Breathable Iron-Based MIL-88 Framework as Dye Adsorbent in Aqueous Solution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of MIL-88B(Fe)

2.3. Characterisation of MIL-88B(Fe)

2.4. Adsorption Experiments

3. Results and Discussion

3.1. Synthesis and Characterisation of MIL-88B(Fe)

3.2. Adsorption Experiments

3.2.1. Effect of pH

3.2.2. Effect of Contact Time

3.2.3. Effect of Initial Dye Concentration

3.2.4. Adsorption Isotherms

3.2.5. Adsorption Kinetics

3.2.6. Adsorption Thermodynamics

3.2.7. Reusability

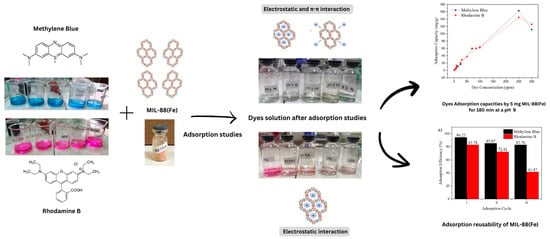

3.2.8. Selective Adsorption Capability

3.2.9. Comparison with Other Adsorbents

3.2.10. Plausible Adsorption Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karmakar, S.; Roy, D.; Janiak, C.; De, S. Insights into Multi-Component Adsorption of Reactive Dyes on MIL-101-Cr Metal Organic Framework: Experimental and Modeling Approach. Sep. Purif. Technol. 2019, 215, 259–275. [Google Scholar] [CrossRef]

- Onu, C.E.; Asadu, C.O.; Ohale, P.E.; Ojukwu, E.V.; Ogunaobi, N.C.; Onu, C.P.; Akaeme, F.C. Recent Trends in Textile Wastewater Treatment Using Agricultural Waste. In Textile Wastewater Treatment; Springer: Singapore, 2022; pp. 89–110. [Google Scholar] [CrossRef]

- Ghasemi, H.; Aghabarari, B.; Alizadeh, M.; Khanlarkhani, A.; Abu-Zahra, N. High Efficiency Decolorization of Wastewater by Fenton Catalyst: Magnetic Iron-Copper Hybrid Oxides. J. Water Process Eng. 2020, 37, 101540. [Google Scholar] [CrossRef]

- Chiu, Y.H.; Chang, T.F.M.; Chen, C.Y.; Sone, M.; Hsu, Y.J. Mechanistic Insights into Photodegradation of Organic Dyes Using Heterostructure Photocatalysts. Catalysts 2019, 9, 430. [Google Scholar] [CrossRef]

- Demissie, H.; An, G.; Jiao, R.; Ritigala, T.; Lu, S.; Wang, D. Modification of High Content Nanocluster-Based Coagulation for Rapid Removal of Dye from Water and the Mechanism. Sep. Purif. Technol. 2021, 259, 117845. [Google Scholar] [CrossRef]

- Zazou, H.; Afanga, H.; Akhouairi, S.; Ouchtak, H.; Addi, A.A.; Akbour, R.A.; Assabbane, A.; Douch, J.; Elmchaouri, A.; Duplay, J.; et al. Treatment of Textile Industry Wastewater by Electrocoagulation Coupled with Electrochemical Advanced Oxidation Process. J. Water Process Eng. 2019, 28, 214–221. [Google Scholar] [CrossRef]

- Zhu, T.T.; Zhang, Z.M.; Chen, W.L.; Liu, Z.J.; Wang, E.B. Encapsulation of Tungstophosphoric Acid into Harmless MIL-101(Fe) for Effectively Removing Cationic Dye from Aqueous Solution. RSC Adv. 2016, 6, 81622–81630. [Google Scholar] [CrossRef]

- Adeyemo, A.A.; Adeoye, I.O.; Bello, O.S. Metal Organic Frameworks as Adsorbents for Dye Adsorption: Overview, Prospects and Future Challenges. Toxicol. Environ. Chem. 2012, 94, 1846–1863. [Google Scholar] [CrossRef]

- Haque, E.; Jun, J.W.; Jhung, S.H. Adsorptive Removal of Methyl Orange and Methylene Blue from Aqueous Solution with a Metal-Organic Framework Material, Iron Terephthalate (MOF-235). J. Hazard. Mater. 2011, 185, 507–511. [Google Scholar] [CrossRef]

- Lin, S.; Song, Z.; Che, G.; Ren, A.; Li, P.; Liu, C.; Zhang, J. Adsorption Behavior of Metal–Organic Frameworks for Methylene Blue from Aqueous Solution. Microporous Mesoporous Mater. 2014, 193, 27–34. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, C.; Wan, H.; Wang, L.; Li, Z.; Li, B.; Guo, Q.; Guan, G. Fabrication of Magnetic NH2-MIL-88B (Fe) Confined Brønsted Ionic Liquid as an Efficient Catalyst in Biodiesel Synthesis. Energy Fuels 2016, 30, 10739–10746. [Google Scholar] [CrossRef]

- Zhu, G.; Xing, X.; Wang, J.; Zhang, X. Effect of Acid and Hydrothermal Treatments on the Dye Adsorption Properties of Biomass-Derived Activated Carbon. J. Mater. Sci. 2017, 52, 7664–7676. [Google Scholar] [CrossRef]

- Shafqat, S.R.; Bhawani, S.A.; Bakhtiar, S.; Ibrahim, M.N.M. Synthesis of Molecularly Imprinted Polymer for Removal of Congo Red. BMC Chem. 2020, 14, 27. [Google Scholar] [CrossRef]

- Rahimi, B.; Jafari, N.; Abdolahnejad, A.; Farrokhzadeh, H.; Ebrahimi, A. Application of Efficient Photocatalytic Process Using a Novel BiVO/TiO2-NaY Zeolite Composite for Removal of Acid Orange 10 Dye in Aqueous Solutions: Modeling by Response Surface Methodology (RSM). J. Environ. Chem. Eng. 2019, 7, 103253. [Google Scholar] [CrossRef]

- Chang, J.; Ma, J.; Ma, Q.; Zhang, D.; Qiao, N.; Hu, M.; Ma, H. Adsorption of Methylene Blue onto Fe3O4/Activated Montmorillonite Nanocomposite. Appl. Clay Sci. 2016, 119, 132–140. [Google Scholar] [CrossRef]

- Mashkoor, F.; Nasar, A. Magsorbents: Potential Candidates in Wastewater Treatment Technology—A Review on the Removal of Methylene Blue Dye. J. Magn. Magn. Mater. 2020, 500, 166408. [Google Scholar] [CrossRef]

- Zango, Z.U.; Jumbri, K.; Sambudi, N.S.; Hanif Abu Bakar, N.H.; Fathihah Abdullah, N.A.; Basheer, C.; Saad, B. Removal of Anthracene in Water by MIL-88(Fe), NH 2 -MIL-88(Fe), and Mixed-MIL-88(Fe) Metal–Organic Frameworks. RSC Adv. 2019, 9, 41490–41501. [Google Scholar] [CrossRef]

- James, S.L. Metal-Organic Frameworks. Chem. Soc. Rev. 2003, 32, 276–288. [Google Scholar] [CrossRef]

- Britt, D.; Tranchemontagne, D.; Yaghi, O.M. Metal-Organic Frameworks with High Capacity and Selectivity for Harmful Gases. Proc. Natl. Acad. Sci. USA 2008, 105, 11623–11627. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Y.; Zhang, J.; Tang, L.; Luo, L.; Zeng, G. Iron Containing Metal-Organic Frameworks: Structure, Synthesis, and Applications in Environmental Remediation. ACS Appl. Mater. Interfaces 2017, 9, 20255–20275. [Google Scholar] [CrossRef]

- Li, C.; Xiong, Z.; Zhang, J.; Wu, C. The Strengthening Role of the Amino Group in Metal-Organic Framework MIL-53 (Al) for Methylene Blue and Malachite Green Dye Adsorption. J. Chem. Eng. Data 2015, 60, 3414–3422. [Google Scholar] [CrossRef]

- Fu, Q.; Lou, J.; Zhang, R.; Peng, L.; Zhou, S.; Yan, W.; Mo, C.; Luo, J. Highly Effective and Fast Removal of Congo Red from Wastewater with Metal-Organic Framework Fe-MIL-88NH2. J. Solid State Chem. 2021, 294, 121836. [Google Scholar] [CrossRef]

- He, J.; Zhang, Y.; Zhang, X.; Huang, Y. Highly Efficient Fenton and Enzyme-Mimetic Activities of NH2-MIL-88B(Fe) Metal Organic Framework for Methylene Blue Degradation. Sci. Rep. 2018, 8, 5159. [Google Scholar] [CrossRef]

- Uddin, M.J.; Ampiaw, R.E.; Lee, W. Adsorptive Removal of Dyes from Wastewater Using a Metal-Organic Framework: A Review. Chemosphere 2021, 284, 131314. [Google Scholar] [CrossRef]

- Abbasi, A.R.; Karimi, M.; Daasbjerg, K. Efficient Removal of Crystal Violet and Methylene Blue from Wastewater by Ultrasound Nanoparticles Cu-MOF in Comparison with Mechanosynthesis Method. Ultrason. Sonochem. 2017, 37, 182–191. [Google Scholar] [CrossRef]

- Zhang, J.; Li, F.; Sun, Q. Rapid and Selective Adsorption of Cationic Dyes by a Unique Metal-Organic Framework with Decorated Pore Surface. Appl. Surf. Sci. 2018, 440, 1219–1226. [Google Scholar] [CrossRef]

- Ghosh, A.; Das, G. Green Synthesis of Sn(II)-BDC MOF: Preferential and Efficient Adsorption of Anionic Dyes. Microporous Mesoporous Mater. 2020, 297, 110039. [Google Scholar] [CrossRef]

- Eltaweil, A.S.; Abd El-Monaem, E.M.; Omer, A.M.; Khalifa, R.E.; Abd El-Latif, M.M.; El-Subruiti, G.M.; Omer, A.M. Efficient Removal of Toxic Methylene Blue (MB) Dye from Aqueous Solution Using a Metal-Organic Framework (MOF) MIL-101(Fe): Isotherms, Kinetics, and Thermodynamic Studies. Desalination Water Treat. 2020, 189, 395–407. [Google Scholar] [CrossRef]

- Saghanejhad Tehrani, M.; Zare-Dorabei, R. Highly Efficient Simultaneous Ultrasonic-Assisted Adsorption of Methylene Blue and Rhodamine B onto Metal Organic Framework MIL-68(Al): Central Composite Design Optimization. RSC Adv. 2016, 6, 27416–27425. [Google Scholar] [CrossRef]

- Guo, H.; Lin, F.; Chen, J.; Li, F.; Weng, W. Metal–Organic Framework MIL-125(Ti) for Efficient Adsorptive Removal of Rhodamine B from Aqueous Solution. Appl. Organomet. Chem. 2015, 29, 12–19. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, L.; Su, Y.; Yu, H.; Liu, H.; Qian, S.; Zheng, W.; Zhao, Y. Zr-MOFs Loaded on Polyurethane Foam by Polydopamine for Enhanced Dye Adsorption. J. Environ. Sci. 2021, 101, 177–188. [Google Scholar] [CrossRef] [PubMed]

- Agustin, M.; Nurani, D.A.; Zulys, A.; Krisnandi, Y.K. Adsorption of Rhodamine B by Yttrium-Succinate Metal Organic Framework (MOF). AIP Conf. Proc. 2020, 2243, 030001. [Google Scholar] [CrossRef]

- Nurani, D.A.; Butar, B.C.B.; Krisnandi, Y.K. Synthesis and Characterization of Metal Organic Framework Using Succinic Acid Ligand with Cobalt and Iron Metals as Methylene Blue Dye Adsorbent. IOP Conf. Ser. Mater. Sci. Eng. 2020, 902, 012055. [Google Scholar] [CrossRef]

- Knyazeva, M.K.; Shkolin, A.V.; Fomkin, A.A.; Tsivadze, A.Y.; Solovtsova, O.V.; Platonova, N.P.; Pulin, A.L.; Men’shchikov, I.E.; Shiryaev, A.A.; Vysotskii, V.V.; et al. Synthesis and Structural-Energy Characteristics of Fe-BDC Metal-Organic Frameworks. Prot. Met. Phys. Chem. Surf. 2018, 54, 1004–1009. [Google Scholar] [CrossRef]

- Pertiwi, R.; Oozeerally, R.; Burnett, D.L.; Chamberlain, T.W.; Cherkasov, N.; Walker, M.; Kashtiban, R.J.; Krisnandi, Y.K.; Degirmenci, V.; Walton, R.I. Replacement of Chromium by Non-Toxic Metals in Lewis-Acid MOFs: Assessment of Stability as Glucose Conversion Catalysts. Catalysts 2019, 9, 437. [Google Scholar] [CrossRef]

- Wu, L.; Chaplais, G.; Xue, M.; Qiu, S.; Patarin, J.; Simon-Masseron, A.; Chen, H. New Functionalized MIL-53(In) Solids: Syntheses, Characterization, Sorption, and Structural Flexibility. RSC Adv. 2019, 9, 1918–1928. [Google Scholar] [CrossRef]

- Wei, Y.S.; Chen, K.J.; Liao, P.Q.; Zhu, B.Y.; Lin, R.B.; Zhou, H.L.; Wang, B.Y.; Xue, W.; Zhang, J.P.; Chen, X.M. Turning on the Flexibility of Isoreticular Porous Coordination Frameworks for Drastically Tunable Framework Breathing and Thermal Expansion. Chem. Sci. 2013, 4, 1539–1546. [Google Scholar] [CrossRef]

- Chaplais, G.; Simon-Masseron, A.; Porcher, F.; Lecomte, C.; Bazer-Bachi, D.; Bats, N.; Patarin, J. IM-19: A New Flexible Microporous Gallium Based-MOF Framework with Pressure- and Temperature-Dependent Openings. Phys. Chem. Chem. Phys. 2009, 11, 5241–5245. [Google Scholar] [CrossRef]

- Volkringer, C.; Loiseau, T.; Guillou, N.; Férey, G.; Elkaïm, E.; Vimont, A. XRD and IR Structural Investigations of a Particular Breathing Effect in the MOF-Type Gallium Terephthalate MIL-53(Ga). Dalton Trans. 2009, 2241–2249. [Google Scholar] [CrossRef]

- Surblé, S.; Serre, C.; Mellot-Draznieks, C.; Millange, F.; Férey, G. A New Isoreticular Class of Metal-Organic-Frameworks with the MIL-88 Topology. Chem. Commun. 2006, 284–286. [Google Scholar] [CrossRef]

- Toby, B.H. R Factors in Rietveld Analysis: How Good Is Good Enough? Powder Diffr. 2006, 21, 67–70. [Google Scholar] [CrossRef]

- Carson, F.; Su, J.; Platero-Prats, A.E.; Wan, W.; Yun, Y.; Samain, L.; Zou, X. Framework Isomerism in Vanadium Metal-Organic Frameworks: MIL-88B(V) and MIL-101(V). Cryst. Growth Des. 2013, 13, 5036–5044. [Google Scholar] [CrossRef]

- Dhanapala, B.D.; Maglich, D.L.; Anderson, M.E. Impact of Surface Functionalization and Deposition Method on Cu-BDC SurMOF Formation, Morphology, Crystallinity, and Stability. Langmuir 2023, 39, 12196–12205. [Google Scholar] [CrossRef] [PubMed]

- Taylor-Pashow, K.M.L.; Della Rocca, J.; Xie, Z.; Tran, S.; Lin, W. Postsynthetic Modifications of Iron-Carboxylate Nanoscale Metal-Organic Frameworks for Imaging and Drug Delivery. J. Am. Chem. Soc. 2009, 131, 14261–14263. [Google Scholar] [CrossRef]

- Rahmani, E.; Rahmani, M. Alkylation of Benzene over Fe-Based Metal Organic Frameworks (MOFs) at Low Temperature Condition. Microporous Mesoporous Mater. 2017, 249, 118–127. [Google Scholar] [CrossRef]

- Vuong, G.T.; Pham, M.H.; Do, T.O. Synthesis and Engineering Porosity of a Mixed Metal Fe2Ni MIL-88B Metal–Organic Framework. Dalton Trans. 2012, 42, 550–557. [Google Scholar] [CrossRef] [PubMed]

- Zou, M.; Dong, M.; Zhao, T. Advances in Metal-Organic Frameworks MIL-101(Cr). Int. J. Mol. Sci. 2022, 23, 9396. [Google Scholar] [CrossRef]

- Shen, T.; Luo, J.; Zhang, S.; Luo, X. Hierarchically Mesostructured MIL-101 Metal–Organic Frameworks with Different Mineralizing Agents for Adsorptive Removal of Methyl Orange and Methylene Blue from Aqueous Solution. J. Environ. Chem. Eng. 2015, 3, 1372–1383. [Google Scholar] [CrossRef]

- Zhao, T.; Zhu, H.; Dong, M.; Zou, M.; Tang, S.; Luo, M.; Li, X. Low-Temperature and Additive-Free Synthesis of Spherical MIL-101(Cr) with Enhanced Dye Adsorption Performance. Inorganics 2022, 10, 33. [Google Scholar] [CrossRef]

- Vo, T.K.; Trinh, T.P.; Nguyen, V.C.; Kim, J. Facile Synthesis of Graphite Oxide/MIL-101(Cr) Hybrid Composites for Enhanced Adsorption Performance towards Industrial Toxic Dyes. J. Ind. Eng. Chem. 2021, 95, 224–234. [Google Scholar] [CrossRef]

- Tan, Y.; Sun, Z.; Meng, H.; Han, Y.; Wu, J.; Xu, J.; Xu, Y.; Zhang, X. Efficient and Selective Removal of Congo Red by Mesoporous Amino-Modified MIL-101(Cr) Nanoadsorbents. Powder Technol. 2019, 356, 162–169. [Google Scholar] [CrossRef]

- Hidalgo, T.; Alonso-Nocelo, M.; Bouzo, B.L.; Reimondez-Troitiño, S.; Abuin-Redondo, C.; De La Fuente, M.; Horcajada, P. Biocompatible Iron(III) Carboxylate Metal–Organic Frameworks as Promising RNA Nanocarriers. Nanoscale 2020, 12, 4839–4845. [Google Scholar] [CrossRef]

- Revellame, E.D.; Fortela, D.L.; Sharp, W.; Hernandez, R.; Zappi, M.E. Adsorption Kinetic Modeling Using Pseudo-First Order and Pseudo-Second Order Rate Laws: A Review. Clean. Eng. Technol. 2020, 1, 100032. [Google Scholar] [CrossRef]

- Zhang, G.; Wo, R.; Sun, Z.; Hao, G.; Liu, G.; Zhang, Y.; Guo, H.; Jiang, W. Effective Magnetic Mofs Adsorbent for the Removal of Bisphenol a, Tetracycline, Congo Red and Methylene Blue Pollutions. Nanomaterials 2021, 11, 1917. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiang, C.; Hou, B.; Wang, Y.; Hao, C.; Wu, J. Carbon Composite Lignin-Based Adsorbents for the Adsorption of Dyes. Chemosphere 2018, 206, 587–596. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Thakore, S.; Jadeja, R. Removal of Organic Dyes Using Fucus Vesiculosus Seaweed Bioadsorbent an Ecofriendly Approach: Equilibrium, Kinetics and Thermodynamic Studies. Environ. Chem. Ecotoxicol. 2022, 4, 67–77. [Google Scholar] [CrossRef]

- Kundu, A.; Mondal, A. Kinetics, Isotherm, and Thermodynamic Studies of Methylene Blue Selective Adsorption and Photocatalysis of Malachite Green from Aqueous Solution Using Layered Na-Intercalated Cu-Doped Titania. Appl. Clay Sci. 2019, 183, 105323. [Google Scholar] [CrossRef]

- Konicki, W.; Hełminiak, A.; Arabczyk, W.; Mijowska, E. Adsorption of Cationic Dyes onto Fe@graphite Core–Shell Magnetic Nanocomposite: Equilibrium, Kinetics and Thermodynamics. Chem. Eng. Res. Des. 2018, 129, 259–270. [Google Scholar] [CrossRef]

- Feng, M.; Yu, S.; Wu, P.; Wang, Z.; Liu, S.; Fu, J. Rapid, High-Efficient and Selective Removal of Cationic Dyes from Wastewater Using Hollow Polydopamine Microcapsules: Isotherm, Kinetics, Thermodynamics and Mechanism. Appl. Surf. Sci. 2021, 542, 148633. [Google Scholar] [CrossRef]

- Liu, H.; Ren, X.; Chen, L. Synthesis and Characterization of Magnetic Metal–Organic Framework for the Adsorptive Removal of Rhodamine B from Aqueous Solution. J. Ind. Eng. Chem. 2016, 34, 278–285. [Google Scholar] [CrossRef]

- Arora, C.; Soni, S.; Sahu, S.; Mittal, J.; Kumar, P.; Bajpai, P.K. Iron Based Metal Organic Framework for Efficient Removal of Methylene Blue Dye from Industrial Waste. J. Mol. Liq. 2019, 284, 343–352. [Google Scholar] [CrossRef]

- Yilmaz, E.; Sert, E.; Atalay, F.S. Synthesis, Characterization of a Metal Organic Framework: MIL-53 (Fe) and Adsorption Mechanisms of Methyl Red onto MIL-53 (Fe). J. Taiwan Inst. Chem. Eng. 2016, 65, 323–330. [Google Scholar] [CrossRef]

- Devic, T.; Horcajada, P.; Serre, C.; Salles, F.; Maurin, G.; Moulin, B.; Heurtaux, D.; Clet, G.; Vimont, A.; Grenéche, J.M.; et al. Functionalization in Flexible Porous Solids: Effects on the Pore Opening and the Host-Guest Interactions. J. Am. Chem. Soc. 2010, 132, 1127–1136. [Google Scholar] [CrossRef]

- Uemura, K.; Matsuda, R.; Kitagawa, S. Flexible Microporous Coordination Polymers. J. Solid State Chem. 2005, 178, 2420–2429. [Google Scholar] [CrossRef]

- Fletcher, A.J.; Thomas, K.M.; Rosseinsky, M.J. Flexibility in Metal-Organic Framework Materials: Impact on Sorption Properties. J. Solid State Chem. 2005, 178, 2491–2510. [Google Scholar] [CrossRef]

- Long, J.; Yaghi, O.; Ge’rard, G.; Férey, F.; Serre, C. Large Breathing Effects in Three-Dimensional Porous Hybrid Matter: Facts, Analyses, Rules and Consequences. Chem. Soc. Rev. 2009, 38, 1380–1399. [Google Scholar] [CrossRef]

| SBET (m2 g–1) a | VTotal (cm3 g–1) b | Avg. Pore Diameter (nm) c | % Wt. d | |||

|---|---|---|---|---|---|---|

| C | O | Fe | Cl | |||

| 28.37 | 0.248 | 6.20 | 61.8 | 25.4 | 10.8 | 2.0 |

| Dyes | Langmuir Model | Freundlich Model | ||||

|---|---|---|---|---|---|---|

| qmax (mg g–1) | KL (L mg–1) | R2 | 1/n | KF | R2 | |

| MB | 218.94 | 0.0807 | 0.9975 | 0.5583 | 22.36 | 0.9953 |

| RhB | 167.67 | 0.1870 | 0.9935 | 0.4392 | 31.46 | 0.9895 |

| Dyes | Parameters | Dyes | |

|---|---|---|---|

| MB | RhB | ||

| Pseudo-second-order model | qcal a (mg g–1) | 4.70 | 3.40 |

| qexp b (mg g–1) | 5.44 | 2.76 | |

| k2 (g mg–1 min–1) | 1.99 × 10−2 | 1.78 × 10−2 | |

| R2 | 0.9951 | 0.9808 | |

| Pseudo-first-order model | qcal a (mg g–1) | 0.3324 | 44.456 |

| k1 (min–1) | 1.6 × 10−3 | 6.0 × 10−4 | |

| R2 | 0.213 | 0.0971 | |

| Intraparticle diffusion models | ki1 (mg g–1 min–1/2) | 0.10 | 0.13 |

| C1 (mg g–1) | 4.04 | 2.44 | |

| R2 | 0.9491 | 0.7908 | |

| ki2 (mg g–1 min–1/2) | 0.12 | 0.17 | |

| C2 (mg g–1) | 7.05 | 6.55 | |

| R2 | 0.8981 | 0.9906 | |

| Dyes | T (K) | ΔG° (kJ/mol) | ΔH° (kJ/mol) | ΔS° (J/mol/K) |

|---|---|---|---|---|

| MB | 298 | –2.42 | 42.98 | 152.30 |

| 308 | –3.95 | |||

| 318 | –5.47 | |||

| RhB | 298 | 1.65 | 28.17 | 88.95 |

| 308 | 0.76 | |||

| 318 | –0.12 |

| No. | Adsorbent | BET Surface Area (m2/g) | Adsorbate | Reaction Conditions | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|

| C0 (mg/L) | pH | Time (min) | Temp (°C) | qmax * (mg/g) | |||||

| 1 | MIL-88B(Fe) | 28.37 | MB | 250 | 9 | 180 | 25 | 218.94 | This work |

| 2 | NH2-MIL-88B(Fe) | 163.9 | MB | 20 | 3–11 | 45 | 35 | 61.46 | [23] |

| 3 | MIL-101(Fe) | 54.71 | MB | 200 | 9 | 500 | 25 | 58.82 | [28] |

| 4 | Fe3O4-activated montmorillonite | 147.92 | MB | 120–1000 | 7.37 | 25 | 20 | 106.38 | [15,16] |

| 5 | MIL-88B(Fe) | 28.37 | RhB | 250 | 9 | 180 | 25 | 167.67 | This work |

| 6 | MIL-68(Al) | 976 | RhB | 15 | 6.45 | 9.9 | 25 | 29.32 | [29] |

| 7 | MIL-125(Ti) | 845 | RhB | 10 | 7 | 180 | 25 | 59.92 | [30] |

| 8 | Zirconium-based MOFs | - | RhB | 10 | 7 | 240 | 25 | 67.73 | [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurani, D.A.; Anisa, N.; Khatrin, I.; Yasmine; Kadja, G.T.M.; Krisnandi, Y.K. Breathable Iron-Based MIL-88 Framework as Dye Adsorbent in Aqueous Solution. Chemistry 2024, 6, 283-298. https://doi.org/10.3390/chemistry6020015

Nurani DA, Anisa N, Khatrin I, Yasmine, Kadja GTM, Krisnandi YK. Breathable Iron-Based MIL-88 Framework as Dye Adsorbent in Aqueous Solution. Chemistry. 2024; 6(2):283-298. https://doi.org/10.3390/chemistry6020015

Chicago/Turabian StyleNurani, Dita A., Nabila Anisa, Irena Khatrin, Yasmine, Grandprix T. M. Kadja, and Yuni K. Krisnandi. 2024. "Breathable Iron-Based MIL-88 Framework as Dye Adsorbent in Aqueous Solution" Chemistry 6, no. 2: 283-298. https://doi.org/10.3390/chemistry6020015