Effect of CNTs Additives on the Energy Balance of Carbon/Epoxy Nanocomposites during Dynamic Compression Test

Abstract

1. Introduction

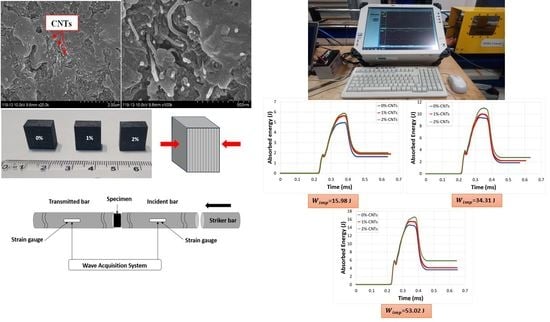

2. Materials and Manufacturing Process

3. Test Procedure

3.1. SHPB Test Method

3.2. Dynamic Compression Testing

3.3. Theorical Characterization of Absorbed Energy

4. Results and Discussion

5. Failure Mode

6. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Ramakrishna, S. Microstructural design of composite materials for crashworthy structural applications. Mater. Des. 1997, 18, 167–173. [Google Scholar] [CrossRef]

- Zhang, L.; Becton, M.; Wang, X. Mechanical analysis of graphene-based woven nano-fabric. Mater. Sci. Eng. 2015, 620, 367–374. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G. Crushing behaviour of aluminium honeycombs under impact loading. Int. J. Impact Eng. 1998, 21, 827–836. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Kang, W.J.; McGee, J.; Guo, W.G.; Isaacs, J.B. Experimental investigation of energy-absorption characteristics of components of sandwich structures. Int. J. Impact Eng. 2007, 34, 1119–1146. [Google Scholar] [CrossRef]

- Hazizan, M.A.; Cantwell, W.J. The low velocity impact response of an aluminium honeycomb sandwich structure. Compos. Part B Eng. 2003, 34, 679–687. [Google Scholar] [CrossRef]

- Chandra, R.; Singh, S.P.; Gupta, K. Damping studies in fiber-reinforced composites e a review. Compos. Struct. 1999, 46, 41–51. [Google Scholar] [CrossRef]

- Sun, C.T.; Chaturvedi, S.K.; Gibson, R.F. Special issue: Advances and trends in structures and dynamics internal damping of short-fiber reinforced polymer matrix composites. Compos. Struct. 1985, 20, 391–400. [Google Scholar] [CrossRef]

- Eitan, A.; Fisher, F.T.; Andrews, R.; Brinson, L.C.; Schadler, L.S. Reinforcement mechanisms in MWCNT-filled polycarbonate. Compos. Sci. Technol. 2005, 66, 1159–1170. [Google Scholar] [CrossRef]

- Ding, W.; Eitan, A.; Fisher, F.T.; Chen, X.; Dikin, D.A.; Andrews, R.; Brinson, L.C.; Schadler, L.S.; Ruoff, R.S. Direct observation of polymer sheathing in carbon nanotube−polycarbonate composites. Nano Lett. 2003, 3, 1593–1597. [Google Scholar] [CrossRef]

- Schadler, L.S.; Brinson, L.C.; Sawyer, W.G. Polymer nanocomposites: A small part of the story. JOM 2007, 59, 53–60. [Google Scholar] [CrossRef]

- Watcharotone, S.; Wood, C.D.; Friedrich, R.; Chen, X.; Qiao, R.; Putz, K.; Brinson, L.C. Interfacial and substrate effects on local elastic properties of polymers using coupled experiments and modeling of nanoindentation. Adv. Eng. Mater. 2011, 13, 400–404. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, S. Polymer/Carbon nanotube nano composite fibers—A review. ACS Appl. Mater. Interfaces 2014, 6, 6069–6087. [Google Scholar] [CrossRef]

- Chen, X.; Huang, Y. Nanomechanics modeling and simulation of carbon nanotubes. J. Eng. Mech. 2008, 134, 211–216. [Google Scholar] [CrossRef]

- Delfani, M.R.; Shodja, H.M.; Ojaghnezhad, F. Mechanics and morphology of single-walled carbon nanotubes: From graphene to the elastic. Philos. Mag. 2013, 93, 2057–2088. [Google Scholar] [CrossRef]

- Wang, C.M.; Zhang, Y.Y.; Xiang, Y.; Reddy, J.N. Recent studies on buckling of carbon nanotubes. Appl. Mech. Rev. 2010, 63. [Google Scholar] [CrossRef]

- Becton, M.; Zhang, L.; Wang, X. Molecular dynamics study of programmable nanoporous grapheme. J. Nanomech. Micromech. 2014, 4. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Li, J. Simulation of collisions between buckyballs and graphene sheets. Int. J. Smart Nano Mater. 2012, 3, 14–22. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X. Atomistic insights into the nanohelix of hydrogenated graphene: Formation, characterization and application. Phys. Chem. Chem. Phys. 2014, 16, 2981–2988. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X. Tailoring pull-out properties of single-walled carbon nanotube bundles by varying binding structures through molecular dynamics simulation. J. Chem. Theory Comput. 2014, 10, 3200–3206. [Google Scholar] [CrossRef]

- Lattanzi, L.; De Nardo, L.; Raney, J.R.; Daraio, C. Mechanical properties of carbon nanotube foams. Adv. Eng. Mater. 2014, 16, 1026–1031. [Google Scholar] [CrossRef]

- Gui, X.; Zeng, Z.; Zhu, Y.; Li, H.; Lin, Z.; Gan, Q.; Xiang, R.; Cao, A.; Tang, Z. Three-dimensional carbon nanotube sponge-array architectures with high-energy dissipation. Adv. Mater. 2014, 26, 1248–1253. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.Q.; Ma, W.; Zhang, Z. Macroscopic carbon nanotube assemblies: Preparation, properties, and potential applications. Small 2011, 7, 1504–1520. [Google Scholar] [CrossRef] [PubMed]

- Thostenson, E.T.; Ren, Z.F.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Sun, L.F.; Gibson, R.; Gordaninejad, F.; Suhr, J. Energy absorption capability of nanocomposites: A review. Compos. Sci. Technol. 2009, 69, 2392–2409. [Google Scholar] [CrossRef]

- Drdlová, M.; Prachař, V. High strain rate characteristics of nanoparticle modified blast energy absorbing materials. Procedia Eng. 2016, 151, 214–221. [Google Scholar] [CrossRef][Green Version]

- Chen, H.; Zhang, L.; Chen, J. Energy dissipation capability and impact response of carbon nanotube buckypaper: A coarse-grained molecular dynamics study. Carbon 2016, 103, 242–252. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, L.; Becton, M. Molecular dynamics study of a CNT-buckyball-enabled energy absorption system. Phys. Chem. Chem. Phys. 2015, 17, 17311–17321. [Google Scholar] [CrossRef]

- Weidt, D.; Buggy, M. Prediction of energy absorption characteristics of aligned carbon nanotube/epoxy nanocomposites. IOP Conf. Ser. Mater. Sci. Eng. 2012, 40, 2028. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; Alaoui, A.E.M. Mechanical behavior and damage kinetics of woven E-glass/Vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; Alaoui, A.E.M. Dynamical characterization and damage mechanisms of E-glass/Vinylester woven composites at high strain rates compression. J. Compos. Mater. 2016, 50, 3313–3323. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; Bouery, C.; Alaoui, A.E.M. Comparison study of mechanical properties and damage kinetics of 2D and 3D woven composites under high-strain rate dynamic compressive loading. Int. J. Damage Mech. 2016, 25, 1–22. [Google Scholar] [CrossRef]

- Al-Lafi, W.; Jie, J.; Xu, S.; Song, M. Performance of MWCNT/HDPE nanocomposites at high strain rates. Macromol. Mater. Eng. 2010, 295, 519–522. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Neme, A.; Choukri, S. Damage kinetics of glass/epoxy composite materials under dynamic compression. J. Compos. Mater. 2009, 43, 1137–1154. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Nachtane, M.; Benyahia, H. Strain rate effects on the dynamic compressive response and the failure behavior of polyester matrix. Compos. Part B Eng. 2019, 174, 107040. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Neme, A. Dynamic response of symmetric and asymmetric e-glass/epoxy laminates at high strain rates. Key Eng. Mater. 2010, 446, 73–82. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Benyahia, H. Experimental study of the out-of-plane dynamic behaviour of adhesively bonded composite joints using split Hopkinson pressure bars. J. Compos. Mater. 2018, 52, 2875–2885. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Benyahia, H. An investigation of in-plane dynamic behavior of adhesively-bonded composite joints under dynamic compression at high strain rate. Compos. Struct. 2018, 191, 168–179. [Google Scholar] [CrossRef]

- Feng, B.; Fang, X.; Wang, H.-X.; Dong, W.; Li, Y.-C. The effect of crystallinity on compressive properties of Al-PTFE. Polymers 2016, 8, 356. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, C.; Huang, G.; Li, W.; Feng, S. A hyper-viscoelastic constitutive model for polyurea under uniaxial compressive loading. Polymers 2016, 8, 133. [Google Scholar] [CrossRef]

- Gardea, F.; Glaz, B.; Riddick, J.; Lagoudas, D.C.; Naraghi, M. Identification of energy dissipation mechanisms in CNT-reinforced nanocomposites. Nanotechnology 2016, 27, 10. [Google Scholar] [CrossRef]

- Gardea, F.; Cole, D.; Glaz, B.; Riddick, J. Strain energy dissipation mechanisms in carbon nanotube composites fabricated by additive manufacturing. Mech. Addit. Adv. Manuf. 2018, 9, 29–36. [Google Scholar]

- El Moumen, A.; Tarfaoui, M.; Nachtane, M.; Lafdi, K. Carbon nanotubes as a player to improve mechanical shock wave absorption. Compos. Part B Eng. 2019, 164, 67–71. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Nachtane, M.; El Moumen, A. Energy dissipation of stitched and unstitched woven composite materials during dynamic compression test. Compos. Part B Eng. 2019, 167, 487–496. [Google Scholar] [CrossRef]

- Park, S.W.; Zhou, M.; Veazie, D.R. Time-resolved impact response and damage of fiber reinforced Composite laminates. J. Compos. Mater. 2000, 34, 879–904. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of fibre orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef]

- Suhr, J.; Koratkar, N.A. Energy dissipation in carbon nanotube composites: A review. J. Mater. Sci. 2008, 43, 4370–4382. [Google Scholar] [CrossRef]

- Gardea, F.; Glaz, B.; Riddick, J.; Lagoudas, D.C.; Naraghi, M. Energy dissipation due to interfacial slip in nanocomposites reinforced with aligned carbon nanotubes. ACS Appl. Mater. Interfaces 2015, 7, 9725–9735. [Google Scholar] [CrossRef]

| Carbon fiber | Epoxy matrix | CNT | |||

|---|---|---|---|---|---|

| E11 (GPa) | 230 | E (GPa) | 2.72 | E (GPa) | 500 |

| E22 (GPa) | 15 | v | 0.3 | v | 0.261 |

| E33 (GPa) | 15 | ||||

| v12 | 0.28 | ||||

| v13 | 0.28 | ||||

| v23 | 0.28 | ||||

| G12 (GPa) | 15 | ||||

| G13 (GPa) | 15 | ||||

| G23 (GPa) | 15 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chihi, M.; Tarfaoui, M.; Bouraoui, C.; El Moumen, A. Effect of CNTs Additives on the Energy Balance of Carbon/Epoxy Nanocomposites during Dynamic Compression Test. Polymers 2020, 12, 194. https://doi.org/10.3390/polym12010194

Chihi M, Tarfaoui M, Bouraoui C, El Moumen A. Effect of CNTs Additives on the Energy Balance of Carbon/Epoxy Nanocomposites during Dynamic Compression Test. Polymers. 2020; 12(1):194. https://doi.org/10.3390/polym12010194

Chicago/Turabian StyleChihi, Manel, Mostapha Tarfaoui, Chokri Bouraoui, and Ahmed El Moumen. 2020. "Effect of CNTs Additives on the Energy Balance of Carbon/Epoxy Nanocomposites during Dynamic Compression Test" Polymers 12, no. 1: 194. https://doi.org/10.3390/polym12010194

APA StyleChihi, M., Tarfaoui, M., Bouraoui, C., & El Moumen, A. (2020). Effect of CNTs Additives on the Energy Balance of Carbon/Epoxy Nanocomposites during Dynamic Compression Test. Polymers, 12(1), 194. https://doi.org/10.3390/polym12010194