Polymer Nanocomposites

Abstract

:1. Introduction

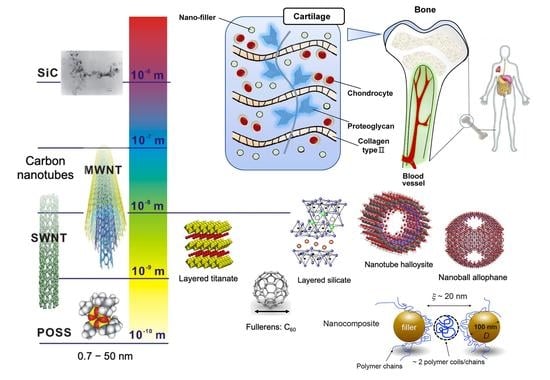

2. Nanomaterials

3. Multifunctional Properties

4. Structure and Characterization Techniques for Nanocomposites

- (1)

- Intercalation of polymer or pre-polymer from solution

- (2)

- In situ intercalative polymerization method

- (3)

- Melt intercalation method

5. Types of Polymers so far Used for Polymer–Layered Silicate (PLS) Nanocomposites

6. Commercial Market Opportunities

7. Future Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sinha Ray, S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Anastasiadis, S.H.; Russel, T.P.; Satija, S.K.; Majkrzak, C.F. The morphology of symmetric diblock copolymers as revealed by neutron reflectivity. J. Chem. Phys. 1990, 92, 5677–5691. [Google Scholar] [CrossRef]

- Okamoto, M. Clay-based Polymeric Nanocomposites: Network formation and solid-state shear processing. In Processing Polymer Nanocomposites; Kenig, S., Ed.; Carl Hanser Verlag GmbH & Co.: Munich, Germany, 2019; pp. 255–295. [Google Scholar]

- Thostenson, E.; Li, C.; Chou, T. Review Nanocomposites in Context. J. Compo. Sci. Tech. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Schmidt, D.; Shah, D.; Giannelis, E.P. New Advances in Polymer/Layered Silicate Nanocomposites. Curr. Opin. Solid State Mater. Sci. 2002, 6, 205–212. [Google Scholar] [CrossRef]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Composite Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Usuki, A.; Kawasumi, M.; Kojima, Y.; Okada, A.; Kurauchi, T.; Kamigaito, O.J. Swelling Behavior of Montmorillonite Cation Exchanged for V-amino Acids by E-caprolactam. J. Mater. Res. 1993, 8, 1174–1178. [Google Scholar] [CrossRef]

- Utracki, L.A. Clay-Containing Polymeric Nanocomposites; Rapra Technology Ltd.: Shawbury, UK, 2004. [Google Scholar]

- Advani, S.G. (Ed.) Processing and Properties of Nanocomposites; World Scientific & Imperial College Press: London, UK, 2007. [Google Scholar]

- Ruiz-Hitzky, E.; Ariga, K.; Lvov, Y.M. (Eds.) Bio-Inorganic Hybrid Nanomaterials; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar]

- Lau, A.K.-T.; Hussain, F.; Lafdi, K. (Eds.) Nano-and Biocomposites; CRC Press: Boca Raton, FL, USA; Taylor and Francis: New York, NY, USA, 2009. [Google Scholar]

- Avérous, L.; Pollet, E. (Eds.) Environmental Silicate Nano-Biocomposites; Springer: London, UK, 2012. [Google Scholar]

- Thomas, S.; Stephen, R. (Eds.) Rubber Nanocomposites: Preparation, Properties, and Application; John Wiley & Sons: Singapore, 2010. [Google Scholar]

- Gao, F. (Ed.) Advances in Polymer Nanocomposites: Types and Application; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Theng, B.K.G. (Ed.) Formation and Properties of Clay-Polymer Complexes in Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4. [Google Scholar]

- Mittal, V. (Ed.) Characterization Techniques for Polymer Nanocomposites; Wiley-VCH: Weinheim, Germany, 2012. [Google Scholar]

- Sinha Ray, S. (Ed.) Clay-Containing Polymer Nanocomposites: From Fundamental to Real Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Sinha Ray, S. (Ed.) Environmentally Friendly Polymer Nanocomposites: Types, Processing and Properties; Woodhead Publishing: London, UK, 2013. [Google Scholar]

- Okada, A.; Usuki, A. The Chemistry of Polymer-Clay Hybrids. Mater. Sci. Eng. C 1995, 3, 109–115. [Google Scholar] [CrossRef]

- Hsieh, A.J. Ballistic Impact Measurements of Polycarbonate Layered Silicate Nanocomposites; ANTEC; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Koo, J.; Pilato, L. Polymer Nanostructured Materials for High Temperature Applications. SAMPE J. 2005, 41, 7–15. [Google Scholar]

- Transparent Nanocomposites for Aerospace Applications. Adv. Compos. Bull. 2004. Available online: https://www.technical-textiles.net (accessed on 10 January 2023).

- Timmerman, J.; Hayes, B.; Seferis, J. Nanoclay Reinforcement Effects on the Cryogenic Micro Cracking of Carbon Fiber/Epoxy Composites. Compo. Sci. Tech. 2002, 62, 1249–1258. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Okamoto, M.; Ogami, A.; Ueda, K. New Polylactide/Layered Silicate Nanocomposites. 3. High-Performance Biodegradable Materials. Chem. Mater. 2003, 15, 1456–1465. [Google Scholar]

- Blumstein, A.; Malhotra, S.L.; Watterson, A.C. Polymerization of monolayers. V. Tacticity of the insertion poly(methyl methacrylate). J. Polym. Sci. Part A-2 Polym.Phys. 1970, 8, 1599–1615. [Google Scholar] [CrossRef]

- Lee, D.C.; Jang, L.W. Preparation and characterization of PMMA–clay composite by emulsion polymerization. J. Appl. Polym. Sci. 1996, 61, 1117–1122. [Google Scholar] [CrossRef]

- Chen, G.; Chen, X.; Lin, Z.; Ye, W.; Yao, K. Preparation and properties of PMMA/clay nanocomposite. J. Mater. Sci. Lett. 1999, 18, 1761–1763. [Google Scholar] [CrossRef]

- Chen, G.; Yao, K.; Zhao, J. Montmorillonite clay/poly(methylmethacrylate) hybrid resin and its barrier property to the plasticizer within poly(vinyl chloride) composite. J. Appl. Polym. Sci. 1999, 73, 425–430. [Google Scholar] [CrossRef]

- Tabtiang, A.; Lumlong, S.; Venables, R.A. Influence of preparation method upon structure and relaxation characteristics PMMA/clay composites. Eur. Polym. J. 2000, 36, 2559–2568. [Google Scholar] [CrossRef]

- Tabtiang, A.; Lumlong, S.; Venables, R.A. The effects of shear and thermal history upon the microstructure of solution polymerized poly(methyl methacrylate)/clay composites. Polym. Plast. Technol. Eng. 2000, 39, 293–303. [Google Scholar] [CrossRef]

- Okamoto, M.; Morita, S.; Taguchi, H.; Kim, Y.H.; Kotaka, T.; Tateyama, H. Synthesis and structure of smectic clay/poly(methyl methacrylate) and clay polystyrene nanocomposites via in situ intercalative polymerization. Polymer 2000, 41, 3887–3890. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Giannelis, E.P. Thermal and thermomechanical properties of PMMA nanocomposites. Polym. Mater. Sci. Eng. 2000, 82, 208–209. [Google Scholar]

- Huang, X.; Brittain, W.J. Synthesis and characterization of PMMA nanocomposites by suspension and emulsion polymerization. Macromolecules 2001, 34, 3255–3260. [Google Scholar] [CrossRef]

- Zeng, C.; Lee, L.J. Poly(methyl meacrylate) and polystyrene/clay nanocomposites prepared by in-situ polymerization. Macromolecules 2000, 34, 4098–4103. [Google Scholar] [CrossRef]

- Salahuddin, N.; Shehata, M. Poly(methyl methacrylate)–montmorillonite composites: Preparation, characterization and properties. Polymer 2001, 42, 8379–8385. [Google Scholar] [CrossRef]

- Bottcher, H.; Hallensleben, M.L.; Nu, S.; Wurm, H.; Bauer, J.; Behrens, P. Organic/inorganic hybrids by living’/controlled ATRP grafting from layered silicates. J. Mater. Chem. 2002, 12, 1351–1354. [Google Scholar] [CrossRef]

- Zerda, A.S.; Caskey, T.C.; Lesser, A.J. Highly concentrated, intercalated silicate nanocomposites: Synthesis and characterization. Macromolecules 2003, 36, 1603–1608. [Google Scholar] [CrossRef]

- Su, S.; Wilkie, C.A. Exfoliated poly(methyl methacrylate) and polystyrene nanocomposites occur when the clay cation contains a vinyl monomer. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1124–1135. [Google Scholar] [CrossRef]

- Forte, C.; Geppi, M.; Giamberini, S.; Ruggeri, G.; Veracini, C.A.; Mendez, B. Structure determination of clay/methylmethacrylate copolymer interlayer complexes by means of 13C solid state nmr. Polymer 1998, 39, 2651–2656. [Google Scholar] [CrossRef]

- Dietsche, F.; Thomann, Y.; Thomann, R.; Mulhaupt, R. Translucent acrylic nanocomposites containing anisotropic laminated nanoparticles derived from intercalated layered silicates. J. Appl. Polym. Sci. 2000, 75, 396–405. [Google Scholar] [CrossRef]

- Okamoto, M.; Morita, S.; Kotaka, T. Dispersed structure and ionic conductivity of smectic clay/polymer nanocomposites. Polymer 2001, 42, 2685–2688. [Google Scholar] [CrossRef]

- Okamoto, M.; Morita, S.; Kim, Y.H.; Kotaka, T.; Tateyama, H. Dispersed structure change of smectic clay/poly(methylmethacrylate) nanocomposites by copolymerization with polar comonomers. Polymer 2001, 42, 1201–1206. [Google Scholar] [CrossRef]

- Seckin, T.; Onal, Y.; Aksoy, I.; Yakinci, M.E. Synthesis and characterization of novel polyacrylate– clay sol– gel materials. J. Mater. Sci. 1996, 31, 3123–3127. [Google Scholar] [CrossRef]

- Dietsche, F.; Mulhaupt, R. Thermal properties and flammability of acrylic nanocomposites based upon organophilic layered silicates. Polym. Bull. 1999, 43, 395–402. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, C.; Liu, S.; Zhang, Y.; Gong, K. Synthesis, characterization and properties of clay–polyacrylate hybrid materials. J. Appl. Polym. Sci. 2000, 75, 796–801. [Google Scholar] [CrossRef]

- Billingham, J.; Breen, C.; Yarwood, J. Adsorption of polyamine, polyacrylic acid and poly(ethylene glycol) on montmorillonite: An situ study using ATR-FTIR. Vib. Spectrosc. 1997, 14, 19–34. [Google Scholar] [CrossRef]

- Lin, J.; Wu, J.; Yang, Z.; Pu, M. Synthesis and properties of poly(acrylic acid)/mica superabsorbent nanocomposite. Macromol. Rapid. Commun. 2001, 22, 422–424. [Google Scholar] [CrossRef]

- Blumstein, R.; Blumstein, A.; Parikh, K.K. Synthesis and properties of polyacrylonitrile/clay nanocomposite. Appl. Polym. Symp. 1994, 25, 81–89. [Google Scholar]

- Sugahara, Y.; Satakawa, S.; Kuroda, K.; Kato, C. Evidence for the formation of interlayer polyacrylonitrile in kaolinite. Clays Clay Miner. 1988, 36, 343–348. [Google Scholar] [CrossRef]

- Bergaya, F.; Kooli, F. Intercalated polyacrylonitrile/clay nanocomposite. Clay Miner. 1991, 26, 33–40. [Google Scholar] [CrossRef]

- Choi, Y.S.; Wang, K.H.; Xu, M.; Chung, I.J. Synthesis of exfoliated polyacrylonitrile/Na-MMT nanocomposites via emulsion polymerization. Chem. Mater. 2002, 14, 2936–2939. [Google Scholar] [CrossRef]

- Kato, C.; Kuroda, K.; Takahara, H. Preparation and electrical properties of quaternary ammonium montmorillonite–polystyrene complexes. Clays Clay Miner. 1981, 29, 294–298. [Google Scholar] [CrossRef]

- Akelah, A. Polystyrene/clay nanocomposites. In Polymers and Other Advanced Materials: Emerging Technologies and Business Opportunities; Prasad, P.N., Mark, J.E., Ting, F.J., Eds.; Plenum Press: New York, NY, USA, 1995; pp. 625–630. [Google Scholar]

- Vaia, R.A.; Jant, K.D.; Kramer, E.J.; Giannelis, E.P. Microstructural evaluation of melt-intercalated polymer-organically modified layered silicate nanocomposites. Chem. Mater. 1996, 8, 2628–2635. [Google Scholar] [CrossRef]

- Park, C.I.; Park, O.O.; Lim, J.G.; Kim, H.J. The fabrication of syndiotactic polystyrene/organophilic clay nanocomposites and their properties. Polymer 2001, 42, 7465–7475. [Google Scholar] [CrossRef]

- Akelah, A.; Moet, M. Polymer–clay nanocomposites: Freeradical grafting of polystyrene on to organophilic montmorillonite interlayers. J. Mater. Sci. 1996, 31, 3589–3596. [Google Scholar] [CrossRef]

- Sikka, M.; Cerini, L.N.; Ghosh, S.S.; Winey, K.I. Melt intercalation of polystyrene in layered silicates. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1443–1449. [Google Scholar] [CrossRef]

- Laus, M.; Camerani, M.; Lelli, M.; Sparnacci, K.; Sandrolini, F.; Francescangeli, O.F. Hybrid nanocomposites based on polystyrene and a reactive organophilic clay. J. Mater. Sci. 1998, 33, 2883–2888. [Google Scholar] [CrossRef]

- Doh, J.G.; Cho, I. Synthesis and properties of polystyrene–organoammonium montmorillonite hybrid. Polym. Bull. 1998, 41, 511–518. [Google Scholar] [CrossRef]

- Porter, T.L.; Hagerman, M.E.; Reynolds, B.P.; Eastman, M.E. Inorganic/organic host–guest materials: Surface and interclay reactions of styrene with copper(II)-exchanged hectorite. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 673–679. [Google Scholar] [CrossRef]

- Hasegawa, N.; Okamoto, H.; Kawasumi, M.; Usuki, A. Preparation and mechanical properties of polystyrene/clay hybrid. J. Appl. Polym. Sci. 1999, 74, 3359–3364. [Google Scholar] [CrossRef]

- Noh, M.W.; Lee, D.C. Synthesis and characterization of PS–clay nanocomposite by emulsion polymerization. Polym. Bull. 1999, 42, 619–626. [Google Scholar] [CrossRef]

- Weimer, M.W.; Chen, H.; Giannelis, E.P.; Sogah, D.Y. Direct synthesis of dispersed nanocomposites by in situ living free radical polymerization using a silicate-anchored initiator. J. Am. Chem. Soc. 1999, 121, 1615–1616. [Google Scholar] [CrossRef]

- Fu, X.; Qutubuddin, S. Polymer–clay nanocomposites: Exfoliation of organophilic montmorillonite nanolayers in polystyrene. Polymer 2001, 42, 807–813. [Google Scholar] [CrossRef]

- Chen, G.; Liu, S.; Zhang, S.; Qi, Z. Self-assembly in a polystyrene/montmorillonite nanocomposite. Macromol. Rapid Commun. 2000, 21, 746–749. [Google Scholar] [CrossRef]

- Lim, Y.T.; Park, O.O. Rheological evidence for the microstructure of intercalated polymer/layered silicate nanocomposite. Macromol. Rapid Commun. 2000, 21, 231–235. [Google Scholar] [CrossRef]

- Hoffman, B.; Dietrich, C.; Thomann, R.; Friedrich, C.; Mulhaupt, R. Morphology and rheology of polystyrene nanocomposites based upon organoclay. Macromol. Rapid Commun. 2000, 21, 57–61. [Google Scholar] [CrossRef]

- Zilg, C.; Thomann, R.; Baumert, M.; Finter, J.; Mulhaupt, R. Organic/inorganic hybrid materials and nanocomposites based upon layered silicate modified with cyclic imidines. Macromol. Rapid Commun. 2000, 21, 1214–1219. [Google Scholar] [CrossRef]

- Wu, H.D.; Tseng, C.R.; Chang, F.C. Chain conformation and crystallization behavior of the syndiotactic polystyrene nanocomposites studied using Fourier transform infrared analysis. Macromolecules 2001, 34, 2992–2999. [Google Scholar] [CrossRef]

- Xiao, P.; Xiao, M.; Gong, K. Preparation of exfoliated graphite/polystyrene composite by polymerization-filling technique. Polymer 2001, 42, 4813–4816. [Google Scholar] [CrossRef]

- Tseng, C.-R.; Wu, J.-Y.; Lee, H.-Y.; Chang, F.-C. Preparation and crystallization behavior of syndiotactic polystyrene–clay nanocomposites. Polymer 2001, 42, 10063–10070. [Google Scholar] [CrossRef]

- Zhu, J.; Morgan, A.B.; Lamelas, F.J.; Wilkie, C.A. Fire properties of polystyrene–clay nanocomposites. Chem. Mater. 2001, 13, 3774–3780. [Google Scholar] [CrossRef]

- Zeng, Q.H.; Wang, D.Z.; Yu, A.B.; Lu, G.Q. Synthesis of polymer–montmorillonite nanocomposites by in situ intercalative polymerization. Nanotechnology 2002, 13, 549–553. [Google Scholar] [CrossRef]

- Beyer, F.L.; Tan, N.C.B.; Dasgupta, A.; Galvin, M.E. Polymerlayered silicate nanocomposites from model surfactants. Chem. Mater. 2002, 14, 2983–2988. [Google Scholar] [CrossRef]

- Gilman, J.W.; Awad, W.H.; Davis, R.D.; Shields, J.; Harris, R.H., Jr.; Davis, C.; Morgan, A.B.; Sutto, T.E.; Callahan, J.; Trulove, P.C.; et al. Polymer/layered silicate nanocomposites from thermally stable trialkylimidazolium-treated montmorillonite. Chem. Mater. 2002, 14, 3776–3785. [Google Scholar] [CrossRef]

- Argoti, S.D.; Reeder, S.; Zhao, H.; Shipp, D.A. Polystyrene nanocomposites using atom transfer radical polymerization. Polym. Prepr. 2002, 43, 267–268. [Google Scholar]

- Gelfer, M.Y.; Hyun, H.S.; Liu, L.; Hsiao, B.S.; Chu, B.; Rafailovich, M.; Si, M.; Zaitsev, V. Effect of organoclays on morphology and thermal and rheological properties of polystyrene and poly(methyl methacrylate) blends. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 44–54. [Google Scholar] [CrossRef]

- Friedlander, H.Z.; Frink, C.R. Organized polymerization. III. Monomers intercalated in montmorillonite. J. Polym. Sci. Part B 1964, 2, 475–479. [Google Scholar] [CrossRef]

- Churochkina, N.A.; Starodoubtsev, S.G.; Khokhlov, A.R. Swelling and collapse of the gel composites based on natural and slightly charged poly(acrylamide) gels containing Na+-montmorillonite. Polym. Gels Netw. 1998, 6, 205–215. [Google Scholar] [CrossRef]

- Gao, D.; Heimann, R.B.; Williams, M.C.; Wardhaugh, L.T.; Muhammad, M. Rheological properties of poly(acrylamide)–bentonite composite hydrogels. J. Mater. Sci. 1999, 34, 1543. [Google Scholar] [CrossRef]

- Xia, X.; Yih, J.; D’Souza, N.A.; Hu, Z. Swelling and mechanical behavior of poly(N-isopropylacrylamide)/Na+ montmorillonite layered silicates composite gels. Polymer 2003, 44, 3389–3393. [Google Scholar] [CrossRef]

- Wheeler, A. Poly(vinyl alcohol)/clay nanocomposites. U.S. Patent 2,847,391, 12 August 1958. [Google Scholar]

- Ogata, N.; Kawakage, S.; Ogihara, T. Poly(vinyl alcohol)–clay and poly(ethylene oxide)–clay blend prepared using water as solvent. J. Appl. Polym. Sci. 1997, 66, 573–581. [Google Scholar] [CrossRef]

- Matsuyama, H.; Young, J.F. Intercalation of polymers in calcium silicate hydrate: A new synthetic approach to biocomposites. Chem. Mater. 1999, 11, 16–19. [Google Scholar] [CrossRef]

- Strawhecker, K.E.; Manias, E. Structure and properties of poly(vinyl alcohol)/Na.-montmorillonite nanocomposites. Chem. Mater. 2000, 12, 2943–2949. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Yan, D. Properties of poly(vinyl alcohol)/montmorillonite nanocomposite fiber. Polym. Prepr. 2003, 44, 1102–1103. [Google Scholar]

- Francis, C.W. Adsorption of polyvinylpyrrolidone on reference clay minerals. Soil Sci. 1973, 115, 40–54. [Google Scholar] [CrossRef]

- Carrado, K.A.; Xu, L. In-situ synthesis of polymer–clay nanocomposites from silicate gel. Chem. Mater. 1998, 10, 1440–1445. [Google Scholar] [CrossRef]

- Gultek, A.; Seckin, T.; Onal, Y.; Icduygu, G. Preparation and phenol captivating properties of polyvinylpyrrolidone–montmorillonite hybrid materials. J. Appl. Polym. Sci. 2001, 81, 512–519. [Google Scholar] [CrossRef]

- Levy, R.; Francis, C.W. Interlayer adsorption of polyvinylpyrrolidone on montmorillonite. J. Colloid Interface Sci. 1975, 50, 442–450. [Google Scholar] [CrossRef]

- Koo, C.M.; Ham, H.T.; Choi, M.H.; Kim, S.O.; Chung, I.J. Characteristic of poly(vinyl pyrrolidone)-layered silicate nanocomposites prepared by attrition ball milling. Polymer 2003, 44, 681–689. [Google Scholar] [CrossRef]

- Komori, Y.; Sugahara, Y.; Kuroda, K. Direct intercalation of poly(vinylpyrrolidinone) into kaolinite by a refined guest displacement method. Chem. Mater. 1999, 11, 3–6. [Google Scholar] [CrossRef]

- Nisha, A.; Rajeswari, M.K.; Dhamodharan, R. Intercalative redox polymerization and characterization of poly(n-vinyl-2-pyrrolidinone) in the gallery of vermiculite: A novel inorganic–organic hybrid material. J. Appl. Polym. Sci. 2000, 76, 1825–1830. [Google Scholar] [CrossRef]

- Fournaris, K.G.; Karakassides, M.A.; Petridis, D.; Yiannakopoulou, K. Clay–polyvinylpyridine nanocomposites. Chem. Mater. 1999, 11, 2372–2381. [Google Scholar] [CrossRef]

- Parfitt, R.L.; Greenland, D.J. The adsorption of poly(ethylene glycols) on clay minerals. Clay Miner. 1970, 8, 305–315. [Google Scholar] [CrossRef]

- Zhao, X.; Urano, K.; Ogasawara, S. Adsorption of poly(ethylene vinyl alcohol) from aqueous solution on montmorillonite clays. Colloid Polym. Sci. 1989, 267, 899–906. [Google Scholar] [CrossRef]

- Priya, L.; Jog, J.P. Intercalated poly(vinylidene fluoride)/clay nanocomposites: Structure and properties. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 31–38. [Google Scholar] [CrossRef]

- Oriakhi, C.O.; Zhang, X.; Lerner, M.M. Synthesis and luminescence properties of a poly( p-phenylenevinylene)/montmorillonite layered nanocomposite. Appl. Clay. Sci. 1999, 15, 109–118. [Google Scholar] [CrossRef]

- Hsu, S.L.C.; Chang, K.C. Synthesis and properties of polybenzoxazole–clay nanocomposites. Polymer 2002, 43, 4097–4101. [Google Scholar] [CrossRef]

- Kim, S.W.; Jo, W.H.; Lee, M.S.; Ko, M.B.; Jho, J.Y. Preparation of clay-dispersed poly(styrene-co-acrylonitrile) nanocomposites using poly(1-caprolactone) as a compatibilizer. Polymer 2001, 42, 9837–9842. [Google Scholar] [CrossRef]

- Artzi, N.; Nir, Y.; Nakris, M.; Seigmann, A. Melt blending of ethylene–vinyl alcohol copolymer/clay nanocomposites: Effect of the clay type and processing conditions. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 1741–1753. [Google Scholar] [CrossRef]

- Ren, J.; Silva, A.S.; Krishnamoorti, R. Linear viscoelasticity of disordered polystyrene–polyisoprene block copolymer based layered-silicate nanocomposites. Macromolecules 2000, 33, 3739–3746. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Krishnamoorti, R. Rheological properties of diblock copolymer/layered-silicate nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 1434–1443. [Google Scholar] [CrossRef]

- Mark, J.E. Ceramic reinforced polymers and polymermodified ceramics. Polym. Eng. Sci. 1996, 36, 2905–2920. [Google Scholar] [CrossRef]

- Usuki, A.; Kojima, Y.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Synthesis of nylon-6–clay hybrid. J. Mater. Res. 1993, 8, 1179–1183. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Mechanical properties of nylon6–clay hybrid. J. Mater. Res. 1993, 8, 1185–1189. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Synthesis of nylon-6 hybrid by montmorillonite intercalated with 1-caprolactam. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 983–986. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. One-pot synthesis of nylon 6–clay hybrid. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 1755–1758. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Sorption of water in nylon 6–clay hybrid. J. Appl. Polym. Sci. 1993, 49, 1259–1264. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O.; Kaji, K. Fine structure of nylon 6–clay hybrid. J. Polym. Sci. Part B Polym. Phys. 1994, 32, 625–630. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O.; Kaji, K. Novel preferred orientation in injection-molded nylon 6–clay nanocomposites. J. Polym. Sci. Part B Polym. Phys. 1995, 33, 1039–1045. [Google Scholar] [CrossRef]

- Usuki, A.; Koiwai, A.; Kojima, Y.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Nylon 6/clay nanocomposites. J. Appl. Polym. Sci. 1995, 55, 119–123. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater Sci. Eng. Eng. R 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Liu, L.M.; Qi, Z.N.; Zhu, X.G. Studies on nylon 6/clay nanocomposites by melt-intercalation process. J. Appl. Polym. Sci. 1999, 71, 1133–1138. [Google Scholar] [CrossRef]

- Wu, S.H.; Wang, F.Y.; Ma, C.-C.M.; Chang, W.C.; Kuo, C.T.; Kuan, H.C.; Chen, W.J. Mechanical, thermal and morphological properties of glass fiber and carbon fiber reinforced polyamide-6 and polyamide-6/clay nanocomposites. Mater. Lett. 2001, 49, 327–333. [Google Scholar] [CrossRef]

- Lincoln, D.M.; Vaia, R.A.; Wang, Z.G.; Hsiao, B.S. Secondary structure and elevated temperature crystallite morphology of nylon-6/layered silicate nanocomposites. Polymer 2001, 42, 1621–1631. [Google Scholar] [CrossRef]

- Medellin-Rodriguez, F.J.; Burger, C.; Hsiao, B.S.; Chu, B.; Vaia, R.A.; Phillips, S. Time-resolved shear behavior of end-tethered nylon 6–clay nanocomposites followed by non-isothermal crystallization. Polymer 2001, 42, 9015–9023. [Google Scholar] [CrossRef]

- Dennis, H.R.; Hunter, D.L.; Chang, D.; Kim, S.; White, J.L.; Cho, J.W.; Paul, D.R. Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 2001, 42, 9513–9522. [Google Scholar] [CrossRef]

- VanderHart, D.L.; Asano, A.; Gilman, J.W. Solid-state NMR investigation of paramagnetic nylon-6 clay nanocomposites. 1. Crystallinity, morphology, and the direct influence of Fe3+ on nuclear spins. Chem. Mater. 2001, 13, 3781–3795. [Google Scholar] [CrossRef]

- Shelley, J.S.; Mather, P.T.; DeVries, K.L. Reinforcement and environmental degradation of nylon 6/clay nanocomposites. Polymer 2001, 42, 5849–5858. [Google Scholar] [CrossRef]

- Fornes, T.D.; Yoon, P.J.; Keskkula, H.; Paul, D.R. Nylon 6 nanocomposites: The effect of matrix molecular weight. Polymer 2001, 42, 9929–9940. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q. Phase transition in nylon 6/clay nanocomposites on annealing. Polymer 2002, 43, 1933–1936. [Google Scholar] [CrossRef]

- Fornes, T.D.; Yoon, P.J.; Hunter, D.L.; Keskkula, H.; Paul, D.R. Effect of organoclay structure on nylon-6 nanocomposite morphology and properties. Polymer 2002, 43, 5915–5933. [Google Scholar] [CrossRef]

- Kamal, M.R.; Borse, N.K.; Garcia-Rejon, A. The effect of pressure and clay on the crystallization behavior and kinetics of polyamide-6 in nanocomposites. Polym. Eng. Sci. 2002, 42, 1883–1896. [Google Scholar] [CrossRef]

- Bureau, M.N.; Denault, J.; Cole, K.C.; Enright, G.D. The role of crystallinity and reinforcement in the mechanical behavior of polyamide-6/clay nanocomposites. Polym. Eng. Sci. 2002, 42, 1897–1907. [Google Scholar] [CrossRef]

- Uribe-Arocha, P.; Mehler, C.; Puskas, J.E.; Altstadt, V. Effect of sample thickness on the mechanical properties of molded polyamide-6 and polyamide-6 clay nanocomposites. Polymer 2003, 44, 2441–2446. [Google Scholar] [CrossRef]

- Hasegawa, N.; Okamoto, H.; Kato, M.; Usuki, A.; Sato, N. Nylon 6–montmorillonite nanocomposites prepared by compounding nylon 6 with Na-montmorillonite slurry. Polymer 2003, 44, 2933–2937. [Google Scholar] [CrossRef]

- Ding, Y.; Jones, D.J.; Maireles-Torres, P.; Roziere, J. Twodimensional nanocomposites: Alternating inorganic–organic polymer layers in zirconium phosphate. Chem. Mater. 1995, 7, 562–571. [Google Scholar] [CrossRef]

- Reichert, P.; Kressler, J.; Thomann, R.; Mulhaupt, R.; Stoppelmann, G. Nanocomposites based on a synthetic layer silicate and polyamide-12′. Acta Polym. 1998, 49, 116–123. [Google Scholar] [CrossRef]

- Hoffman, B.; Kressler, J.; Stoppelmann, G.; Friedrich, C.; Kim, G.M. Rheology of nanocomposites based on layered silicate and polyamide-12′. Colloid Polym. Sci. 2000, 278, 629–636. [Google Scholar] [CrossRef]

- Giza, E.; Ito, H.; Kikutani, T.; Okui, N. Structural control of polyamide 6/clay nanocomposites fibers in-line drawing process. J. Polym. Eng. 2000, 20, 403–425. [Google Scholar] [CrossRef]

- Kim, G.M.; Lee, D.H.; Hoffmann, B.; Kresler, J.; Stoppelmann, G. Influence of nanofillers on the deformation process in layered silicate/polyamide-12 nanocomposites. Polymer 2001, 42, 1095–1100. [Google Scholar] [CrossRef]

- Nair, S.V.; Goettler, L.A.; Lysek, B.A. Toughness of nanoscale and multiscale polyamide-6,6 composites. Polym. Eng. Sci. 2002, 42, 1872–1882. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q.; Zhang, Q.; Mo, Z. Phase transition in polyamide-66/montmorillonite nanocomposites on annealing. J. Polym. Sci. Part B Polym. Phys. 2003, 44, 6367. [Google Scholar] [CrossRef]

- Messersmith, P.B.; Giannelis, E.P. Polymer-layered silicate nanocomposites: In-situ intercalative polymerization of ε-caprolactone in layered silicates. Chem. Mater. 1993, 5, 1064–1066. [Google Scholar] [CrossRef]

- Jimenez, G.; Ogata, N.; Kawai, H.; Ogihara, T. Structure and thermal/mechanical properties of poly(ε-caprolactone)–clay blend. J. Appl. Polym. Sci. 1997, 64, 2211–2220. [Google Scholar] [CrossRef]

- Krishnamoorti, R.; Giannelis, E.P. Rheology of end-tethered polymer layered silicate nanocomposites. Macromolecules 1997, 30, 4097–4102. [Google Scholar] [CrossRef]

- Pantoustier, N.; Alexandre, M.; Degee, P.; Calberg, C.; Jerome, R.; Henrist, C.; Cloots, R.; Rulmont, A.; Dubois, P. Poly(ε-caprolactone) layered silicate nanocomposites: Effect of clay surface modifiers on the melt intercalation process. e-Polymer 2001, 9, 1–9. [Google Scholar] [CrossRef]

- Shima, R.; Utracki, L.A.; Garcia-Rejon, A. Pressure–volume–temperature relations of a poly-ε-caprolactam and its nanocomposite. Compos. Interfaces 2001, 8, 345–353. [Google Scholar]

- Pantoustier, N.; Lepoittevin, B.; Alexandre, M.; Kubies, D.; Calberg, C.; Jerome, R.; Dubois, P. Biodegradable polyester layered silicate nanocomposites based on poly(ε-caprolactone). Polym. Eng. Sci. 2002, 42, 1928–1937. [Google Scholar] [CrossRef]

- Lepoittevin, B.; Pantoustier, N.; Devalckenaere, M.; Alexandre, M.; Kubies, D.; Calderg, C.; Jerome, R.; Dubois, P. Poly(ε-caprolactone)/clay nanocomposites by in-situ intercalative polymerization catalyzed by dibutyltindimethoxide. Macromolecules 2002, 35, 8385–8390. [Google Scholar] [CrossRef]

- Lepoittevin, B.; Devalckenaere, M.; Pantoustier, N.; Alexandre, M.; Kubies, D.; Calberg, C.; Jerome, R.; Dubois, P. Poly(ε-caprolactone)/clay nanocomposites prepared by melt intercalation: Mechanical, thermal and rheological properties. Polymer 2002, 43, 4017–4023. [Google Scholar] [CrossRef]

- Gorrasi, G.; Tortora, M.; Vittoria, V.; Pollet, E.; Lepoittenvin, B.; Alexandre, M.; Dubois, P. Vapor barrier properties of polycaprolactone montmorillonite nanocomposites: Effect of clay dispersion. Polymer 2003, 44, 2271–2279. [Google Scholar] [CrossRef]

- Utracki, L.A.; Simha, R.; Garcia-Rejon, A. Pressure–volume–temperature dependence of poly-ε-caprolactam/clay nanocomposites. Macromolecules 2003, 36, 2114–2121. [Google Scholar] [CrossRef]

- Lepoittevin, B.; Pantoustier, N.; Devalckenaere, M.; Alexandre, M.; Calberg, C.; Jerome, R.; Henrist, C.; Rulmont, A.; Dubois, P. Polymer/layered silicate nanocomposites by combined intercalative polymerization and melt intercalation: A master batch process. Polymer 2003, 44, 2033–2040. [Google Scholar] [CrossRef]

- Wu, T.M.; Cheng, J.-C.; Yan, M.-C. Crystallization and thermoelectric behavior of conductive-filler-filled poly(ε-caprolactone)/poly(vinyl butyral)/montmorillonite nanocomposites. Polymer 2003, 44, 2553–2562. [Google Scholar] [CrossRef]

- Ke, Y.C.; Long, C.; Qi, Z. Crystallization, properties, and crystal and nanoscale morphology of PET–clay nanocomposites. J. Appl. Polym. Sci. 1999, 71, 1139–1146. [Google Scholar] [CrossRef]

- Sekelik, D.J.; Stepanov Enazarenko, S.; Schiraldi, D.; Hiltner, A.; Baer, E. Oxygen barrier properties of crystallized and talcfilled poly(ethylene terephthalate). J. Polym. Sci. Part B Polym. Phys. 1999, 37, 847–857. [Google Scholar] [CrossRef]

- Matayabas, J.C., Jr.; Turner, S.R.; Sublett, B.J.; Connell, G.W.; Barbee, R.B. Nanocomposite technology for enhancing the gas barrier of polyethylene terephthalate. PCT Int. Appl. Wo. 1998, 98, 29499. [Google Scholar]

- Takekoshi, T.; Khouri, F.F.; Campbell, J.R.; Jordan, T.C.; Dai, K.H.; General Electric Co. PET nanocomposites prepared by in situ incorporation of varying amounts of four different organoclays. U.S. Patent 5,530,052, 25 June 1996. [Google Scholar]

- Tsai, T.Y. Polyethylene terephthalate–clay nanocomposites. In Polymer–Clay Nanocomposites; Pinnavaia, T.J., Beall, G.W., Eds.; John Wiley and Sons: Chichester, UK, 2000; pp. 173–189. [Google Scholar]

- Davis, C.H.; Mathias, L.J.; Gilman, J.W.; Schiraldi, D.A.; Shields, J.R.; Trulove, P.; Sutto, T.E.; Delong, H.C. Effects of melt-processing conditions on the quality of poly(ethylene terephthalate) montmorillonite clay nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 2661–2666. [Google Scholar] [CrossRef]

- Imai, Y.; Nishimura, S.; Abe, E.; Tateyama, H.; Abiko, A.; Yamaguchi, A.; Aoyama, T.; Taguchi, H. High-modulus poly(ethylene terephthalate)/expandable fluorine mica nanocomposites with a novel reactive compatibilizer. Chem. Mater. 2002, 14, 477–479. [Google Scholar] [CrossRef]

- Liu, Z.; Yan, D.; Chen, K. Preparation of poly(trimethylene terephthalate)/montmorillonite nanocomposite by melt intercalation. Polym. Prepr. 2003, 44, 1138–1139. [Google Scholar]

- Duan, Q.; Yan, D. Poly(trimethylene terephthalate)–montmorillonite nanocomposite made by in situ polymerization. Polym. Prepr. 2003, 44, 1140–1141. [Google Scholar]

- Chisholm, B.J.; Moore, R.B.; Barber, G.; Khouri, F.; Hempstead, A.; Larsen, M.; Olson, E.; Kelley, J.; Balch, G.; Caraher, J. Nanocomposites derived from sulfonated poly(butylene terephthalate). Macromolecules 2002, 35, 5508–5516. [Google Scholar] [CrossRef]

- Huang, X.; Lewis, S.; Brittain, W.J.; Vaia, R.A. Synthesis of polycarbonate-layered silicate nanocomposites via cyclic oligomers. Macromolecules 2000, 33, 2000–2004. [Google Scholar] [CrossRef]

- Mitsunaga, M.; Ito, Y.; Sinha Ray, S.; Okamoto, M.; Hironaka, K. Polycarbonate/clay nanocomposites: Nanostructure control and foam processing. Macromol. Mater. Eng. 2003, 288, 543–548. [Google Scholar] [CrossRef]

- Wu, J.; Lerner, M.M. Structural, thermal, and electrical characterization of layered nanocomposites derived from sodium-montmorillonite and polyethers. Chem. Mater. 1993, 5, 835–838. [Google Scholar] [CrossRef]

- Vaia, R.A.; Vasudevan, S.; Krawiec, W.; Scanlon, L.G.; Giannelis, E.P. New polymer electrolyte nanocomposites: Melt intercalation of poly(ethylene oxide) in mica-type silicates. Adv. Mater. 1995, 7, 154–156. [Google Scholar] [CrossRef]

- Wong, S.; Vasudevan, S.; Vaia, R.A.; Giannelis, E.P.; Zax, D. Dynamics in a confined polymer electrolyte: A 7Li and 2H NMR study. J. Am. Chem. Soc. 1995, 117, 7568–7569. [Google Scholar] [CrossRef]

- Vaia, R.A.; Sauer, B.B.; Tse, O.K.; Giannelis, E.P. Relaxations of confined chains in polymer nanocomposites: Glass transition properties of poly(ethylene oxide) intercalated in montmorillonite. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 59–67. [Google Scholar] [CrossRef]

- Aranda, P.; Galvan, J.C.; Ruiz-Hitzky, E. Isotropic PEO–clay nanocomposites prepared by microwave-assisted blending intercalation. In Organic/Inorganic Hybrid Materials: MRS Symposium Proceedings; Laine, R.M., Sanchez, C., Brinker, J.F., Giannelis, E.P., Eds.; Cambridge University Press: Warrendale, PA, USA, 1998; Volume 519, pp. 375–380. [Google Scholar]

- Hatharasinghe, H.L.M.; Smalley, M.V.; Swenson, J.; Willians, C.D.; Heenan, R.K.; King, S.M. Neutron scattering study of vermiculite–PEO mixtures. J. Phys. Chem. B 1998, 102, 6804–6808. [Google Scholar] [CrossRef]

- Hernan, L.; Morales, J.; Santos, J. Synthesis and characterization of poly(ethylene oxide) nanocomposites of misfit layer chalcogenides. J. Solid State Chem. 1998, 141, 327–329. [Google Scholar] [CrossRef]

- Harris, D.J.; Bonagamba, T.J.; Schmidt-Rhor, K. Conformation of poly(ethylene oxide) intercalated in clay and MoS2 studied by two dimensional double-quantum NMR. Macromolecules 1999, 32, 6718–6724. [Google Scholar] [CrossRef]

- Chen, W.; Xu, Q.; Yuan, R.Z. Modification of poly(ethylene oxide) with polymethylmethacrylate in polymer-layered silicate nanocomposites. J. Mater. Sci. Lett. 1999, 18, 711–713. [Google Scholar] [CrossRef]

- Bujdak, J.; Hackett, E.; Giannelis, E.P. Effect of layer charge on the intercalation of poly(ethylene oxide) in layered silicates: Implications on nanocomposite polymer electrolytes. Chem. Mater. 2000, 12, 2168–2174. [Google Scholar] [CrossRef]

- Schmidt, G.; Nakatani, A.I.; Butler, P.D.; Karim, A.; Han, C.C. Shear orientation of viscoelastic polymer–clay solutions probed by flow birefringence and SANS. Macromolecules 2000, 33, 7219–7222. [Google Scholar] [CrossRef]

- Xiao, Y.; Hu, K.A.; Yu, Q.C.; Wu, R.J. Preparation of polyethylene oxide/LixV2–δO4–δ nanocomposites. J. Appl. Polym. Sci. 2001, 80, 2162–2166. [Google Scholar] [CrossRef]

- Choi, H.J.; Kim, S.G.; Hyun, Y.H.; Jhon, M.S. Preparation and rheological characteristics of solvent-cast poly(ethylene oxide)/montmorillonite nanocomposites. Macromol. Rapid Commun. 2001, 22, 320–325. [Google Scholar] [CrossRef]

- Hyun, Y.H.; Lim, S.T.; Choi, H.J.; Jhon, M.S. Rheology of poly(ethylene oxide)/organoclay nanocomposites. Macromolecules 2001, 34, 8084–8093. [Google Scholar] [CrossRef]

- Liao, B.; Song, M.; Liang, H.; Pang, Y. Polymer-layered silicate nanocomposites. 1. A study of poly(ethylene oxide)/Na+-montmorillonite nanocomposites as polyelectrolytes and polyethylene-block-poly(ethylene glycol) copolymer/Na+-montmorillonite nanocomposites as fillers for reinforcement of polyethylene. Polymer 2001, 42, 10007–10011. [Google Scholar]

- Chen, H.W.; Chang, F.C. The novel polymer electrolyte nanocomposite composed of poly(ethylene oxide), lithium triflate and mineral clay. Polymer 2001, 42, 9763–9769. [Google Scholar] [CrossRef]

- Chen, H.W.; Chiu, C.Y.; Wu, H.D.; Shen, I.W.; Chang, F.C. Solidstate electrolyte nanocomposites based on poly(ethylene oxide), poly(oxypropylene) diamine, mineral clay and lithium perchlorate. Polymer 2002, 43, 5011–5016. [Google Scholar] [CrossRef]

- Shen, Z.; Simon, G.P.; Cheng, Y.B. Comparison of solution intercalation and melt intercalation of polymer–clay nanocomposites. Polymer 2002, 43, 4251–4260. [Google Scholar] [CrossRef]

- Lim, S.K.; Kim, J.W.; Chin, I.; Kwon, Y.K.; Choi, H.J. Preparation and interaction characteristics of organically modified montmorillonite nanocomposite with miscible polymer blend of poly(ethylene oxide) and poly(methyl methacrylate). Chem. Mater. 2002, 14, 1989–1994. [Google Scholar] [CrossRef]

- Strawhecker, K.E.; Manias, E. Crystallization behavior of poly(ethylene oxide) in the presence of Na+-montmorillonite fillers. Chem. Mater. 2003, 15, 844–849. [Google Scholar] [CrossRef]

- Chaiko, D.J. New poly(ethylene oxide)–clay composites. Chem. Mater. 2003, 15, 1105–1110. [Google Scholar] [CrossRef]

- Fischer, H.R.; Gielgens, L.H.; Koster, T.P.M. Ethylene oxide copolypers/clay nanocomposites. In Organic/Inorganic Hybrid Materials: MRC Symposium Proceedings; Laine, R.M., Sanchez, C., Brinker, J.F., Giannelis, E.P., Eds.; Cambridge University Press: Warrendale, PA, USA, 1998; Volume 519, pp. 517–520. [Google Scholar]

- Fischer, H.R.; Gielgens, L.H.; Koster, T.P.M. Nanocomposites from polymers and layered minerals. Acta. Polym. 1999, 50, 122–126. [Google Scholar] [CrossRef]

- Wei, L.; Rocci-Lane, M.; Brazis, P.; Kanneworf, C.R.; Kim, Y.I.; Lee, W.; Choy, J.H.; Kanatzidis, M.G. α-RuCl3/polymer nanocomposites: The first group of intercalative nanocomposites with transition metal halides. J. Am. Chem. Soc. 2000, 122, 6629–6640. [Google Scholar]

- Burnside, S.D.; Giannelis, E.P. Synthesis and properties of new poly(dimethylsiloxane) nanocomposites. Chem. Mater. 1995, 7, 1597–1600. [Google Scholar] [CrossRef]

- Wang, S.J.; Long, C.; Wang, X.; Li, Q.; Qi, Z. Synthesis and properties of silicone rubber organomontmorillonite hybrid nanocomposites. J. App.l Polym. Sci. 1998, 69, 1557–1561. [Google Scholar] [CrossRef]

- Takeuchi, H.; Cohen, C. Reinforcement of poly(dimethylsiloxane) elastomers by chain-end anchoring to clay particles. Macromolecules 1999, 32, 6792–6799. [Google Scholar] [CrossRef]

- Burnside, S.D.; Giannelis, E.P. Nanostructure and properties of polysiloxane-layered silicate nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 1595–1604. [Google Scholar] [CrossRef]

- Bokobza, L.; Nugay, N. Orientational effect of mica in fumed silica reinforced composites. J. Appl. Polym. Sci. 2001, 81, 215–222. [Google Scholar] [CrossRef]

- Osman, M.A.; Atallah, A.; Muller, M.; Suter, U.W. Reinforcement of poly(dimethylsiloxane) networks by mica flakes. Polymer 2001, 42, 6545–6556. [Google Scholar] [CrossRef]

- Nugay, N.; Kusefoglu, S.; Erman, B. Swelling and staticdynamic mechanical behavior of mica-reinforced linear and star-branched polybutadiene composites. J. Appl. Polym. Sci. 1997, 66, 1943–1952. [Google Scholar] [CrossRef]

- Akelah, A.; El-Borai, M.A.; El-Aal, M.F.A.; Rehab, A.; Abou-Zeid, M.S. New catalytic systems based on intercalated polymer–montmorillonite supports. Macromol. Chem. Phys. 1999, 200, 955–963. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Wang, Y.; Sui, Y.; Yu, D. Morphology and mechanical properties of clay/styrene-butadiene rubber nanocomposites. J. Appl. Polym. Sci. 2000, 78, 1873–1878. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Tang, C.; Yu, D. Preparation and characterization of rubber–clay nanocomposites. J. Appl. Polym. Sci. 2000, 78, 1879–1883. [Google Scholar] [CrossRef]

- Manna, A.K.; Tripathy, D.K.; De, P.P.; De, S.K.; Chatterjee, M.K.; Pfeiffer, D.G. Bonding between epoxidized natural rubber and clay in presence of silane coupling agent. J. Appl. Polym. Sci. 1999, 72, 1895–1903. [Google Scholar] [CrossRef]

- Vu, Y.T.; Mark, J.E.; Pham, L.H.; Engelhardt, M. Clay nanolayer reinforcement of cis-1,4-polyisoprene and epoxidized natural rubber. J. Appl. Polym. Sci. 2001, 82, 1391–1403. [Google Scholar] [CrossRef]

- Messersmith, P.B.; Giannelis, E.P. Synthesis and characterization of layered silicate-epoxy nanocomposites. Chem. Mater. 1994, 6, 1719–1725. [Google Scholar] [CrossRef]

- Lan, T.; Pinnavaia, T.J. Clay-reinforced epoxy nanocomposites. Chem. Mater. 1994, 6, 2216–2219. [Google Scholar] [CrossRef]

- Wang, M.S.; Pinnavaia, T.J. Clay–polymer nanocomposites formed from acidic derivatives of montmorillonite and an epoxy resin. Chem. Mater. 1994, 6, 468–474. [Google Scholar] [CrossRef]

- Lan, T.; Kaviratna, P.D.; Pinnavaia, T.J. Mechanism of clay tactoid exfoliation in epoxy-clay nanocomposites. Chem. Mater. 1995, 7, 2144–2150. [Google Scholar] [CrossRef]

- Wang, Z.; Lan, T.; Pinnavaia, T.J. Hybrid organic–inorganic nanocomposites formed from an epoxy polymer and a layered silicic acid (Magadiite). Chem. Mater. 1996, 8, 2200–2204. [Google Scholar] [CrossRef]

- Shi, H.; Lan, T.; Pinnavaia, T.J. Interfacial effects on the reinforcement properties of polymer–organoclay nanocomposites. Chem. Mater. 1996, 8, 1584–1587. [Google Scholar] [CrossRef]

- Pinnavaia, T.J.; Lan, T.; Wang, Z.; Shi, H.; Kaviratna, P.D. Mechanism of clay tactoid exfoliation in epoxy-clay nanocomposites. In Nanotechnology: Molecularly Designated Materials; ACS Symposium Series; Chow, G.M., Gonsalves, K.E., Eds.; American Chemical Society: Washington, DC, USA, 1996; Volume 622, pp. 244–250. [Google Scholar]

- Wang, Z.; Pinnavaia, T.J. Hybrid organic–inorganic nanocomposites: Exfoliation of magadiite nanolayers in an elastomeric epoxy polymer. Chem. Mater. 1998, 10, 1820–1826. [Google Scholar] [CrossRef]

- Wang, Z.; Massam, J.; Pinnavaia, T.J. Epoxy-clay nanocomposites. In Polymer–Clay Nanocomposites; Pinnavaia, T.J., Beall, G.W., Eds.; John Wiley and Sons: New York, NY, USA, 2000; pp. 127–149. [Google Scholar]

- Lee, D.C.; Jang, J.W. Characterization of epoxy-clay hybrid composite prepared by emulsion polymerization. J. Appl. Polym. Sci. 1998, 68, 1997–2005. [Google Scholar] [CrossRef]

- Zilg, C.; Mulhaupt, R.; Finter, J. Morphology and toughness/stiffness balance of nanocomposites based upon anhydridecured epoxy resins and layered silicates. Macromol. Chem. Phys. 1999, 200, 661–670. [Google Scholar] [CrossRef]

- Kornmann, X.; Lindberg, H.; Berglund, L.A. Synthesis of epoxyclay nanocomposites: Influence of the nature of the clay on structure. Polymer 2001, 42, 1303–1310. [Google Scholar] [CrossRef]

- Jiankun, L.; Yucai, K.; Zongneng, Q.; Xiao-Su, Y. Study on intercalation and exfoliation behavior of organoclays in epoxy resin. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 115–120. [Google Scholar] [CrossRef]

- Chin, I.J.; Albrecht, T.; Kim, H.C.; Russell, T.P.; Wang, J. On exfoliation of montmorillonite in epoxy. Polymer 2001, 42, 5947–5952. [Google Scholar] [CrossRef]

- Zerda, A.S.; Lesser, A.J. Intercalated clay nanocomposites: Morphology, mechanics, and fracture behavior. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 1137–1146. [Google Scholar] [CrossRef]

- Kornmann, X.; Thomann, R.; Mulhaupt, R.; Finter, J.; Berglund, L.A. High performance epoxy-layered silicate nanocomposites. Polym. Eng. Sci. 2002, 42, 1815–1826. [Google Scholar] [CrossRef]

- Feng, W.; Ait-Kadi, A.; Rield, B. Polymerization compounding: Epoxy-montmorillonite nanocomposites. Polym. Eng. Sci. 2002, 42, 1827–1835. [Google Scholar] [CrossRef]

- Becker, O.; Varley, R.; Simon, G. Morphology, thermal relaxations and mechanical properties of layered silicate nanocomposites based upon high-functionality epoxy resins. Polymer 2002, 43, 4365–4373. [Google Scholar] [CrossRef]

- Chen, J.S.; Poliks, M.D.; Ober, C.K.; Zhang, Y.; Wiesner, U.; Giannelis, E.P. Study of the interlayer expansion mechanism and thermal–mechanical properties of surface-initiated epoxy nanocomposites. Polymer 2002, 43, 4895–4904. [Google Scholar] [CrossRef]

- Kong, D.; Park, C.H. Real time exfoliation behavior of clay layers in epoxy-clay nanocomposites. Chem. Mater. 2003, 15, 419–424. [Google Scholar] [CrossRef]

- Park, J.H.; Jana, C.H. The relationship between nanoand micro-structures and mechanical properties in PMMA-epoxy-nanoclay composites. Polymer 2003, 44, 2091–2100. [Google Scholar] [CrossRef]

- Park, J.H.; Jana, C.H. Mechanism of exfoliation of nanoclay particles in epoxy-clay nanocomposites. Macromolecules 2003, 36, 2758–2768. [Google Scholar] [CrossRef]

- Choi, M.H.; Chung, I.J.; Lee, J.D. Morphology and curing behaviors of phenolic resin-layered silicate nanocomposites prepared by melt intercalation. Chem. Mater. 2000, 12, 2977–2983. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, T.; Zhi, L.; Yan, Y.; Yu, Y. Synthesis of novolac/layered silicate nanocomposites by reaction exfoliation using acid-modified montmorillonite. Macromol. Rapid. Commun. 2002, 23, 44–48. [Google Scholar] [CrossRef]

- Wang, Z.; Pinnavaia, T.J. Nanolayer reinforcement of elastomeric polyurethane. Chem. Mater. 1998, 10, 3769–3771. [Google Scholar] [CrossRef]

- Chen, T.K.; Tien, Y.I.; Wei, K.H. Synthesis and characterization of novel segmented polyurethane/clay nanocomposite via poly(ε--caprolactone)/clay. J. Polym. Sci. Part A Polym. Chem. 1999, 37, 2225–2233. [Google Scholar] [CrossRef]

- Tien, Y.I.; Wei, K.H. Hydrogen bonding and mechanical properties in segmented montmorillonite/polyurethane nanocomposites of different hard segment ratios. Polymer 2001, 42, 3213–3221. [Google Scholar] [CrossRef]

- Yao, K.J.; Song, M.; Hourston, D.J.; Luo, D.Z. Polymer/layered clay nanocomposites: 2. Polyurethane nanocomposites. Polymer 2002, 43, 1017–1020. [Google Scholar] [CrossRef]

- Xu, R.; Manias, E.; Snyder, A.J.; Runt, J. Low permeability biomedical polyurethane nanocomposites. J. Biomed. Mater. Res. A 2003, 64, 114–119. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Manias, E.; Snyder, A.J.; Runt, J. New biomedical poly(urethane uera)-layered silicate nanocomposites. Macromolecules 2001, 34, 337–339. [Google Scholar] [CrossRef]

- Lan, T.; Kaviratna, P.D.; Pinnavaia, T.J. On the nature of polyimide–clay hybrid composites. Chem. Mater. 1994, 6, 573–575. [Google Scholar] [CrossRef]

- Yano, K.; Usuki, A.; Okada, A. Synthesis and properties of polyimide–clay hybrid films. J. Polym. Sci. Part A Polym. Chem. 1997, 35, 2289–2294. [Google Scholar] [CrossRef]

- Zhu, Z.-K.; Yang, Y.; Yin, J.; Wang, X.Y.; Ke, Y.C.; Qi, Z.N. Preparation and properties of organosoluble montmorillonite/polyimide hybrid materials. J. Appl. Polym. Sci. 1999, 73, 2063. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, Z.K.; Yin, J.; Wang, X.Y.; Qi, Z.E. Preparation and properties of hybrids of organo-soluble polyimide and montmorillonite with various chemical surface modification methods. Polymer 1999, 40, 4407–4414. [Google Scholar] [CrossRef]

- Tyan, H.L.; Wei, K.H.; Hsieh, T.E. Mechanical properties of clay–polyimide (BTDA-ODA) nanocomposites via ODAmodified organoclay. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2873. [Google Scholar] [CrossRef]

- Gu, A.; Chang, F.C. A novel preparation of polyimide/clay hybrid films with low coefficient of thermal expansion. J. Appl. Polym. Sci. 2001, 79, 289–294. [Google Scholar] [CrossRef]

- Gu, A.; Kuo, S.W.; Chang, F.C. Syntheses and properties of PI/clay hybrids. J. Appl. Polym. Sci. 2001, 79, 1902–1910. [Google Scholar] [CrossRef]

- Hsiao, S.H.; Liou, G.S.; Chang, L.M. Synthesis and properties of organosoluble polyimide/clay hybrids. J. Appl. Polym. Sci. 2001, 80, 2067–2672. [Google Scholar] [CrossRef]

- Tyan, H.L.; Leu, C.M.; Wei, K.H. Effect of reactivity of organicsmodified montmorillonite on the thermal and mechanical properties of montmorillonite/polyimide nanocomposites. Chem. Mater. 2001, 13, 222–226. [Google Scholar] [CrossRef]

- Huang, J.C.; Zhu, Z.K.; Ma, X.D.; Qian, X.F.; Yin, J. Preparation and properties of montmorillonite/organo-soluble polyimide hybrid materials prepared by a one-step approach. J. Mater. Sci. 2001, 36, 871. [Google Scholar] [CrossRef]

- Agag, T.; Koga, T.; Takeichi, T. Studies on thermal and mechanical properties of polyimide–clay nanocomposites. Polymer 2001, 42, 3399–3408. [Google Scholar] [CrossRef]

- Morgan, A.B.; Gilman, J.W.; Jackson, C.L. Characterization of the dispersion of clay in a polyetherimide nanocomposite. Macromolecules 2001, 34, 2735–2738. [Google Scholar] [CrossRef]

- Leu, C.M.; Wu, Z.W.; Wei, K.H. Synthesis and properties of covalently bonded layered silicates/polyimide (BTDA-ODA) nanocomposites. Chem. Mater. 2001, 14, 3016–3021. [Google Scholar] [CrossRef]

- Magaraphan, R.; Lilayuthalert, W.; Sirivat, A.; Schwank, J.W. Preparation, structure, properties and thermal behavior of rigid-rod polyimide/montmorillonite nanocomposites. Compos. Sci. Technol. 2001, 61, 1253–1264. [Google Scholar] [CrossRef]

- Delozier, D.M.; Orwoll, R.A.; Cahoon, J.F.; Ladislaw, J.S.; Smith, J.G., Jr.; Connell, J.W. Polyimide nanocomposites prepared from high-temperature reduced charge organoclays. Polymer 2003, 44, 2231–2241. [Google Scholar] [CrossRef]

- Liang, Z.-M.; Yin, J.; Xu, H.-J. Polyimide/montmorillonite nanocomposites based on thermally stable, rigid-rod aromatic amine modifiers. Polymer 2003, 44, 1391–1399. [Google Scholar] [CrossRef]

- Tyan, H.L.; Liu, Y.C.; Wei, K.H. Enhancement of imidization of poly(amic acid) through poly(amic acid)/organoclay nanocomposites. Polymer 1999, 40, 4877–4886. [Google Scholar] [CrossRef]

- Kim, J.; Ahmed, R.; Lee, S.J. Synthesis and linear viscoelastic behavior of poly(amic acid)–organoclay hybrid. J. Appl. Polym. Sci. 2001, 80, 592–603. [Google Scholar] [CrossRef]

- Sur, G.S.; Sun, H.L.; Lyu, S.G.; Mark, J.E. Synthesis, structure, mechanical properties, and thermal stability of some polysulfone/organoclay nanocomposites. Polymer 2001, 42, 9783–9789. [Google Scholar] [CrossRef]

- Lee, J.; Takekkoshi, T.; Giannelis, E.P. Fire retardant polyetherimide nanocomposites. Mater. Res. Soc. Symp.Proc. 1997, 457, 513–518. [Google Scholar] [CrossRef]

- Huang, J.C.; Zhu, Z.K.; Qian, X.F.; Sun, Y.Y. Poly(etherimide)/ montmorillonite nanocomposites prepared by melt intercalation: Morphology, solvent resistance properties and thermal properties. Polymer 2001, 42, 873–877. [Google Scholar] [CrossRef]

- Vora, R.H.; Pallathadka, P.K.; Goh, S.H.; Chung, T.-S.; Lim, Y.X.; Bang, T.K. Preparation and characterization of 4,4′-bis(4-aminophenoxy)diphenyl sulphone based fluoropoly(etherimide)/organo-modified clay. Macromol. Mater. Eng. 2003, 288, 337–356. [Google Scholar] [CrossRef]

- Kurokawa, Y.; Yasuda, H.; Oya, A. Preparation of nanocomposites of polypropylene and smectite. J. Mater. Sci. Lett. 1996, 15, 1481–1487. [Google Scholar] [CrossRef]

- Furuichi, N.; Kurokawa, Y.; Fujita, K.; Oya, A.; Yasuda, H.; Kiso, M. Preparation and properties of polypropylene reinforced by smectite. J Mater Sci 1996, 31, 4307–4310. [Google Scholar] [CrossRef]

- Tudor, J.; Willington, L.; O’Hare, D.; Royan, B. Intercalation of catalytically active metal complexes in phyllosilicates and their application as propene polymerization catalyst. Chem. Commun. 1996, 17, 2031–2032. [Google Scholar] [CrossRef]

- Kurokawa, Y.; Yasuda, H.; Kashiwagi, M.; Oya, A. Structure and properties of a montmorillonite/polypropylene nanocomposite. J. Mater. Sci. Lett. 1997, 16, 1670–1672. [Google Scholar] [CrossRef]

- Nyden, M.R.; Gilman, J.W. Molecular dynamics simulations of the thermal degradation of nano-confined polypropylene. Comput. Theor. Polym. Sci. 1997, 7, 191–198. [Google Scholar] [CrossRef]

- Kato, M.; Usuki, A.; Okada, A. Synthesis of polypropylene oligomer–clay intercalation compounds. J. Appl. Polym. Sci. 1997, 66, 1781–1785. [Google Scholar] [CrossRef]

- Usuki, A.; Kato, M.; Okada, A.; Kurauchi, T. Synthesis of polypropylene–clay hybrid. J. Appl. Polym. Sci. 1997, 63, 137–138. [Google Scholar] [CrossRef]

- Kawasumi, M.; Hasegawa, N.; Kato, M.; Usuki, A.; Okada, A. Preparation and mechanical properties of polypropylene–clay hybrids. Macromolecules 1997, 30, 6333–6338. [Google Scholar] [CrossRef]

- Hasegawa, N.; Kawasumi, M.; Kato, M.; Usuki, A.; Okada, A. Preparation and mechanical properties of polypropylene–clay hybrids using a maleic anhydride-modified polypropylene oligomer. J. Appl. Polym. Sci. 1998, 67, 87–92. [Google Scholar] [CrossRef]

- Oya, A. Polypropylene–clay nanocomposites. In Polymer–Clay Nanocomposites; Pinnavaia, T.J., Beall, G.W., Eds.; John Wiley and Sons: London, UK, 2000; pp. 151–172. [Google Scholar]

- Hasegawa, N.; Okamoto, H.; Kato, M.; Usuki, A. Preparation and mechanical properties of polypropylene–clay hybrids based on modified polypropylene and organophilic clay. J. Appl. Polym. Sci. 2000, 78, 1918–1922. [Google Scholar] [CrossRef]

- Oya, A.; Kurokawa, Y.; Yasuda, H. Factors controlling mechanical properties of clay mineral/polypropylene nanocomposites. J. Mater. Sci. 2000, 35, 1045–1050. [Google Scholar] [CrossRef]

- Lee, J.W.; Lim, Y.T.; Park, O.O. Thermal characteristics of organoclay and their effects upon the formation of polypropylene/organoclay nanocomposites. Polym. Bull. 2000, 45, 191–198. [Google Scholar] [CrossRef]

- Zhang, Q.; Fu, Q.; Jiang, L.; Lei, Y. Preparation and properties of polypropylene/montmorillonite layered nanocomposites. Polym. Int. 2000, 49, 1561–1564. [Google Scholar] [CrossRef]

- Garces, J.M.; Moll, D.J.; Bicerano, J.; Fibiger, R.; McLeod, D.G. Polymeric nanocomposites for automotive applications. Adv. Mater. 2000, 12, 1835–1839. [Google Scholar] [CrossRef]

- Hasegawa, N.; Okamoto, H.; Kawasumi, M.; Kato, M.; Tsukigase, A.; Usuki, A. Polyolefin–clay hybrids based on modified polyolefins and organoclay. Macromol. Mater. Eng. 2000, 281, 76–79. [Google Scholar] [CrossRef]

- Hambir, S.; Bulakh, N.; Kodgire, P.; Kalgaonkar, R.; Jog, J.P. PP/clay nanocomposites: A study of crystallization and dynamic mechanical behavior. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 446–450. [Google Scholar] [CrossRef]

- Zanetti, M.; Camino, G.; Reichert, P.; Mulhaupt, R. Thermal behaviour of poly(propylene) layered silicate nanocomposites. Macromol. Rapid Commun. 2001, 22, 176–180. [Google Scholar] [CrossRef]

- Galgali, G.; Ramesh, C.; Lele, A. A rheological study on the kinetics of hybrid formation in propylene nanocomposites. Macromolecules 2001, 34, 852–858. [Google Scholar] [CrossRef]

- Solomon, M.J.; Almusallam, A.S.; Seefeldt, K.F.; Somwangthanaroj, A.; Varadan, P. Rheology of polypropylene/clay hybrid materials. Macromolecules 2001, 34, 1864–1872. [Google Scholar] [CrossRef]

- Gloaguen, J.M.; Lefebvre, J.M. Plastic deformation behavior of thermoplastic/clay nanocomposites. Polymer 2001, 42, 5841–5847. [Google Scholar] [CrossRef]

- Garcia-Martinez, J.M.; Laguna, O.; Areso, S.; Collar, E.P. Polypropylene/mica composites modified by succinic anhydride-grafted atactic polypropylene: A thermal and mechanical study under dynamic conditions. J. Appl. Polym. Sci. 2001, 81, 625–636. [Google Scholar] [CrossRef]

- Reichert, P.; Hoffman, B.; Bock, T.; Thomann, R.; Mulhaupt, R.; Friedrich, C. Morphological stability of polypropylene nanocomposites. Macromol. Rapid Commun. 2001, 22, 519–523. [Google Scholar] [CrossRef]

- Nam, P.H.; Maiti, P.; Okamoto, M.; Kotaka, T.; Hasegawa, N.; Usuki, A. A hierarchical structure and properties of intercalated polypropylene/clay nanocomposites. Polymer 2001, 42, 9633–9640. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q. PP/clay nanocomposites prepared by grafting-melt intercalation. Polymer 2001, 42, 10013–10019. [Google Scholar] [CrossRef]

- Manias, E. A direct-blending approach for polypropylene/clay nanocomposites enhances properties. Mater. Res. Soc. Bull. 2001, 26, 862–863. [Google Scholar]

- Okamoto, M.; Nam, P.H.; Maiti, P.; Kotaka, T.; Hasegawa, N.; Usuki, A. A house-of-cards structure in polypropylene/clay nanocomposites under elongational flow. Nano. Lett. 2001, 1, 295–298. [Google Scholar] [CrossRef]

- Okamoto, M.; Nam, P.H.; Maiti, M.; Kotaka, T.; Nakayama, T.; Takada, M.; Ohshima, M.; Usuki, A.; Hasegawa, N.; Okamoto, H. Biaxial flow-induced alignment of silicate layers in polypropylene/clay nanocomposite foam. Nano. Lett. 2001, 1, 503–505. [Google Scholar] [CrossRef]

- Sun, T.; Garces, J.M. High-performance polypropylene–clay nanocomposites by in-situ polymerization with metallocene/clay catalysts. Adv. Mater. 2002, 14, 128–130. [Google Scholar] [CrossRef]

- Maiti, P.; Nam, P.H.; Okamoto, M.; Kotaka, T.; Hasegawa, N.; Usuki, A. Influence of crystallization on intercalation, morphology, and mechanical properties of propylene/clay nanocomposites. Macromolecules 2002, 35, 2042–2049. [Google Scholar] [CrossRef]

- Maiti, P.; Nam, P.H.; Okamoto, M.; Kotaka, T.; Hasegawa, N.; Usuki, A. The effect of crystallization on the structure and morphology of polypropylene/clay nanocomposites. Polym. Eng. Sci. 2002, 42, 1864–1871. [Google Scholar] [CrossRef]

- Nam, P.H.; Maiti, P.; Okamoto, M.; Kotaka, T.; Nakayama, T.; Takada, M.; Ohshima, M.; Usuki, A.; Hasegawa, N.; Okamoto, H. Foam processing and cellular structure of polypropylene/clay nanocomposites. Polym. Eng. Sci. 2002, 42, 1907–1918. [Google Scholar] [CrossRef]

- Hambir, S.; Bulakh, N.; Jog, J.P. Propylene/clay nanocomposites: Effect of compatibilizer on the thermal, crystallization and dynamic mechanical behavior. Polym. Eng. Sci. 2002, 42, 1800–1807. [Google Scholar] [CrossRef]

- Kaempfer, D.; Thomann, R.; Mulhaupt, R. Melt compounding of syndiotactic polypropylene nanocomposites containing organophilic layered silicates and in situ formed core/shell nanoparticles. Polymer 2002, 43, 2909–2916. [Google Scholar] [CrossRef]

- Lele, A.; Mackley, M.; Galgali, G.; Ramesh, C. In situ rheo-Xray investigation of flow-induced orientation in layered silicate-syndiotactic polypropylene nanocomposite melt. J. Rheol. 2002, 46, 1091–1110. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Y.; Fu, Q. Shear-induced change of exfoliation and orientation in polypropylene/montmorillonite nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1–10. [Google Scholar] [CrossRef]

- Somwangthanaroj, A.; Lee, E.C.; Solomon, M.J. Early stage quiescent and flow-induced crystallization of intercalated polypropylene nanocomposites by time-resolved light scattering. Macromolecules 2003, 36, 2333–2342. [Google Scholar] [CrossRef]

- Morgan, A.B.; Harris, J.D. Effects of organoclay soxhlet extraction on mechanical properties, flammability properties and organoclay dispersion of polypropylene nanocomposites. Polymer 2003, 44, 2113–2120. [Google Scholar] [CrossRef]

- Jeon, H.G.; Jung, H.T.; Lee, S.W.; Hudson, S.D. Morphology of polymer silicate nanocomposites. High density polyethylene and a nitrile. Polym. Bull. 1998, 41, 107–113. [Google Scholar] [CrossRef]

- Heinemann, J.; Reichert, P.; Thomson, R.; Mulhaupt, R. Polyolefin nanocomposites formed by melt compounding and transition metal catalyzed ethane homo- and copolymerization in the presence of layered silicates. Macromol. Rapid Commun. 1999, 20, 423–430. [Google Scholar] [CrossRef]

- Privalko, V.P.; Calleja, F.J.B.; Sukhorukov, D.I.; Privalko, E.G.; Walter, R.; Friedrich, K. Composition-dependent properties of polyethylene/Kaolin composites. Part II. Thermoelastic behavior of blow-molded samples. J. Mater. Sci. 1999, 34, 497–508. [Google Scholar] [CrossRef]

- Bergman, J.S.; Chen, H.; Giannelis, E.P.; Thomas, M.G.; Coates, G.W. Synthesis and characterization of polyolefin-silicate nanocomposites: A catalyst intercalation and in situ polymerization approach. J. Chem. Soc. Chem. Commun. 1999, 21, 2179–2180. [Google Scholar] [CrossRef]

- Rong, J.; Jing, J.; Li, H.; Sheng, M. A polyethylene nanocomposite prepared via in-situ polymerization. Macromol. Rapid Commun. 2001, 22, 329–334. [Google Scholar] [CrossRef]

- Wang, K.H.; Choi, M.H.; Koo, C.M.; Choi, Y.S.; Chung, I.J. Synthesis and characterization of maleated polyethylene/clay nanocomposites. Polymer 2001, 42, 9819–9826. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P.; Sun, T.; Graces, J.M.; Jerome, R. Polyethylene-layered silicate nanocomposites prepared by the polymerization-filling technique: Synthesis and mechanical properties. Polymer 2002, 43, 2123–2132. [Google Scholar] [CrossRef]

- Gopakumar, T.G.; Lee, J.A.; Kontopoulou, M.; Parent, J.S. Influence of clay exfoliation on the physical properties of montmorillonite/polyethylene composites. Polymer 2002, 43, 5483–5491. [Google Scholar] [CrossRef]

- Jin, Y.-H.; Park, H.-J.; Im, S.-S.; Kwak, S.-Y.; Kwak, S. Polyethylene/clay nanocomposite by in situ exfoliation of montmorillonite during Ziegler–Natta polymerization of ethylene. Macromol. Rapid. Commun. 2001, 23, 135–140. [Google Scholar] [CrossRef]

- Bafna, A.; Beaucage, G.; Mirabella, F.; Mehta, S. 3D hierarchical orientation in polymer–clay nanocomposite films. Polymer 2003, 44, 1103–1115. [Google Scholar] [CrossRef]

- Osman, M.A.; Seyfang, G.; Suter, U.W. Two-dimensional melting of alkane monolayers ionically bonded to mica. J. Phys. Chem. B 2000, 104, 4433–4439. [Google Scholar] [CrossRef]

- Zanetti, M.; Camino, G.; Thomann, R.; Mulhaupt, R. Synthesis and thermal behavior of layered silicate-EVA nanocomposites. Polymer 2001, 42, 4501–4507. [Google Scholar] [CrossRef]

- Usuki, A.; Tukigase, A.; Kato, M. Preparation and properties of EPMD–clay hybrids. Polymer 2002, 43, 2185–2189. [Google Scholar] [CrossRef]

- Wanjale, S.D.; Jog, J.P. Poly(1-butene)/clay nanocomposites: Preparation and properties. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1014–1021. [Google Scholar] [CrossRef]

- Nazzal, A.I.; Street, G.B. Pyrrole-styrene graft copolymers. J. Chem. Soc. Chem. Commun. 1985, 375, 83–84. [Google Scholar] [CrossRef]

- Sun, Y.; Ruckenstein, E. Polypyrrole-bearing conductive composite prepared by an inverted emulsion pathway involving nonionic surfactants. Synth. Met. 1995, 72, 261–267. [Google Scholar] [CrossRef]

- Wang, L.; Brazis, P.; Rocci, M.; Kannewurf, C.R.; Kanatzidis, M.G. A new redox host for intercalative polymerization: Insertion of polyaniline into α-RuCl3′. Chem. Mater. 1999, 10, 3298–3300. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Biswas, M. Preparation and evaluation of composites from montmorillonite and some heterocyclic polymers: 3. A water dispersible nanocomposite from pyrrole–montmorillonite polymerization system. Mater. Res. Bull. 1998, 35, 1187–1194. [Google Scholar]

- Kim, J.W.; Liu, F.; Choi, H.J.; Hong, S.H.; Joo, J. Intercalated polypyrrole/Na.-montmorillonite nanocomposite via an inverted emulsion pathway method. Polymer 2003, 44, 289–293. [Google Scholar] [CrossRef]

- Biswas, M.; Sinha Ray, S. Preparation and evaluation of composites from montmorillonite and some heterocyclic polymers 1, poly(N-vinylcarbazole)–montmorillonite system. Polymer 1998, 39, 6423–6428. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Biswas, M. Preparation and evaluation of composites from montmorillonite and some heterocyclic polymers, II. Nanocomposite from N-vinylcarbazole and ferric chloride impregnated montmorillonite polymerization system. J. Appl. Polym. Sci. 1999, 73, 2971–2976. [Google Scholar]

- Kim, J.W.; Kim, S.G.; Choi, H.J.; Jhon, M.S. Synthesis and electrorheological properties of polyaniline–Na.-montmorillonite suspensions. Macromol. Rapid. Commun. 1999, 20, 450–452. [Google Scholar] [CrossRef]

- Biswas, M.; Sinha Ray, S. Water-dispersible nanocomposites of polyaniline and montmorillonite. J. Appl. Polym. Sci. 2000, 77, 2948–2956. [Google Scholar] [CrossRef]

- Dai, L.; Wang, Q.; Wan, M. Direct observation of conformational transitions for polyaniline chains intercalated in clay particles upon secondary doping. J. Mater. Sci. Lett. 2000, 19, 1645–1647. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Char, K.; Kim, J. Expansion distribution of basal spacing of the silicate layers in polyaniline/Na+-montmorillonite nanocomposites monitored with X-ray diffraction. Macromol. Rapid. Commun. 2000, 21, 1136–1139. [Google Scholar] [CrossRef]

- Wu, Q.; Xue, Z.; Qi, Z.; Wang, F. Synthesis and characterization of PAn/clay nanocomposite with extended chain conformation of polyaniline. Polymer 2000, 41, 2029–2032. [Google Scholar] [CrossRef]

- Uemura, S.; Yoshie, M.; Kobyashi, N.; Nakahira, T. Photopolymerization of aniline dimer by photocatalytic reaction of ruthenium trisbipyridyl in the interlayer of hectorite clay. Polym. J. 2000, 32, 987–990. [Google Scholar] [CrossRef]

- Kim, B.H.; Jung, J.H.; Joo, J.; Kim, J.W.; Choi, H.J. Charge transport and structure of nanocomposites of polyaniline and inorganic clay. J. Korean. Phys. Soc. 2000, 36, 366–370. [Google Scholar]

- Yeh, J.M.; Liou, S.J.; Lai, C.Y.; Wu, P.C.; Tsai, T.Y. Enhancement of corrosion protection effect in polyaniline via the formation of polyaniline–clay nanocomposite materials. Chem. Mater. 2001, 13, 1131–1136. [Google Scholar] [CrossRef]

- Feng, B.; Su, Y.; Song, J.; Kong, K. Electropolymerization of polyaniline/montmorillonite nanocomposite. J. Mater. Sci. Lett. 2001, 20, 293–294. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, S.G.; Choi, H.J.; Suh, M.S.; Shin, M.J.; Jhon, M.S. Synthesis and electrorheological characterization of polyaniline and Na+-montmorillonite clay nanocomposite. Int. J. Mod. Phys. 2001, 15, 657–664. [Google Scholar] [CrossRef]

- Kim, B.H.; Jung, J.H.; Kim, J.W.; Choi, H.J.; Joo, J. Physical characterization of polyaniline–Na+-montmorillonite nanocomposite intercalated by emulsion polymerization. Synth. Met. 2001, 117, 115–118. [Google Scholar] [CrossRef]

- Choi, H.J.; Kim, J.W.; Joo, J.; Kim, B.H. Synthesis and electrorheology of emulsion intercalated PANI–clay nanocomposite. Synth. Met. 2001, 121, 1325–1326. [Google Scholar] [CrossRef]

- Cho, M.S.; Choi, H.J.; Kim, K.Y.; Ahn, W.S. Synthesis and characterization of polyaniline/mesoporous SBA-15 nanocomposite. Macromol. Rapid Commun. 2002, 23, 713–716. [Google Scholar] [CrossRef]

- Kim, B.H.; Jung, J.H.; Hong, S.H.; Joo, J.; Epstein, A.J.; Mizoguchi, K.; Kim, J.W.; Choi, H.J. Nanocomposite of polyaniline and Na+-montmorillonite clay. Macromolecules 2002, 35, 1419–1423. [Google Scholar] [CrossRef]

- Nascimento GMdo Constantino, V.R.L.; Temperini, M.L.A. Spectroscopic characterization of a new type of conducting polymer–clay nanocomposite. Macromolecules 2002, 35, 7535–7537. [Google Scholar] [CrossRef]

- Winkler, B.; Dai, L.; Mau, A.W.-H. Organic–inorganic hybrid light-emitting composites: Poly( p-phenylene vinylene) intercalated clay nanoparticles. J. Mater. Sci. Lett. 1999, 18, 1539–1541. [Google Scholar] [CrossRef]

- Wright, M.E.; Schorman, D.A.; Feher, F.J.; Jin, R.-Z. Characterization of clays by organic compounds. Clay Miner. 1981, 16, 1–21. [Google Scholar]

- Kawasumi, M.; Hasegawa, N.; Usuki, A.; Okada, A. Nematic liquid crystal/clay mineral composites. Mater. Sci. Eng. C 1998, 6, 135–143. [Google Scholar] [CrossRef]

- Vaia, R.A.; Giannelis, E.P. Liquid crystal polymer nanocomposites: Direct intercalation of thermotropic liquid crystalline polymers into layered silicates. Polymer 2001, 42, 1281–1285. [Google Scholar] [CrossRef]

- Zhou, W.; Mark, J.E.; Unroe, M.R.; Arnold, F.E. Some clay nanocomposites based on a high temperature, high performance polymer. J. Macromol. Sci. Pure Appl. Chem. A 2001, 38, 1–9. [Google Scholar] [CrossRef]

- Chang, J.H.; Seo, B.S.; Hwang, D.H. An exfoliation of organoclay in thermotropic liquid crystalline polyester nanocomposites. Polymer 2002, 43, 2969–2974. [Google Scholar] [CrossRef]

- Plummer, C.J.G.; Garamszegi, L.; Leterrier, Y.; Rodler, T.M.; Manson, J.-A.E. Hyperbranched polymer-layered silicate nanocomposites. Chem. Mater. 2002, 14, 486–488. [Google Scholar] [CrossRef]

- Ganguli, S.; Dean, D.; Jordan, K.; Price, G.; Vaia, R. Mechanical properties of intercalated cyanate ester-layered silicate nanocomposites. Polymer 2003, 44, 1315–1319. [Google Scholar] [CrossRef]

- Young, S.K.; Mauritz, K.A. Nafion®/(organically modified silicate) nanocomposites via polymer in situ sol–gel reactions: Mechanical tensile properties. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 2237–2247. [Google Scholar] [CrossRef]

- Wright, M.E.; Schorman, D.A.; Feher, F.J.; Jin, R.-Z. Synthesis and thermal curing of aryl-ethyl-terminated coPOSS imide oligomers: New inorganic/organic hybrid resins. Chem. Mater. 2003, 15, 264–268. [Google Scholar] [CrossRef]

- Ogata, N.; Jimenez, G.; Kawai, H.; Ogihara, T. Structure and thermal/mechanical properties of poly(L-lactide)–clay blend. J. Polym. Sci. Part. B Polym. Phys. 1997, 35, 389–396. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Maiti, P.; Okamoto, M.; Yamada, K.; Ueda, K. New polylactide/layered silicate nanocomposites. 1. Preparation, characterization and properties. Macromolecules 2002, 35, 3104–3110. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, K.; Yamada, K.; Okamoto, M. Novel porous ceramic material via burning of polylactide/layered silicate nanocomposite. Nano Lett. 2002, 2, 423–426. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Yamada, K.; Okamoto, M.; Ueda, K. New polylactide/layered silicate nanocomposite: A novel biodegradable material. Nano Lett. 2002, 2, 1093–1096. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Yamada, K.; Ogami, A.; Okamoto, M.; Ueda, K. New polylactide layered silicate nanocomposite. Nanoscale control of multiple properties. Macromol. Rapid Commun. 2002, 23, 493–497. [Google Scholar]

- Maiti, P.; Yamada, K.; Okamoto, M.; Ueda, K.; Okamoto, K. New polylactide/layered silicate nanocomposites. Role of organoclay. Chem. Mater. 2002, 14, 4654–4661. [Google Scholar] [CrossRef]

- Pluta, M.; Caleski, A.; Alexandre, M.; Paul, M.-A.; Dubois, P. Polylactide/montmorillonite nanocomposites and microcomposites prepared by melt blending: Structure and some physical properties. J. Appl. Polym. Sci. 2002, 79, 1497–1506. [Google Scholar] [CrossRef]

- Paul, M.-A.; Alexandre, M.; Degee, P.; Henrist, C.; Rulmont, A.; Dubois, P. New nanocomposite materials based on plasticized poly(L-lactide) and organo-modified montmorillonites: Thermal and morphological study. Polymer 2003, 44, 443–450. [Google Scholar] [CrossRef]

- Chang, J.-H.; Uk-An, Y.; Sur, G.S. Poly(lactic acid) nanocomposites with various organoclays. I. Thermomechanical properties, morphology, and gas permeability. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 94–103. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Yamada, K.; Okamoto, M.; Ueda, K. New polylactide/layered silicate nanocomposites. 2. Concurrent improvements of material properties, biodegradability and melt rheology. Polymer 2003, 44, 857–866. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, K.; Maiti, P.; Okamoto, M. New poly(butylene succinate)/layered silicate nanocomposites. 1. Preparation, characterization, and mechanical properties. J. Nanosci. Nanotechnol. 2002, 2, 171–176. [Google Scholar]

- Sinha Ray, S.; Okamoto, K.; Okamoto, M. Structure–property relationship in biodegradable poly(butylene succinate)/layered silicate nanocomposites. Macromolecules 2003, 36, 2355–2367. [Google Scholar] [CrossRef]

- Gao, F. New poly(butylene succinate)/layered silicate nanocomposites. 2. Effect of organically modified layered silicates on morphology, materials properties, melt rheology, and biodegradability. J. Polym. Sci. Part B 2003, 41, 3160–3172. [Google Scholar]

- Kornmann, X.; Berglund, L.A.; Sterete, J.; Giannelis, E.P. Nanocomposites based on montmorillonite and unsaturated polyester. Polym. Eng. Sci. 1998, 38, 1351–1358. [Google Scholar] [CrossRef]

- Choi, H.J.; Kim, J.H.; Kim, J. Mechanical spectroscopy studies on biodegradable synthetic and biosynthetic aliphatic polyesters. Macromol. Symp. 1997, 119, 149–155. [Google Scholar] [CrossRef]

- Park, S.H.; Choi, H.J.; Lim, S.T.; Shin, T.K.; Jhon, M.S. Viscoelasticity of biodegradable polymer blends of poly(3-hydroxybutyrate) and poly(ethylene oxide). Polymer 2001, 42, 5737–5742. [Google Scholar] [CrossRef]

- Maiti, P.; Batt, C.A.; Giannelis, E.P. Renewable plastics: Synthesis and properties of PHB nanocomposites. Polym. Mater. Sci. Eng. 2003, 88, 58–59. [Google Scholar]

- Lee, S.R.; Park, H.M.; Lim, H.L.; Kang, T.; Li, X.; Cho, W.J.; Ha, C.S. Microstructure, tensile properties, and biodegradability of aliphatic polyester/clay nanocomposites. Polymer 2002, 43, 2495–2500. [Google Scholar] [CrossRef]

- Lepoittevin, B.; Pantoustier, N.; Alexander, M.; Calberg, C.; Jerome, R.; Dubois, P. Polyester layered silicate nanohybrids by controlled grafting polymerization. J. Mater. Chem. 2002, 12, 3528–3532. [Google Scholar] [CrossRef]

- Bharadwaj, R.K.; Mehrabi, A.R.; Hamilton, C.; Murga, M.F.; Chavira, A.; Thompson, A.K. Structure–property relationships in cross-linked polyester–clay nanocomposites. Polymer 2002, 43, 3699–3705. [Google Scholar] [CrossRef]

- Lim, S.T.; Hyun, Y.H.; Choi, H.J.; Jhon, M.S. Synthetic biodegradable aliphatic polyester/montmorillonite nanocomposites. Chem. Mater. 2002, 14, 1839–1844. [Google Scholar] [CrossRef]

- Gao, F. Clay/Polyme Composites: The Story. Mater. Today 2004, 7, 50–55. [Google Scholar] [CrossRef]

- Okamoto, M. Propertoes and Applications of Polyme Nanocompostes. Seikei–Kakou 2013, 25, 63–67. [Google Scholar]

- Koo, J. (Ed.) Fundamentals, Propertoes, and Applications of Polyme Nanocompostes; Cambridge University Press: New York, NY USA, 2016; p. 697. [Google Scholar]

| Improved Properties | Disadvantages |

|---|---|

| Mechanical properties (tensile strength, | Melt viscosity increase |

| stiffness, toughness) | Dispersion difficulties of nano-fillers |

| Gas permeability | Haze properties |

| Free volume reduction in matrix polymer | Sedimentation |

| Heat resistance | Color issues |

| Flame retardant | Cost of creating nano-fillers |

| Dimensional stability | Safety of nano-fillers |

| Thermal expansion | |

| Electrical conductivity | |

| Proton conductivity | |

| Field emission | |

| Ablation resistance | |

| Chemical resistance | |

| Optical properties | |

| Biodegradability | |

| Crystallization control | |

| Rheological properties | |

| Processability |

| Vinyl Polymer Systems | References |

|---|---|

| methyl methacrylate (MMA) | [25,26,27,28,29,30,31,32,33,34,35,36,37,38] |

| MMA copolymers | [39,40,41,42] |

| polyacrylates | [43,44,45] |

| polyacrylic acid | [46,47] |

| polyacrylonitrile (AN) | [48,49,50,51] |

| polystyrene (S) | [52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77] |

| 4-vinylpyridine | [78] |

| polyacrylamide | [79,80,81] |

| polytetrafluoro ethylene | [82] |

| poly(vinyl alcohol) | [83,84,85,86] |

| poly(N-vinyl pyrrolidone) | [87,88,89,90,91] |

| poly(vinyl pyrrolidinone) | [92,93] |

| poly(vinyl pyridine) | [94] |

| poly(ethylene glycol) | [95] |

| poly(ethylene vinyl alcohol) | [96] |

| poly(vinylidene fluoride) | [97] |

| poly(p-phenylenevinylene) | [98] |

| polybenzoxazole | [99] |

| poly(S-co-AN) | [100] |

| ethyl vinyl alcohol copolymer | [101] |

| PS-polyisoprene diblock copolymer | [102,103] |

| other | [104] |

| Condensation Polymer Systems | References |

|---|---|

| Nylon-6 | [6,18,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127] |

| Other polyamides | [128,129,130,131,132,133,134] |

| poly(ε-caprolactone) (PCL) | [135,136,137,138,139,140,141,142,143,144,145,146] |

| Poly(ethylene terephtalate) (PET) | [147,148,149,150,151,152,153] |

| poly (trimethylene terephthalate) | [154,155] |

| poly(butylene terephthalate) | [156] |

| polycarbonate | [157,158] |

| Polyethylene oxide | [159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179] |

| polyethylene oxide copolymers | [180,181] |

| poly (ethylene imine) | [182] |

| poly (dimethyl siloxane) | [183,184,185,186,187,188] |

| polybutadiene | [189] |

| polybutadiene copolymers | [190,191,192] |

| epoxidized natural rubber | [193,194] |

| epoxy polymer resins | [195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,213,214,215,216] |

| phenolic resins | [217,218] |

| polyurethanes | [219,220,221,222,223] |

| polyurethane uera | [224] |

| polyimides | [225,226,227,228,229,230,231,232,233,234,235,236,237,238,239,240] |

| poly(amic acid) | [241,242] |

| polysulphone | [243] |

| polyetherimide | [244,245] |

| fluoropoly(ether-imide) | [246] |

| Polyolefines | References |

|---|---|

| PP | [247,248,249,250,251,252,253,254,255,256,257,258,259,260,261,262,263,264,265,266,267,268,269,270,271,272,273,274,275,276,277,278,279,280,281,282,283,284] |

| PE | [285,286,287,288,289,290,291,292,293,294] |

| PE oligomers | [295] |

| poly(ethylene-co-vinyl acetate) | [296] |

| ethylene propylene diene methylene linkage | [297] |

| poly(1-butene) | [298] |

| Specialty Polymers | References |

|---|---|

| polypyrrole | [299,300,301,302,303,304] |

| poly (N-vinylcarbazole) | [305,306] |

| polyaniline | [307,308,309,310,311,312,313,314,315,316,317,318,319,320] |