E-Beam Irradiation and Ozonation as an Alternative to the Sulphuric Method of Wine Preservation

Abstract

:Highlights

1. Introduction

2. Results and Discussion

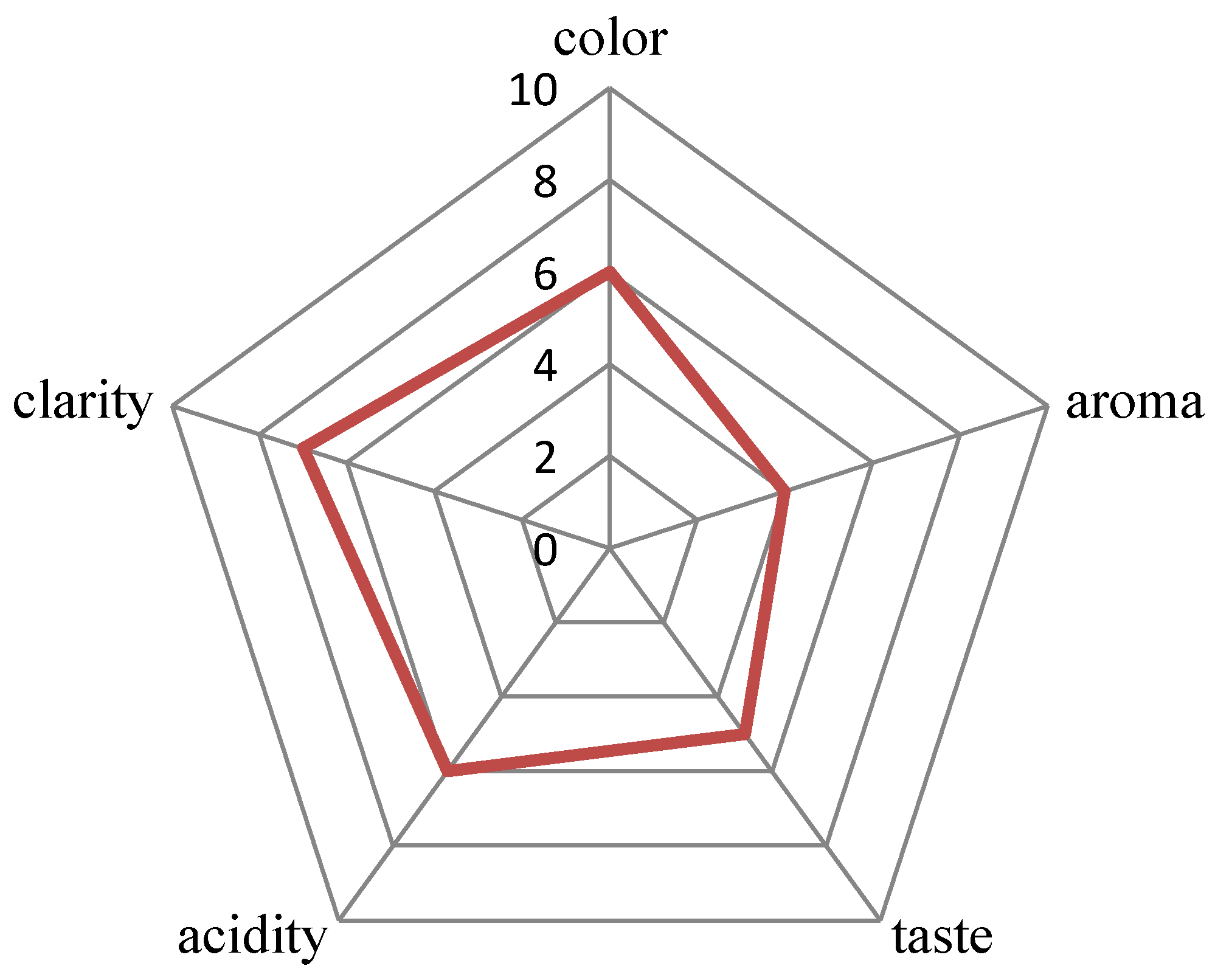

2.1. Sulphurization—Influence on Chemical and Organoleptic Properties of Wine and Yeast Viability

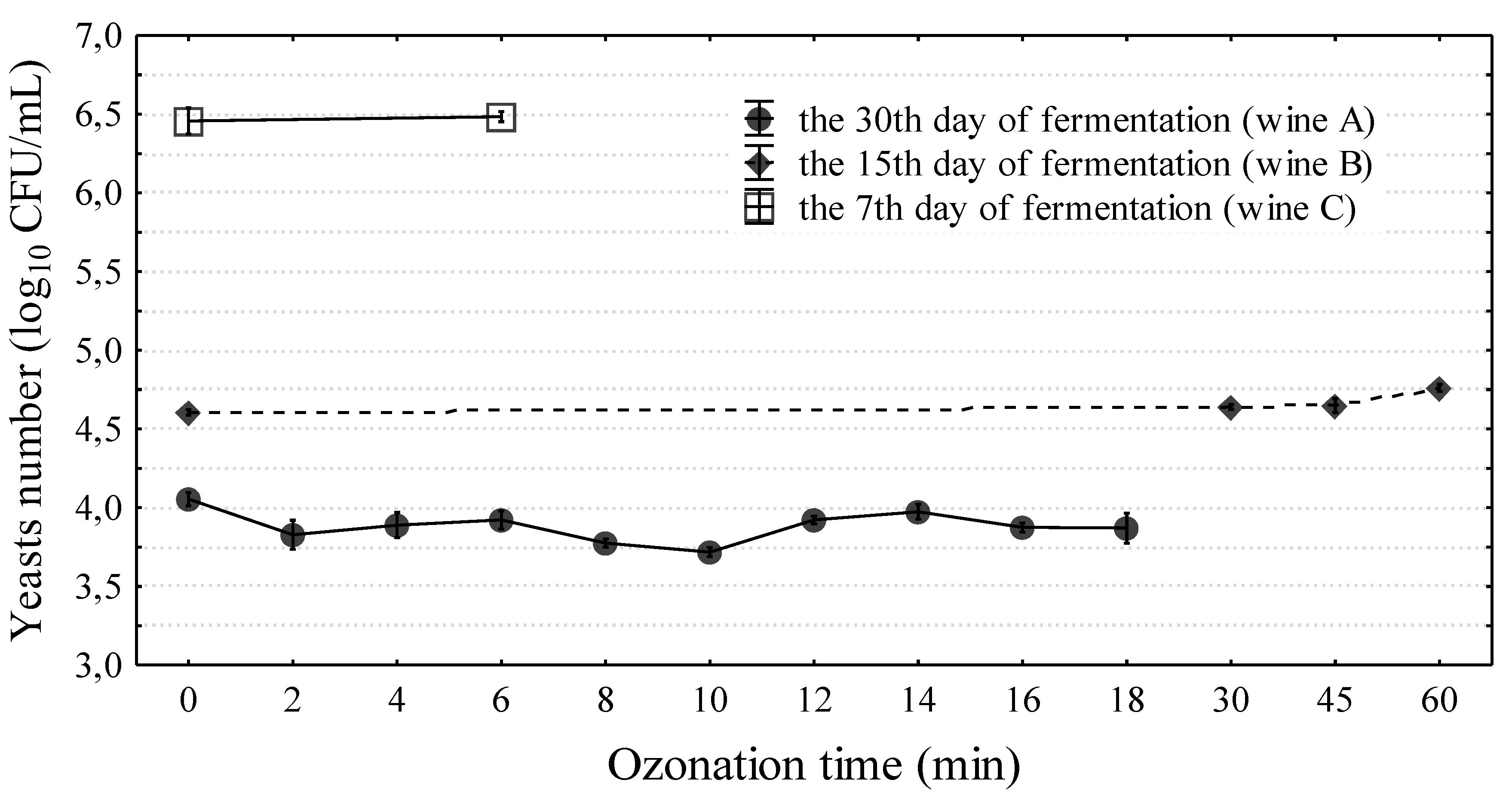

2.2. Ozonation—Influence on Chemical and Organoleptic Properties of Wine and Yeast Elimination Efficiency

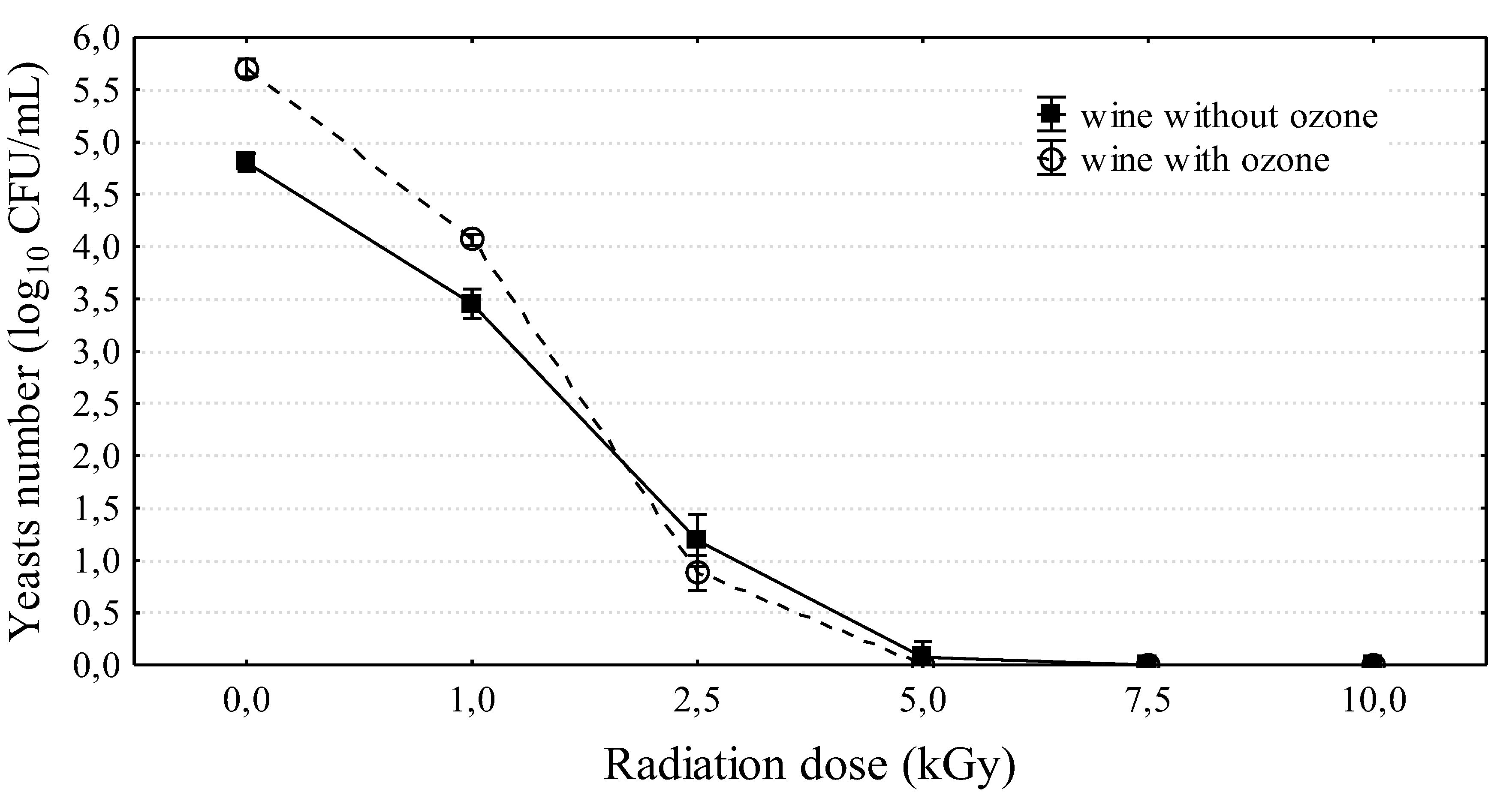

2.3. Irradiation—Influence on Chemical and Organoleptic Properties of Wine and Yeast Elimination Efficiency

Polyphenolic Compounds

3. Material and Methods

3.1. Characteristics of the Area of Research and Plant Material

3.2. Description of the Variety and Production of Wine

3.3. Yeast, Assessment of Their Numbers in the Wine

3.4. Ozonation Process

3.5. Irradiation

3.6. Color Measurement

3.7. Identification of Phenolic Compounds with the UPLC-PDA-MS/MS Method

3.8. Sensory Evaluation

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anand, S.P.; Sati, N. Artificial Preservatives and their harmful effects: Looking toward nature for safer alternatives. Int. J. Pharm. Sci. Res. 2013, 4, 2496–2501. [Google Scholar] [CrossRef]

- Francesca, N.; Sannino, C.; Settanni, L.; Corona, O.; Barone, E.; Moschetti, G. Microbiological and chemical monitoring of Marsala base wine obtained by spontaneous fermentation during large-scale production. Ann. Microbiol. 2014, 64, 1643–1657. [Google Scholar] [CrossRef] [Green Version]

- Freire, A.L.; Ramos, C.L.; Schwan, R.F. Microbiological and chemical parameters during cassava based-substrate fermentation using potential starter cultures of lactic acid bacteria and yeast. Food Res. Int. 2015, 76, 787–795. [Google Scholar] [CrossRef] [Green Version]

- Grogan, K.A. The value of added sulphur dioxide in French organic wine. Agric. Econ. 2015, 3, 19. [Google Scholar] [CrossRef]

- Quirós-Alcalá, L.; Hansel, N.N.; McCormack, M.C.; Matsui, E.C. Paraben exposures and asthma-related outcomes among children from the US general population. J. Allergy Clin. Immunol. 2018, 14, 948–956. [Google Scholar] [CrossRef]

- Chandra, M.; Oro, I.; Ferreira-Dias, S.; Malfeito-Ferreira, M. Effect of Ethanol, Sulfur Dioxide and Glucose on the Growth of Wine Spoilage Yeasts Using Response Surface Methodology. PLoS ONE 2015, 10, e0128702. [Google Scholar] [CrossRef]

- Silva, M.; Lidon, F. Food preservatives—An overview on applications and side effects. Emir. J. Food Agric. 2016, 28, 366–373. [Google Scholar] [CrossRef]

- EFSA. Panel on Food Additives and Nutrient Sources added to Food (ANS) Guidance for submission for food additive evaluations. EFSA J. 2012, 10, 2760. Available online: www.efsa.europa.eu/efsajournal (accessed on 11 July 2019). [CrossRef]

- Magnuson, B.; Munro, I.; Abbot, P.; Baldwin, N.; Lopez Garcia, R.; Ly, K.; McGirr, L.; Roberts, A.; Socolovsky, S. Review of the regulation and safety assessment of food substances in various countries and jurisdictions. Food Addit. Contam. Part A 2013, 30, 1147–1220. [Google Scholar] [CrossRef] [PubMed]

- Gajda-Wyrębek, J.; Kuźma, K.; Świtka, A.; Jarecka, J.; Beresińska, M.; Postupolski, J. Exposure of Polish children to Southampton food colors. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2017, 34, 1–9, Epub 24 November 2016. [Google Scholar] [CrossRef]

- Loira, I.; Morata, A.; Palomero, F.; González, C.; Suárez-Lepe, J.A. Schizosaccharomyces pombe: A Promising Biotechnology for Modulating Wine Composition. Fermentation 2018, 4, 70. [Google Scholar] [CrossRef]

- FSA. Technical Guidance Food Allergen Labelling and Information Requirements under the EU Food Information for Consumers Regulation No. 1169/2011. 2015. Available online: https://www.food.gov.uk/sites/default/files/media/document/food-allergen-labelling-technical-guidance.pdf (accessed on 18 March 2019).

- Vally, H.; Thompson, P.J. Role of sulfite additives in wine induced asthma: Single dose and cumulative dose studies. Thorax 2001, 56, 763–769. [Google Scholar] [CrossRef]

- Barrett, D.M.; Lloyd, B. Advanced preservation methods and nutrient retention in fruits and vegetables. J. Agric. Food Chem. 2012, 92, 7–22. [Google Scholar] [CrossRef]

- Du Toit, M.; Pretorius, I.S. Microbial spoilage and preservation of wine: Using weapons from nature’s own arsenal a review. S. Afr. J. Enol. Vitic. 2000, 21, 74–96. [Google Scholar] [CrossRef]

- Lisanti, M.T.; Blaiotta, G.; Nioi, C. Alternative Methods to SO2 for Microbiological Stabilization of Wine. Compr. Rev. Food Sci. Food Saf. 2019, 18, 455–479. [Google Scholar] [CrossRef]

- Horvitz, S.; Cantalejo, M.J. Application of ozone for the postharvest treatment of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2014, 54, 312–339. [Google Scholar] [CrossRef] [PubMed]

- Botondi, R.; De Sanctis, F.; Moscatelli, N.; Vettraino, A.M.; Catelli, C.; Mencarelli, F. Ozone fumigation for safety and quality of wine grapes in postharvest dehydration. Food Chem. 2015, 188, 641–647. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Aguayo, E.; Artés, F.; Tomás-Barberán, F. Enriched ozone atmosphere enhances bioactive phenolics in seedless table grapes after prolonged shelf life. J. Sci. Food Agric. 2007, 87, 824–831. [Google Scholar] [CrossRef]

- Englezos, V.; Rantsiou, K.; Torchio, F.; Pollon, M.; Giacosa, S.; Segade, S.R.; Cocolin, L. Effectiveness of Ozone against Different Strains of Brettanomyces bruxellensis on Postharvested Winegrapes and Impact on Wine Composition. Am. J. Enol. Vitic. 2019, 70, 249–258. [Google Scholar] [CrossRef]

- Krosowiak, K.; Migielski, K.; Kwapisz, E.; Marchut, O. Remediation of soil contaminated with petroleum hydrocarbons. Food Chem. Biotechnol. 2008, 1029, 89–97. [Google Scholar]

- Joint FAO/IAEA/WHO Expert Committee on the Technical Basis for Legislation on Irradiated Food, World Health Organization, Food and Agriculture Organization of the United Nations International Atomic Energy Agency. Wholesomeness of Irradiated Food Report of a Joint FAO/IAEA/WHO Expert Committee [Meeting Held in Geneva from 27 October to 3 November 1980]. World Health Organization, 1981. Available online: https://apps.who.int/iris/handle/10665/41508 (accessed on 17 July 2019).

- Ehlermann, D.A.E. The early history of food irradiation. Radiat. Phys. Chem. 2016, 129, 10–12. [Google Scholar] [CrossRef]

- Roberts, P.B. Food irradiation: Standards, regulations and world-wide trade. Radiat. Phys. Chem. 2016, 129, 30–34. [Google Scholar] [CrossRef]

- Gryczka, U.; Migdał, W.; Bułka, S. The effectiveness of the microbiological radiation decontamination processof agricultural products with the use of low energy electron beam. Radiat. Phys. Chem. 2018, 143, 59–62. [Google Scholar] [CrossRef]

- Buchanan, R.L.; Edelson, S.G.; Snipes, K.; Boyd, G. Inactivation of Escherichia coli O157:H7 in Apple Juice by Irradiation. Appl. Environ. Microbiol. 1998, 64, 4533–4535. [Google Scholar] [PubMed]

- Orlikowski, L.; Migdał, W.; Ptaszek, M.; Gryczka, U. Effectiveness of electron beam irradiation in the control of some soilborne pathogens. Nukleonika 2011, 56, 357–362. [Google Scholar]

- Nieto-Sandoval, J.M.; Almela, L.; Fernández-López, J.A.; Muñoz, J.A. Effect of electron beam irradiation on color and microbial bioburden of red paprika. J. Food Prot. 2000, 63, 633–637. [Google Scholar] [CrossRef] [PubMed]

- Pateraki, C.; Paramithiotis, S.; Doulgeraki, A.I.; Kallithraka, S.; Kotseridis, Y.; Drosinos, E.H. Effect of sulfur dioxide addition in wild yeast population dynamics and polyphenolic composition during spontaneous red wine fermentation from Vitis vinifera cultivar Agiorgitiko. Eur. Food Res. Technol. 2014, 239, 1067. [Google Scholar] [CrossRef]

- Salaha, M.I.; Kallithraka, S.; Marmaras, I.; Koussissi, E.; Tzourou, I. A natural alternative to sulphur dioxide for red wine production: Influence on color, antioxidant activity and anthocyanin content. J. Food Compos. Anal. 2008, 21, 660–666. [Google Scholar] [CrossRef]

- Segovia-Bravo, K.A.; Garcia-Garcia, P.; Arroyo-Lòpez, F.N.; Lòpez-Lòpez, A.; Garrido-Fernàndez, A. Ozonation process for the regeneration and recycling of Spanish green table olive fermentation brines. Eur. Food Res. Technol. 2008, 227, 463–472. [Google Scholar] [CrossRef]

- Dziugan, P.; Balcerek, M.; Binczarski, M.J.; Kregiel, D.; Kucner, M.; Kunicka-Styczynska, A.; Pielech-Przybylska, K.; Smigielski, K.; Witonska, I.A. Ozonation as an effective way to stabilize new kinds of fermentation media used in biotechnological production of liquid fuel additives. Biotechnol. Biofuels 2016, 9, 150. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.G.; Yousef, A.E.; Dave, S. Application of ozone for enhancing the microbiological safety and quality of foods: A review. J. Food Prot. 1999, 62, 1071–1087. [Google Scholar] [CrossRef] [PubMed]

- Najafi, M.B.H.; Khodaparast, M.H.H. Efficacy of ozone to reduce microbial populations in date fruits. Food Control 2009, 20, 27–30. [Google Scholar] [CrossRef]

- Mahapatra, A.K.; Muthukumarappan, K.; Julson, J.L. Applications of ozone, bacteriocins and irradiation in food processing: A review. Crit. Rev. Food Sci. Nutr. 2005, 45, 447–461. [Google Scholar] [CrossRef] [PubMed]

- Quijada-Morín, N.; Regueiro, J.; Simal-Gándara, J.; Tomás, E.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T. Relationship between the sensory-determined astringency and the flavanolic composition of red wines. J. Agric. Food Chem. 2012, 60, 12355–12361. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Bañuelos, M.A.; Tesfaye, W.; Loira, I.; Palomero, F.; Benito, S.; Callejo, M.J.; Villa, A.; González, M.C.; Suárez-Lepe, J.A. Electron Beam Irradiation of Wine Grapes: Effect on Microbial Populations, Phenol Extraction and Wine Quality. Food Bioproc. Tech. 2015, 8, 1845–1853. [Google Scholar] [CrossRef]

- Kang, J.-H.; Chun, H.-H.; Song, N.-B.; Oh, D.-H.; Song, K.B. Effects of electron beam and ultraviolet-C irradiation on quality and microbial populations of leafy vegetables during storage. J. Korean Soc. Appl. Biol. Chem. 2013, 56, 301–307. [Google Scholar] [CrossRef]

- Lanza, C.M.; Mazzaglia, A.; Paladino, R.; Auditore, L.; Barnà, R.C.; Loria, D.; Trifirò, A.; Trimarchi, M.; Bellia, G. Characterization of peeled and unpeeled almond (Prunus amygdalus) flour after electron beam processing. Radiat. Phys. Chem. 2013, 86, 140–144. [Google Scholar] [CrossRef]

- Bhat, R.; Sridhar, K.R.; Karim, A.A. Microbial quality evaluation and effective decontamination of nutraceutically valued lotus seeds by electron beams and gamma irradiation. Radiat. Phys. Chem. 2010, 79, 976–981. [Google Scholar] [CrossRef]

- Cabrera-Díaz, A.; Pereda-Reyes, I.; Dueñas-Moreno, J.; Véliz-Lorenzo, E.; Díaz-Marrero, M.A.; Menéndez-Gutiérrez, C.L.; Zaiat, M. Combined treatment of vinasse by an upflow anaerobic filter-reactor and ozonation process. Braz. J. Chem. Eng. 2016, 33, 753–762. [Google Scholar] [CrossRef]

- Rodriguez, T.; Botelho, D.; Cleto, E. Tratamiento de efluentes industriales de naturaleza recalcitrante usando ozono, peróxido de hidrógeno y radiación ultravioleta. Rev. Fac. Ing-Univ. Ant. 2008, 46, 24–38. Available online: http://aprendeenlinea.udea.edu.co/revistas/index.php/ingenieria/article/view/17926 (accessed on 27 March 2019).

- Gupta, S.; Padole, R.; Variyar, P.S.; Sharma, A. Influence of radiation processing of grapes on wine quality. Radiat. Phys. Chem. 2015, 111, 46–56. [Google Scholar] [CrossRef]

- Beaulieu, M.G.; Béliveau, G.; D’Aprano, M.; Lacroix, M. Dose rate effect of gamma irradiation on phenolic compounds, polyphenol oxidase (PPO) and browning of mushrooms Agaricus bisporus. J. Agric. Food Chem. 1999, 47, 2537–2543. [Google Scholar] [CrossRef]

- Kapusta, I.; Cebulak, T.; Oszmiański, J. Characterization of polish wines produced from the interspecific hybrid grapes grown in south-east Poland. Eur. Food Res. Technol. 2018, 244, 441–455. [Google Scholar] [CrossRef]

- Lambert, M.; Meudec, E.; Verbaere, A.; Mazerolles, G.; Wirth, J.; Masson, G.; Sommerer, N. A high-throughput UHPLC-QqQ-MS method for polyphenol profiling in rosé wines. Molecules 2015, 20, 7890–7914. [Google Scholar] [CrossRef] [PubMed]

- Wirth, J.; Caillé, S.; Souquet, J.M.; Samson, A.; Dieval, J.B.; Vidal, S.; Cheynier, V. Impact of post-bottling oxygen exposure on the sensory characteristics and phenolic composition of Grenache rosé wines. Food Chem. 2012, 132, 1861–1871. [Google Scholar] [CrossRef]

- Benito, Á.; Calderón, F.; Benito, S. The combined use of Schizosaccharomyces pombe and Lachancea thermotolerans-Effect on the anthocyanin wine composition. Molecules 2017, 22, 739. [Google Scholar] [CrossRef] [PubMed]

- Mori, K.; Goto-Yamamoto, N.; Kitayama, M.; Hashizume, K. Loss of anthocyanins in red-wine grape under high temperature. J. Exp. Bot. 2007, 58, 1935–1945. [Google Scholar] [CrossRef]

- Figueiredo-González, M.; Martínez-Carballo, E.; Cancho-Grande, B.; Santiago, J.L.; Martínez, M.C.; Simal-Gándara, J. Pattern recognition of three Vitis vinifera L. red grapes varieties based on anthocyanin and flavonol profiles, with correlations between their biosynthesis pathways. Food Chem. 2012, 130, 9–19. [Google Scholar] [CrossRef]

- Rio Segade, S.; Orriols, I.; Gerbi, V.; Rolle, L. Phenolic characterization of thirteen red grape cultivars from Galicia by anthocyanin profile and flavanol composition. J. Int. Sci. Vigne Vin. 2009, 43, 189–198. [Google Scholar] [CrossRef]

- Figueiredo-González, M.; Simal-Gándara, J.; Boso, S.; Martínez, M.C.; Santiago, J.L.; Cancho-Grande, B. Anthocyanins and flavonols berries from Vitis vinifera L. cv. Brancellao separately collected from two different positions within the cluster. Food Chem. 2012, 135, 47–56. [Google Scholar] [CrossRef]

- Variyar, P.S.; Bandyopadhyay, C.; Thomas, P. Effect of gamma irradiation on the phenolic acids of some Indian spices. Int. J. Food Sci. Tech. 1998, 33, 533–537. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Artés, F.; Tomás-Barberán, F.A. Quality and enhancement of bioactive phenolics in cv. Napoleon table grapes exposed to different postharvest gaseous treatments. J. Agric. Food Chem. 2003, 51, 5290–5295. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, W.; Giustiniano, F.; Eda, G. Effect of oxygen and ozone on p-type doping of ultra-thin WSe 2 and MoSe 2 field effect transistors. Phys. Chem. Chem. Phys. 2016, 18, 4304–4309. [Google Scholar] [CrossRef] [PubMed]

- Adamo, M.D.; Capitani, L.; Mannina, M.; Cristinzio, P.; Ragni, A. Truffles decontamination treatment by ionizing radiation. Radiat. Phys. Chem. 2004, 71, 165–168. [Google Scholar] [CrossRef]

- Bautista-Ortín, A.B.; Fernández-Fernández, J.I.; López-Roca, J.M.; Gómez-Plaza, E. The effects of enological practices in anthocyanins, phenolic compounds and wine color and their dependence on grape characteristics. J. Food Compos. Anal. 2007, 20, 546–552. [Google Scholar] [CrossRef]

- Lopez, N.; Puértolas, E.; Condón, S.; Álvarez, I.; Raso, J. Application of pulsed electric fields for improving the maceration process during vinification of red wine: Influence of grape variety. Eur. Food Res. Technol. 2008, 227, 1099. [Google Scholar] [CrossRef]

- Mijowska, K.; Cendrowski, K.; Grygorcewicz, B.; Oszmiański, J.; Nawrotek, P.; Ochmian, I.; Zielińska, B. Preliminary study on the influence of UV-C irradiation on microorganism viability and polyphenol compounds content during winemaking of ‘Regent’red grape cultivar. Pol. J. Chem. Technol. 2017, 19, 130–137. [Google Scholar] [CrossRef]

- Song, H.P.; Kim, D.H.; Jo, C.; Lee, C.H.; Kim, K.S.; Byun, M.W. Effect of gamma irradiation on the microbiological quality and antioxidant activity of fresh vegetable juice. Food Microbiol. 2006, 23, 372–378. [Google Scholar] [CrossRef]

- Sajilata, M.G.; Singhal, R.S. Effect of irradiation and storage on the antioxidative activity of cashew nuts. Radiat. Phys. Chem. 2006, 75, 297–300. [Google Scholar] [CrossRef]

- Breitfellner, F.; Solar, S.; Sontag, G. Effect of γ-irradiation on phenolic acids in strawberries. J. Food Sci. 2002, 67, 517–521. [Google Scholar] [CrossRef]

- Murcia, M.A.; Egea, I.; Romojaro, F.; Parras, P.; Jiménez, A.M.; Martínez-Tomé, M. Antioxidant evaluation in dessert spices compared with common food additives. Influence of irradiation procedure. J. Agric. Food Chem. 2004, 52, 1872–1881. [Google Scholar] [CrossRef] [PubMed]

- Mijowska, K.; Ochmian, I.; Oszmiański, J. Impact of cluster zone leaf removal on grapes cv. Regent polyphenol content by the UPLC-PDA/MS method. Molecules 2016, 21, 1688. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. ISO 21527-1:2008 Horizontal Method for the Enumeration of Yeasts and Molds. Part 1: Colony Count Technique in Products with Water Activity Greater than 0,95. 2008. Available online: https://www.iso.org/obp/ui/#iso:std:iso:21527:-1:ed-1:v1:en (accessed on 27 March 2019).

- Ptaszek, M.; Orlikowski, L.B.; Migdał, W.; Gryczka, U. E-beam irradiation for the control of Phytophthora nicotianae var. nicotianae in stonewool cubes. Nukleonika 2015, 60, 679–682. [Google Scholar] [CrossRef]

- Hunterlab. Measuring Color Using Hunter L, a, b versus CIE 1976 L*a*b*. AN 1005.00, 1–4. 2012. Available online: www.hunterlab.com/an-1005b (accessed on 25 February 2017).

Sample Availability: Samples of the compounds are not available from the authors. |

| Ozonation Time | Color CIE | ||

|---|---|---|---|

| L* 100 White; 0 Black | a* Redness | b* Yellow | |

| control—0 | 32.9 a* | 58.4 m | 27.5 l |

| 1 | 33.0 a | 58.3 lm | 27.5 l |

| 2 | 33.2 a | 57.9 lm | 27.6 l |

| 3 | 34.5 a | 57.3 lm | 27.4 kl |

| 4 | 35.1 ab | 55.2 kl | 27.1 jkl |

| 5 | 35.7 abc | 53.1 k | 27.0 jkl |

| 6 | 37.9 bcd | 48.4 j | 26.8 jkl |

| 7 | 38.3 cde | 45.0 i | 26.3 hijkl |

| 8 | 39.5 def | 43.8 hi | 26.0 hijk |

| 9 | 41.4 fg | 40.9 gh | 25.7 ghij |

| 10 | 44.0 g | 39.1 fg | 25.2 fghi |

| 11 | 48.2 h | 38.4 efg | 24.8 efgh |

| 12 | 50.7 hi | 37.5 def | 24.4 efg |

| 13 | 52.6 ij | 36.6 def | 23.9 ef |

| 14 | 53.9 j | 35.7 de | 23.4 e |

| 15 | 56.6 j | 34.3 d | 22.8 d |

| 30 | 62.5 k | 29.8 c | 17.6 c |

| 45 | 69.8 l | 22.5 b | 12.0 b |

| 60 | 73.6 m | 14.7 a | 6.4 a |

| Color CIE | ||||

|---|---|---|---|---|

| Irradiation Dose (kGy) | L* 100 White; 0 Black | a* Redness | b* Yellow | |

| without ozone | K | 32.6 a* | 59.0 ef | 26.9 g |

| 1 | 34.4 ab | 59.0 ef | 22.9 f | |

| 2,5 | 36.3 bc | 58.6 ef | 19.5 e | |

| 5 | 37.2 cd | 57.2 def | 17.2 d | |

| 7,5 | 39.3 d | 56.3 de | 15.3 cd | |

| 10 | 42.2 e | 54.5 d | 13.0 b | |

| ozone | K | 36.5 bc | 51.1 c | 26.3 g |

| 1 | 37.4 cd | 42.5 b | 25.8 g | |

| 2,5 | 42.7 e | 36.4 a | 23.2 f | |

| 5 | 47.1 f | 34.3 a | 22.1 f | |

| 7,5 | 54.1 g | 35.9 a | 19.1 e | |

| 10 | 55.0 g | 35.6 a | 17.9 e | |

| dose K2S2O5 (mg/L) | ||||

| sulfurized | 50 | 38.7 cd | 59.5 f | 14.8 bc |

| 100 | 45.6 f | 50.6 c | 9.3 a | |

| Compounds | Rt (min) | MS [M−H]− (m/z) | MS/MS [M−H]− (m/z) |

|---|---|---|---|

| Gallic acid | 0.87 | 169 | 125 |

| Delphinidin 3,5-diglucoside | 2.43 | 627 | 465/303 |

| GRP—2-S-glutathionylcaftaric acid (cis- and trans- isomers) | 2.55 | 616 | |

| Caftaric acid (cis- and trans- isomers) | 2.63 | 311 | 179/135 |

| Caftaric acid (cis- and trans- isomers) | 2.78 | 311 | 179/136 |

| Coutaric acid (cis- and trans- isomers) | 2.92 | 295 | 163 |

| Cyanidin 3,5O-diglucoside | 2.93 | 611 | 449/287 |

| Delphinidin 3-O-glucoside | 3.23 | 465 | 303 |

| (+)-Catechin | 3.38 | 289 | |

| Malvidin 3,5-O-diglucoside | 3.63 | 655 | 493/331 |

| Coutaric acid (cis- and trans- isomers) | 3.80 | 295 | 163 |

| Fertaric acid | 3.86 | 325 | 193/149 |

| Petunidin 3-O-glucoside | 4.02 | 479 | 317 |

| Procyanidin dimer | 4.13 | 577 | 289 |

| (-)-Epicatechin | 4.24 | 289 | |

| Peonidin 3-O-glucoside | 4.54 | 463 | 301 |

| Malvidin 3-O-glucoside | 4.72 | 493 | 331 |

| Myricetin 3-O-galactosode | 5.20 | 479 | 317 |

| Myricetin 3-O-glucoside | 5.22 | 479 | 317 |

| Delphinidin 3-O-(6″-O-acetyl)-glucoside | 5.23 | 507 | 465/303 |

| Cyanidin 3-O-(6″-O-acetyl)-glucoside | 5.69 | 491 | 449/287 |

| Petunidin 3-O-(6″-O-acetyl)-glucoside | 5.86 | 521 | 317 |

| Quercetin-3-O-glucoside | 6.05 | 463 | 301 |

| (epi)cat-ethyl-malvidin 3-O-glucoside (4 isomers) | 6.07 | 809 | 357 |

| Quercetin 3-O-glucuronide | 6.17 | 477 | 301 |

| (epi)cat-ethyl-malvidin 3-O-glucoside (4 isomers) | 6.33 | 809 | 357 |

| (epi)cat-ethyl-malvidin 3-O-glucoside (4 isomers) | 6.54 | 809 | 357 |

| Cyanidin 3-O-(6″-O-p-coumaroyl)-glucoside | 7.06 | 595 | 287 |

| Petunidin 3-O-(6″-O-p-coumaroyl)-glucoside | 7.16 | 625 | 317 |

| Malvidin 3-O-(6″-O-p-coumaroyl)-glucoside | 7.73 | 639 | 331 |

| Quercetin | 8.60 | 301 |

| Polyphenolic Compounds | Without Ozone | Sulfation | Ozone | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Radiation Dose | Dose K2S205 (mg/L) | Radiation Dose | ||||||||||||

| K | 1 | 2,5 | 5 | 7,5 | 10 | 50 | 100 | 0 | 1 | 2,5 | 5 | 7,5 | 10 | |

| anthocyanins | ||||||||||||||

| Delphinidin 3,5-diglucoside | 22.65h | 21.47g | 20.65f | 19.50de | 17.17bc | 16.07a | 23.70i | 18.03c | 19.95de | 20.12ef | 19.13d | 17.31bc | 16.05a | 16.89ab |

| Cyanidin 3,5O-diglucoside | 51.21g | 51.61g | 48.69f | 48.65f | 43.04e | 39.69d | 47.19f | 43.03e | 42.12e | 39.43d | 35.27c | 32.59b | 30.03a | 28.29a |

| Delphinidin 3-O-glucoside | 27.65e | 25.09d | 24.50d | 24.70d | 20.56b | 18.90a | 24.34cd | 18.59a | 26.77e | 27.84e | 24.52d | 24.64d | 22.98c | 21.35b |

| Malvidin 3,5-O-diglucoside | 318.24i | 313.98hi | 307.30h | 280.16g | 264.53f | 242.13d | 275.57g | 253.53e | 258.76ef | 252.67e | 230.57c | 225.44bc | 216.06a | 219.24ab |

| Petunidin 3-O-glucoside | 23.87efg | 23.56efg | 26.54g | 20.85def | 15.67ab | 12.96a | 24.58fg | 18.91bcd | 20.53cde | 19.66bcd | 19.89cde | 18.03bcd | 16.67abc | 17.08bcd |

| Peonidin 3-O-glucoside | 11.01g | 9.75f | 9.57f | 7.29b | 8.84e | 7.79bc | 8.47de | 8.22cd | 8.95e | 8.93e | 8.52de | 7.64b | 6.28a | 6.59a |

| Malvidin 3-O-glucoside | 49.23j | 48.49j | 46.22i | 45.47ih | 39.64f | 34.44c | 44.46gh | 43.76g | 37.65e | 36.26de | 34.89cd | 28.56b | 23.30a | 24.77a |

| Delphinidin 3-O-(6″-O-acetyl)-glucoside | 1.56ef | 1.59f | 1.47def | 1.34cde | 1.28cd | 1.13bc | 1.50def | 1.29cd | 1.31cd | 1.19bc | 1.15bc | 0.98ab | 0.95ab | 0.82a |

| Cyanidin 3-O-(6″-O-acetyl)-glucoside | 1.70ij | 1.73j | 1.57hi | 1.38fg | 1.18cd | 1.08bc | 1.52gh | 1.32def | 1.46fgh | 1.53gh | 1.28de | 1.19cd | 1.02b | 0.88a |

| Petunidin 3-O-(6″-O-acetyl)-glucoside | 2.24g | 2.17fg | 2.11f | 2.01e | 1.82bc | 1.73ab | 1.90cd | 1.87cd | 1.90cd | 1.97de | 1.82bc | 1.74ab | 1.70a | 1.77ab |

| (epi)cat-ethyl-malvidin 3-O-glucoside (isomers) | 0.90ef | 0.88ef | 0.91f | 0.88ef | 0.86cde | 0.82bc | 0.81bc | 0.83cd | 0.77ab | 0.74a | 0.81bc | 0.76a | 0.73a | 0.74a |

| (epi)cat-ethyl-malvidin 3-O-glucoside (isomers) | 1.35h | 1.31h | 1.26g | 1.00c | 1.02cd | 0.86a | 1.21f | 1.03cd | 1.19f | 1.22fg | 1.05d | 1.11e | 1.04cd | 0.94b |

| (epi)cat-ethyl-malvidin 3-O-glucoside (isomers) | 5.45hij | 5.49ij | 5.39hi | 5.53j | 5.91h | 5.13f | 5.34gh | 5.22fg | 4.86e | 4.27cd | 4.30d | 4.16c | 3.93b | 3.58a |

| Cyanidin 3-O-(6″-O-p-coumaroyl)-glucoside | 1.12g | 1.07fg | 1.08fg | 1.02ef | 0.99def | 0.78c | 1.06fg | 0.94de | 0.99def | 0.91d | 0.72c | 0.55b | 0.52b | 0.37a |

| Petunidin 3-O-(6″-O-p-coumaroyl)-glucoside | 1.55k | 1.50jk | 1.47j | 1.37i | 1.31h | 1.12f | 1.26gh | 1.21g | 1.15f | 1.06e | 0.89d | 0.81c | 0.67b | 0.53a |

| Malvidin 3-O-(6″-O-p-coumaroyl)-glucoside | 4.03g | 3.96g | 3.77f | 3.78f | 3.43e | 3.47e | 2.78c | 2.49a | 3.09d | 3.03d | 2.85c | 2.62ab | 2.84c | 2.71bc |

| total anthocyanins | 523.77G | 513.65FG | 502.49F | 464.94E | 427.26D | 388.10C | 465.68E | 420.29D | 431.45D | 420.83D | 387.67C | 368.12B | 344.77A | 346.53A |

| hydroxycinnamic acids and derivatives | ||||||||||||||

| GRP (cis- and trans- isomers | 24.46efg | 24.29defg | 22.79cd | 25.23fg | 23.43de | 21.53bc | 24.14def | 25.70g | 25.20fg | 25.73g | 24.88efg | 24.20def | 20.27b | 18.44a |

| Caftaric acid (cis- and trans- isomers) Tr 2,63 | 10.84d | 11.81ef | 12.18f | 13.28g | 13.43h | 13.69h | 11.62e | 14.32i | 9.15c | 9.32c | 8.94c | 9.11c | 7.45b | 5.71a |

| Caftaric acid (cis- and trans- isomers) Tr 2,78 | 0.13c | 0.15d | 0.15d | 0.18e | 0.20f | 0.17e | 0.09b | 0.07a | 0.15d | 0.15d | 0.17e | 0.13c | 0.12c | 0.06a |

| Coutaric acid (cis- and trans- isomers Tr 2,92 | 238.26de | 234.21de | 230.48cd | 222.95c | 213.87b | 212.96b | 234.13de | 212.45b | 241.97e | 232.21d | 234.52de | 206.03b | 193.80a | 197.44a |

| Coutaric acid (cis- and trans- isomers Tr 3,80 | 5.03ij | 4.96hi | 4.86h | 4.57g | 4.22f | 3.40d | 5.16j | 4.23f | 4.50g | 4.11f | 3.78e | 2.87c | 1.98b | 1.17a |

| Fertaric acid | 93.24f | 91.19f | 89.02ef | 90.44f | 76.85b | 79.70bc | 85.16de | 77.06b | 84.71d | 83.77cd | 85.28de | 81.54bcd | 68.25a | 70.13a |

| total hydroxycinnamic acids and derivatives | 371.95F | 366.61EF | 359.48EF | 356.65DE | 331.99BC | 331.44BC | 360.30EF | 342.83CD | 365.68EF | 355.29DE | 357.57DEF | 323.88B | 291.87A | 292.95A |

| flavonols | ||||||||||||||

| Myricetin 3-O-galactosode | 24.55k | 24.35k | 20.28i | 17.66g | 17.08f | 15.99e | 22.11j | 19.55h | 17.75g | 14.28c | 14.88d | 13.29b | 13.04ab | 12.65a |

| Myricetin 3-O-glucoside | 2.53ef | 2.46e | 2.26cd | 2.60f | 2.10b | 2.30d | 2.19bc | 2.48e | 2.31d | 2.74g | 2.58f | 2.60f | 1.87a | 1.93a |

| Quercetin-3-O-glucoside | 8.19de | 8.11de | 8.68f | 9.03g | 9.58h | 12.58j | 7.29c | 6.37a | 9.97i | 8.24e | 7.58c | 7.89d | 7.26c | 6.88b |

| Quercetin 3-O-glucuronide | 117.40hj | 115.22gh | 112.57fg | 119.20j | 124.32k | 115.97ghj | 115.03gh | 104.56c | 108.02cde | 110.37ef | 107.24cde | 108.56de | 96.72b | 84.25a |

| Quercetin | 8.11g | 7.94fg | 7.47e | 9.05h | 9.66i | 9.21h | 7.11cd | 7.80f | 7.85f | 7.92f | 7.34de | 5.88bc | 5.65b | 5.24a |

| Total flavonols | 160.77GH | 158.08FGH | 151.26DE | 157.54FGH | 162.73H | 156.05EFG | 153.73EF | 140.76BC | 145.89CD | 143.55BC | 139.62B | 138.22B | 124.54B | 110.95A |

| flavan-3-ols | ||||||||||||||

| (+)Catechin | 44.95l | 43.74l | 39.86k | 26.15g | 23.20f | 17.25d | 38.19k | 34.22j | 31.62i | 28.44h | 19.05e | 14.72c | 12.18b | 7.50a |

| Dimer B2 | 9.21h | 9.34h | 7.18e | 6.75d | 5.78b | 7.23e | 8.13g | 8.37g | 7.74f | 7.11e | 7.25e | 6.48cd | 6.20c | 4.89a |

| (-)Epicatechin | 11.74j | 9.89i | 9.02h | 6.01d | 5.42b | 4.54a | 7.51f | 5.73c | 8.25g | 8.89h | 7.32f | 6.90e | 4.48a | 4.57a |

| total flavan-3-ols | 65.90I | 62.97I | 56.06H | 38.91E | 34.40D | 29.02C | 53.83H | 48.32G | 47.60G | 44.44F | 33.62D | 28.10C | 22.86B | 16.96A |

| Gallic acid | 4.76e | 4.73e | 5.33g | 5.69h | 4.58e | 4.17d | 3.82bc | 4.06d | 4.11d | 4.57e | 5.04f | 3.79b | 4.02cd | 3.48a |

| TOTAL POLYPHENOLS | 1127.15I | 1106.05HI | 1074.61H | 1023.73FG | 960.96D | 908.79C | 1037.36G | 956.26D | 994.74EF | 968.68DE | 923.52C | 862.11B | 788.06A | 770.87A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Błaszak, M.; Nowak, A.; Lachowicz, S.; Migdał, W.; Ochmian, I. E-Beam Irradiation and Ozonation as an Alternative to the Sulphuric Method of Wine Preservation. Molecules 2019, 24, 3406. https://doi.org/10.3390/molecules24183406

Błaszak M, Nowak A, Lachowicz S, Migdał W, Ochmian I. E-Beam Irradiation and Ozonation as an Alternative to the Sulphuric Method of Wine Preservation. Molecules. 2019; 24(18):3406. https://doi.org/10.3390/molecules24183406

Chicago/Turabian StyleBłaszak, Magdalena, Agata Nowak, Sabina Lachowicz, Wojciech Migdał, and Ireneusz Ochmian. 2019. "E-Beam Irradiation and Ozonation as an Alternative to the Sulphuric Method of Wine Preservation" Molecules 24, no. 18: 3406. https://doi.org/10.3390/molecules24183406