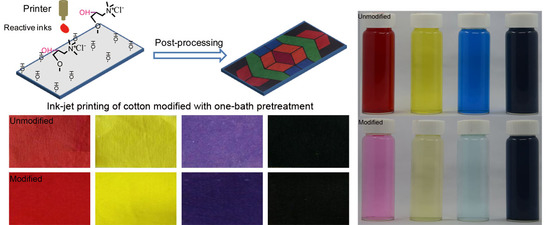

One-Bath Pretreatment for Enhanced Color Yield of Ink-Jet Prints Using Reactive Inks

Abstract

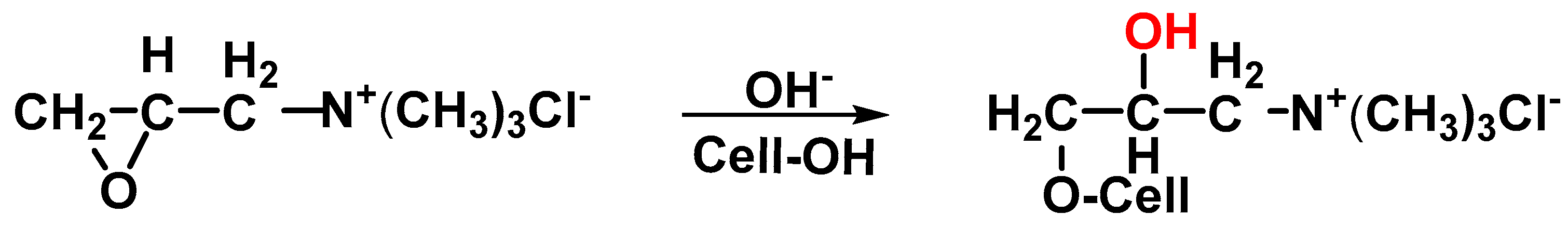

:1. Introduction

2. Results and Discussion

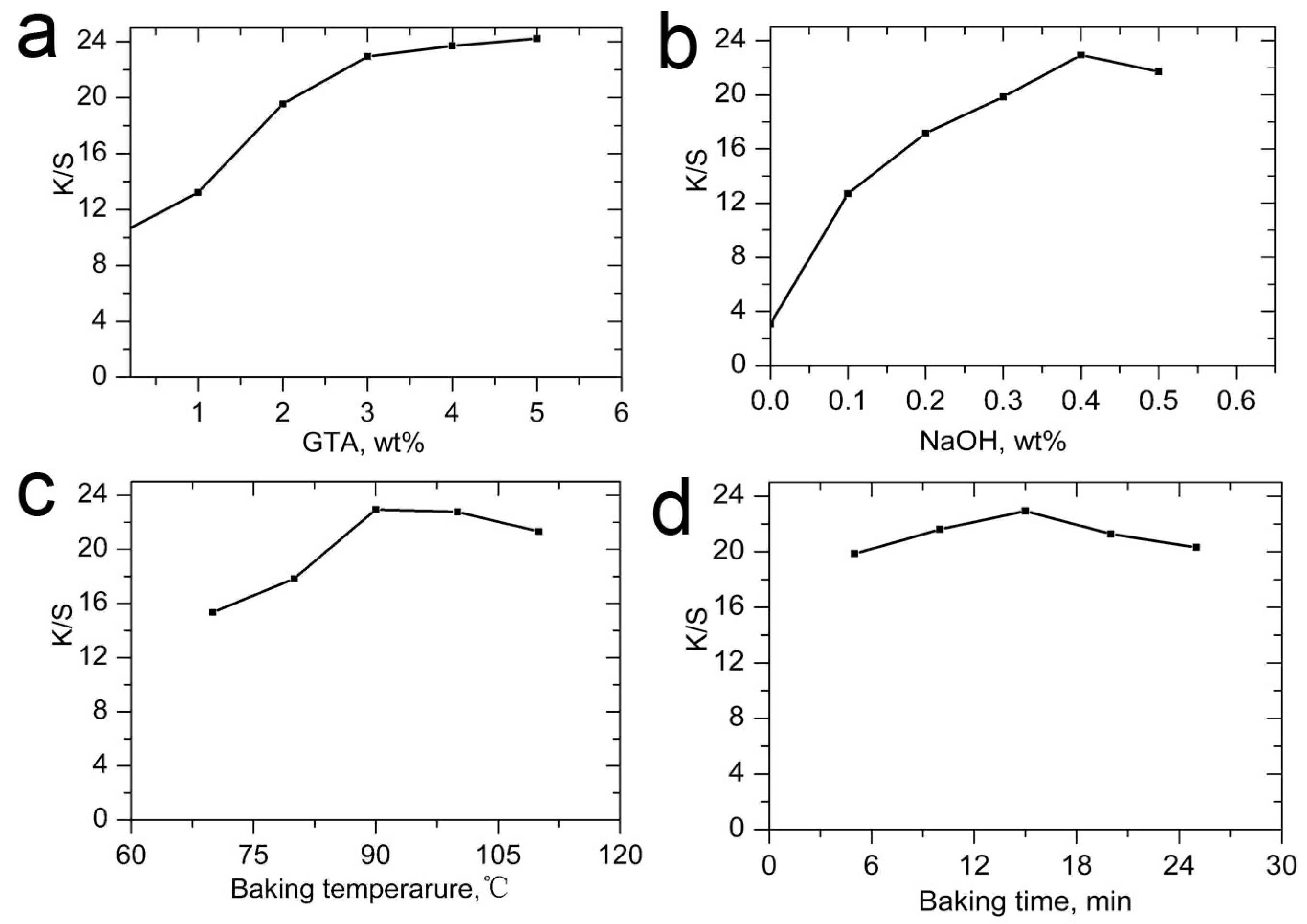

2.1. Effect of Concentration of GTA on Color Yield of Magenta Ink

2.2. Effect of NaOH Concentration

2.3. Effect of Baking Temperature

2.4. Effect of Baking Time on K/S of Magenta Ink

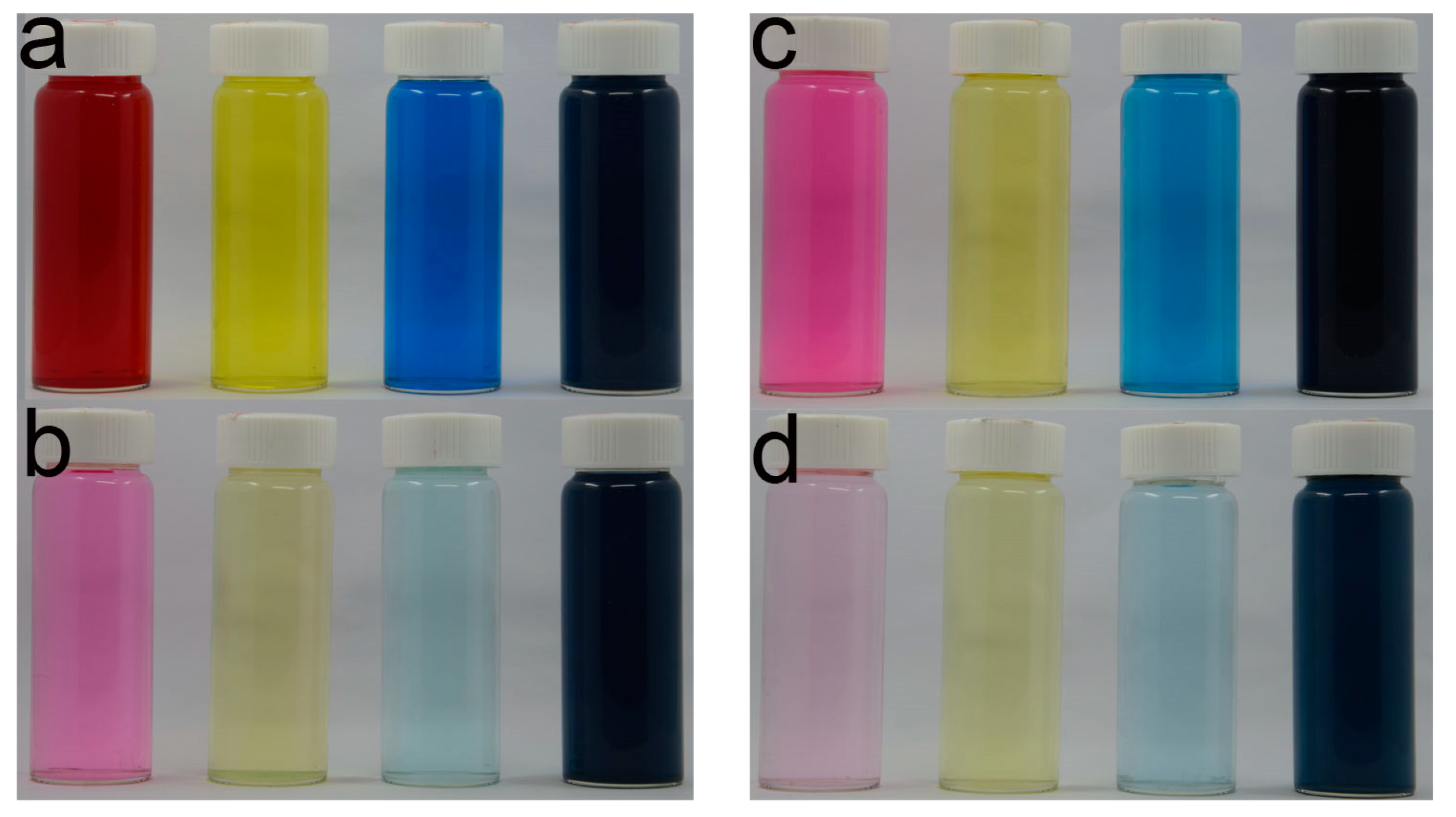

2.5. Stability of the Pretreatment Agent

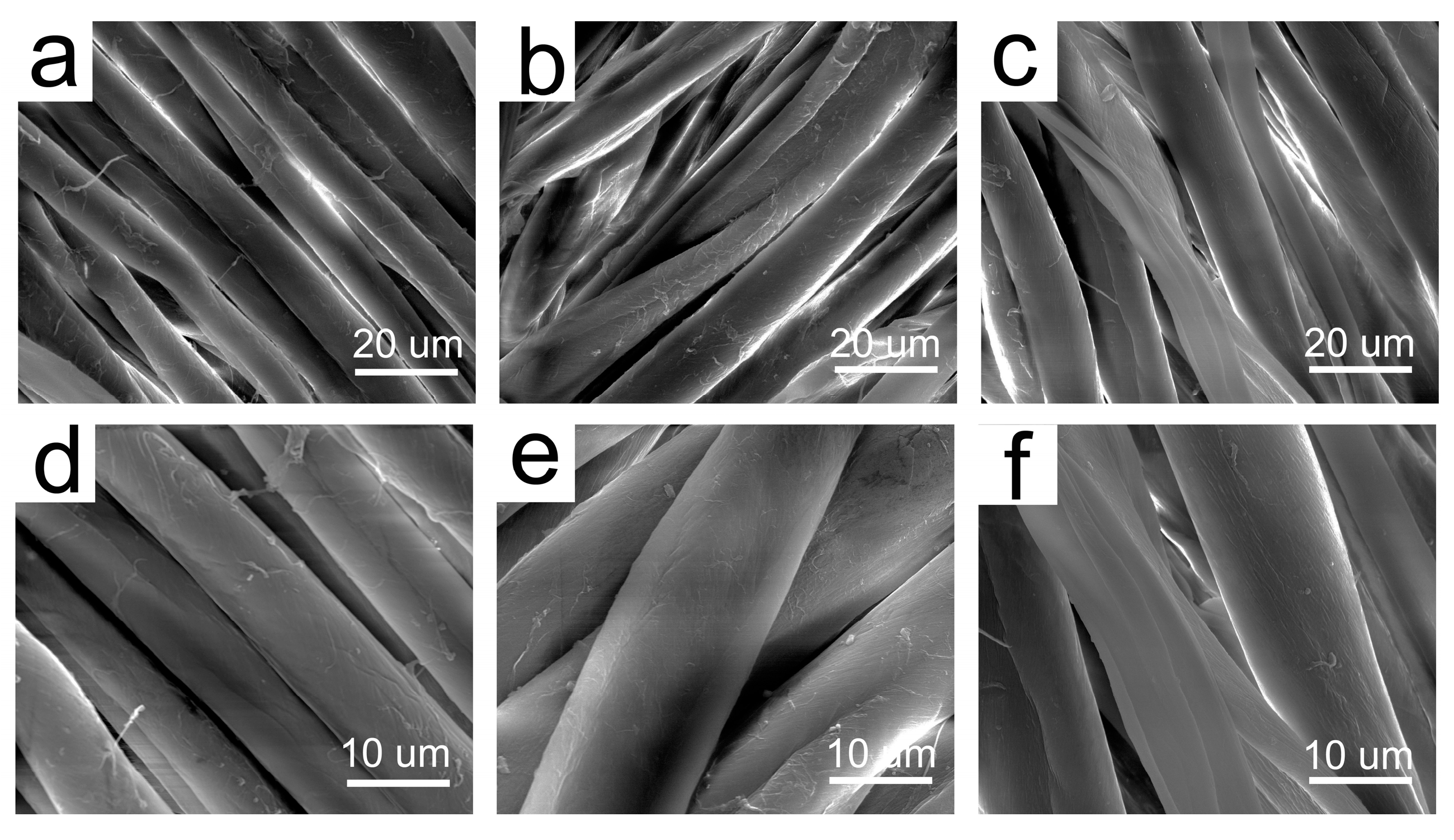

2.6. Surface Morphology

2.7. Tear Strength

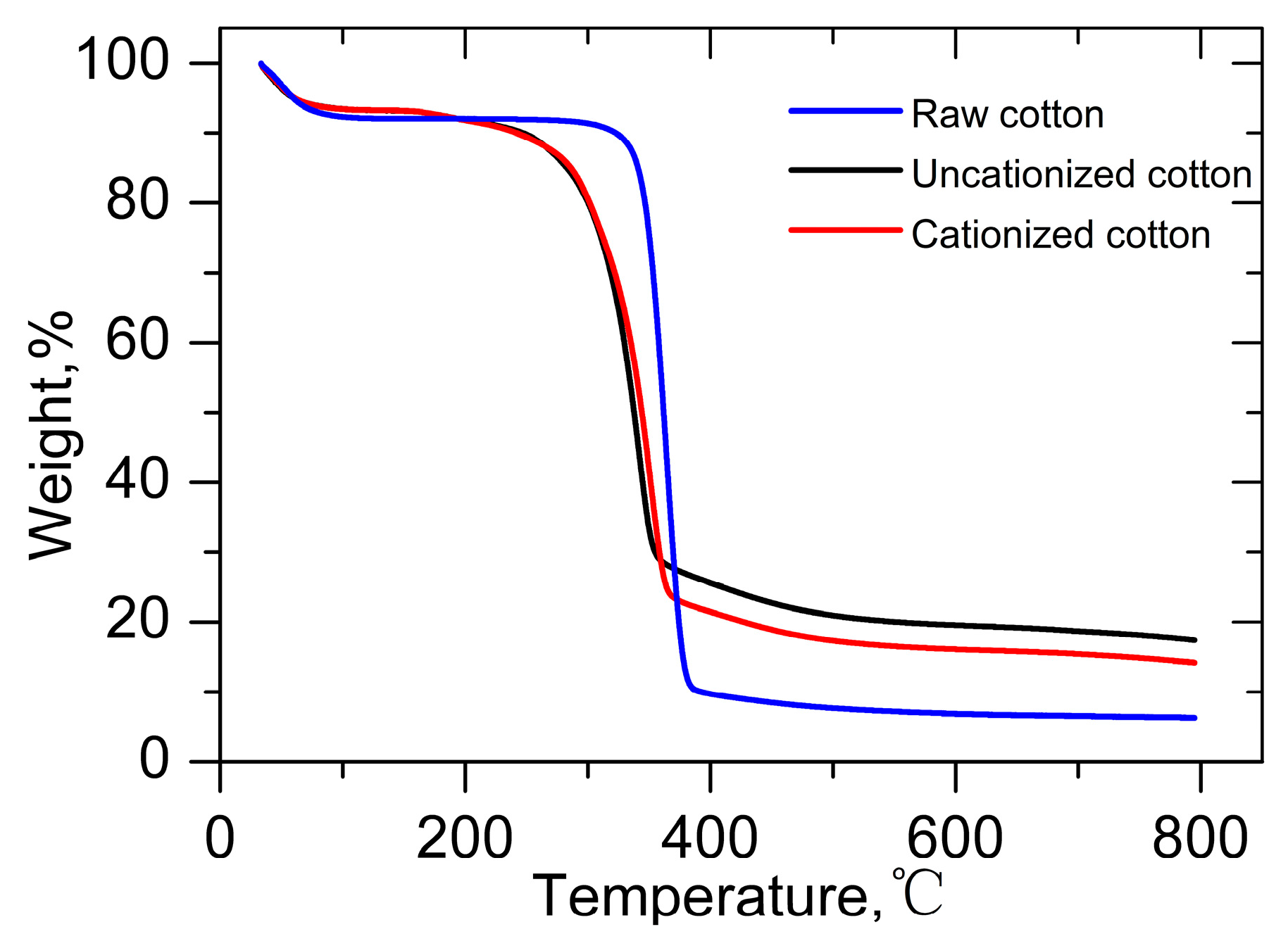

2.8. Determination of Thermal Properties

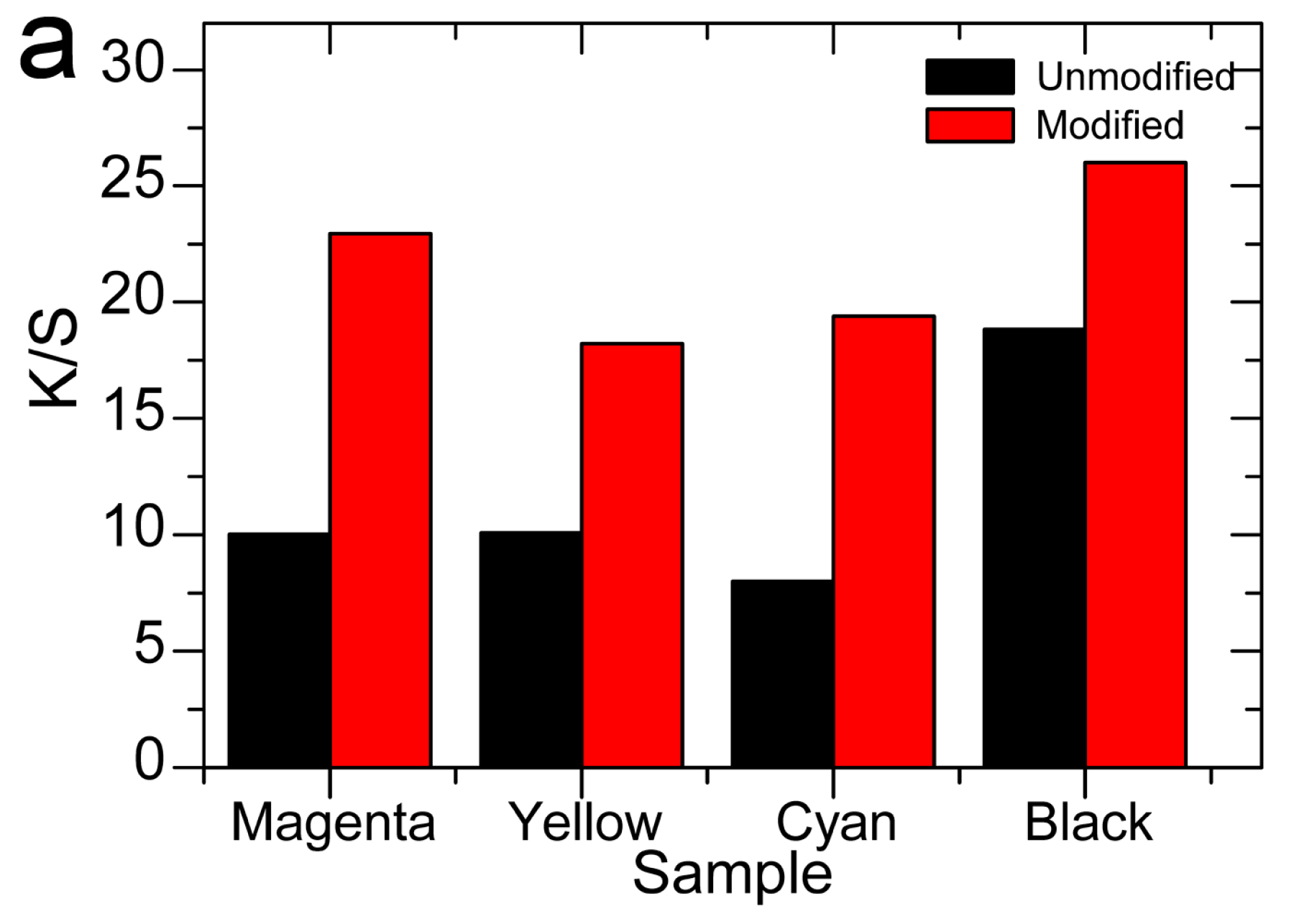

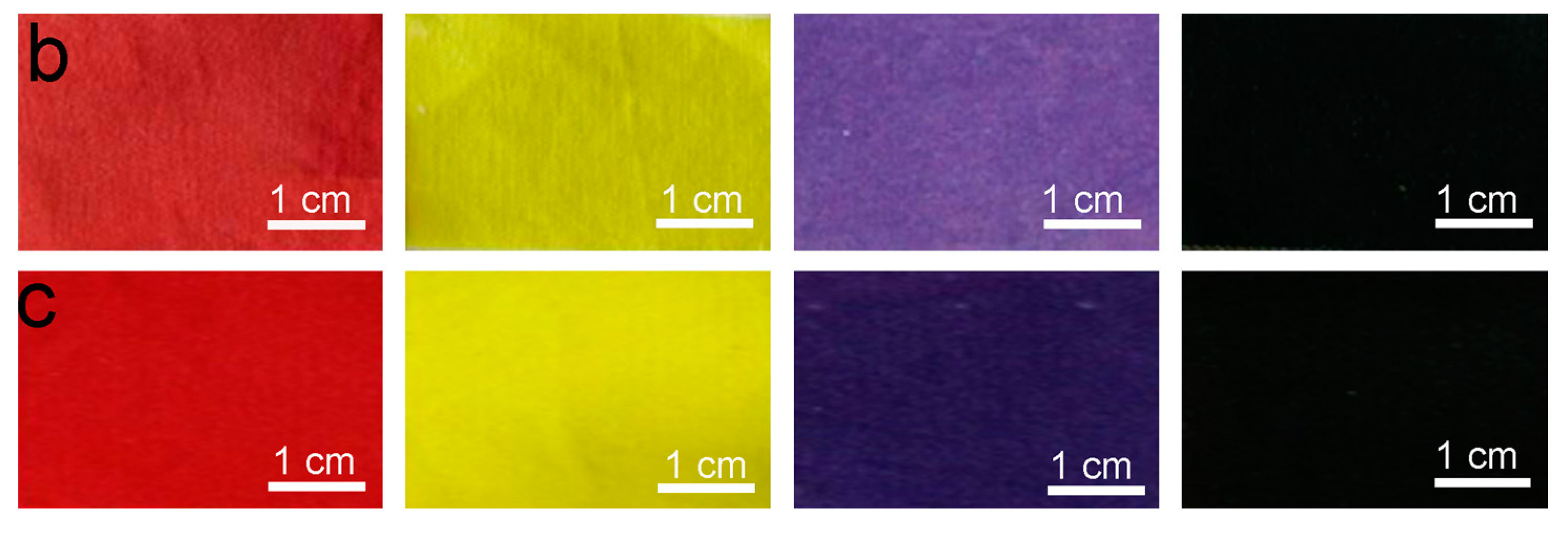

2.9. Effect of GTA Modification on Different Colors of Ink and Colorfastness

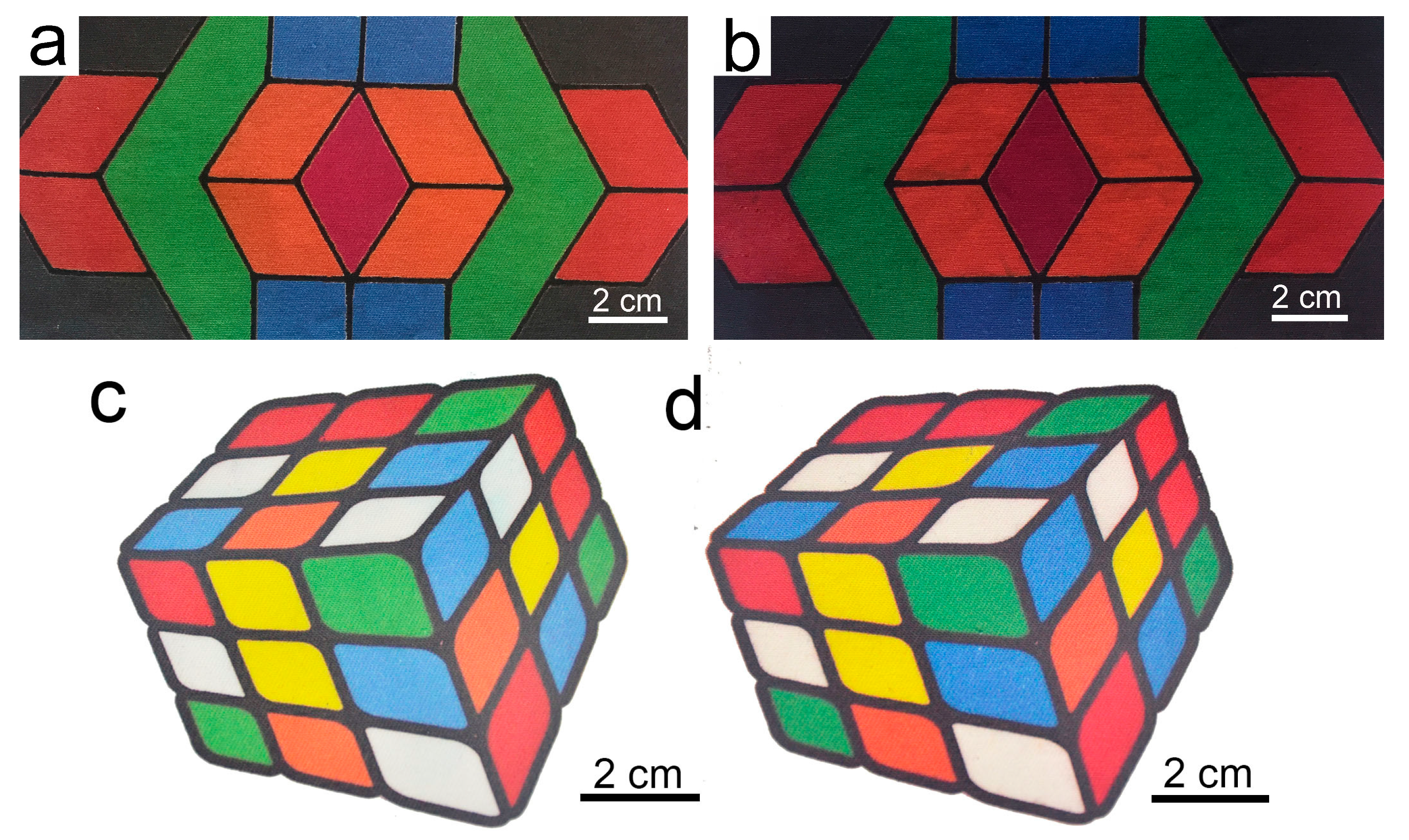

2.10. Colorful Pictures

3. Experimental

3.1. Materials

3.2. Pretreatment of Cotton Fabrics

3.3. Ink-Jet Printing

3.4. Wash-Off Procedure

3.5. Measurement of Color Yield

3.6. Determination of Nitrogen Content

3.7. Scanning Electronic Microscopy

3.8. Thermogravimetric Analysis

3.9. Tear Strength Testing

3.10. Colorfastness Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kan, C.W.; Yuen, C.W.M.; Tsoi, W.Y. Using atmospheric pressure plasma for enhancing the deposition of printing paste on cotton fabric for digital ink-jet printing. Cellulose 2011, 18, 827–839. [Google Scholar] [CrossRef]

- Liu, Z.; Fang, K.; Gao, H.; Liu, X.; Zhang, J. Effect of cotton fabric pretreatment on drop spreading and colour performance of reactive dye inks. Color. Technol. 2016, 132, 407–413. [Google Scholar] [CrossRef]

- Pransilp, P.; Pruettiphap, M.; Bhanthumnavin, W.; Paosawatyanyong, B.; Kiatkamjornwong, S. Surface modification of cotton fabrics by gas plasmas for color strength and adhesion by inkjet ink printing. Appl. Surf. Sci. 2016, 364, 208–220. [Google Scholar] [CrossRef]

- Soleimani-Gorgani, A.; Najafi, F.; Karami, Z. Modification of cotton fabric with a dendrimer to improve ink-jet printing process. Carbohydr. Polym. 2015, 131, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Guan, F.L.; Zhang, L.Y.; Li, Y.H. Color management for enhancing the performance of superfine nylon ink jet printing with reactive dyes inks. Color. Res. Appl. 2017, 42, 346–351. [Google Scholar] [CrossRef]

- Kaimouz, A.W.; Wardman, R.H.; Christie, R.M. Ink-jet printing process for lyocell and cotton fibres. Part 2: The relationship of colour strength and dye fixation to ink penetration. Color. Technol. 2010, 126, 342–347. [Google Scholar] [CrossRef]

- Chapman, K. Printing 2002: A digital odyssey—New developments give us more reasons to invest in digital textile technology. AATCC Rev. 2002, 2, 12–15. [Google Scholar]

- Eckman, A.L. Developments in textile inkjet printing—Working towards wider acceptance. AATCC Rev. 2004, 4, 8–11. [Google Scholar]

- Ervine, S.; Siegel, B.; Siemensmeyer, K. A simple, universal approach to ink jet printing textile fabrics. Text. Chem. Color. Am. D 2000, 32, 26–27. [Google Scholar]

- Gupta, S. Inkjet printing—A revolutionary ecofriendly technique for textile printing. Indian J. Fibre Text. 2001, 26, 156–161. [Google Scholar]

- Patino, A.; Canal, C.; Rodriguez, C.; Caballero, G.; Navarro, A.; Canal, J.M. Surface and bulk cotton fibre modifications: Plasma and cationization. Influence on dyeing with reactive dye. Cellulose 2011, 18, 1073–1083. [Google Scholar] [CrossRef]

- Soleimani-Gorgani, A.; Karami, Z. The effect of biodegradable organic acids on the improvement of cotton ink-jet printing and antibacterial activity. Fiber Polym. 2016, 17, 512–520. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Wang, C.X.; Chen, K.L.; Yin, Y.J. Improvement of ink-jet printing performances using β-cyclodextrin forming inclusion complex on cotton fabric. Fiber Polym. 2017, 18, 619–624. [Google Scholar] [CrossRef]

- Wang, L.L.; Ma, W.; Zhang, S.F.; Teng, X.X.; Yang, J.Z. Preparation of cationic cotton with two-bath pad-bake process and its application in salt-free dyeing. Carbohydr. Polym. 2009, 78, 602–608. [Google Scholar] [CrossRef]

- Teng, X.X.; Zhang, S.F.; Ma, W. Application of a hydrolyzable cationic agent, poly(acryloxyethyl trimethylammonium chloride), in salt-free reactive dyeing for good dyeing properties. J. Appl. Polym. Sci. 2011, 122, 2741–2748. [Google Scholar] [CrossRef]

- Egbuta, M.A.; McIntosh, S.; Waters, D.L.; Vancov, T.; Liu, L. Biological importance of cotton by-products relative to chemical constituents of the cotton plant. Molecules 2017, 22. [Google Scholar] [CrossRef] [PubMed]

- Le, H.P. Progress and trends in ink-jet printing technology. J. Imaging Sci. Technol. 1998, 42, 49–62. [Google Scholar]

- Fan, Q.G.; Kim, Y.K.; Perruzzi, M.K.; Lewis, A.F. Fabric pretreatment and digital textile print quality. J. Imaging Sci. Technol. 2003, 47, 400–407. [Google Scholar]

- Yuen, C.W.M.; Ku, S.K.A.; Choi, P.S.; Kan, C.W. The effect of the pretreatment print paste contents on colour yield of an ink-jet printed cotton fabric. Fiber Polym. 2004, 5, 117–121. [Google Scholar] [CrossRef]

- Kaimouz, A.W.; Wardman, R.H.; Christie, R.M. The inkjet printing process for lyocell and cotton fibres. Part 1: The significance of pre-treatment chemicals and their relationship with colour strength, absorbed dye fixation and ink penetration. Dyes Pigments 2010, 84, 79–87. [Google Scholar] [CrossRef]

- Khatri, A.; Peerzada, M.H.; Mohsin, M.; White, M. A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J. Clean. Prod. 2015, 87, 50–57. [Google Scholar] [CrossRef]

- Chen, W.G.; Zhao, S.C.; Wang, X.G. Improving the color yield of ink-jet printing on cationized cotton. Text. Res. J. 2004, 74, 68–71. [Google Scholar] [CrossRef]

- Kanik, M.; Hauser, P.J. Ink-jet printing of cationised cotton using reactive inks. Color. Technol. 2003, 119, 230–234. [Google Scholar] [CrossRef]

- Montazer, M.; Malek, R.M.A.; Rahimi, A. Salt free reactive dyeing of cationized cotton. Fiber Polym. 2007, 8, 608–612. [Google Scholar] [CrossRef]

- Bu, G.J.; Wang, C.X.; Fu, S.H.; Tian, A.L. Water-soluble cationic chitosan derivative to improve pigment-based inkjet printing and antibacterial properties for cellulose substrates. J. Appl. Polym. Sci. 2012, 125, 1674–1680. [Google Scholar] [CrossRef]

- Choi, P.S.R.; Yuen, C.W.M.; Ku, S.K.A.; Kan, C.W. Digital ink-jet printing for chitosan-treated cotton fabric. Fiber Polym. 2005, 6, 229–234. [Google Scholar] [CrossRef]

- Yuen, C.W.M.; Ku, S.K.A.; Kan, C.W.; Choi, P.S.R. A two-bath method for digital ink-jet printing of cotton fabric with chitosan. Fiber Polym. 2007, 8, 625–628. [Google Scholar] [CrossRef]

- Yuen, C.W.M.; Ku, S.K.A.; Kan, C.W.; Choi, P.S.R. Enhancing textile ink-jet printing with chitosan. Color. Technol. 2007, 123, 267–270. [Google Scholar] [CrossRef]

- Liu, Z.T.; Yang, Y.N.; Zhang, L.L.; Liu, Z.W.; Xiong, H.P. Study on the cationic modification and dyeing of ramie fiber. Cellulose 2007, 14, 337–345. [Google Scholar] [CrossRef]

- Kanik, M.; Hauser, P.J. Printing of cationised cotton with reactive dyes. Color. Technol. 2002, 118, 300–306. [Google Scholar] [CrossRef]

- Jordinson, F.; Lockwood, R. Further notes on reactive dyes and their identification on cellulosic fibres. J. Soc. Dyers Colour. 1964, 80, 202–204. [Google Scholar] [CrossRef]

- Lewis, D.M.; Lei, X.P. New methods for improving the dyeability of cellulose fibers with reactive dyes. J. Soc. Dyers Colour. 1991, 107, 102–109. [Google Scholar] [CrossRef]

- Alimohammadi, F.; Gashti, M.P.; Shamei, A.; Kiumarsi, A. Deposition of silver nanoparticles on carbon nanotube by chemical reduction method: Evaluation of surface, thermal and optical properties. Superlattice Microstruct. 2012, 52, 50–62. [Google Scholar] [CrossRef]

- Cabrales, L.; Abidi, N. On the thermal degradation of cellulose in cotton fibers. J. Therm. Anal. Calorim. 2010, 102, 485–491. [Google Scholar] [CrossRef]

- Tian, H.Y.; Wei, X.F.; Huang, B.Q. Influence of ink performance on ink-jet printing quality. Appl. Mech. Mater. 2014, 469, 348–353. [Google Scholar] [CrossRef]

Sample Availability: Ink-jet printed samples of this paper are available from the authors. |

| Cotton | Warp (N) | Weft (N) |

|---|---|---|

| Raw | 12.4 | 10.2 |

| Uncationized | 12.2 | 9.8 |

| Cationized | 12.1 | 9.5 |

| Color | Cotton | K/S | L | a | b | Wash Fastness | Crock Fastness | Light Fastness | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Change | Staining | Dry | Wet | ||||||||

| Cotton | Wool | ||||||||||

| Magenta | I | 10.03 | 39.86 | 47.95 | 23.90 | 4–5 | 4–5 | 4–5 | 4–5 | 3–4 | 3–4 |

| II | 22.94 | 35.91 | 48.60 | 19.57 | 4–5 | 4–5 | 4–5 | 4–5 | 4–5 | 5 | |

| Yellow | I | 10.07 | 84.00 | −11.28 | 87.16 | 5 | 4–5 | 4–5 | 4–5 | 4 | 5 |

| II | 18.22 | 79.07 | −13.27 | 82.53 | 4–5 | 4 | 4–5 | 4–5 | 4–5 | 6 | |

| Cyan | I | 8.00 | 34.11 | 13.37 | −31.46 | 4–5 | 4–5 | 4–5 | 4–5 | 4 | 3 |

| II | 19.40 | 24.72 | 12.37 | −32.09 | 4–5 | 4–5 | 4–5 | 4–5 | 3–4 | 3–4 | |

| Black | I | 18.83 | 18.30 | –0.39 | −3.54 | 4–5 | 4–5 | 4–5 | 5 | 4 | 4 |

| II | 26.01 | 15.96 | 0.11 | −3.45 | 4–5 | 4–5 | 4–5 | 4–5 | 3–4 | 4 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Shen, K.; Li, S.; Zhan, M.; Zhang, S. One-Bath Pretreatment for Enhanced Color Yield of Ink-Jet Prints Using Reactive Inks. Molecules 2017, 22, 1959. https://doi.org/10.3390/molecules22111959

Ma W, Shen K, Li S, Zhan M, Zhang S. One-Bath Pretreatment for Enhanced Color Yield of Ink-Jet Prints Using Reactive Inks. Molecules. 2017; 22(11):1959. https://doi.org/10.3390/molecules22111959

Chicago/Turabian StyleMa, Wei, Kezhan Shen, Shuang Li, Meichen Zhan, and Shufen Zhang. 2017. "One-Bath Pretreatment for Enhanced Color Yield of Ink-Jet Prints Using Reactive Inks" Molecules 22, no. 11: 1959. https://doi.org/10.3390/molecules22111959