Polymers 2022, 14(21), 4607; https://doi.org/10.3390/polym14214607 - 30 Oct 2022

Cited by 19 | Viewed by 3383

Abstract

New bio-thermoplastic elastomer composites with self-healing capacities based on epoxidized natural rubber and polycaprolactone blends reinforced with alginates were developed. This group of salts act as natural reinforcing fillers, increasing the tensile strength of the unfilled rubber from 5.6 MPa to 11.5 MPa

[...] Read more.

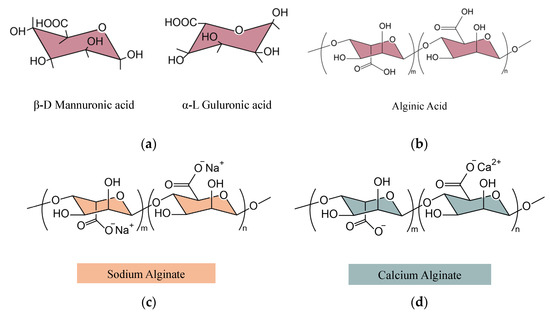

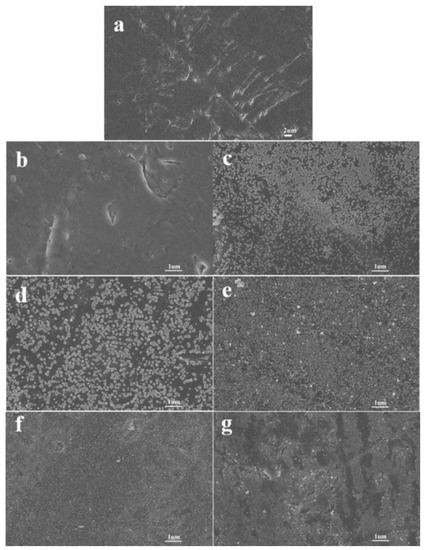

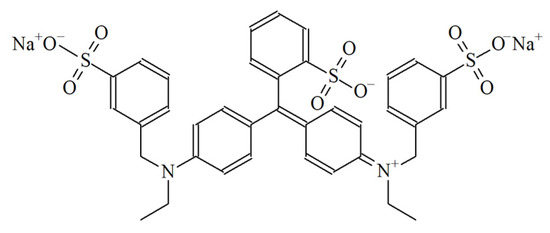

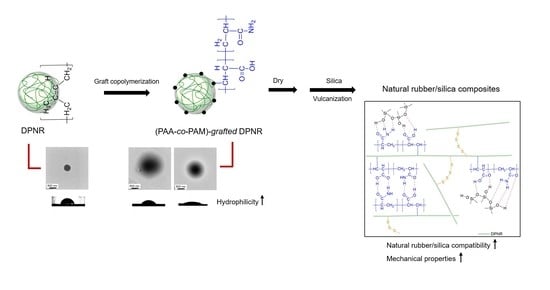

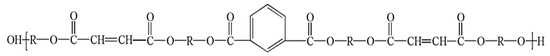

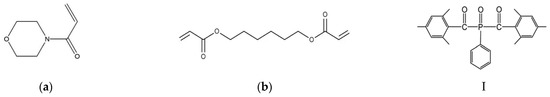

New bio-thermoplastic elastomer composites with self-healing capacities based on epoxidized natural rubber and polycaprolactone blends reinforced with alginates were developed. This group of salts act as natural reinforcing fillers, increasing the tensile strength of the unfilled rubber from 5.6 MPa to 11.5 MPa without affecting the elongation at break (~1000% strain). In addition, the presence of ionic interactions and hydrogen bonds between the components provides the material with a thermally assisted self-healing capacity, as it is able to restore its catastrophic damages and recover diverse mechanical properties up to ~100%. With the results of this research, an important and definitive step is planned toward the circularity of elastomeric materials.

Full article

(This article belongs to the Special Issue Sustainable Polymer Composites: Properties, Characterizations and Applications)

►

Show Figures