Open AccessArticle

Investigation of the Nature of the Interaction of Me-MeN-(Me,Mo,Al)N Coatings (Where Me = Zr, Ti, or Cr) with a Contact Medium Based on the Ni-Cr System

by

Sergey Grigoriev, Oleg Yanushevich, Natella Krikheli, Alexey Vereschaka, Filipp Milovich, Nikolay Andreev, Anton Seleznev, Alexander Shein, Olga Kramar, Sergey Kramar and Pavel Peretyagin

Cited by 4 | Viewed by 2425

Abstract

This paper discusses the results of a study focused on the nature of the interaction of Me-MeN-(Me,Mo,Al)N coatings (where Me = zirconium (Zr), titanium (Ti), or chromium (Cr)) with a contact medium based on the Ni-Cr system. The studies were carried out during

[...] Read more.

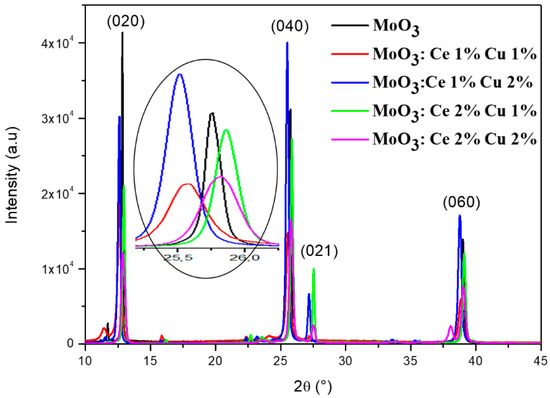

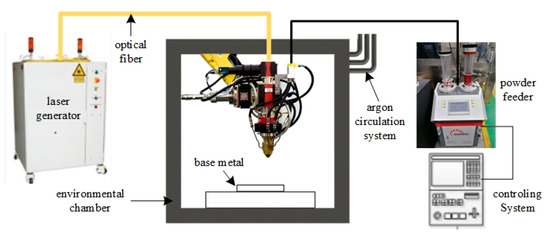

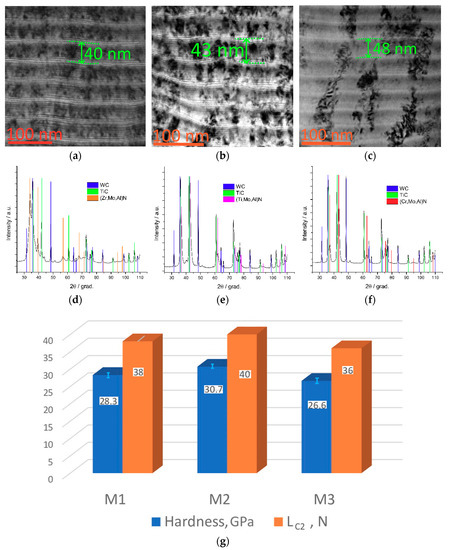

This paper discusses the results of a study focused on the nature of the interaction of Me-MeN-(Me,Mo,Al)N coatings (where Me = zirconium (Zr), titanium (Ti), or chromium (Cr)) with a contact medium based on the Ni-Cr system. The studies were carried out during the turning of nickel–chromium alloy at different cutting speeds. The hardness of the coatings was found, and their nanostructure and phase composition were studied. The experiments were conducted using transmission electron microscopy (TEM), X-ray diffraction (XRD), and selected area electron diffraction (SAED). According to the studies, at elevated cutting speeds, the highest wear resistance is demonstrated by the tools with the ZrN-based coating, while at lower cutting speeds, the tools with the TiN- and CrN-based coatings had higher wear resistance. At elevated cutting speeds, the experiments detected the active formation of oxides in the ZrN-based coating and less active formation of oxides in the CrN-based coating. No formation of oxides was detected in the TiN-based coating. The patterns of cracking in the coatings were also studied.

Full article

►▼

Show Figures