1. Introduction

Modified engineering materials have been widely used for electronic devices, automobiles and aerospace applications in the past few decades [

1,

2,

3,

4]. However, the cutting-edge compact, complex and integrated designs of devices have raised the requirements for engineering materials which have to bear the ability to be assembled in a small integrated space, light weight, super heat dissipation, and flame retardancy properties [

5,

6]. Even when metal and ceramic materials fit well in heat dissipation and flame retardancy properties, their extreme processing conditions and high densities lead them to be disqualified for such applications [

7]. Polymer composites (e.g., polyamide 6 (PA6)), on the other hand, which have many excellent properties, such as an ease of processing, lightweight, good electrical insulation and tailorable mechanical properties [

8,

9], have been considered as the most promising candidates for compact and integrated electronics and new energy device applications, even if challenges regarding their thermal conductivity and fire retardancy still need to be addressed.

Polyamide 6 (PA6) is an important engineering plastic that has been vastly used due to its excellent mechanical properties, good heat resistance, and good chemical resistance [

10,

11,

12,

13,

14,

15,

16]. PA6 can be easily applied to automobile components, electrical connectors, switch components, high power light emitting diodes (LEDs) field, etc. [

17]. However, its applications are restricted to those fields that require high flame retardance and thermal conductivity due to its inadequate flame retardancy, severe flammable melt dripping, and relative low thermal conductivity [

18,

19]. Taking its application in electrical products as an example, during the usage of electrical products, the high temperature generated from circuits or other components is required to be emitted instantly, otherwise overheating may occur, thus sacrificing performance. Therefore, it is necessary to ensure that the PA6 used for such applications has good thermal conductivity. Additionally, the electrical components using PA6 are required to have high flame retardancy to avoid fires during electrical breakdown or other abnormal conditions. With these considerations, exploring the PA6 composites with both flame retardancy and thermal conductivity is of academic significance and practical value. However, thus far, most research has focused on either the fire retardancy or thermal conductive properties of PA6; limited reports have combined these two properties together in single studies, which are of course significant for applications. Yuan D. et al. [

20] investigated the thermal conductivity of a PA6/PA66 1:1 blend by aluminum nitride (AlN) and found thermal conductivity of the PA6/PA66/AlN composite with 50% AlN was 1.5 W/mK, but the flame retardancy of the composite materials was not discussed. Zhong Y. et al. [

21] reported the effect of boron nitride (BN) on the flame retardancy and thermal stability of flame retardant PA6, but the thermal conductivity of the flame-retardant-thermal conductive-PA6 (FR-TC-PA6) composites was not fully discussed.

To date, varieties of halogen-free flame retardants have been proposed for polyamide, including ammonium polyphosphate (APP) [

22], melamine cyanurate (MCA) [

23,

24], and aluminum diethylphosphinate (AlPi) [

25,

26]. Among them, AlPi is phosphorus flame retardant which has been developed and commercialized. This material has been proven to be an effective flame retardant for PA6 [

27,

28]. Wirasaputra A. et al. [

25] reported that the PA6/AlPi composites passed the UL-94 (vertical burning test) V-2 rating, and the limiting oxygen index (LOI) value reached up to 29.3% when 13 wt% AlPi was loaded. Ma K. et al. [

19] reported that when the loading of AlPi was 13 wt%, thee LOI value of the PA6/AlPi composites increased to 30% and passed the UL-94 V-0 rating. However, these reports only focused on the flame retardancy properties of PA6; the thermal conductivity of flame retardant PA6 was not discussed.

A simple and effective method to enhance the thermal conductivity of a polymer matri, is to directly incorporate thermally conductive (TC) fillers, such as aluminum nitride (AlN) [

20], boron nitride (BN) [

29], alumina (Al

2O

3) [

30], silicon carbide (SiC) [

31], carbon nanotubes [

32], and graphene [

33]. Research has been conducted to evaluate the properties of the polymer/TC composites, and strategies have been proposed to improve the thermal conductivity of the polymer/TC composites by improving the dispersion of TC fillers in a polymer matrix. For example, Nikoo G. et al. [

34] used the relationship between normalized storage modulus and angular frequency as a method to compare the degree of dispersion of BN particles in a PA6 and cyclic olefin copolymer (COC) matrix; they found that BN particles had a better dispersion in the PA6 matrix than in the COC matrix due to better compatibility between PA6 and BN. Tang D. et al. [

35] studied the dispersion of KH550-modified BN in an epoxy matrix and its effect on the thermal conductivity and mechanical properties of the composite; it was found that KH550-BN could be more uniformly dispersed in the matrix than pristine BN, and the epoxy/KH550-BN composite had a relatively higher thermal conductivity. In addition, different processing methods have been found to have different effects on the thermal conductivity of composites. It has been found that the fillers in the melt are oriented by the flow during extrusion stretching or injection molding, and this leads to different thermal conductivities for anisotropic fillers [

36].

As inorganic fillers, TC fillers may have either favorable or unfavorable effect on the flame retardancy of polymer composites, but reports on related research are limited. Almeras X. et al. [

37] investigated the effect of fillers (talc and calcium carbonate) on the fire performance of a polypropylene/ammonium polyphosphate/polyamide-6 blend. It was found that the fire performance strongly depended on the nature of the fillers used, as talc increased and calcium carbonate decreased the flame retardancy performance of the corresponding composites.

In this study, we prepared halogen-free flame retardant (HFFR)-TC-PA6 composites bearing both a high thermal conductivity and excellent flame retardancy for potential application in an electrical field. The HFFR-TC-PA6 composites with fire retardant AlPi and different types of TC fillers were compounded by using extrusion and injection molding, and the effect of TC fillers on the mechanical properties, thermal conductivity, flame retardance properties and thermal behavior of the HFFR-TC-PA6 composites were investigated.

2. Experimental

2.1. Materials

Commercial grade PA6 pellets (1013B) were sourced from Ube Industries, Ltd., Tokyo, Japan. The flame retardant aluminum diethylphosphinate (AlPi) Exolit OP1230 was purchased from Clariant Co., Frankfurt, Germany. Thermal conductive filler (TC filler) aluminum nitride (two grades AlN, a spherical AlN-550RFS with an average particle size of 55 µm and aspherical AlN-300SFS with an average particle size of 10 µm) and boron nitride (two grades BN, a BN-NW04 with an average particle size of 0.5 µm and BN-SW08 with an average particle size of 6 µm) were purchased from Global Top Trading Co., Ltd. (Kunshan, China).

2.2. Preparation of HFFR-TC-PA6 Composites

The composites of HFFR-TC-PA6 were prepared by melt mixing through a twin-screw co-rotating extruder (model AK36, L/D ratio = 40, Nanjing Keya Chemical Complete Equipment Co., Ltd, Nanjing, China). The mixing ratios are given in

Table 1. Firstly, PA6 was dried under vacuum at 100 °C for 24 h, while AlPi, AlN-550RFS, AlN-300SFS, BN-SW08 and BN-NW04 were all dried at 80 °C for 24 h before use. Secondly, the dried PA6, AlPi, and the TC fillers were mixed in a high-speed mixer at a speed of 1200 rpm for 2 min, the mixtures were fed into twin-screw extruder, the temperature profiles were set to 220, 225, 230, 240, 240, 240, 240, 240, 240 and 240 °C, from hopper to die, and then the extrudates were pelletized after cooling. After drying at 110 °C for 24h, the HFFR-TC-PA6 pellets were injection-molded to standard testing bars by using an injection molding machine (model TW-25V, clamping force 25 tons, Dongguan Taiwang Machinery Co., Ltd. Dongguan, China). The temperature profiles were set to 220 °C (hopper), 230 °C and 240 °C (nozzle).

2.3. Characterization

Mechanical properties were evaluated by tensile, flexural and Izod impact tests. Tensile and flexural tests were performed on an MTS-CMT 6104 universal mechanical tester (MTS, Eden Prairie, MN, USA). The dimension of the type 1A dumbbell-shaped specimens for tensile test was 150 × 20 × 4.0 mm in accordance with ISO 527: 2019, the speed of the test was 50 mm/min, the dimensions of rectangular bars for the flexural test were 80 × 10 × 4.0 mm in accordance with ISO 178: 2016, and the speed of the test was 2 mm/min. The notched Izod impact test was carried out with the MTS-ZBC 8400-B impact tester (MTS, Eden Prairie, MN, USA), the dimensions of the specimens with a type A notch were 80 × 10 × 4.0 mm in accordance with ISO 180: 2016. Each value of the mechanical properties was an average of five specimens.

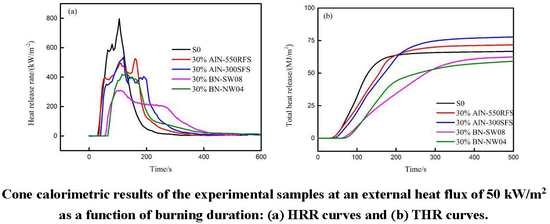

The vertical burning test was performed according to UL-94, and the dimensions of all specimens were 125 × 13 × 3.0 mm and 125 × 13 × 1.6 mm. The limiting oxygen index (LOI) values were measured according to ISO 4589-2: 2017, and the dimensions of all samples were 80 × 10 × 4.0 mm. According to ISO 5660-1: 2015, the fire behavior of the samples was measured by a cone calorimeter device. Samples having size of 100 × 100 × 3.0 mm were exposed to a radiant cone (50 kW/m2). The plaques were placed in the sample holder with a retainer frame, and the top surface of the sample was directly exposed the heat source.

The thermal conductivity of the HFFR-TC-PA6 composite was measured using the steady state heat flow method and conducted on a Longwin instrument (model LW-9389, Longwin company, Dongguan, China). Measurements were performed according to ASTM D5470-17, and the dimensions of the samples were 27 × 27 × 5 mm. This method is based on idealized heat conduction between two parallel, isothermal surfaces separated by a test specimen of uniform thickness. The thermal gradient imposed on the specimen by the temperature difference between the two contacting surfaces causes the heat flow through the specimen. This heat flow is perpendicular to the test surface and is uniform across the surfaces with no lateral heat spreading. The thermal conductivity was calculated using the following equation:

where

λ is the thermal conductivity of the material,

Qh is the heat flow in hot meter bar,

Qc is the heat flow in cold meter bar,

L is the thickness of the sample, and Δ

T is the temperature difference between the upper surface and lower surface of the sample.

Thermogravimetric (TG) experiments were conducted on a TA instruments (model Q50, TA Instruments, Newcastle, DE, USA) with a nitrogen flow rate of 40 mL/min. Samples (~2 mg) were heated in Al2O3 pans from 40 to 700 °C at a heating rate of 20 °C/min. The onset decomposition temperature, T5%, at which 5 wt% of the original weight was lost, and Tmax, at which the products possessed the maximum weight loss rate, were recorded together with the residue weight.

The morphologies of the HFFR-TC-PA6 composites were obtained from fracture surfaces from the impact test by using a scanning electron microscope (SEM, HITACHI S-550, Tokyo, Japan) operated at a 10 kV accelerating voltage. Samples were sputter-coated with gold before test.

Differential scanning calorimeter (DSC) analysis was carried out on DSC-60A, Shimadzu instruments. The specimen was heated from 40 to 260 °C at a heating rate of 10 °C/min, held for 3 min, cooled to 40 °C at a rate of 10 °C/min, and then finally reheated to 260 °C at a heating rate of 10 °C/min. The degrees of crystallinity of PA6 in the resulting composites were calculated as follows:

where Δ

Hm is the melting enthalpy, obtained from melting peak of second heating curve of PA6,

pi is weight percent of PA6, and

is 100% crystalline enthalpy of PA6, which is 230 J/g [

20].