Metals 2022, 12(3), 380; https://doi.org/10.3390/met12030380 - 23 Feb 2022

Cited by 13 | Viewed by 3559

Abstract

Nickel Aluminum Bronze (NAB) and Manganese Aluminum Bronze (MAB) are high-alloyed bronzes that are increasingly employed in several industrial sectors, mainly related to hostile environments due to their excellent properties against corrosion, cavitation, erosion and improved mechanical properties in relation to other copper-based

[...] Read more.

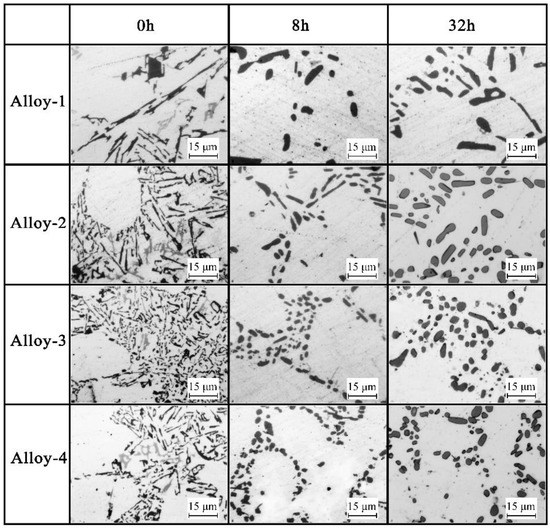

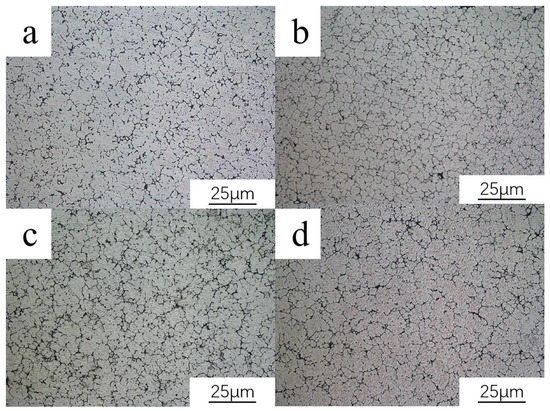

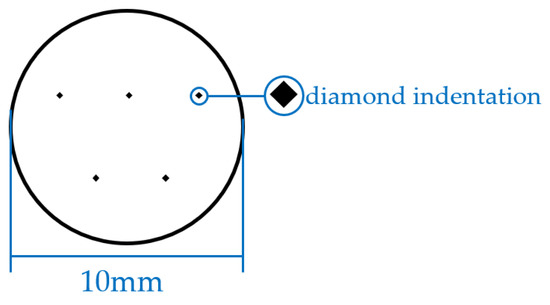

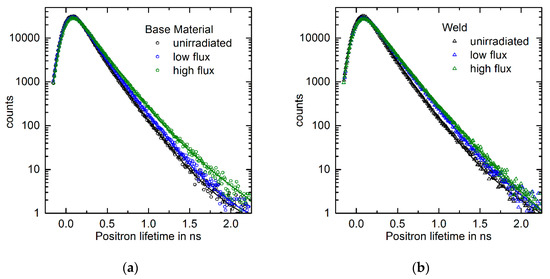

Nickel Aluminum Bronze (NAB) and Manganese Aluminum Bronze (MAB) are high-alloyed bronzes that are increasingly employed in several industrial sectors, mainly related to hostile environments due to their excellent properties against corrosion, cavitation, erosion and improved mechanical properties in relation to other copper-based alloys. These materials are very sensitive against thermal treatments due to a multiphase microstructure in as-cast condition. To contribute to the knowledge of the behavior of both alloys, the effect of thermal treatments on the corrosion behavior of NAB (CuAl10Fe5Ni5) and MAB (CuMn12Al8Fe4Ni2) was studied. As-cast material was subjected to various combinations of quenching and quenching and tempering at 850 °C and 600 °C. Corrosion testing was carried out using simulated sea and fresh water. The microstructures of the as-cast and heat-treated samples were characterized by metallography using two chemical agents with FeCl3 and NH4OH solutions and examination by optical and scanning electron microscopy. The major effect of thermal treatments on corrosion was found in influencing the amount and distribution of β-phase, which is prone to selective corrosion in both electrolytes.

Full article

(This article belongs to the Section Corrosion and Protection)

►

Show Figures