Optimization of Flavonoids Extraction Process in Panax notoginseng Stem Leaf and a Study of Antioxidant Activity and Its Effects on Mouse Melanoma B16 Cells

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effect of Surfactant Types on Extraction Efficiency of SLPF

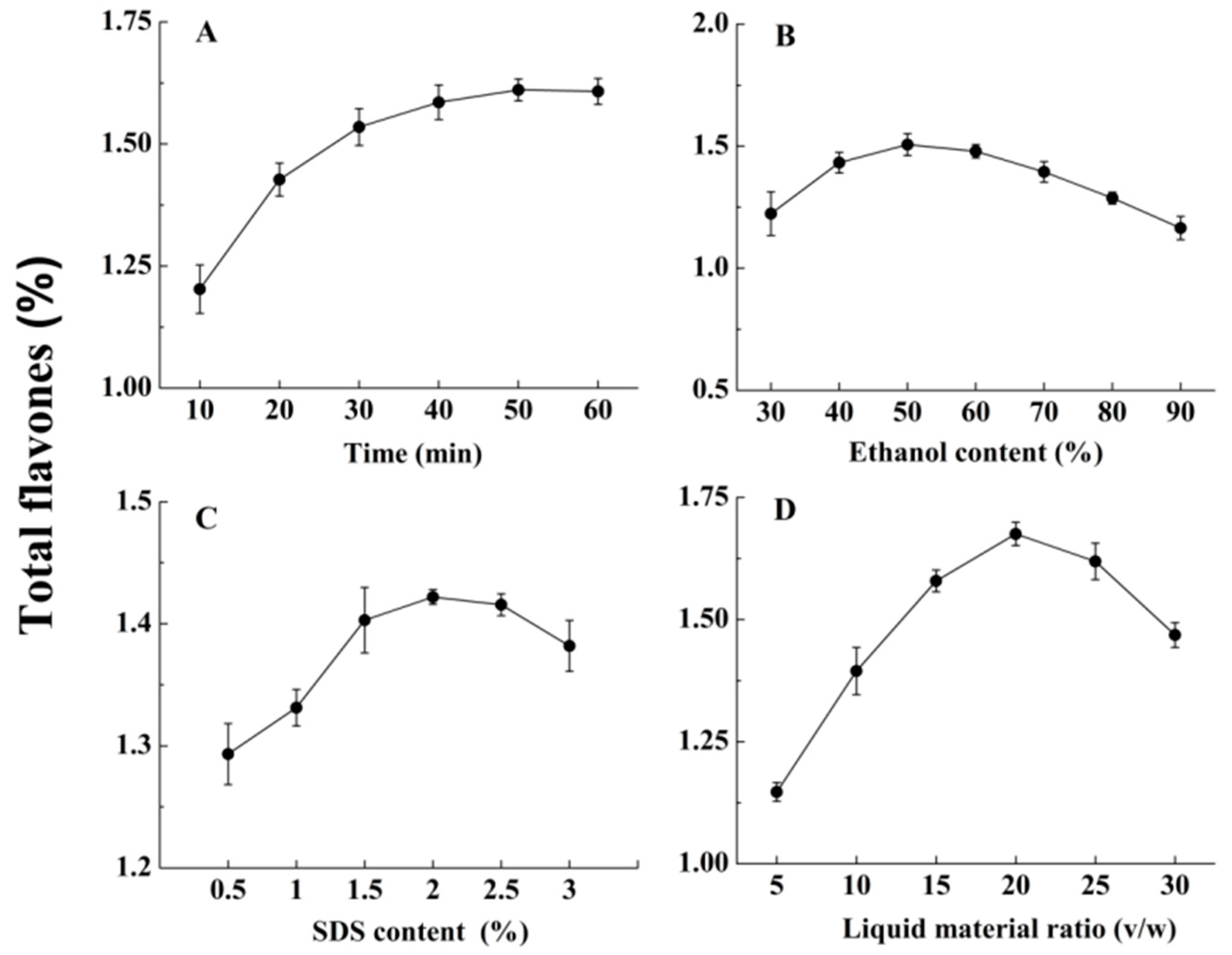

2.2. Single Factor Experiments

2.3. Model Fitting and Optimization of SLPF

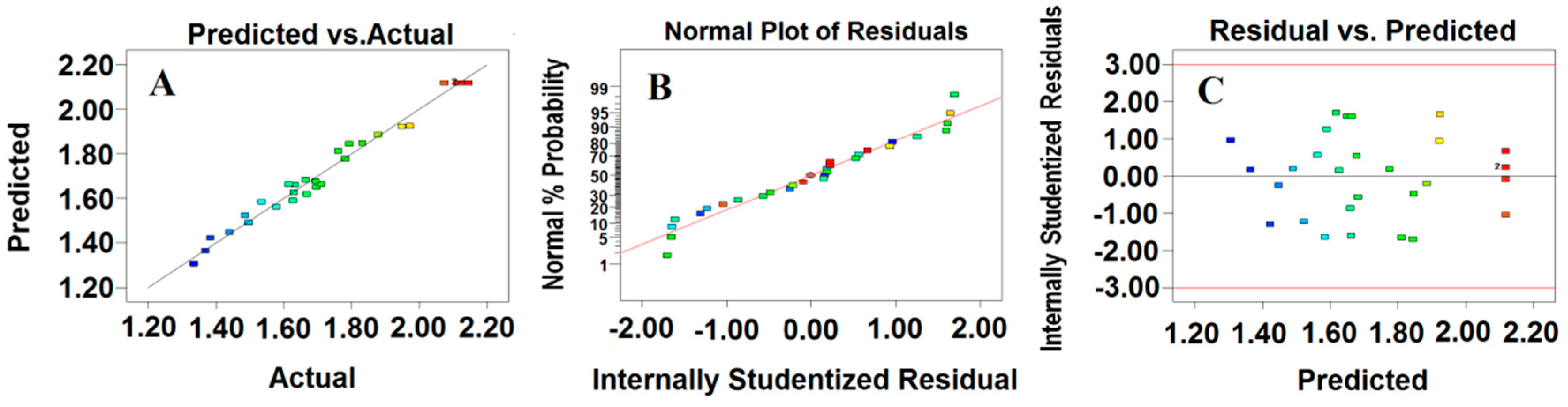

2.3.1. Model Fitting

0.010BC − 0.001BD − 0.076CD − 0.003A2 − 0.002B2 − 0.683C2 − 0.010D2

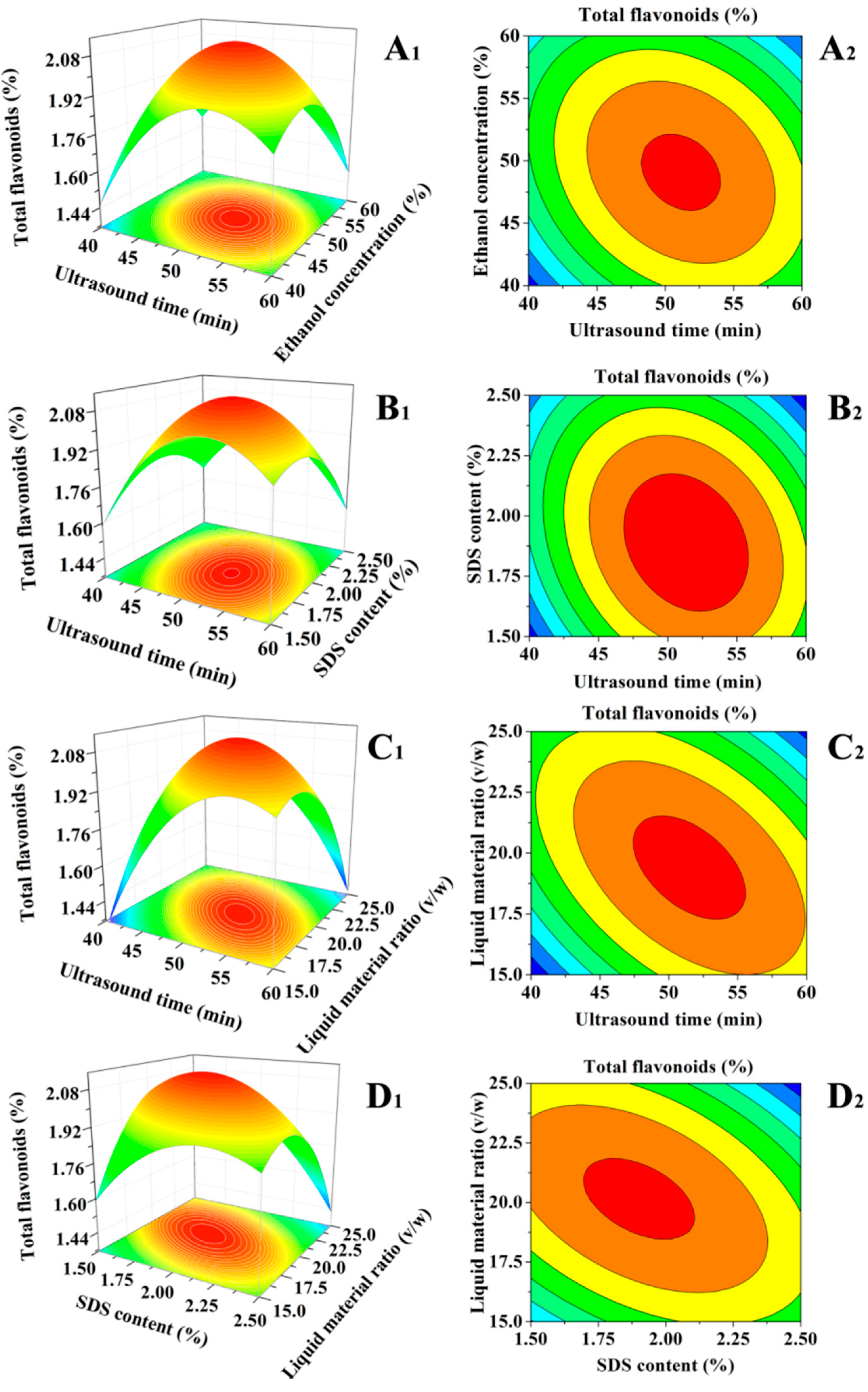

2.3.2. Analysis of Response Surface

2.3.3. Validation of the Model

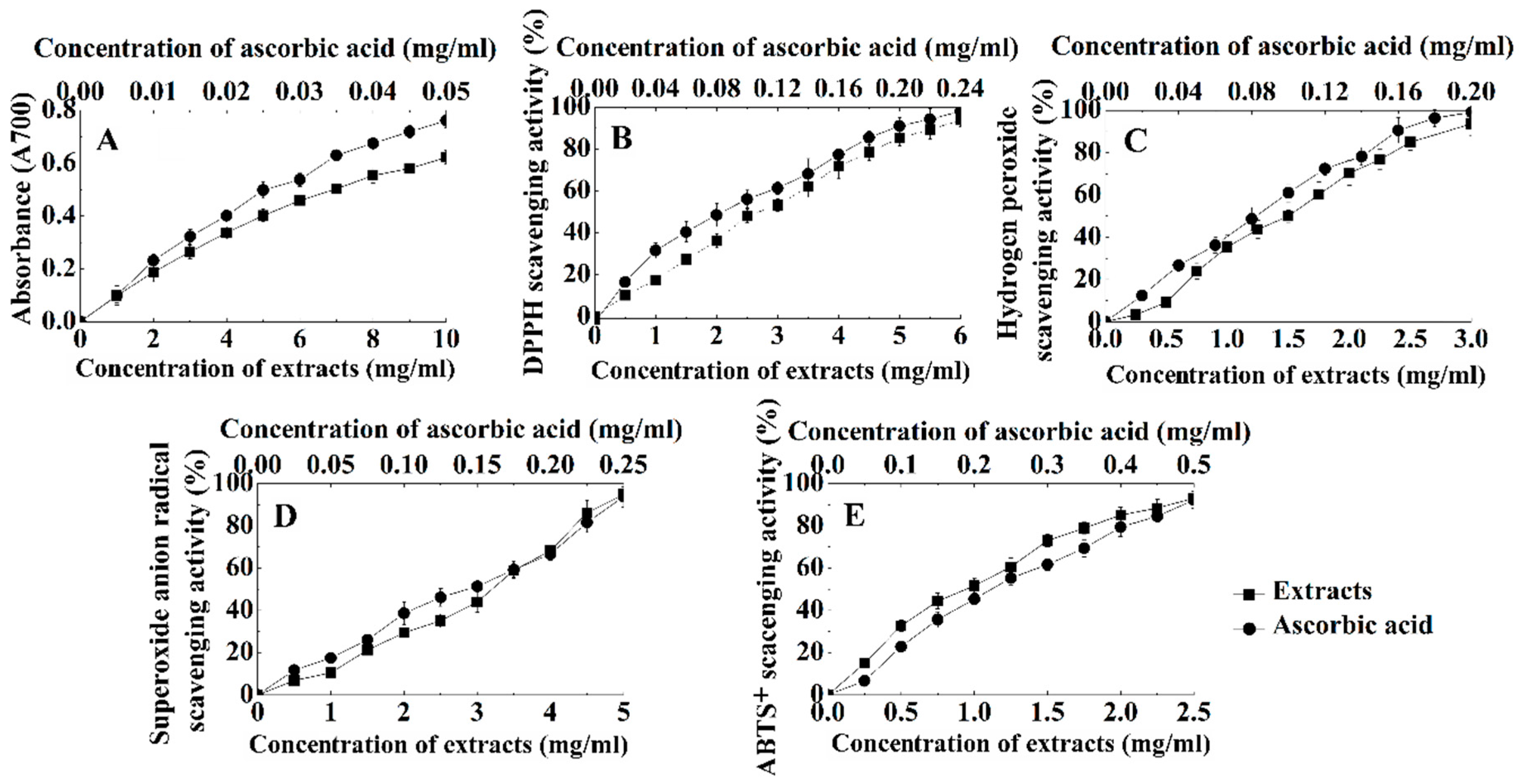

2.4. Antioxidant Activities of the P. notoginseng Stem Leaf Extracts

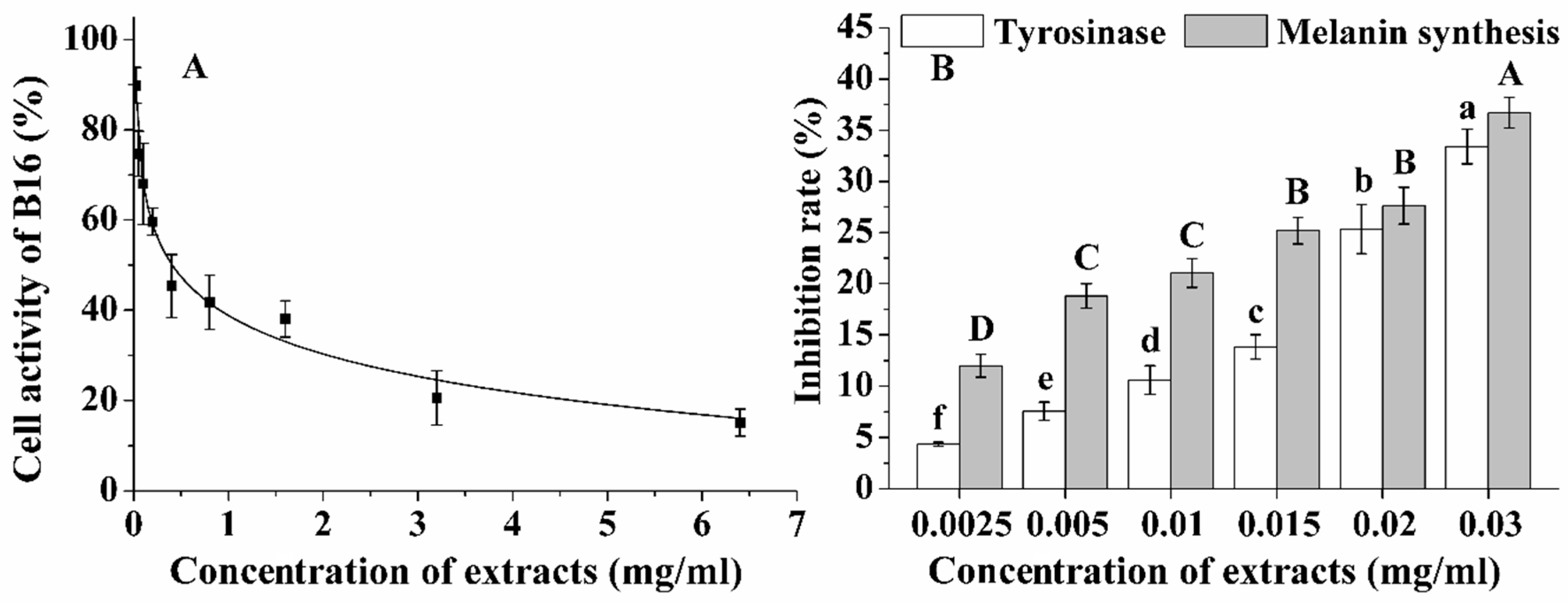

2.5. Effect of Extracts on B16 Cell Activity

3. Materials and Methods

3.1. Plant Materials

3.2. Chemicals and Reagents

3.3. Optimization of Extraction Condition Selection

3.4. Experimental Design of RSM

3.5. Total Flavonoid Assay

3.6. In Vitro Antioxidant Activity Assays

3.6.1. Reducing Power Assay

3.6.2. DPPH Radical Scavenging Capacity

3.6.3. Detection of ABTS+ Scavenging Assay

3.6.4. Assay of Hydroxyl Radical Scavenging Activity

3.6.5. Detection of Superoxide Anion Scavenging Activity

3.7. Cell Experiment

3.7.1. Cell Culture

3.7.2. α-MSH Treatment

3.7.3. Intracellular Tyrosinase Activity

3.7.4. Melanin Content Assay

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ABTS | 2,2-azino-bis-3-ethylbenzthiazoline-6-sulphonic acid |

| BBD | Box-Behnken design |

| DPPH | 2,2-diphenyl-1-picrylhydrazyl |

| RSM | Response surface methodology |

| SLPF | stem and leaf of P. notoginseng flavonoid |

References

- Lv, Q.Y. Chemical composition and pharmacological action of Panax notoginsegnoside in the leaves. Lishizhen Med. Mater. Med. Res. 2006, 17, 2065–2066. (In Chinese) [Google Scholar]

- Yunnan provincial health and Family Planning Commission. Dried Panax notoginseng Stem and Leaf; DBS 53/024-2017; Yunnan Standard Press: Kunming, China, 2017. [Google Scholar]

- Geng, J.L.; Shen, Y.; Song, X.W. Development Studies on Saponins in Panax notoginseng Leaves. J. Yunnan Coll. Tradit. Chin. Med. 2001, 24, 7–8. [Google Scholar]

- Zhang, Z.X.; Song, G.B. Extraction technology of total flavonoids in the stalk and leaves of Panax notoginseng. Biotechnology 2006, 16, 65–67. [Google Scholar]

- Wang, T.; Guo, R.; Zhou, G.H.; Zhou, X.D.; Kou, Z.Z.; Sui, F.; Li, C.; Tang, L.Y.; Wang, Z.J. Traditional uses, botany, phytochemistry, pharmacology and toxicology of Panax notoginseng (Burk.) F.H. Chen: A review. J. Ethnopharmacol. 2016, 188, 234–258. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.X. Preliminary Study on Flavonoids in Stalk and Leaves of Panax notoginseng; Chongqing University: Chongqing, China, 2005. [Google Scholar]

- Uysal, A.; Zengin, G.; Mollica, A.; Gunes, E.; Locatelli, M.; Yilmaz, T.; Aktumsek, A. Chemical and biological insights on Cotoneaster integerrimus: A new (−)-epicatechin source for food and medicinal applications. Phytomedicine 2016, 23, 979–988. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Ma, X.; Wang, S.; Wang, X. A study on the extraction of flavonoids from the leaves of acer truncatum. J. Northwest For. College 1997, 12, 64–67. [Google Scholar]

- Zhang, Z.X.; Zhang, S.X.; Song, G.B. Study of microwave-alkali water method for extraction of total flavone from Panax notoginseng stalks and leaves. Pharm. Biotechnol. 2005, 12, 389–392. [Google Scholar]

- Gong, K.; Zhan, X.L.; Guo, Z.T.; Xue, J.P.; Jin-Bu, L.I.; Sheng, W. Study on extraction of total flavonoids from pomegranate leaf by surfactant. Sci. Technol. Food Ind. 2014, 23, 261–264, 322. [Google Scholar]

- Dong, S.G. Process research of the surfactant-assisted extraction of total flavonoids extraction from Mulbery leaves. J. Anhui Agric. Sci. 2011, 39, 19778–19780. [Google Scholar]

- Eng, A.T.; Heng, M.Y.; Ong, E.S. Evaluation of surfactant assisted pressurized liquid extraction for the determination of glycyrrhizin and ephedrine in medicinal plants. Anal. Chim. Acta 2007, 583, 289–295. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yan, Z.; Xiaoli, L.U. Surfactant assisted ultrasonic extraction of flavonoids from peanut hull. China Oils Fats 2012, 37, 57–60. [Google Scholar]

- Fan, T.; Hu, J.G.; Fu, L.D.; Zhang, L.J. Optimization of enzymolysis-ultrasonic assisted extraction of polysaccharides from Momordica charabtia L. by response surface methodology. Carbohydr. Polym. 2015, 115, 701–706. [Google Scholar] [CrossRef] [PubMed]

- Alara, O.R.; Abdurahman, N.H.; Olalere, O.A. Optimization of microwave-assisted extraction of flavonoids and antioxidants from Vernonia amygdalina leaf using response surface methodology. Food Bioprod. Process. 2018, 107, 36–48. [Google Scholar] [CrossRef]

- Sheng, Z.L.; Wan, P.F.; Dong, C.L.; Li, Y.H. Optimization of total flavonoids content extracted from flos populi using response surface methodology. Ind. Crop. Prod. 2013, 43, 778–786. [Google Scholar] [CrossRef]

- Zeković, Z.; Vidović, S.; Vladić, J.; Radosavljević, R.; Cvejin, A.; Elgndi, M.A.; Pavlić, B. Optimization of subcritical water extraction of antioxidants from coriandrum sativum, seeds by response surface methodology. J. Supercrit. Fluids 2014, 95, 560–566. [Google Scholar] [CrossRef]

- Zengin, G.; Uysal, A.; Aktumsek, A.; Mocan, A.; Mollica, A.; Locatelli, M.; Mahomoodally, M.F. Euphorbia denticulata lam.: A promising source of phyto-pharmaceuticals for the development of novel functional formulations. Biomed. Pharmacother. 2017, 87, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Preece, D.; Montgomery, D. Design and Analysis of Experiments; Wiley: New York, NY, USA, 2010. [Google Scholar]

- Draper, N.R.; Smith, H. Applied Regression Analysis; Wiley: New York, NY, USA, 1966. [Google Scholar]

- Babaki, M.; Yousefi, M.; Habibi, Z.; Mohammadi, M. Process optimization for biodiesel production from waste cooking oil using multi-enzyme systems through response surface methodology. Renew. Energy 2017, 105, 465–472. [Google Scholar] [CrossRef]

- Noordin, M.Y.; Venkatesh, V.C.; Sharif, S.; Elting, S.; Abdullah, A. Application of response surface methodology in describing the performance of coated carbide tools when turning aisi 1045 steel. J. Mater. Process. Technol. 2004, 145, 46–58. [Google Scholar] [CrossRef]

- Sivaraman, B.; Shakila, R.J.; Jeyasekaran, G.; Sukumar, D.; Manimaran, U.; Sumathi, G. Antioxidant activities of squid protein hydrolysates prepared with papain using response surface methodology. Food Sci. Biotechnol. 2016, 25, 665–672. [Google Scholar] [CrossRef]

- Amari, A.; Gannouni, A.; Chlendi, M.; Bellagi, A. Optimization by response surface methodology (RSM) for toluene adsorption onto prepared acid activated clay. Can. J. Chem. Eng. 2008, 86, 1093–1102. [Google Scholar] [CrossRef]

- Muralidhar, R.V.; Chirumamila, R.R. A response surface approach for the comparison of lipase production by Canida cylindracea using two different carbon sources. Biochem. Eng. J. 2001, 9, 17–23. [Google Scholar] [CrossRef]

- Fan, L.; Li, J.; Deng, K.; Ai, L. Effects of drying methods on the antioxidant activities of polysaccharides extracted from Ganoderma lucidum. Carbohydr. Polym. 2012, 87, 1849–1854. [Google Scholar] [CrossRef]

- Wu, S.; Huang, X. Preparation and antioxidant activities of oligosaccharides from Crassostrea gigas. Food Chem. 2017, 216, 243–246. [Google Scholar] [CrossRef] [PubMed]

- Qiao, D.; Ke, C.; Hu, B.; Luo, J.G.; Ye, H.; Sun, Y.; Yan, X.Y.; Zeng, X.X. Antioxidant activities of polysaccharides from Hyriopsis cumingii. Carbohydr. Polym. 2009, 78, 199–204. [Google Scholar] [CrossRef]

- Parsa, A.; Salout, S.A. Investigation of the antioxidant activity of electrosynthesized polyaniline/reduced graphene oxide nanocomposite in a binary electrolyte system on abts and dpph free radicals. J. Electroanal. Chem. 2016, 760, 113–118. [Google Scholar] [CrossRef]

- Farombi, E.O.; Akanni, O.O.; Emerole, G.O. Antioxidant and scavenging activities of flavonoid extract (kolaviron) of Garcinia kola seeds. Pharm. Biol. 2002, 40, 107–116. [Google Scholar] [CrossRef]

- Srisawat, U.; Panunto, W.; Kaendee, N.; Tanuchit, S.; Itharat, A.; Lerdvuthisopon, N.; Hansakul, P. Determination of phenolic compounds, flavonoids, and antioxidant activities in water extracts of thai red and white rice cultivars. J. Med. Assoc. Thail. 2010, 7, 83–91. [Google Scholar]

- Hearing, V.J. Biochemical control of melanogenesis and melanosomal organization. J. Investig. Dermatol. Symp. Proc. 1999, 4, 24–28. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.S. An updated review of tyrosinase inhibitors. Int. J. Mol. Sci. 2009, 10, 2440–2475. [Google Scholar] [CrossRef] [PubMed]

- Rajasimman, M.; Murugaiyan, K. Sorption of nickel by hypnea valentiae: Application of response surface methodology. World Acad. Sci. Eng. Technol. 2011, 1, 7. [Google Scholar]

- Karadenïz, F.; Burdurlu, H.S.; Koca, N.; Soyer, Y. Antioxidant activity of selected fruits and vegetables grown in turkey. Turkish J. Agric. For. 2005, 29, 297–303. [Google Scholar]

- Park, S.Y.; Je, J.Y.; Hwang, J.Y.; Ahn, C.B. Abalone protein hydrolysates: Preparation, angiotensin i converting enzyme inhibition and cellular antioxidant activity. Prev. Nutr. Food Sci. 2015, 20, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Li, C.; Zhang, C.; Zeng, C.; Fu, C. Optimization of infrared-assisted extraction of Bletilla striata polysaccharides based on response surface methodology and their antioxidant activities. Carbohydr. Polym. 2016, 148, 345–353. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.L.; Yang, W.; Tang, Y.Y.; Xu, Q.; Huang, S.L.; Yao, J.; Zhang, J.; Lei, Z.Q. Regioselective sulfation of artemisia sphaerocephala polysaccharide: Solution conformation and antioxidant activities in vitro. Carbohydr. Polym. 2016, 136, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.K.; Jin, X.; Lai, F.Y.; Lin, Q.S.; Jiang, J.G. Chemical analysis and antioxidant activities in vitro, of polysaccharide extracted from Opuntia ficus indica, Mill. cultivated in China. Carbohydr. Polym. 2010, 82, 722–727. [Google Scholar] [CrossRef]

- Gülçin, İ. Antioxidant activity of caffeic acid (3,4-dihydroxycinnamic acid). Toxicology 2006, 217, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Tada, H.; Shiho, O.; Kuroshima, K.; Koyama, M.; Tsukamoto, K. An improved colorimetric assay for interleukin 2. J. Immunol. Methods 1986, 93, 157–165. [Google Scholar] [CrossRef]

- Skandrani, I.; Pinon, A.A.; Ghedira, K.; Chekir, G.L. Chloroform extract from Moricandia arvensis, inhibits growth of b16-f0 melanoma cells and promotes differentiation in vitro. Cell Prolif. 2010, 43, 471–479. [Google Scholar] [CrossRef] [PubMed]

- Uchida, R.; Ishikawa, S.; Tomoda, H. Inhibition of tyrosinase activity and melanine pigmentation by 2-hydroxytyrosol. Acta Pharm. Sin. B 2014, 4, 141–145. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the extracts are available from the authors. |

| Std. Order | Run Order | Variable | Total Flavonoids Y (%) | ||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | Observed | Predicted | ||

| 25 | 1 | 50 (0) | 50 (0) | 2 (0) | 20:1 (0) | 2.127 | 2.117 |

| 8 | 2 | 50 (0) | 50 (0) | 2.5 (1) | 25:1 (1) | 1.384 | 1.422 |

| 11 | 3 | 40 (−1) | 50 (0) | 2 (0) | 25:1 (1) | 1.781 | 1.776 |

| 22 | 4 | 50 (0) | 60 (1) | 2 (0) | 15:1 (−1) | 1.615 | 1.662 |

| 12 | 5 | 60 (1) | 50 (0) | 2 (0) | 25:1 (1) | 1.369 | 1.364 |

| 20 | 6 | 60 (1) | 50 (0) | 2.5 (1) | 20:1 (0) | 1.579 | 1.562 |

| 1 | 7 | 40 (−1) | 40 (−1) | 2 (0) | 20:1 (0) | 1.441 | 1.448 |

| 6 | 8 | 50 (0) | 50 (0) | 2.5 (1) | 15:1 (−1) | 1.794 | 1.844 |

| 10 | 9 | 60 (1) | 50 (0) | 2 (0) | 15:1 (−1) | 1.949 | 1.922 |

| 17 | 10 | 40 (−1) | 50 (0) | 1.5 (−1) | 20:1 (0) | 1.535 | 1.584 |

| 9 | 11 | 40 (−1) | 50 (0) | 2 (0) | 15:1 (−1) | 1.335 | 1.306 |

| 21 | 12 | 50 (0) | 40 (−1) | 2 (0) | 15:1 (−1) | 1.630 | 1.626 |

| 27 | 13 | 50 (0) | 50 (0) | 2 (0) | 20:1 (0) | 2.127 | 2.117 |

| 2 | 14 | 60 (1) | 40 (−1) | 2 (0) | 20:1 (0) | 1.762 | 1.811 |

| 16 | 15 | 50 (0) | 60 (1) | 2.5 (1) | 20:1 (0) | 1.711 | 1.663 |

| 7 | 16 | 50 (0) | 50 (0) | 1.5 (−1) | 25:1 (1) | 1.973 | 1.924 |

| 23 | 17 | 50 (0) | 40 (−1) | 2 (0) | 25:1 (1) | 1.694 | 1.678 |

| 28 | 18 | 50 (0) | 50 (0) | 2 (0) | 20:1 (0) | 2.145 | 2.117 |

| 14 | 19 | 50 (0) | 60 (1) | 1.5 (−1) | 20:1 (0) | 1.666 | 1.683 |

| 29 | 20 | 50 (0) | 50 (0) | 2 (0) | 20:1 (0) | 2.074 | 2.117 |

| 15 | 21 | 50 (0) | 40 (−1) | 2.5 (1) | 20:1 (0) | 1.669 | 1.618 |

| 4 | 22 | 60 (1) | 60 (1) | 2 (0) | 20:1 (0) | 1.496 | 1.490 |

| 13 | 23 | 50 (0) | 40 (−1) | 1.5 (−1) | 20:1 (0) | 1.832 | 1.846 |

| 18 | 24 | 60 (1) | 50 (0) | 1.5 (−1) | 20:1 (0) | 1.879 | 1.885 |

| 5 | 25 | 50 (0) | 50 (0) | 1.5 (−1) | 15:1 (−1) | 1.627 | 1.590 |

| 19 | 26 | 40 (−1) | 50 (0) | 2.5 (1) | 20:1 (0) | 1.634 | 1.659 |

| 26 | 27 | 50 (0) | 50 (0) | 2 (0) | 20:1 (0) | 2.114 | 2.117 |

| 24 | 28 | 50 (0) | 60 (1) | 2 (0) | 25:1 (1) | 1.486 | 1.522 |

| 3 | 29 | 40 (−1) | 60 (1) | 2 (0) | 20:1 (0) | 1.697 | 1.649 |

| Source | Sum of Squares | DF | Mean Square | F Value | p Value Prob > F | Significance |

|---|---|---|---|---|---|---|

| Model | 1.589 | 14 | 0.114 | 53.850 | <0.0001 | *** |

| A | 0.031 | 1 | 0.031 | 14.757 | 0.0018 | ** |

| B | 0.011 | 1 | 0.011 | 5.026 | 0.0417 | * |

| C | 0.046 | 1 | 0.046 | 21.826 | 0.0004 | *** |

| D | 0.006 | 1 | 0.006 | 2.750 | 0.1195 | |

| AB | 0.068 | 1 | 0.068 | 32.313 | <0.0001 | *** |

| AC | 0.040 | 1 | 0.040 | 18.891 | 0.0007 | *** |

| AD | 0.263 | 1 | 0.263 | 124.984 | <0.0001 | *** |

| BC | 0.011 | 1 | 0.011 | 5.165 | 0.0393 | * |

| BD | 0.009 | 1 | 0.009 | 4.360 | 0.0555 | |

| CD | 0.143 | 1 | 0.143 | 67.750 | <0.0001 | *** |

| A2 | 0.487 | 1 | 0.487 | 230.873 | <0.0001 | *** |

| B2 | 0.386 | 1 | 0.386 | 182.935 | <0.0001 | *** |

| C2 | 0.189 | 1 | 0.189 | 89.704 | <0.0001 | *** |

| D2 | 0.409 | 1 | 0.409 | 194.231 | <0.0001 | *** |

| Residual | 0.030 | 14 | 0.002 | |||

| Lack of Fit | 0.027 | 10 | 0.003 | 3.858 | 0.1025 | |

| Pure Error | 0.003 | 4 | 0.001 | |||

| Cor Total | 1.619 | 28 | ||||

| Std. Dev. | 0.046 | R2 | 0.982 | |||

| Mean | 1.728 | R2Adj | 0.964 | |||

| C.V. (%) | 2.657 | R2Pred | 0.902 | |||

| PRESS | 0.158 | RSN | 24.553 |

| Name | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight |

|---|---|---|---|---|---|

| A: Ultrasound time (min) | is in range | 40 | 60 | 1 | 1 |

| B: Ethanol concentration (%) | is in range | 40 | 60 | 1 | 1 |

| C: SDS content (%) | is in range | 1.5 | 2.5 | 1 | 1 |

| D: Liquid material ratio (v/w) | is in range | 15 | 25 | 1 | 1 |

| Total flavonoids content (%) | maximize | 1.33502 | 100 | 1 | 1 |

| Category | Ultrasound time (min) | Ethanol concentration (%) | SDS content (%) | Liquid material ratio (v/w) | Total flavonoids content (%) |

| Predicted value | 51.84 | 48.68 | 1.88 | 19.81:1 | 2.13 ± 0.008a |

| Experimental value | 52 | 48.7 | 1.9 | 20:1 | 2.10 ± 0.017a |

| Surfactant | SDS | Triton X-100 | Tween-20 | Tween-80 | Span-20 |

|---|---|---|---|---|---|

| HLB | 40 | 14.6 | 16.7 | 15 | 8.6 |

| Types | Anionic | Nonionic | Nonionic | Nonionic | Nonionic |

| Factors | Codes | Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Ultrasound time (min) | A | 40 | 50 | 60 |

| Ethanol concentration (%) | B | 40 | 50 | 60 |

| SDS content (%) | C | 1.5 | 2 | 2.5 |

| Liquid material ratio (v/w) | D | 15:1 | 20:1 | 25:1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, C.-Y.; Liu, P.-F.; Liao, P.-R.; Qu, Y.; Wang, C.-X.; Yang, Y.; Cui, X.-M. Optimization of Flavonoids Extraction Process in Panax notoginseng Stem Leaf and a Study of Antioxidant Activity and Its Effects on Mouse Melanoma B16 Cells. Molecules 2018, 23, 2219. https://doi.org/10.3390/molecules23092219

Dai C-Y, Liu P-F, Liao P-R, Qu Y, Wang C-X, Yang Y, Cui X-M. Optimization of Flavonoids Extraction Process in Panax notoginseng Stem Leaf and a Study of Antioxidant Activity and Its Effects on Mouse Melanoma B16 Cells. Molecules. 2018; 23(9):2219. https://doi.org/10.3390/molecules23092219

Chicago/Turabian StyleDai, Chun-Yan, Peng-Fei Liu, Pei-Ran Liao, Yuan Qu, Cheng-Xiao Wang, Ye Yang, and Xiu-Ming Cui. 2018. "Optimization of Flavonoids Extraction Process in Panax notoginseng Stem Leaf and a Study of Antioxidant Activity and Its Effects on Mouse Melanoma B16 Cells" Molecules 23, no. 9: 2219. https://doi.org/10.3390/molecules23092219