Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying

Abstract

:1. Introduction

2. Experimental Details

| Plasma gas | Ar/H2 |

|---|---|

| Primary gas flow, Ar (L/min) | 90 |

| Second gas flow (L/min) | 5 |

| Arc voltage (V) | 110 |

| Arc current (A) | 330 |

| Powder feeding rate (g/min) | 30 |

| Spray distance (mm) | 100 |

3. Results and Discussion

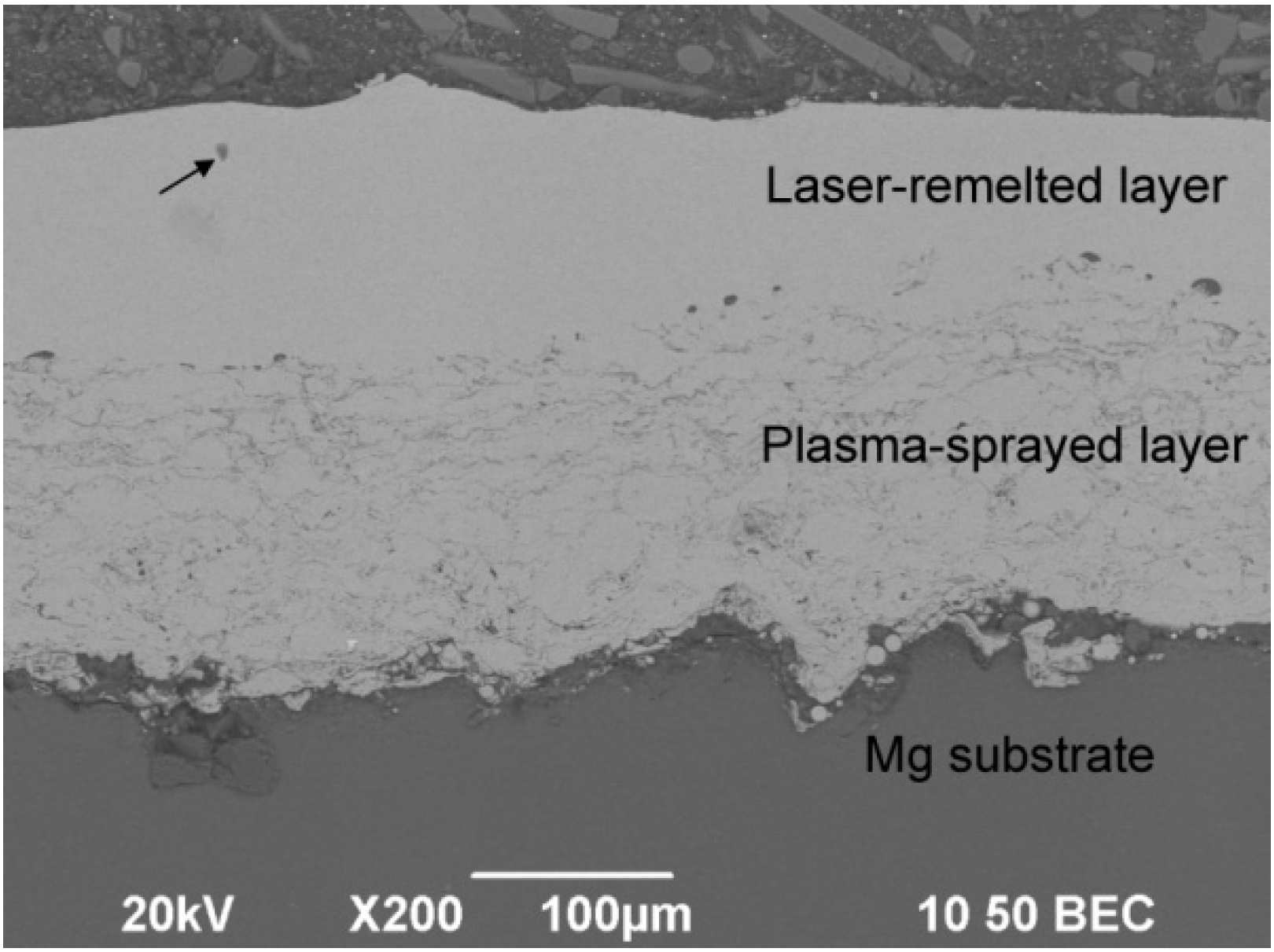

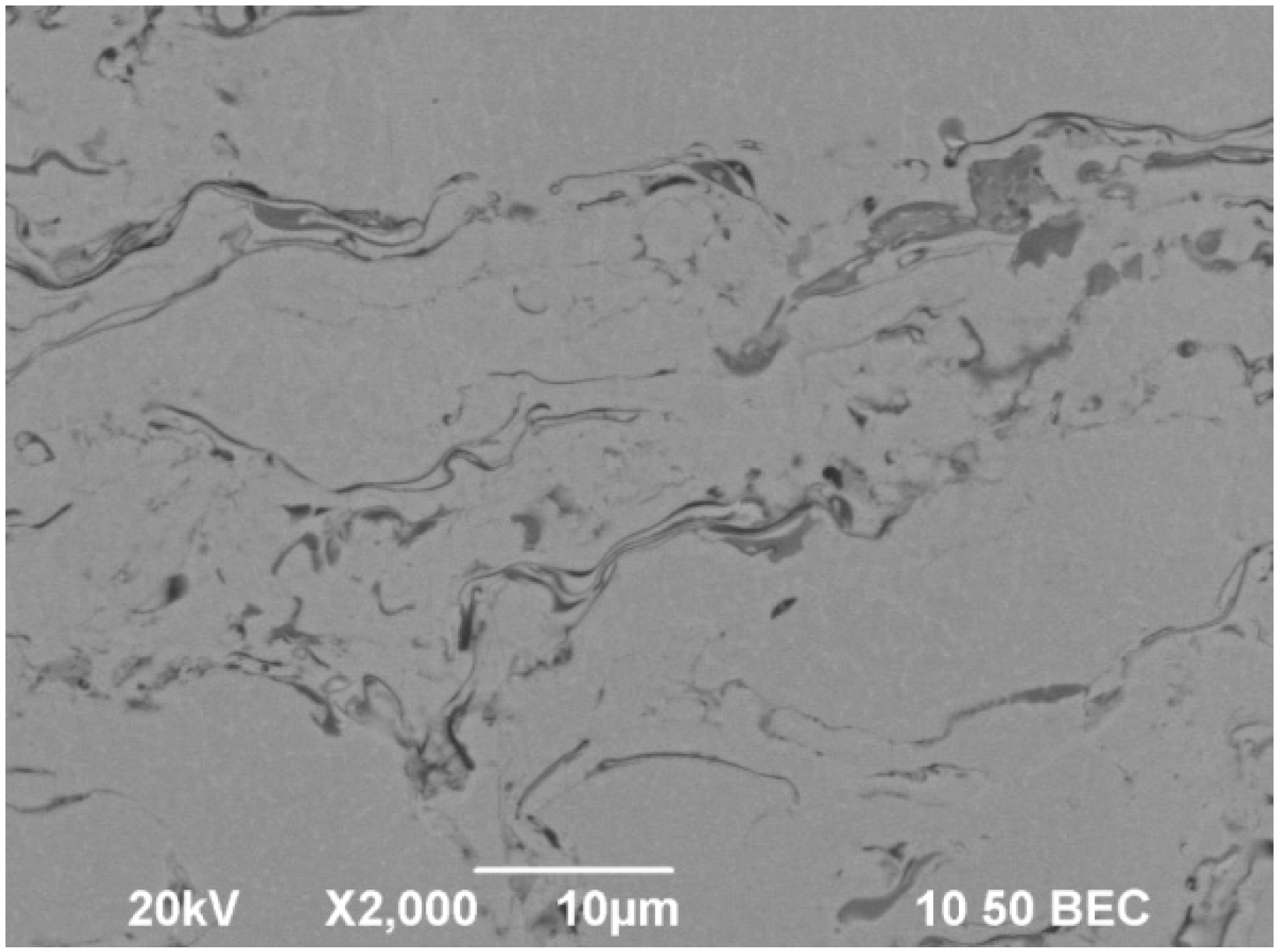

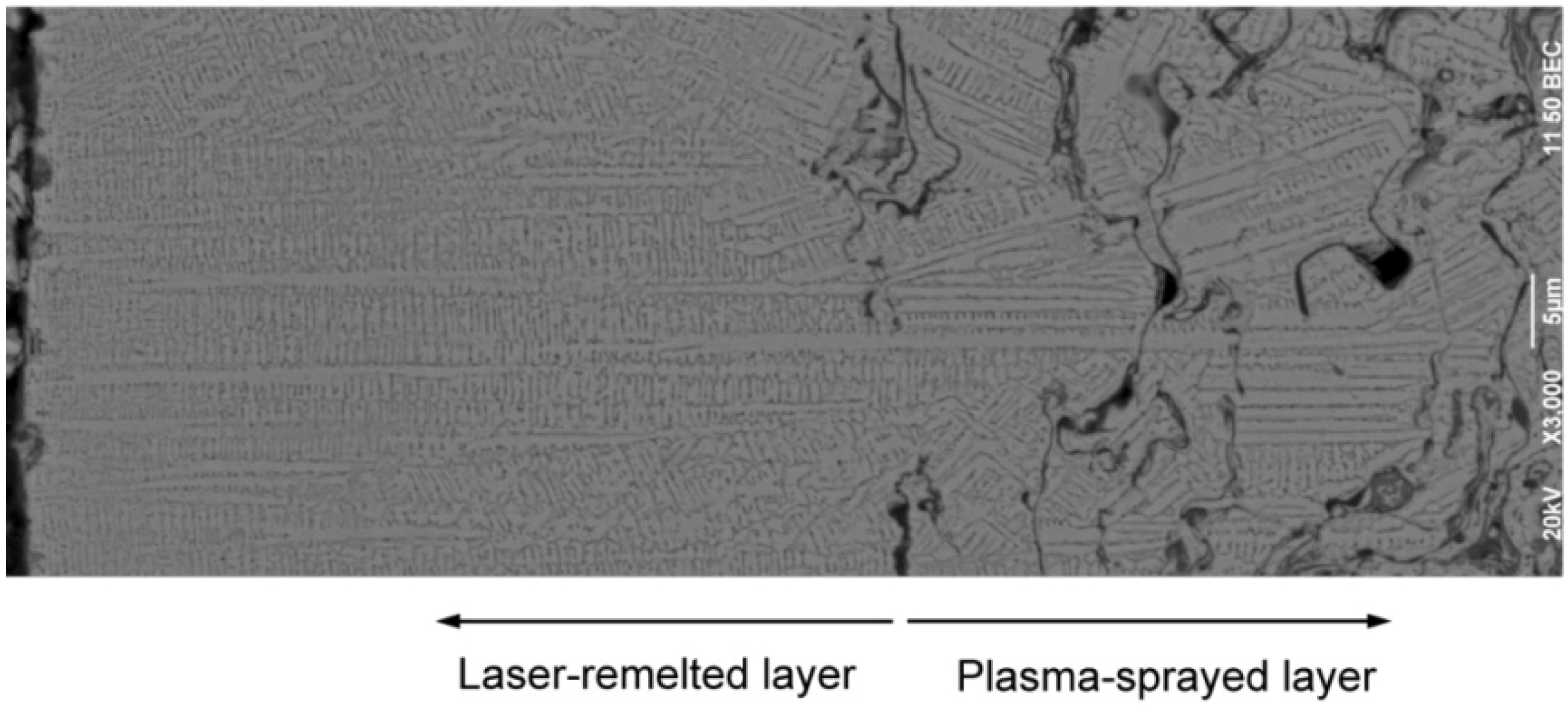

3.1. Microstructure and Epitaxial Growth

| Al | Cr | Fe | Co | Ni | Cu | |

|---|---|---|---|---|---|---|

| Dendrite | 11.50 | 18.96 | 19.22 | 19.68 | 19.06 | 11.56 |

| Interdendritic | 12.94 | 17.31 | 18.05 | 19.04 | 17.51 | 15.14 |

| Liquidus temperature of AlCoCrCuFeNi, TL | 1501.17 K * |

| Gibbs-Thomson coefficient, Γ | 2.47 × 10−7 K m |

| Linear kinetic coefficient, µk | 4.696 m/s K |

| Length scale for solute trapping, a0 | 5 × 10−9 m |

| Latent heat, ΔH | 4.3992 × 104 J mol−1 |

| Concentration of chromium, C0Cr | 16.67 at% |

| Concentration of cobalt, C0Co | 16.67 at% |

| Concentration of iron, C0Fe | 16.67 at% |

| Concentration of aluminum, C0Al | 16.67 at% |

| Concentration of copper, C0Cu | 16.67 at% |

| Partition coefficient for chromium, kCr | 0.237 * |

| Partition coefficient for cobalt, kCo | 1.148 * |

| Partition coefficient for iron, kFe | 0.512 * |

| Partition coefficient for aluminum, kAl | 2.02 * |

| Partition coefficient for copper, kCu | 0.399 |

| Slope of liquidus surface with respect to aluminum concentration, mAl | 15.36 K/at% * |

| Slope of liquidus surface with respect to cobalt concentration, mCo | −1.039 K/at% * |

| Slope of liquidus surface with respect to chromium concentration, mCr | −2.625 K/at% * |

| Slope of liquidus surface with respect to iron concentration, mFe | −3.175 K/at% * |

| Slope of liquidus surface with respect to copper concentration, mCu | −3.974 K/at% * |

| Pre-exponential diffusion coefficient for aluminum, | 1.53 × 10−7 m2/s |

| Pre-exponential diffusion coefficient for cobalt, | 2.30 × 10−7 m2/s |

| Pre-exponential diffusion coefficient for chromium, | 2.22 × 10−7 m2/s |

| Pre-exponential diffusion coefficient for iron, | 2.29 × 10−7 m2/s |

| Pre-exponential diffusion coefficient for copper, | 2.15 × 10−7 m2/s |

| Activation energy for Al diffusion, QAl | 4.7893 × 10−4 J/mol |

| Activation energy for Co diffusion, QCo | 6.5314 × 10−4 J/mol |

| Activation energy for Cr diffusion, QCr | 6.6466 × 10−4 J/mol |

| Activation energy for Cu diffusion, QCu | 6.0630 × 10−4 J/mol |

| Activation energy for Fe diffusion, QFe | 6.5515 × 10−4 J/mol |

| Thermal diffusion coefficient, a | 3.89 × 10−6 m2/s |

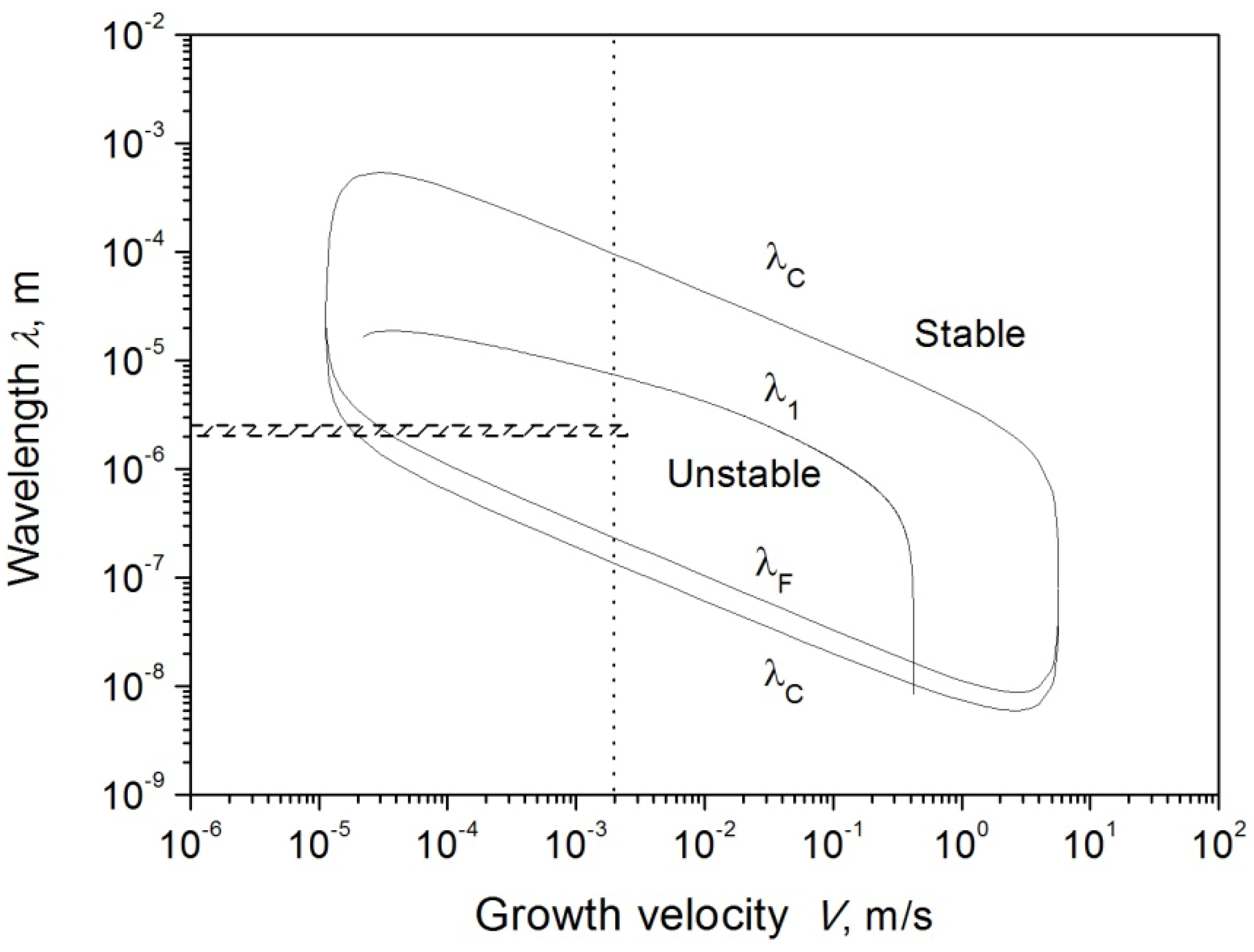

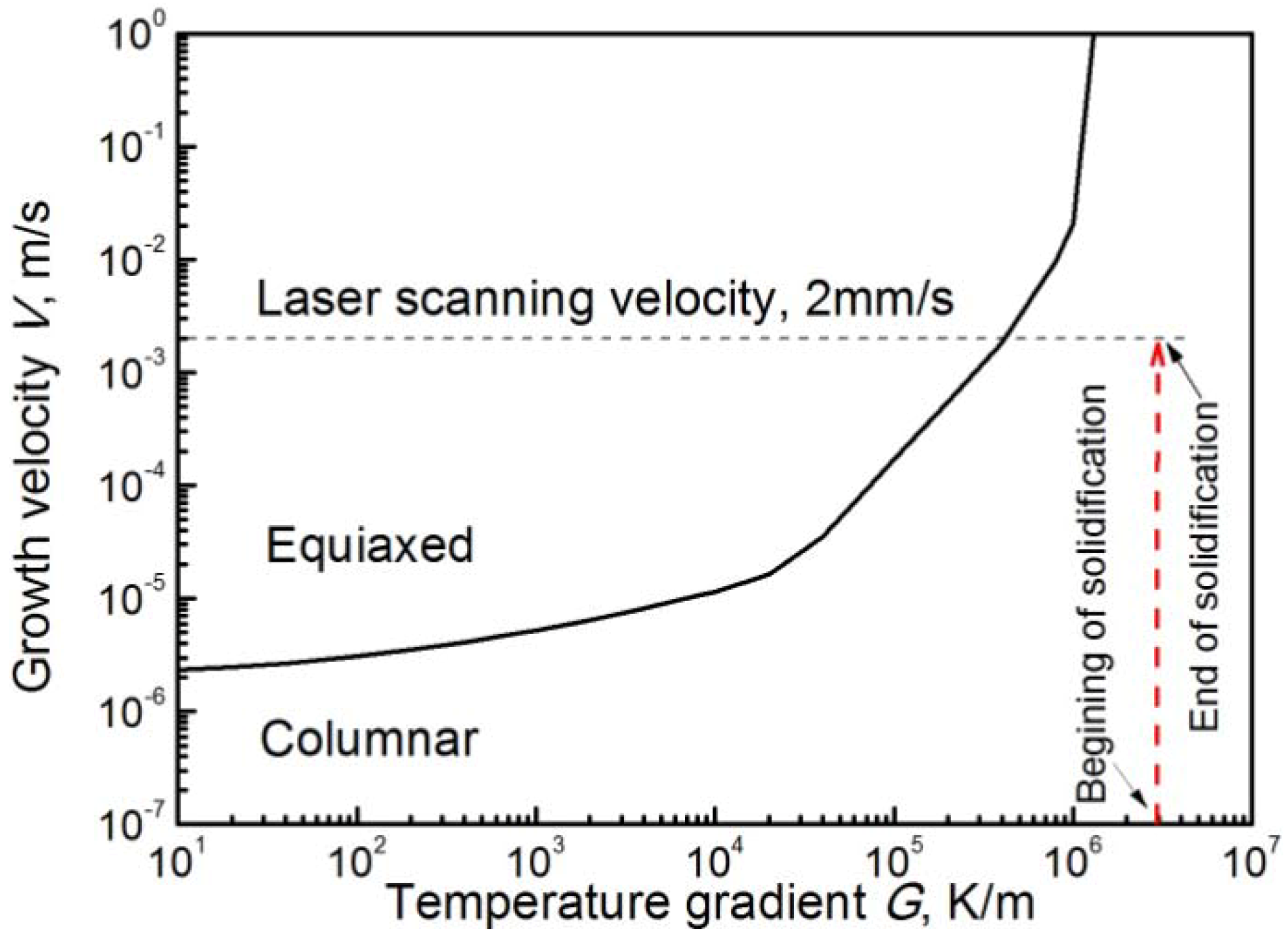

3.2. Columnar to Equiaxed Transition

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Cole, G.S. Summary of “Magnesium vision 2020: A North American automotive strategic vision for magnesium”. In Magnesium Technology 2007, Proceedings of the Symposium on Magnesium Technology, TMS Annual Meeting and Exhibition, Orlando, FL, USA, 25 February–1 March 2007; Beals, R.S., Luo, A.A., Neelameggham, N.R., Pekguleryuz, M.O., Eds.; Minerals, Metals & Materials Society: Warrendale, PA, USA, 2007; pp. 35–40. [Google Scholar]

- Dieringa, H.; Bohlen, J.; Hort, N.; Letzig, D.; Kainer, K.U. Advances in manufacturing processes for magnesium alloys. In Magnesium Technology 2007, Proceedings of the Symposium on Magnesium Technology, TMS Annual Meeting and Exhibition, Orlando, FL, USA, 25 February–1 March 2007; Beals, R.S., Luo, A.A., Neelameggham, N.R., Pekguleryuz, M.O., Eds.; Minerals, Metals & Materials Society: Warrendale, PA, USA, 2007; pp. 3–8. [Google Scholar]

- Gray, J.E.; Luan, B. Protective coatings on magnesium and its alloys—a critical review. J. Alloys Compd. 2002, 336, 88–113. [Google Scholar] [CrossRef]

- Yue, T.M.; Su, Y.P. Laser multi-layer cladding of Zr65Al7.5Ni10Cu17.5 amorphous alloy on magnesium substrates. J. Mater. Sci. 2007, 42, 6153–6160. [Google Scholar] [CrossRef]

- Yue, T.M.; Li, T. Laser cladding of Ni/Cu/Al functionally graded coating on magnesium substrate. Surf. Coat. Technol. 2008, 202, 3043–3049. [Google Scholar] [CrossRef]

- Yue, T.M.; Li, T.; Lin, X. Microstructure and phase evolution in laser cladding of Ni/Cu/Al multilayer on magnesium substrates. Metall. Mater. Trans. A 2010, 41, 212–223. [Google Scholar] [CrossRef]

- Subramanian, R.; Sircar, S.; Mazumder, J. Laser cladding of zirconium on magnesium for improved corrosion properties. J. Mater. Sci. 1991, 26, 951–956. [Google Scholar]

- Wang, A.A.; Sircar, S.; Mazumder, J. Laser cladding of Mg-Al alloys. J. Mater. Sci. 1993, 28, 5113–5122. [Google Scholar] [CrossRef]

- Maiwald, T.; Galun, R.; Mordike, B.L.; Feikus, F.J. Microstructure and corrosion properties of laser clads of magnesium base alloys for laser generated cylinder liners. Lasers Eng. 2002, 12, 227–238. [Google Scholar] [CrossRef]

- Volovitch, P.; Masse, J.E.; Fabre, A.; Barrallier, L.; Saikaly, W. Microstructure and corrosion resistance of magnesium alloy ZE41 with laser surface cladding by Al-Si powder. Surf. Coat. Technol. 2008, 202, 4901–4914. [Google Scholar] [CrossRef]

- Singh, A.; Harimkar, S.P. Laser surface engineering of magnesium alloys: A review. JOM 2012, 64, 716–733. [Google Scholar] [CrossRef]

- Yue, T.M.; Hu, Q.W.; Mei, Z.; Man, H.C. Laser cladding of stainless steel on magnesium ZK60/SiC composite. Mater. Lett. 2001, 47, 165–170. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.O. Eutectic growth in laser cladding of Zr-coating on AZ91D magnesium substrate. Mater. Trans. 2012, 53, 1119–1123. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim.-Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Li, Q.H.; Yue, T.M.; Guo, Z.N.; Lin, X. Microstructure and corrosion properties of AlCoCrFeNi high entropy alloy coatings deposited on AISI 1045 Steel by the electrospark process. Metall. Mater. Trans. A 2013, 44, 1767–1778. [Google Scholar] [CrossRef]

- Qiu, X.W.; Liu, C.G. Microstructure and properties of Al2CrFeCoCuTiNix high-entropy alloys prepared by laser cladding. J. Alloys Compd. 2013, 553, 216–220. [Google Scholar] [CrossRef]

- Braic, V.; Vladescu, A.; Balaceanu, M.; Luculescu, C.R.; Braic, M. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surf. Coat. Technol. 2012, 211, 117–121. [Google Scholar] [CrossRef]

- Li, C.J.; Sun, B. Microstructure and property of Al2O3 coating microplasma-sprayed using a novel hollow cathode torch. Mater. Lett. 2004, 58, 179–183. [Google Scholar] [CrossRef]

- Pan, Q.Y.; Lin, X.; Huang, W.D.; Li, Y.M.; Zhou, Y.H. Microstructure evolution of Cu-Mn alloy under laser rapid solidification condition-Banded structure and planar front growth. Prog. Nat. Sci. 1998, 8, 79–86. [Google Scholar]

- Arnberg, L.; Mathiesen, R.H. Imaging of aluminium alloy solidification by synchrotron X radiation. Mater. Forum 2004, 28, 47–52. [Google Scholar]

- Melo, M.L.N.M.; Rizzo, E.M.S.; Santos, R.G. Numerical model to predict the position, amount and size of microporosity formation in Al-Cu alloys by dissolved gas and solidification shrinkage. Mat. Sci. Eng. A-Struct. 2004, 374, 351–361. [Google Scholar] [CrossRef]

- Hunziker, O. Theory of plane front and dendritic growth in multicomponent alloys. Acta Mater. 2001, 49, 4191–4203. [Google Scholar] [CrossRef]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification, 4th ed.; Trans Tech Publications: Stafa-Zurich, Switzerland, 1998; p. 83. [Google Scholar]

- Lima, M.S.F.; Goldenstein, H. Morphological instability of the austenite growth front in a laser remelted iron-carbon-silicon alloy. J. Cryst. Growth 2000, 208, 709–716. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing, 4th ed.; Springer-Verlag London Limited: London, UK, 2010; pp. 317–318. [Google Scholar]

- Saunders, N.; Fahrmann, M.; Small, C.J. The application of CALPHAD calculations to Ni-based superalloys. In Superalloys 2000; Pollock, T.M., Kissinger, R.D., Bowman, R.R., Green, K.A., McLean, M., Olson, S.L., Schirra, J.J., Eds.; Minerals, Metals & Materials Society: Warrendale, PA, USA, 2000; pp. 803–811. [Google Scholar]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Laser rapid forming of SS316L/Rene88DT graded material. Mat. Sci. Eng. A-Struct. 2005, 391, 325–336. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady-state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Gäumann, M.; Trivedi, R.; Kurz, W. Nucleation ahead of the advancing interface in directional solidification. Mater. Sci. Eng. A 1997, 226, 763–769. [Google Scholar] [CrossRef]

- Lipton, J.; Kurz, W.; Trivedi, R. Rapid dendrite growth in undercooled alloys. Acta Metall. 1987, 35, 957–964. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys; Van Nostrand Reinhold Company: New York, NY, USA, 1981; p. 290. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Yue, T.M.; Xie, H.; Lin, X.; Yang, H.; Meng, G. Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying. Entropy 2013, 15, 2833-2845. https://doi.org/10.3390/e15072833

Yue TM, Xie H, Lin X, Yang H, Meng G. Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying. Entropy. 2013; 15(7):2833-2845. https://doi.org/10.3390/e15072833

Chicago/Turabian StyleYue, Tai M., Hui Xie, Xin Lin, Haiou Yang, and Guanghui Meng. 2013. "Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying" Entropy 15, no. 7: 2833-2845. https://doi.org/10.3390/e15072833