1. Introduction

Originated from Mexico, vanilla is one of the most important and popular aromatic spices, now widely planted in tropical and subtropical areas [

1]. It has attracted much interest because of its multiple important applications in herbal cigarettes, alcoholic beverages, foodstuffs, cosmetics and aromatherapy [

2,

3]. Fully mature vanilla is called vanilla beans which are the fruits of

Vanilla planifolia Andrews (Orchidaceae). The original unprocessed vanilla beans are flavorless until they are processed under a laborious curing process that lasts more than 6 months to give them their characteristic aroma [

4,

5].

The single most characteristic component of vanilla flavor is vanillin (4-hydroxy-3-methoxybenzaldehyde) [

5,

6]. Since vanilla is one of the most expensive and desirable spices, efforts to increasing the production of natural, effective, and safe vanillin have never stopped because the application of synthetic vanillin in valued food products is restricted due to the concerns about its safety [

7,

8]. Therefore, a market-driven strong need for high-quality natural vanillin has continuously pushed up its price in recent years.

Plant materials are rich in natural phytochemicals such as flavour compounds. They are difficult to separate because of their chemical sequestration, mainly by natural polymers such as pectins, which leads to incomplete solvent extraction [

1,

9]. Vanilla belongs to the monocots and is rich in pectin substances [

10]. The glucovanillin content in green vanilla beans ranged from 10% to 15% (dry weight basis) which could produce between 4.8% and 7.3% vanillin [

4]. The natural vanilla beans are flavorless because: (1) glucovanillin is exclusively located in the placentae and papillae while β-glucosidase is concentrated in the cytoplasm of mesocarp and endocarp, so the enzymatic reaction between the glucovanallin substrate and the enzyme cannot happen; (2) it is regulated by cellular compartmentation [

11,

12]. As a result, different kinds of processing technologies to increase the vanillin production from natural vanilla beans have been investigated. Partial cell destruction by mechanic forces and/or the use of enzymes to make intracellular compounds more readily available for separation and solvent extraction have been studied. The ‘scalding’ and ‘sweating’ stages of vanilla curing initiate the release of vanillin due to cellular decompartmentation as recently reported by Pérez-Silva

et al. [

6] The cellular compartmentation of the green vanilla beans could be disrupted by freezing and thawing so as to increase the extractability of vanillin as reported by Odoux

et al. [

12], and by Ansaldi

et al. who filed a patent [

13]. Some other investigators have studied the treatment of cured beans using exogenous pectinase and β-glycosidase to increase the vanillin yield [

1,

14]. Other researchers have investigated the effects of exogenous cellulase, pectinase, β-glycosidase and an enzyme extracted from tea leaf on the vanillin yield and vanilla flavor using green vanilla beans as raw material [

2,

3,

5,

9,

15]. In addition, cellular disruption by mechanical means and freezing together with added pectinase, cellulase, and β-glusosidase increased the vanillin yield from the green vanilla beans as reported by Perera and Owen [

4]. By contrast, the traditional extraction methods for vanillin are commonly associated with longer extraction times, higher temperatures and more organic solvent consumption, despite their lower extraction efficiency. In recent years, enzyme-assisted extraction has undoubtedly emerged as a new technology applied in many kinds of processing in the food industry since it has many advantages, such as faster extraction, higher recovery, reduced solvent usage, simplified processing and lower energy consumption when compared to the non-enzymatic methods. Thus, enzyme-assisted extraction has been considered an effective, feasible and practical technique for the extraction of vanillin. Immobilization shows many advantages for enzymes such as enhancing enzyme activity, stability, resistance to inhibition, selectivity towards non-natural substrates and so on [

16,

17]. Enzyme immobilization technology could be one way to further improve the process of enzyme reaction. However, to the best of our knowledge, none of the reported investigations involve the use of pectinase-assisted extraction combined with pre-freezing and thawing to produce vanillin from vanilla beans. Furthermore, compared with many other studies of the enzyme-assisted extraction in other applications, little effort has been devoted to optimizing the production of vanillin from green vanilla beans with this method.

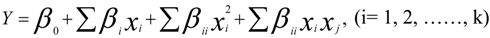

Response surface methodology (RSM) is a powerful and efficient mathematical approach that enables evaluation of several process parameters such as time, temperature, enzyme type and concentration [

18,

19,

20,

21]. It can determine parameters’ interactions, the best optimal condition of the process, and the effect of factors on characteristic properties [

19,

21,

22]. In addition, it is less laborious and can provide more information of the variables than other approaches. RSM has been found to be successful and economical during optimization of various industrial extraction processes [

18,

23].

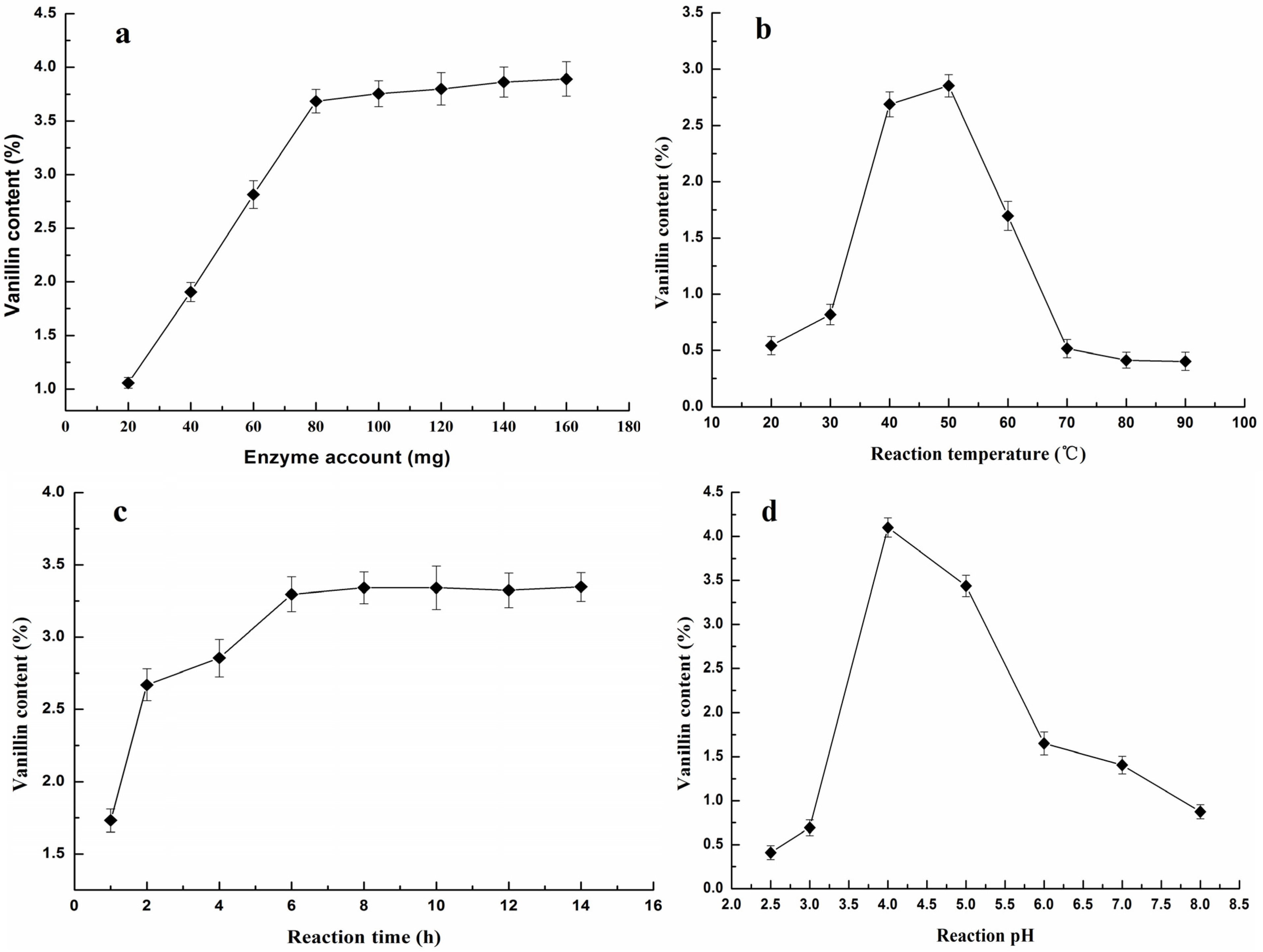

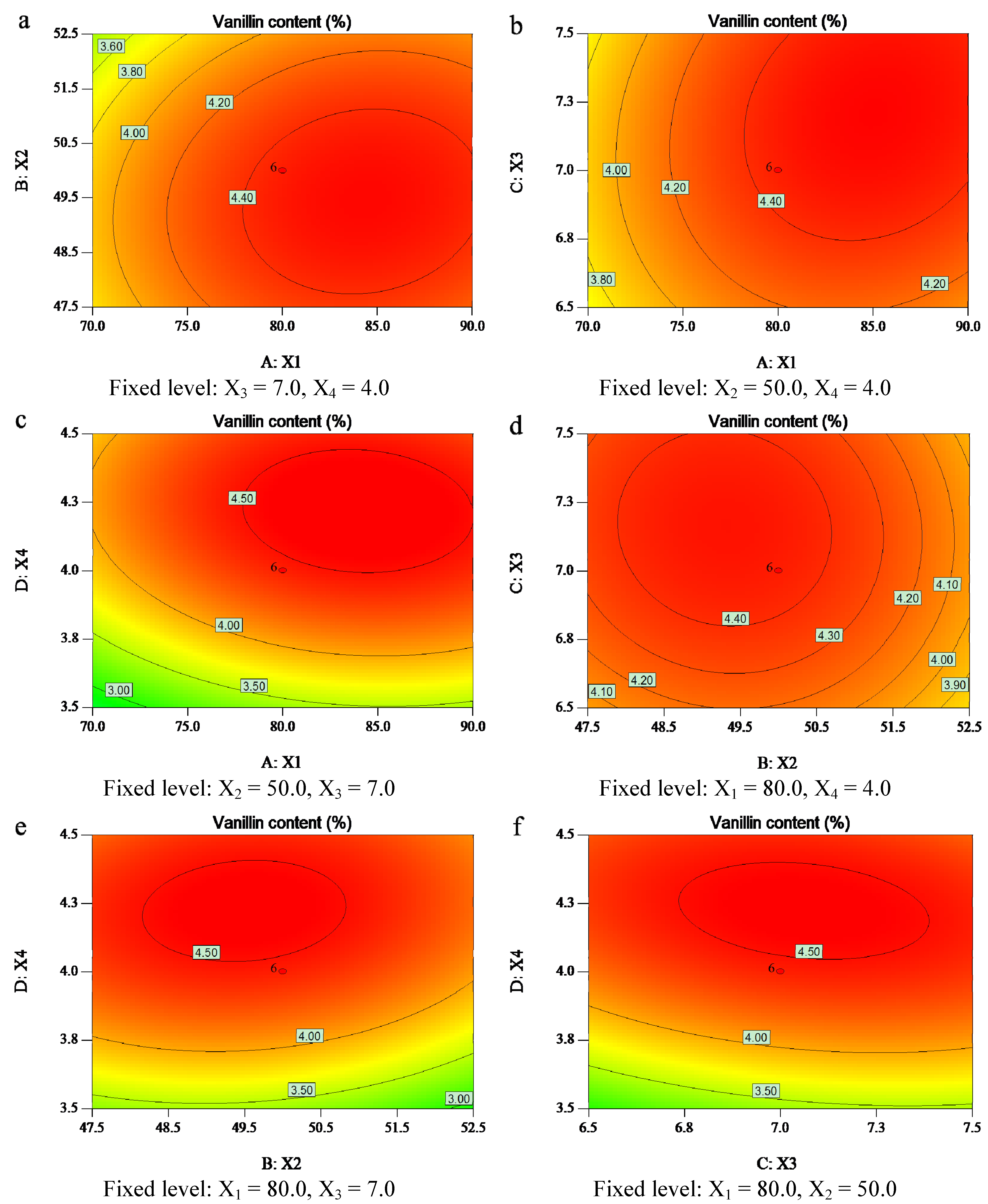

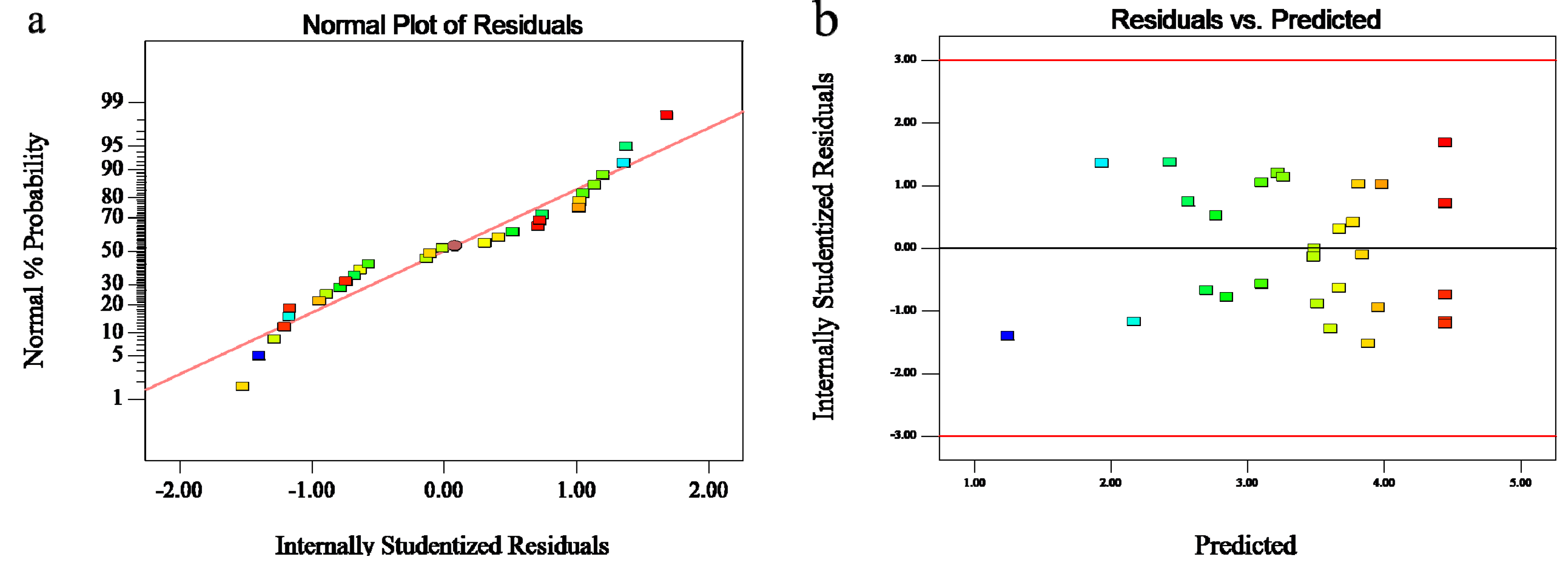

The purpose of the present study was to produce vanillin from vanilla beans by using the technique of pectinase-assisted extraction combined with pre-freezing and thawing, and then optimize the process. Compared to previous research, enzyme-assisted extraction combined with pre-freezing and thawing could significantly increase the vanillin content from green vanilla pods. The green vanilla pods were first pre-frozen and then thawed in order to destroy cellular compartmentation. The extraction reactions referred to various aspects including enzyme amount, temperature, time, and pH. The pectinase amount, reaction temperature, time, and pH were identified as key factors influencing the extraction of vanillin based on our preliminary experiments. In the first part of this study, the process for extraction of vanillin from the vanilla beans was optimized by employing a central composite design (CCD) (four factors and five levels) and RSM to study the effects of the abovementioned variables on vanillin production. In the second part, the experimental model was validated by the optimized method. Finally, the method was compared with the traditional curing and viscozyme extraction methods.