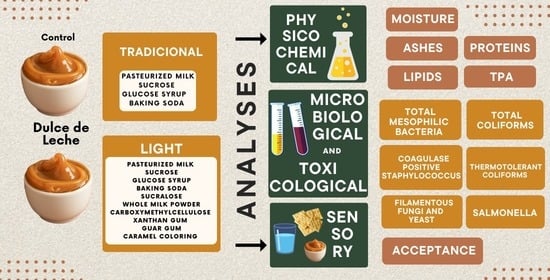

3.1. Dulce de Leche Characterization

The production of the traditional dulce de leche formulations took about 3 h to obtain the desired ideal point with a yield of 34.0%, obtaining 1.020 Kg from 3 L of pasteurized milk. The total solids concentration of the final product was 69.7° Brix, corroborating the desired endpoint for the product.

The traditional dulce de leche presented the characteristic color and odor of the product, obtained through the caramelization of carbohydrates and the Maillard reaction [

19]. The consistency of the final product was also characteristic of the product. The concentration of solids through the evaporation of water results in an increase in the viscosity of the formulation, providing the desired rheological characteristics [

20].

The light dulce de leche formulation also took about 3 h to obtain the desired point with a 32.9% yield, achieving 987 g from 3 L of pasteurized milk. The time and productivity of the formulations were similar, in a way that the productive difference between them was not significant.

The light dulce de leche reached 56.6° Brix, which is an acceptable value considering that there must be a reduction in the nutrient content for light food. Due to the reduction of total sugar, however, the characteristic color of the Maillard reaction did not occur in this formulation, leading to a lighter color product and requiring the addition of caramel coloring to adjust until a desirable characteristic [

21].

The texture of the finished product was thick only due to the food additives, as the concentration of total solids with sugar reduction does not increase the viscosity in the final product. The use of milk powder and thickeners to compose the rheological characteristics of the product are important methods, making it necessary, however, to process the final dough in a mixer to give the final product creaminess [

20].

The sucralose used in this work followed the established by the manufacturer’s information, where the sweetening power is equivalent to 100 times the conventional sucrose. So, 25 g of sucralose was used to result in the desired concentration, and another 5 g of sucralose was added at the end to enhance the sweet taste. The addition was carried out at the end of the process to avoid prolonged contact with heat that could cause the sucralose’s degradation [

22].

The various sucralose on the market has different sweetening potential. For the development of formulations and to maintain the approximate flavor, it is necessary to take this potential into account and adjust the recipes accordingly.

While there is a considerable reduction in the amount of sucrose present in the mixture, for the light dulce de leche to present a similar characterization to the traditional one, it is necessary to add other compounds. This can lead to a more expensive final product. However, it also allows more selective or restricted consumers to access the product.

3.2. Physical-Chemical and Nutritional Characterization

After carrying out the aforementioned analysis tests, the physical-chemical data were arranged in

Table 2 below with the principal nutrient composition.

The dulce de leche parameters follow the MERCOSUL legislation [

23]. This guideline standardizes the criteria of the economic block formed by most countries in South America. Within these guidelines, dulce de leche has a series of standards, as described in

Table 2.

Based on these data, we can see that the traditional dulce de leche moisture (29.88%) and ashes (1.42%) remained within the legislation (<30.00%; <2.00%), whereas the light dulce de leche (35.63% and 2.88%, respectively) surpassed both established limits. Both formulations had an amount of fat below the established by MERCOSUL (6.00–9.00%), with the traditional dulce de leche reaching a value of 2.65% whilst the light formulation had a value of 3.50%. Both also showed a protein percentage above the minimum required, as the traditional showed 7.54% and the light, 12.07%.

The moisture difference observed is probably caused by the thickening additives that must have evaporated along with the water. The differences observed in the ashes, lipid concentration, and protein percentage may be associated with the addition of powdered milk, since it has its solids and is rich in protein and fat. This difference was expected and proves the direct influence of powdered milk that significantly increases the value of the nutrient in the light formulation [

24].

When evaluating the rheological parameters of the developed dulce de leche, both samples showed excellent adhesiveness and firmness, with the gumminess of the light formulation being slightly higher but with no significant difference observed (

p < 0.05). The results obtained demonstrate that, qualitatively, the replacement of sugar with the other ingredients can offer the necessary characteristics for the characterization of the product. Higher gumminess, adhesiveness, and firmness are undesirable characteristics in DL used for cooking or confectionery purposes. In the case of direct consumption, the increase in texture parameters is well accepted by consumers [

1].

Regarding the energy value, the value for traditional dulce de leche was 288.05 Kcal, and for the light product 263.46 Kcal. According to Brazilian legislation [

6], for a product to be considered “light”, the reduction in energy value should be at least 25.0%. The observed values represent a reduction of 8.54%, and, therefore, the light formulation was not successful in this regard. The limited reduction in energy content can be elucidated by the incorporation of components aimed at substituting sucrose in the formulation, notably powdered milk, which has the potential to elevate protein, fat, and lactose levels [

25]. Notwithstanding the presence of lactose originating from whole milk powder, the reduction in additional glucose content was adequate to ensure that the product remains in accordance with the regulatory guidelines pertaining to added sugars in dulce de leche.

However, although the desired caloric reduction was not obtained, future studies focused on improving the methodology used to obtain products with functional characteristics since the comparative results between the two samples proved to be favorable.

3.3. Microbiological and Toxicological Characterizations

The microbiological parameters of the two formulations of dulce de leche and their raw material can be observed in

Table 3 below:

Regarding the safety parameters, despite the risk of post-processing contamination, all the raw materials and both final products were considered safe to consume according to recommended microbiological standards.

The appliance of a quality standard to the raw materials for human consumption products is needed to ensure final product safety. The selection of high-quality materials is an important factor in ensuring the standard and security of the final product, as a higher contaminant concentration can be a risk to the whole manufacturing and the consumers, especially in highly manipulated products [

2,

23].

The microbiological concentration in the raw materials, while below the legislation limit [

12], has a significant difference in comparison to both dulce de leches formulations. That significant decrease in microbial populations indicates that the manufacturing process may contribute to the conservation and security of the final products. Heat treatment, as well as high sugar concentration, are traditional procedures to reduce the microbiological population [

1,

26], and their association can be observed in both formulations.

The total mesophilic counts observed in this work confirm the efficiency of the heat treatment applied. In the raw material, total mesophilic counts were above 2.40 log

10 CFU g

−1 and drastically reduced after thermal processing, being present in minimal concentrations in the final products. Although not required in Brazilian legislation, the total mesophilic bacteria count is an important parameter to be evaluated during the development of a product, being directly correlated with the sanitation of the process [

27,

28,

29].

The microbiological evaluation after the storage period is presented in

Table 4:

As seen in the table above, after a 30 day storage period under refrigeration, it was not possible to observe microbial growth in the evaluated formulations, attesting that the products remained suitable for consumption under adequate storage.

The use of heat treatment and reduction of water content as a food preservation technique aims to inactivate and prevent microbial growth with the maintenance of the parameters indicating that effectiveness. The treatment shows the capacity to inactivate the initially viable cells, prolonging their storage period and serving as a basis for stipulating shelf life for food products [

30,

31,

32].

The application of heat for this purpose, however, presents risks to the quality of the product, which may cause changes in the sensorial and nutritional characteristics of the product. That also influences the determination of the product’s shelf life [

33].

Regarding the antimicrobial properties of higher sugar concentration, it is known that hypertonic media can generate cell lysis in different types of bacteria, and those resistant to this physical phenomenon enter a state of latency. [

34,

35]. Both dulce de leche formulations present this effect, especially after the reduction of water content during heat treatment, resulting in a high sugar concentration. The moisture reduction itself also generates an inhibitory effect in most microorganisms [

36].

In this way, the addition of sugar and sweeteners not only has the role of technologically assisting the processing of dulce de leche, but also plays an important role in the conservation of the final product when associated with the thermal treatment, guaranteeing a safe product for consumption and with a higher shelf life.

As for the toxicological evaluations, none of the evaluated samples showed a positive result for staphylococcal enterotoxin and AFM1, in compliance with Brazilian legislation.

Staphylococcal enterotoxins are primarily responsible for food poisoning caused by

Staphylococcus aureus, often found in milk and dairy products [

36,

37]. Pasteurization effectively reduces the concentration of microorganisms in milk and, consequently, in its derivatives. Despite this, the detection of staphylococcal enterotoxins is necessary as it is thermoresistant and can cause outbreaks of food poisoning even in the absence of the pathogen [

37,

38].

While the Brazilian legislation does not present maximum limits allowed for AFM1 in dulce de leche, the quantification of raw materials and final products, especially dairies, is essential to guarantee the consumers’ security and good health. AFM1 is a thermoresistant substance with global occurrence, having carcinogenic, cytotoxic, teratogenic, and genotoxic properties, and prolonged exposure can also cause chronic conditions such as immunosuppression, hepatocarcinoma, and stunted growth in children [

39,

40,

41].

3.4. Product Acceptance

From the analysis of the data acquired from the questionnaires, it could be stipulated the average values for product acceptance, as well as flavor, texture, and appearance perception. The data were arranged in the following table (

Table 5).

According to the average values found, the traditional dulce de leche obtained a value close to 2.0 in all the requirements, meaning an acceptance degree of “I like it very much”, which indicates approval from the participants.

The light formulation, as seen in

Table 6 below, obtained an average score of 4.0 in almost all aspects, except for appearance, which was 4.6. The results indicate an acceptance level close to the middle of the scale, in the range of “I liked it slightly”.

The difference observed in the appearance parameter can be associated with the product’s color. The traditional formulation had the expected appearance of traditional dulce de leche in comparison with the light formulation which presented a lighter color.

The flavor of the traditional formulation was described as “not too sweet and not too cloying”, being also approved in the light product. The texture, however, was disapproved in the traditional product, whilst marked as positive points in the light formulation by a large part of the volunteers.

Both the color and texture of the light dulce de leche are related to the absence of biochemical processes that occur in high temperatures. The low percentage of sugar during manufacturing reduces both the Mallard reaction, responsible for the color, and the total solids increase, responsible for the high viscosity of the final product [

20]. Whilst the correction with milk powder and thickeners led to a product with better rheological properties, the caramel coloring adjustment did not have the same effectiveness. The control of these aspects is an advantage in regulating the product until the desired characteristics are based on the volunteers’ feedback.

The buying intention of a product is associated with acceptance, where good acceptability had a higher intention, as seen in the data obtained for both formulations in

Figure 1 below.

When comparing the buying intentions of each product, the results show a preference for the traditional dulce de leche, 30.00% of the volunteers would buy this product often if it was commercialized, while 20.00% would always buy it.

Concerning the light formulation, only 6.70% of the participants would always buy the product if commercialized, with 23.30% stating that they would never buy it.

The medium acceptance for the light dulce de leche led to a low buying intention and, inversely, the traditional formulation, classified as “like it very much”, showed more than 50.00% of the distribution between “would always buy” and “would buy very often”.

The primary objective of this study was to create a product with commercial potential and substantial consumer acceptance, with a primary focus on target consumers with specific dietary restrictions.

The Brazilian consumer market subjected to sensory evaluation is familiar with the traditional sweet flavor characteristic of dulce de leche, which is inherently associated with a high caloric content. In contrast, other consumer markets, particularly those unaccustomed to such consumption, may exhibit a reduced comparative effect, thus rendering increased acceptance in foreign markets more likely and facilitating potential export opportunities. Moreover, products of this nature may find robust acceptance in regions and markets that value and require foods with elevated caloric and nutritional content.

The findings derived from the purchase intention survey align with the observations made during product elaboration, underscoring the capacity to optimize sensory attributes for the purpose of augmenting both acceptance and purchase intent.

Subsequent studies may be conducted, using this work as a starting point, to assess variations in ingredient concentrations, including the exploration of alternative raw materials such as lactose-free milk powder and different sweeteners and thickeners. These explorations aim to enhance the functional properties of the product, particularly in terms of reducing its sugar and energy content. Additionally, the introduction of preservatives can be investigated to enable comparisons in physical-chemical and microbiological stability through extended quality control assessments.