Department of Chemical Engineering, Materials and Industrial Production, University of Napoli Federico II, Piazzale Tecchio 80, 80125 Napoli, Italy

Metals 2018, 8(7), 489; https://doi.org/10.3390/met8070489 - 27 Jun 2018

Cited by 19 | Viewed by 3541

Abstract

Anodic oxidation is an easy and cheap surface treatment to form nanostructures on the surface of titanium items for improving the interaction between metallic implants and the biological environment. The long-term success of the devices is related to their stability. In this work,

[...] Read more.

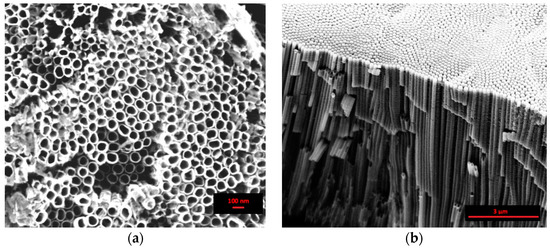

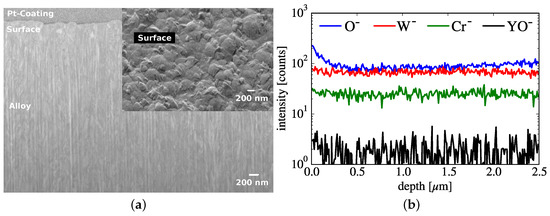

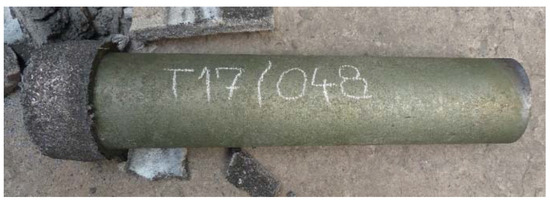

Anodic oxidation is an easy and cheap surface treatment to form nanostructures on the surface of titanium items for improving the interaction between metallic implants and the biological environment. The long-term success of the devices is related to their stability. In this work, titanium nanotubes were formed on a dental screw, made of titanium CP2, through an anodization process using an “organic” solution based on ethylene glycol containing ammonium fluoride and water. Then, the electrochemical stability in the Hank’s solution of these “organic” nanotubes has been investigated for 15 days and compared to that of titanium nanotubes on a similar type of sample grown in an inorganic solution, containing phosphoric and hydrofluoridric acids. Morphological and crystallographic analysis were performed by using scanning electron microscopy (SEM) and X-Ray diffractometry (XRD) tests. Electrochemical measurements were carried out to study the stability of the nanotubes when are in contact with the biological environment. The morphological measurements revealed long nanotubes, small diameters, smooth side walls, and a high density of “organic” nanotubes if compared to the “inorganic” ones. XRD analysis demonstrated the presence of rutile form. An appreciable electrochemical stability has been revealed by Electrochemical Impedance Spectroscopy (EIS) analysis, suggesting that the “organic” nanotubes are more suitable for biomedical devices.

Full article

(This article belongs to the Special Issue Advances in Enhancing Degradation Resistance of Metallic Implants by Surface Engineering)

▼

Show Figures