Xenobiotica 2017, 47, 284–289. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Rosazza, J.P.N. Microbial and enzymatic transformations of flavonoids. J. Nat. Prod. 2006, 69, 499–508. [Google Scholar] [CrossRef] [PubMed]

- Palmer-Brown, W.; Miranda-CasoLuengo, R.; Wolfe, K.H.; Byrne, K.P.; Murphy, C.D. The CYPome of the model xenobiotic-biotransforming fungus Cunninghamella elegans. Sci. Rep. 2019, 9, 9240. [Google Scholar] [CrossRef] [Green Version]

- Črešnar, B.; Petrič, Š. Cytochrome P450 enzymes in the fungal kingdom. Biochim. Biophys. Acta 2011, 1814, 29–35. [Google Scholar] [CrossRef]

- Kelly, S.L.; Kelly, D.E. Microbial cytochromes P450: Biodiversity and biotechnology. Where do cytochromes P450 come from, what do they do and what can they do for us? Philos. Trans. R. Soc. B Biol. Sci. 2013, 368, 20120476. [Google Scholar] [CrossRef] [Green Version]

- Pękala, E.; Kubowicz, P.; Łażewska, D. Cunninghamella as a microbiological model for metabolism of histamine H3 receptor antagonist 1-[3-(4-tert-butylphenoxy)propyl]piperidine. Appl. Biochem. Biotechnol. 2012, 168, 1584–1593. [Google Scholar] [CrossRef] [Green Version]

- Mustapíc, D.Š.; Debeljak, Ž.; Maleš, Ž.; Bojíc, M. The inhibitory effect of flavonoid aglycones on the metabolic activity of CYP3A4 enzyme. Molecules 2018, 23, 2553. [Google Scholar] [CrossRef] [Green Version]

- Quintieri, L.; Bortolozzo, S.; Stragliotto, S.; Moro, S.; Pavanetto, M.; Nassi, A.; Palatini, P.; Floreani, M. Flavonoids diosmetin and hesperetin are potent inhibitors of cytochrome P450 2C9-mediated drug metabolism in vitro. Drug Metab. Pharmacokinet. 2010, 25, 466–476. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.; Xue, X.; Wu, Y.F.; Xin, G.Z.; Qian, Y.; Xie, T.P.; Gong, L.K.; Ren, J. Β-Naphthoflavone protects mice from aristolochic acid-I-induced acute kidney injury in a CYP1A dependent mechanism. Acta Pharmacol. Sin. 2009, 30, 1559–1565. [Google Scholar] [CrossRef] [Green Version]

- Mennes, W.C.; Luijckx, N.B.L.; Wortelboer, H.M.; Blaauboer, B.J. Differences in the effects of model inducers of cytochrome P450 on the biotransformation of scoparone in rat and hamster liver. Arch. Toxicol. 1993, 67, 92–97. [Google Scholar] [CrossRef] [PubMed]

- Pretti, C.; Salvetti, A.; Longo, V.; Giorgi, M.; Gervasi, P.G. Effects of β-naphthoflavone on the cytochrome P450 system, and phase II enzymes in gilthead seabream (Sparus aurata). Comp. Biochem. Physiol. C 2001, 130, 133–144. [Google Scholar] [CrossRef]

- Popłoński, J.; Sordon, S.; Tronina, T.; Bartmańska, A.; Huszcza, E. Fungal metabolism of naphthoflavones. J. Mol. Catal. B Enzym. 2015, 117, 1–6. [Google Scholar] [CrossRef]

- Jiao, J.; Gai, Q.Y.; Wang, X.; Qin, Q.P.; Wang, Z.Y.; Liu, J.; Fu, Y.J. Chitosan elicitation of Isatis tinctoria L. hairy root cultures for enhancing flavonoid productivity and gene expression and related antioxidant activity. Ind. Crops Prod. 2018, 124, 28–35. [Google Scholar] [CrossRef]

- Munim Twaij, B.; Jazar, Z.H.; Hasan, M.N. The effects of elicitors and precursor on in-vitro cultures of Trifolium resupinatum for sustainable metabolite accumulation and antioxidant activity. Biocatal. Agric. Biotechnol. 2019, 22, 101337. [Google Scholar] [CrossRef]

- Wen, T.; Hao, Y.J.; An, X.L.; Sun, H.D.; Li, Y.R.; Chen, X.; Piao, X.C.; Lian, M.L. Improvement of bioactive compound accumulation in cell cultures of Orostachys cartilaginous A. Bor. through elicitation with salicylic acid and effect of cell extract on bioactive activity. Ind. Crops Prod. 2019, 139, 111570. [Google Scholar] [CrossRef]

- Gharari, Z.; Bagheri, K.; Danafar, H.; Sharafi, A. Enhanced flavonoid production in hairy root cultures of Scutellaria bornmuelleri by elicitor induced over-expression of MYB7 and FNSП2 genes. Plant. Physiol. Biochem. 2020, 148, 35–44. [Google Scholar] [CrossRef]

- Jiao, J.; Gai, Q.-Y.; Yao, L.-P.; Niu, L.-L.; Zang, Y.-P.; Fu, Y.-J. Ultraviolet radiation for flavonoid augmentation in Isatis tinctoria L. hairy root cultures mediated by oxidative stress and biosynthetic gene expression. Ind. Crops Prod. 2018, 118, 347–354. [Google Scholar] [CrossRef]

- Yildirim, A.B. Ultraviolet-B-induced changes on phenolic compounds, antioxidant capacity and HPLC profile of in vitro-grown plant materials in Echium orientale L. Ind. Crops Prod. 2020, 153, 112584. [Google Scholar] [CrossRef]

- Lim, Y.J.; Lyu, J.I.; Kwon, S.-J.; Eom, S.H. Effects of UV-A radiation on organ-specific accumulation and gene expression of isoflavones and flavonols in soybean sprout. Food Chem. 2021, 339, 128080. [Google Scholar] [CrossRef]

- Antognoni, F.; Zheng, S.; Pagnucco, C.; Baraldi, R.; Poli, F.; Biondi, S. Induction of flavonoid production by UV-B radiation in Passiflora quadrangularis callus cultures. Fitoterapia 2007, 78, 345–352. [Google Scholar] [CrossRef]

- Nocchi, N.; Duarte, H.M.; Pereira, R.C.; Konno, T.U.P.; Soares, A.R. Effects of UV-B radiation on secondary metabolite production, antioxidant activity, photosynthesis and herbivory interactions in Nymphoides humboldtiana (Menyanthaceae). J. Photochem. Photobiol. B Biol. 2020, 212, 112021. [Google Scholar] [CrossRef] [PubMed]

- Gaid, M.; Wucherpfennig, T.; Scholl, S.; Beerhues, L.; Krull, R. Challenges for the Cultivation of Plant Cells on the Example of Hypericum perforatum and Taxus chinensis. In Bioprocessing of Plant In Vitro Systems; Springer Publishing: New York, NY, USA, 2016; pp. 1–26. [Google Scholar]

- Davoodi, A.; Khoshvishkaie, E.; Azadbakht, M. Plant cells technology as an effective biotechnological approach for high scale production of pharmaceutical natural compounds: A meta-analysis study. Pharm. Biomed. Res. 2019, 5, 1–9. [Google Scholar] [CrossRef]

- Vaquero, E.; Robles, C.; Ruiz, M.L. A method for long-term micropropagation of Phaseolus coccineus L. Plant. Cell Rep. 1993, 12, 395–398. [Google Scholar] [CrossRef] [PubMed]

| Substrate | Product | |

|---|---|---|

| Days | Flavanone (1) | Flavone (1a) |

| 7 | 99.4% | 0.6% |

| 14 | 98.9% | 1.1% |

| 5-Methoxyflavanone (2) | 5-Methoxyflavone (2b) | |

| 7 | 99.8% | 0.2% |

| 14 | 99.8% | 0.2% |

| 6-Methoxyflavanone (3) | 6-Methoxyflavone (3a) | |

| 7 | 98.9% | 1.1% |

| 14 | 97.7% | 2.3% |

| Substrate | Product | |

|---|---|---|

| Days | Flavanone (1) | Flavone (1a) |

| 7 | 98.7% | 1.3% |

| 14 | 97.4% | 2.6% |

| 5-Methoxyflavanone (2) | 5-Methoxyflavone (2b) | |

| 7 | 99.5% | 0.5% |

| 14 | 99.5% | 0.5% |

| 6-Methoxyflavanone (3) | 6-Methoxyflavone (3a) | |

| 7 | 95.3% | 4.7% |

| 14 | 92.5% | 7.5% |

| Substrate | Product |

|---|---|

| Flavanone (1) | Flavone (1a) |

| 99.7% | 0.3% |

| 5-Methoxyflavanone (2) | 5-Methoxyflavone (2b) |

| 98.7% | 1.3% |

| 6-Methoxyflavanone (3) | 6-Methoxyflavone (3a) |

| 98.5% | 1.5% |

Sample Availability: Samples of the compounds 1, 1a, 2, 2a, 3, 3a are available from the authors. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dymarska, M.; Janeczko, T.; Kostrzewa-Susłow, E. The Callus of Phaseolus coccineus and Glycine max Biotransform Flavanones into the Corresponding Flavones. Molecules 2020, 25, 5767. https://doi.org/10.3390/molecules25235767

Dymarska M, Janeczko T, Kostrzewa-Susłow E. The Callus of Phaseolus coccineus and Glycine max Biotransform Flavanones into the Corresponding Flavones. Molecules. 2020; 25(23):5767. https://doi.org/10.3390/molecules25235767

Chicago/Turabian StyleDymarska, Monika, Tomasz Janeczko, and Edyta Kostrzewa-Susłow. 2020. "The Callus of Phaseolus coccineus and Glycine max Biotransform Flavanones into the Corresponding Flavones" Molecules 25, no. 23: 5767. https://doi.org/10.3390/molecules25235767