1

Center for Advanced Materials (CAM), Qatar University, Doha 2713, Qatar

2

Department of Metallurgical and Materials Engineering, Faculty of Petroleum and Mining Engineering, Suez University, Suez 43721, Egypt

3

Department of Chemical Engineering, Qatar University, Doha 2713, Qatar

Coatings 2018, 8(10), 343; https://doi.org/10.3390/coatings8100343 - 26 Sep 2018

Cited by 24 | Viewed by 4120

Abstract

▼

Show Figures

The dry erosion behavior of API-X120 pipeline steel was investigated, under the erosive interaction of aluminum oxide particulates, in a range of speed (43–167 m·s−1) and impact angle (30°–90°). Erosion behavior is characterized by surface profile measurement, weight loss measurement, and

[...] Read more.

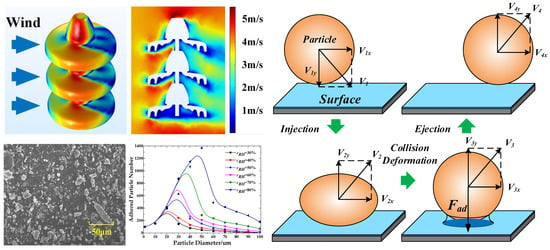

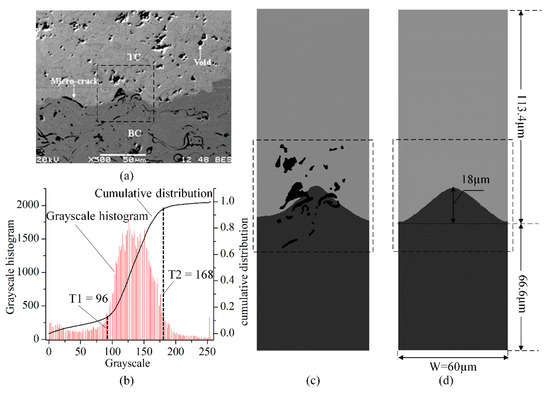

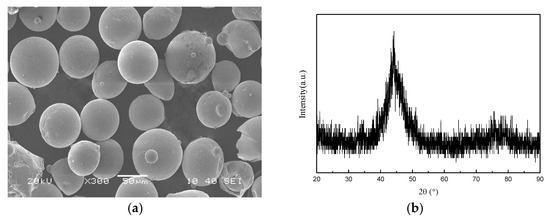

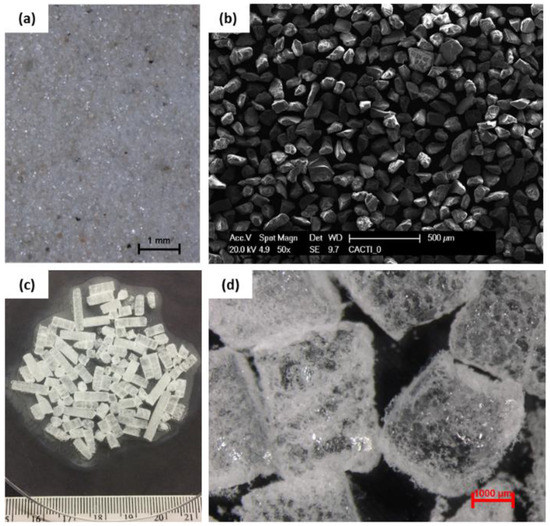

The dry erosion behavior of API-X120 pipeline steel was investigated, under the erosive interaction of aluminum oxide particulates, in a range of speed (43–167 m·s−1) and impact angle (30°–90°). Erosion behavior is characterized by surface profile measurement, weight loss measurement, and surface morphology analysis by SEM/EDX. Optical profilometry revealed that the eroded area increased with elevating speed of particles while the penetration depth increased with the increases in impact angle as well as particle speed. Percent weight loss and normalized erosion rate indicated that the lower impact angles and higher speeds led to higher materials loss and erosion. SEM analyses on various combinations of impact angles and particle speeds demonstrated the predominant erosion mechanism under those specific conditions; attributed to the intensity of the resolved components of the momentum vector horizontal or normal to the target metal surface under those conditions.

Full article