Probabilistic Assessment of Biodeterioration Effects on Reinforced Concrete Sewers

Abstract

:1. Introduction

2. Influence of Biodeterioration on Concrete Properties

- Biodeterioration can reduce the expected service life span from 50–100 years to less than 10 years [17].

- Temperature and relative humidity variations in the headspace can modify the sulfide uptake and lead to important variations in biodeterioration dynamics [27].

- Real H2S concentrations can vary from a few to hundreds of ppm. It has been observed that concrete deterioration increases when the H2S concentration becomes higher [66]. The biological and chemical nature of deterioration processes impose high variability in the sewer behavior, such that the use of analysis with probabilistic models is highly recommended [6,18,27,71].

- Biodeterioration effects are typically concentrated in zones located in crown and waterline walls. The washing effect produced by running water and temperature and relative humidity variations lead to larger thickness losses in the waterline walls than in the crown. Thickness losses in the waterline walls can vary from two to four times those in the crown [16,17,18,19].

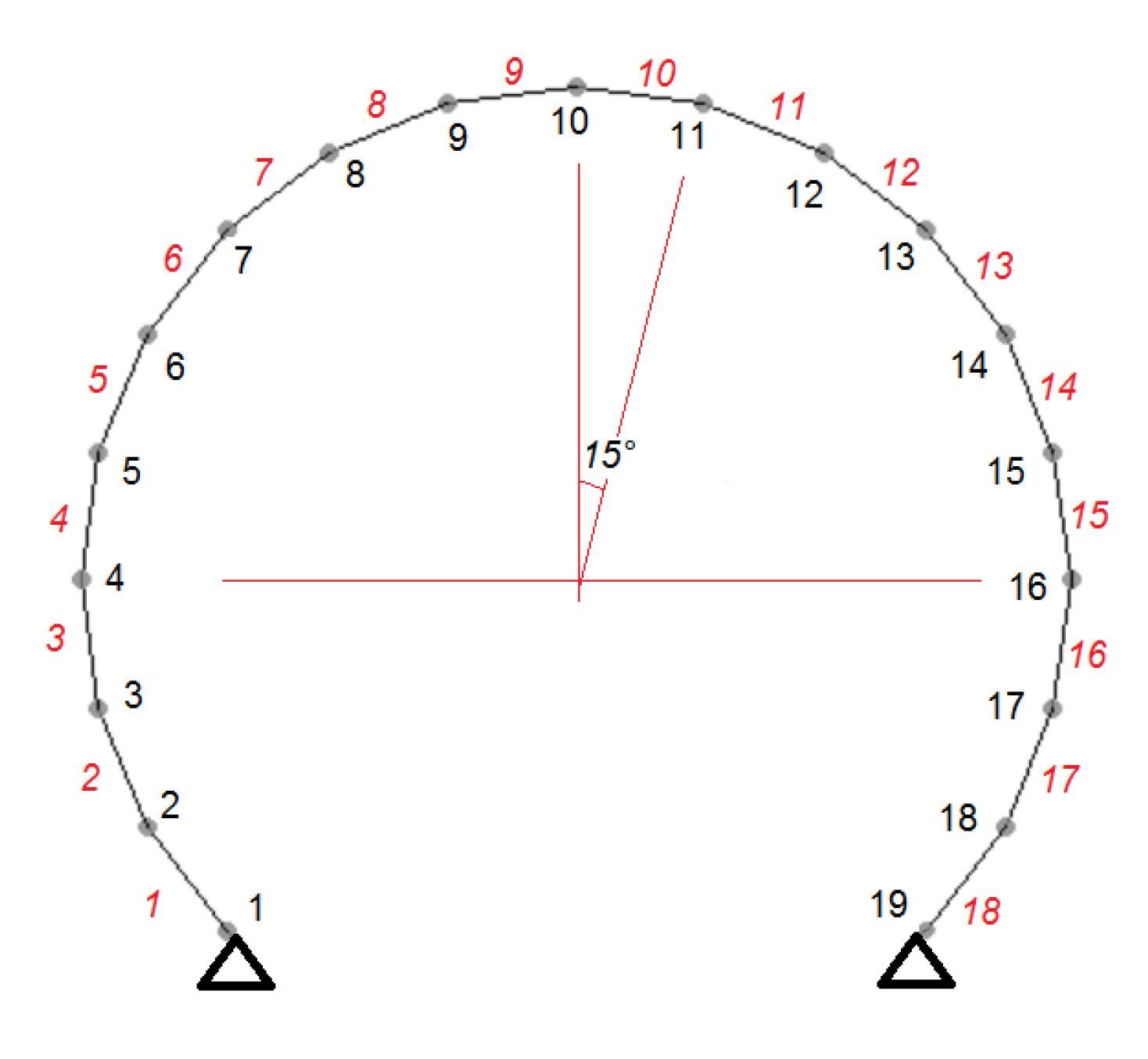

3. Current Practice in the Structural Design of Sewers

- Pipes are placed underground following two configurations: trench and positive embankment. In the trench case, due to the backfill settlement, friction forces at the backfill–in situ material interface will reduce the gravity effects upon the pipe. In the embankment case, the soil placed on the sides of the pipe will settle more than the soil above the pipe, imposing larger gravity loads above the pipe. In both cases, gravity and lateral thrust effects are included in the structural analysis. This paper deals only with the trench condition [77,81].

- The traffic load magnitude is a function of the type of superficial cover (flexible or rigid pavements, or unsurfaced cover), the depth at which the pipe is set, the class of vehicle (trucks, aircrafts, or others) and the direction of travel (parallel or perpendicular to the pipe axis). In general, the deeper the pipe location the lower the traffic effects [77,82].

- Figure 1 shows the typical loads upon a buried sewer pipe. WS is the backfill pressure (kN/m2), WL is the effective traffic load (kN/m2), WP is the weight of the pipe (kN/m2), WF is the fluid (water weight) pressure (kN/m2), and ET and EB are the lateral thrust pressure at the top and bottom of the pipe, respectively (kN/m2). There is a load-spreading configuration along a pipe that is laid parallel to the traffic direction and the so called “effective supporting length of pipe (Le)”. The bedding angle defines the arc length where the pipe is effectively supported. The value and reaction pressure form depend on the bedding material properties [81].

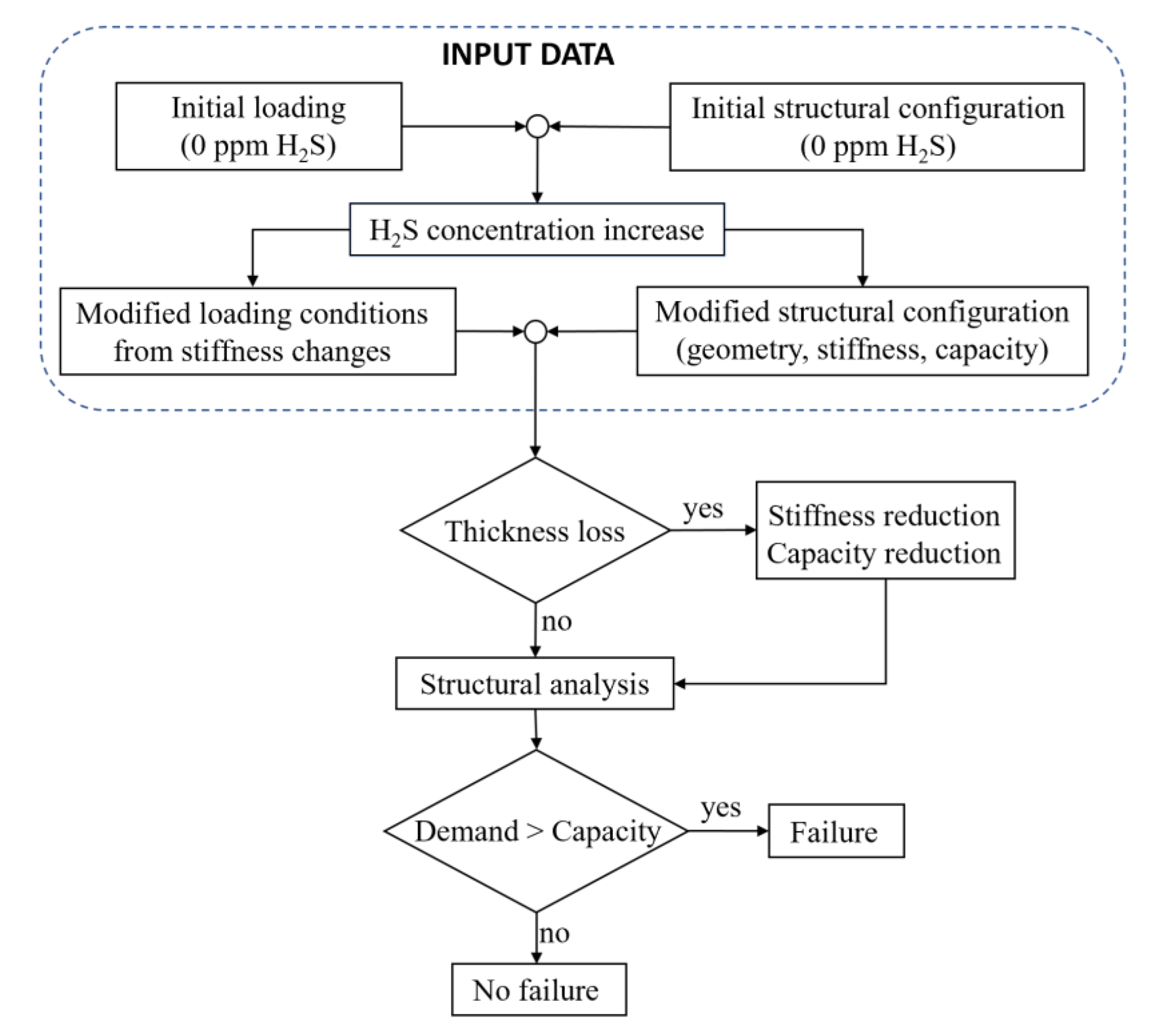

4. Structural Design of Sewers Considering Biodeterioration

4.1. Structural Analysis

4.2. Probabilistic Approach

5. Example: Reliability Assessment of Sewers Considering Biodeterioration

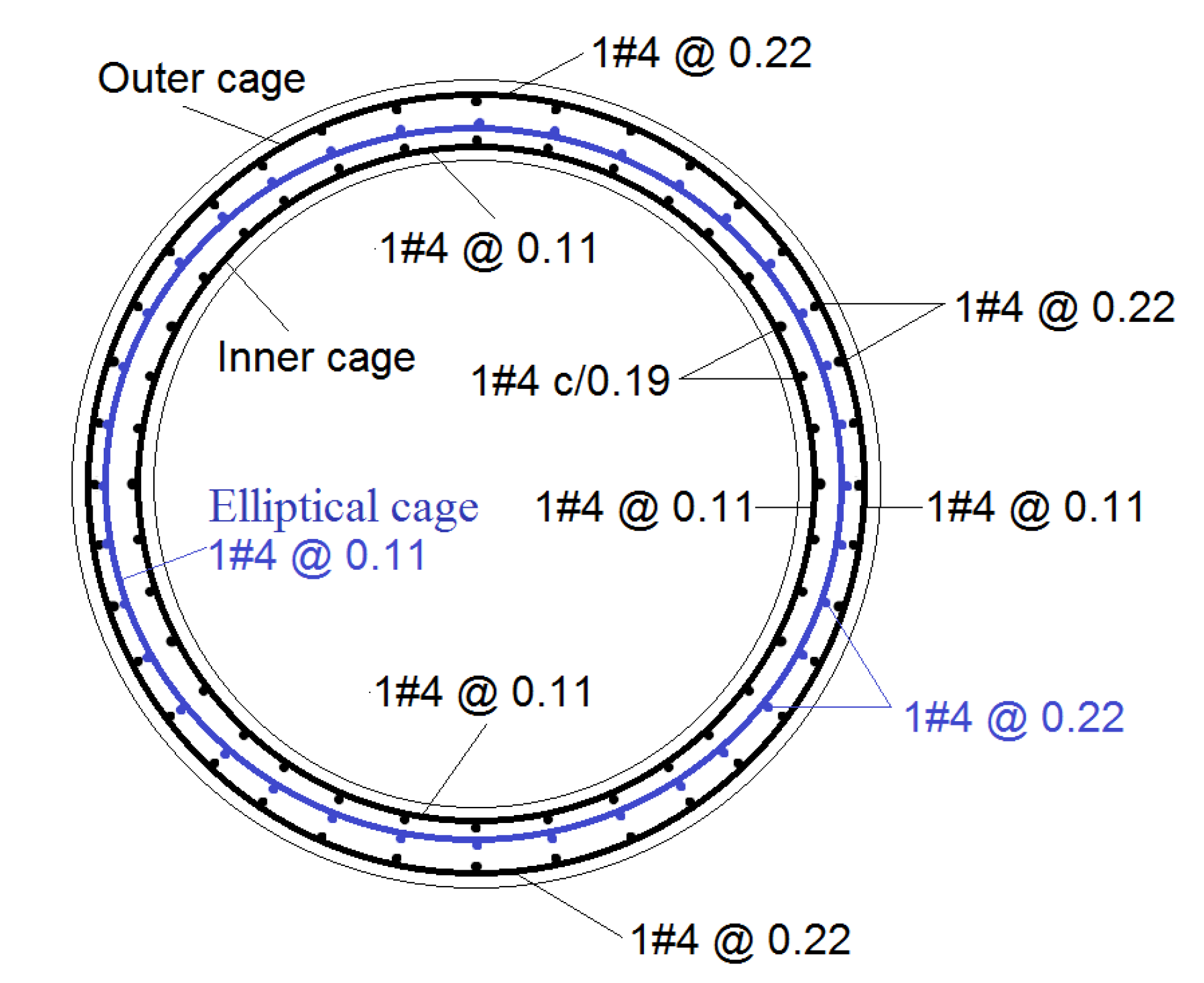

5.1. Description

| Variable | Mean Value | COV | Distribution |

|---|---|---|---|

| (MPa) | 28 | 19% | Lognormal |

| (MPa) | 420 | 10% | Lognormal |

| Modulus of elasticity of steel, Es (MPa) | 200,000 | 6% | Lognormal |

| Concrete cover to reinforcement (mm) | 25 | 10% | Lognormal |

| Reinforcement steel ratio, r (cm2/cm2) | 0.0088 | 5% | Lognormal |

| Thickness loss at the crown, Dtc (mm/year) a: | |||

| H2S concentrations up to 50 ppm | 0.52 | 202% | Lognormal |

| H2S concentration of 100 ppm | 0.74 | 63% | Lognormal |

| H2S concentration of 200 ppm | 1.07 | 35% | Lognormal |

| H2S concentration of 400 ppm | 1.54 | 20% | Lognormal |

| Thickness loss ratio, Dtw/Dtc (mm/mm) | 3 | 19% | Uniform |

| 1.38 | 57% | Lognormal | |

| (kN/m3) | 20 | 10% | Lognormal |

| Backfill height, H (m) | 4 | 15% | Uniform |

| Traffic (live) load, P (kN) b | 223 | 30% | Lognormal |

| Coefficient, Ku (gravel) c | 0.165 | - | Deterministic |

| Trench load coefficient, C c | 0.85 | - | Deterministic |

| Wheel load area, a × b (m × m) | 0.51 × 0.25 | - | Deterministic |

| Spread area a × b (m × m) | 7.48 × 7.22 | - | Deterministic |

5.2. Description of the Failure Modes

5.3. Probability of Failure

6. Conclusions

- A rapid bending strength loss produced by the steel corrosion at the crown or walls generates sloped curves which forecast a rapid failure once the crown concrete cover or most of the compressed concrete in the walls is lost. This conclusion coincides with real failures reported in the literature after 9 to 70 years of service [62,113].

- If the crown failure is accepted as the limit condition related to the sewer pipe failure, the expected service lifespan could be between 55 and 37 years for low and high H2S concentrations, respectively.

7. Recommendations for Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ACPA. Loads and Supporting Strengths. In Concrete Pipe Design Manual; American Concrete Pipe Association: Irving, TX, USA, 2011; pp. 27–82. [Google Scholar]

- He, X.; de los Reyes, F.L.; Leming, M.L.; Dean, L.O.; Lappi, S.E.; Ducoste, J.J. Mechanisms of Fat, Oil and Grease (FOG) Deposit Formation in Sewer Lines. Water Res. 2013, 47, 4451–4459. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Sanchez, M.; Trejo, D.; Gillis, C. Microbial Mediated Deterioration of Reinforced Concrete Structures. Int. Biodeterior. Biodegrad. 2010, 64, 748–754. [Google Scholar] [CrossRef]

- Jensen, H.S.; Nielsen, H.; Lens, P.N.L.; Hvitved-Jacobsen, T.; Vollertsen, J. Hydrogen Sulphide Removal from Corroding Concrete: Comparison between Surface Removal Rates and Biomass Activity. Environ. Technol. 2009, 30, 1291–1296. [Google Scholar] [CrossRef] [PubMed]

- Bastidas-Arteaga, E.; Sánchez-Silva, M.; Chateauneuf, A.; Silva, M.R.; Ribas Silva, M. Coupled Reliability Model of Biodeterioration, Chloride Ingress and Cracking for Reinforced Concrete Structures. Struct. Saf. 2008, 30, 110–129. [Google Scholar] [CrossRef] [Green Version]

- Marquez-Peñaranda, J.; Sanchez-Silva, M.; Husserl, J.; Bastidas-Arteaga, E. Effects of Biodeterioration on the Mechanical Properties of Concrete. Mater. Struct. 2015, 49, 4085–4099. [Google Scholar] [CrossRef]

- Minch, M.Y.; Wróblewski, R.; Kmita, A. Assessment of reinforced concrete sewer after long service: A case study. Urban Water J. 2018, 15, 501–505. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, L.; Liu, P.; Chen, H.; Zhu, H.X.; Xiao, H.; Xiong, Z. Influence mechanisms under different immersion methods and different strengths of concrete in corrosive environments, and verification via long-term field test. Struct. Concr. 2020, 21, 1853–1864. [Google Scholar] [CrossRef]

- Tscheikner-Gratl, F.; Caradot, N.; Cherqui, F.; Leitão, J.P.; Ahmadi, M.; Langeveld, J.G.; Gat, L.; Scholten, L.; Rodríguez, J.P. Sewer asset management—State of the art and research needs. Urban Water J. 2020, 16, 662–675. [Google Scholar] [CrossRef] [Green Version]

- Wells, T.; Melchers, R.E. Microbial Corrosion of Sewer Pipe in Australia—Initial Field Results. In Proceedings of the 18th Intrenational Corrosion Congress, Perth, Australia, 20–24 November 2011; pp. 1–12. [Google Scholar]

- Wells, T.; Melchers, R.E. An Observation-Based Model for Corrosion of Concrete Sewers under Aggressive Conditions. Cem. Concr. Res. 2014, 61–62, 1–10. [Google Scholar] [CrossRef]

- Okabe, S.; Odagiri, M.; Ito, T.; Satoh, H. Succession of Sulfur-Oxidizing Bacteria in the Microbial Community on Corroding Concrete in Sewer Systems. Appl. Environ. Microbiol. 2007, 73, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Grengg, C.; Mittermayr, F.; Baldermann, A.; Böttcher, M.E.; Leis, A.; Koraimann, G.; Grunert, P.; Dietzel, M. Microbiologically Induced Concrete Corrosion: A Case Study from a Combined Sewer Network. Cem. Concr. Res. 2015, 77, 16–25. [Google Scholar] [CrossRef] [Green Version]

- Herisson, J.; van Hullebusch, E.D.; Moletta-Denat, M.; Taquet, P.; Chaussadent, T. Toward an Accelerated Biodeterioration Test to Understand the Behavior of Portland and Calcium Aluminate Cementitious Materials in Sewer Networks. Int. Biodeterior. Biodegrad. 2013, 84, 236–243. [Google Scholar] [CrossRef] [Green Version]

- Oviedo, E.R.; Johnson, D.; Shipley, H. Evaluation of hydrogen sulphide concentration and control in a sewer system. Environ. Technol. 2012, 33, 1207–1215. [Google Scholar] [CrossRef] [PubMed]

- Hudon, E.; Mirza, S.; Frigon, D. Biodeterioration of Concrete Sewer Pipes: State of the Art and Research Needs. J. Pipeline Syst. 2011, 2, 42–52. [Google Scholar] [CrossRef]

- Song, Y.; Tian, Y.; Li, X.; Wei, J.; Zhang, H.; Bond, P.L.; Yuan, Z.; Jiang, G. Distinct Microbially Induced Concrete Corrosion at the Tidal Region of Reinforced Concrete Sewers. Water Res. 2019, 150, 392–402. [Google Scholar] [CrossRef]

- Jiang, G.; Keller, J.; Bond, P.L. Determining the Long-Term Effects of H2S Concentration, Relative Humidity and Air Temperature on Concrete Sewer Corrosion. Water Res. 2014, 65, 157–169. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Jiang, G.; Chiu, T.H.; Zhou, M.; Keller, J.; Bond, P.L. Effects of Surface Washing on the Mitigation of Concrete Corrosion under Sewer Conditions. Cem. Concr. Compos. 2016, 68, 88–95. [Google Scholar] [CrossRef] [Green Version]

- Salmi, E.F.; Asadi, Z.S.; Bayati, M.; Sharifzadeh, M. Assessing the Hydrogeological Conditions Leading to the Corrosion and Deterioration of Pre-cast Segmental Concrete Linings (Case of Zagros Tunnel). Geotech. Geol. Eng. 2019, 37, 3961–3983. [Google Scholar] [CrossRef]

- Kuliczkowska, E.; Parka, A. The structural integrity of corroded concrete sewers. Eng. Fail. Anal. 2019, 104, 409–421. [Google Scholar] [CrossRef]

- Moradian, M.; Shekarchi, M.; Pargar, F.; Bonakdar, A.; Valipour, M. Deterioration of Concrete Caused by Complex Attack in Sewage Treatment Plant Environment. J. Perform. Constr. Facil. 2012, 26, 124–134. [Google Scholar] [CrossRef]

- Zacchei, E.; Bastidas-Arteaga, E. Multifactorial Chloride Ingress Model for Reinforced Concrete Structures Subjected to Unsaturated Conditions. Build. 2022, 12, 107. [Google Scholar] [CrossRef]

- Imounga, H.M.; Bastidas-Arteaga, E.; Moutou Pitti, R.; Ekomy Ango, S.; Wang, X.-H. Bayesian Assessment of the Effects of Cyclic Loads on the Chloride Ingress Process into Reinforced Concrete. App. Sci. 2020, 10, 2040. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Cai, L.; Zhu, W. Predicting Service Life of Concrete Structure Exposed to Sulfuric Acid Environment by Grey System Theory. Int. J. Civ. Eng. 2018, 16, 1017–1027. [Google Scholar] [CrossRef]

- Sanchez-Silva, M.; Klutke, G.-A.; Rosowsky, D.V. Life-Cycle Performance of Structures Subject to Multiple Deterioration Mechanisms. Struct. Saf. 2011, 33, 206–217. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, G.; Bond, P.L.; Wells, T.; Keller, J. A Rapid, Non-Destructive Methodology to Monitor Activity of Sulfide-Induced Corrosion of Concrete Based on H 2 S Uptake Rate. Water Res. 2014, 59, 229–238. [Google Scholar] [CrossRef] [PubMed]

- Erdogmus, E.; Skourup, B.N.; Tadros, M. Recommendations for Design of Reinforced Concrete Pipe. J. Pipeline Syst. Eng. Pract. 2010, 1, 25–32. [Google Scholar] [CrossRef]

- Garcia, C.; Abraham, D.M.; Gokhale, S.; Iseley, T. Rehabilitation Alternatives for Concrete and Brick Sewers. Pract. Period. Struct. Des. Constr. 2002, 7, 164–173. [Google Scholar] [CrossRef]

- Ejaz, N.; Hussain, J.; Ghani, U.; Shabir, F.; Naeem, U.A.; Shahmim, M.A.; Tahir, M.F. Performance of Concrete under Aggressive Wastewater Environment Using Differente Binders. Life Sci. J. 2013, 10, 141–150. [Google Scholar]

- Erdogmus, E.; Maher, K.T. Behavior and Design of Buried Concrete Pipes; University of Nebraska: Lincoln, NE, USA, 2006. [Google Scholar]

- CMA. Design Manual for Concrete Pipe Outfall Sewers; CMA: Bartlett Boksburg, UK, 2009; Volume 47. [Google Scholar]

- Chughtai, F.; Zayed, T. Structural Condition Models for Sewer Pipeline. In Proceedings of the Pipelines 2007: Advances and Experiences with Trenchless Pipeline Projects, ASCE, Boston, MA, USA, 8–11 July 2007; pp. 1–11. [Google Scholar]

- Hong, S. Selective Inhibition of Acidophilic Thiobacilli for Application of Controlling Microbially-Induced Corrosion in Concrete Sewers; The University of Arizona: Tucson, AZ, USA, 1992. [Google Scholar]

- Matthews, J.C. Large-Diameter Sewer Rehabilitation Using a Fiber-Reinforced Cured-in-Place Pipe. Pract. Period. Struct. Des. Constr. 2014, 04014031, 1–5. [Google Scholar] [CrossRef]

- Gu, J.; Mitchell, R. Biodeterioration. In The Prokaryotes—Applied Bacteriology and Biotecnhnology; Rosenberg, E., DeLong, E.F., Lory, S., Stackebrandt, E., Thompson, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 309–341. ISBN 9783642313301. [Google Scholar]

- Shifrin, N.S. Pollution Management in the Twentieth Century. J. Environ. Eng.-ASCE 2005, 131, 676–691. [Google Scholar] [CrossRef]

- Hewayde, E.; Nehdi, M.; Allouche, E.; Nakhla, G. Effect of Mixture Design Parameters and Wetting-Drying Cycles on Resistance of Concrete to Sulfuric Acid Attack. J. Mater. Civ. Eng. 2007, 19, 155–163. [Google Scholar] [CrossRef]

- Parande, A.K. Deterioration of Reinforced Concrete in Sewer Environments. Proc. Inst. Civ. Eng. Munic. Eng. 2006, 159, 11–20. [Google Scholar] [CrossRef]

- Wei, S.; Jiang, Z.; Liu, H.; Zhou, D.; Sanchez-Silva, M. Microbiologically Induced Deterioration of Concrete—A Review. Braz. J. Microbiol. 2013, 1007, 1001–1007. [Google Scholar] [CrossRef] [PubMed]

- Augustyniak, A.; Sikora, P.; Grygorcewicz, B.; Despot, D.; Braun, B.; Rakoczy, R.; Szewzyk, U.; Barjenbruch, M.; Stephan, D. Biofilms in the gravity sewer interfaces: Making a friend from a foe. Environ. Sci. Biotechnol. 2021, 20, 795–813. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Sánchez-Silva, M.; Chateauneuf, A. Structural Reliability of RC Structures Subject to Biodeterioration, Corrosion and Concrete Cracking. In Proceedings of the 10th International Conference on Applications of Statistics and Probability in Civil Engineering, Tokyo, Japan, 31 July–3 August 2007; Kanda, J., Takada, T., Furuta, H., Eds.; Taylor & Francis: London, UK, 2007; pp. 183–190. [Google Scholar]

- Lau, I.; Li, C.-Q.; Chen, F. Analytical and Experimental Investigation on Corrosion-Induced Concrete Cracking. Int. J. Civ. Eng. 2020, 18, 99–112. [Google Scholar] [CrossRef]

- Bielefeldt, A.; Gutierrez-Padilla, M.G.D.; Ovtchinnikov, S.; Silverstein, J.; Hernandez, M. Bacterial Kinetics of Sulfur Oxidizing Bacteria and Their Biodeterioration Rates of Concrete Sewer Pipe Samples. J. Environ. Eng. 2010, 136, 731–738. [Google Scholar] [CrossRef]

- Gu, J.; Ford, T.E.; Berke, N.S.; Mitchell, R. Biodeterioration of Concrete by the Fungus Fusariuml. Int. Biodeterior. Biodegrad. 1998, 41, 101–109. [Google Scholar] [CrossRef]

- George, R.P.P.; Ramya, S.; Ramachandran, D.; Kamachi Mudali, U. Studies on Biodegradation of Normal Concrete Surfaces by Fungus Fusarium Sp. Cem. Concr. Res. 2013, 47, 8–13. [Google Scholar] [CrossRef]

- Sawyer, C.N.; McCarty, P.L.; Parkin, G.F. Chemistry for Environmental Enginnering and Science; McGraw Hill: New York, NY, USA, 2003. [Google Scholar]

- Dopson, M.; Johnson, D.B. Biodiversity, Metabolism and Applications of Acidophilic Sulfur-Metabolizing Microorganisms. Environ. Microbiol. 2012, 14, 2620–2631. [Google Scholar] [CrossRef]

- Madigan, M.; Martinko, J.M.; Parker, J. Brock Biology of Microorganisms; Prentice-Hall: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Mehta, P.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- O’Connell, M.; McNally, C.; Richardson, M.G. Biochemical Attack on Concrete in Wastewater Applications: A State of the Art Review. Cem. Concr. Compos. 2010, 32, 479–485. [Google Scholar] [CrossRef]

- Nnadi, E.O.; Lizarazo-Marriaga, J. Acid Corrosion of Plain and Reinforced Concrete Sewage Systems. J. Mater. Civ. Eng. 2013, 25, 1353–1356. [Google Scholar] [CrossRef]

- Sand, W. Importance of Hydrogen Sulfide, Thiosulfate, and Methylmercaptan for Growth of Thiobacilli during Simulation of Concrete Corrosion. Appl. Environ. Microbiol. 1987, 53, 1645–1648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Islander, R.L.; Devinny, J.S.; Mansfeld, F.; Adam, P.; Hong, S. Microbial Ecology of Crown Corrosion in Sewers. J. Environ. Eng. 1991, 117, 751–770. [Google Scholar] [CrossRef]

- Hernandez, M.; Marchand, E.A.; Roberts, D.; Peccia, J. In Situ Assessment of Active Thiobacillus Species in Corroding Concrete Sewers Using Fluorescent RNA Probes. Int. Biodeterior. Biodegrad. 2002, 49, 271–276. [Google Scholar] [CrossRef]

- Giannantonio, D.J.; Kurth, J.C.; Kurtis, K.E.; Sobecky, P.A. Molecular Characterizations of Microbial Communities Fouling Painted and Unpainted Concrete Structures. Int. Biodeterior. Biodegrad. 2009, 63, 30–40. [Google Scholar] [CrossRef]

- Coleman, R.N.; Gaudet, I.D. Thiobacillus Neopolitanus Implicated in the Degradation of Concrete Tanks Used for Potable Water Storage. Water Res. 1993, 27, 413–418. [Google Scholar] [CrossRef]

- Kumar, R.; Gardoni, P.; Sanchez-Silva, M. Effect of Cumulative Seismic Damage and Corrosion on the Life-Cycle Cost of Reinforced Concrete Bridges. Earthq. Eng. Struct. Dyn. 2009, 38, 887–905. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Baji, H.; Li, C.-Q. A Theoretical Framework for Risk–Cost-Optimized Maintenance Strategy for Structures. Int. J. Civ. Eng. 2020, 18, 261–278. [Google Scholar] [CrossRef]

- Beddoe, R.E.; Dorner, H.W. Modelling Acid Attack on Concrete: Part I. The Essential Mechanisms. Cem. Concr. Res. 2005, 35, 2333–2339. [Google Scholar] [CrossRef]

- Ba, M.; Qian, C.; Guo, X.; Han, X. Effects of Steam Curing on Strength and Porous Structure of Concrete with Low Water/Binder Ratio. Constr. Build. Mater. 2011, 25, 123–128. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Influence of Porosity on Compressive and Tensile Strength of Cement Mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength, Porosity and Corrosion Resistance of Ternary Blend Portland Cement, Rice Husk Ash and Fly Ash Mortar. Constr. Build. Mater. 2008, 22, 1601–1606. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, Pore Size Distribution and in Situ Strength of Concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Mahmoodian, M.; Alani, A.M. Multi-Failure Mode Assessment of Buried Concrete Pipes Subjected to Time-Dependent Deterioration, Using System Reliability Analysis. J Fail. Anal. Prevent. 2013, 13, 634–642. [Google Scholar] [CrossRef]

- Li, X.; Moore, L.O.; Song, Y.; Bond, P.L.; Yuan, Z.; Wilkie, S.; Hanzic, L.; Jiang, G. The Rapid Chemically Induced Corrosion of Concrete Sewers at High H 2 S Concentration. Water Res. 2019, 162, 95–104. [Google Scholar] [CrossRef]

- De Belie, N. Microorganisms versus Stony Materials: A Love–Hate Relationship. Mater. Struct. 2010, 43, 1191–1202. [Google Scholar] [CrossRef]

- Bohm, M.; Devinny, J.S. A Moving Boundary Diffusion Model for the Corrosion of Concrete Wastewater Systems: Simulation and Experimental Validation. In Proceedings of the 1999 American Control Conference, Cat. No. 99CH36251, San Diego, CA, USA, 2–4 June 1999; pp. 1739–1743. [Google Scholar]

- Gutiérrez-Padilla, M.G.D.; Bielefeldt, A.; Ovtchinnikov, S.; Hernandez, M.; Silverstein, J. Biogenic Sulfuric Acid Attack on Different Types of Commercially Produced Concrete Sewer Pipes. Cem. Concr. Res. 2010, 40, 293–301. [Google Scholar] [CrossRef]

- Ehrich, B.S.; Helard, L.; Letourneux, R.; Willocq, J.; Bock, E. Biogenic and Chemical Sulfuric Acid Corrosion of Mortars. J. Mater. Civ. Eng. 1999, 11, 340–344. [Google Scholar] [CrossRef]

- Li, X.; Khademi, F.; Liu, Y.; Akbari, M.; Wang, C.; Bond, P.L.; Keller, J.; Jiang, G. Evaluation of Data-Driven Models for Predicting the Service Life of Concrete Sewer Pipes Subjected to Corrosion. J. Environ. Manag. 2019, 234, 431–439. [Google Scholar] [CrossRef]

- Choi, Y.; Nesic, S.; Ling, S. Effect of H2S on the CO2 Corrosion of Carbon Steel in Acidic Solutions. Electrochim. Acta 2011, 56, 1752–1760. [Google Scholar] [CrossRef]

- Adebayo, A.; Oluwadare, B. Corrosion of Steels in Water and Hydrogen Sulfide. Rev. Ind. Eng. Lett. 2014, 1, 80–88. [Google Scholar] [CrossRef] [Green Version]

- Gharib, F.E.; Abdulhaq, A.; Abd, A. Experimental Study Of Reinforcing Steel Bars Behaviour Under Corrosive Conditions. Aust. J. Basic Appl. Sci. 2012, 6, 371–377. [Google Scholar]

- New York State Department of Transportation. Geotechnical Aspects of Pipe Design and Installation. In Geotechnical Design Manual; New York State Department of Transportation: Albany, NY, USA, 2013; pp. 1–54. [Google Scholar]

- Goodson, M.W.; Anderson, J.E. Soil-Structure Interaction–A Case Study. In Proceedings of the Structures Congress 2005, ASCE, New York, NY, USA, 20–24 April 2005; pp. 1–11. [Google Scholar]

- ACPA. Concrete Pipe Design Manual; ACPA: St. Louis, MI, USA, 2011; pp. 1–540. [Google Scholar]

- Callaghan, F.W. Pipe Performance and Experiences during Seismic Events in New Zealand over the Last 25 Years. In Proceedings of the Pipelines 2012: Innovations in Design, Construction, Operations, and Maintenance, ASCE, Miami Beach, FL, USA, 19–22 August 2012; pp. 1136–1146. [Google Scholar]

- Rubeiz, C.G. Performance of Pipes during Earthquakes. In Proceedings of the Pipelines 2009: Infrastructure’s Hidden Assets, ASCE, Miami, FL, USA, 19–22 August 2009; pp. 1205–1215. [Google Scholar]

- Doyle, J.M.; Fang, S.J. Design of Buried Pipes. In Handbook of Structural Engineering; Chen, W.F., Ed.; CRC Press: Boca Raton, FL, USA, 1997; Chapter 25; ISBN 0849315697. [Google Scholar]

- CMA. Concrete Pipe and Portal Culvert Handbook; CMA: Bartlett Boksburg, UK, 2012; p. 50. [Google Scholar]

- AASHTO. AASHTO LRFD Bridge Desig Specifications; AASHTO: Washington, DC, USA, 2012. [Google Scholar]

- Chughtai, F.; Zayed, T. Infrastructure Condition Prediction Models for Sustainable Sewer Pipelines. J. Perform. Constr. Facil. 2008, 22, 333–341. [Google Scholar] [CrossRef]

- Chisala, B.N.; Lerner, D.N. Distribution of Sewer Exfiltration to Urban Groundwater. Proc. ICE—Water Manag. 2008, 161, 333–341. [Google Scholar] [CrossRef]

- Park, S.; Lim, H.; Tamang, B.; Jin, J.; Lee, S.; Park, S.; Kim, Y.; Kim, Y. A Preliminary Study on Leakage Detection of Deteriorated Underground Sewer Pipes Using Aerial Thermal Imaging. Int. J. Civ. Eng. 2020, 18, 1167–1178. [Google Scholar] [CrossRef]

- Scheperboer, I.C.; Luimes, R.A.; Suiker, A.S.J.; Bosco, E.; Clemens, F.H.L.R. Experimental-numerical study on the structural failure of concrete sewer pipes. Tunn. Undergr. Sp. Technol. 2021, 116, 104075. [Google Scholar] [CrossRef]

- McCormac, J.C.; Nelson, J.K. Design of Reinforced Concrete; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Products, I.; Division, E.S. Concrete Pipe and Portal Culvert Handbook; CMA: Bartlett Boksburg, UK, 2009. [Google Scholar]

- CSI. CSi Analysis Reference Manual; Computers & Structures Inc: Walnut Creek, CA, USA, 2013. [Google Scholar]

- González, H.D.; Reyes, G.Á. Análisis Comparativo de La Teoría de Martson para Tuberías Enterradas y La Modelación Numérica Con Elementos Finitos; Universidad Nacional de Colombia: Bogota, Columbia, 1999; pp. 1–13. [Google Scholar]

- Agrawal, A.K.; Ramalingam, K.; Rozelman, S.; Kulcsar, F.; Farooqui, N. Asset Management and Nondestructive Evaluation of Force Mains in New York City. In Proceedings of the Pipelines Congress 2008, ASCE, Atlanta, GA, USA, 22–27 July 2008; pp. 1–11. [Google Scholar]

- Ates, S. Numerical Modelling of Continuous Concrete Box Girder Bridges Considering Construction Stages. Appl. Math. Model. 2011, 35, 3809–3820. [Google Scholar] [CrossRef]

- Bento, R.; Falcão-Silva, M.J. Analytical Model for the Seismic Behavior of Buried Pipeline when Subjected to Ground Liquefaction. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Becker, G.; Boduroglu, H.; Camarinopoulos, S.; Frondistou-Yannas, S.; Gedikli, A.; Kallidromitis, V.G.; Kampranis, D.; Sanna, C. Structural Assessment and Upgrading of Sewers Based on Inspection Results. J. Infrastruct. Syst. 2009, 15, 321–329. [Google Scholar] [CrossRef]

- Petry, T.M.; Little, D.N. Review of Stabilization of Clays and Expansive Soils in Pavements and Lightly Loaded Structures—History, Practice, and Future. Mater. Civ. Eng. 2002, 16, 447–460. [Google Scholar] [CrossRef]

- Sert, S.; Kılıc, A.N. Numerical Investigation of Different Superstructure Loading Type Effects in Mat Foundations. Int. J. Civ. Eng. 2016, 14, 171–180. [Google Scholar] [CrossRef]

- ASTM C76M-14; Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric). ASTM: West Conshohocken, PE, USA, 2014; pp. 1–11.

- Sanchez-Silva, M. Introducción a La Confiabilidad y Evaluación de Riesgos. Teoría y Aplicaciones en Ingeniería; Universidad de los Andes, Ed.; Ediciones Uniandes: Bogota, Columbia, 2010; ISBN 9789586955119. [Google Scholar]

- Gilman, M.J. A brief survey of stopping rules in Monte Carlo simulations. J. Optim. Theory Appl. 1989, 4–9. [Google Scholar] [CrossRef]

- Che, J.; Wang, J.; Li, K. A Monte Carlo Based Robustness Optimization Method in New Product Design Process: A Case Study. Am. J. Ind. Bus. Manag. 2014, 4, 360–369. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1417 M; Standard Specification for Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe for Direct Design [Metric]. ASTM: West Conshohocken, PE, USA, 2014; pp. 1–7.

- ASTM C1433 M; Standard Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains and Sewers. ASTM: West Conshohocken, PE, USA, 2014; pp. 1–22.

- ASTM C655M-14; Standard Specification for Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer Pipe (Metric). ASTM: West Conshohocken, PE, USA, 2014; pp. 1–6.

- del Giudice, G.; Padulano, R.; Siciliano, D. Multivariate probability distribution for sewer system vulnerability assessment under data-limited conditions. Water Sci. Technol. 2016, 73, 751–760. [Google Scholar] [CrossRef] [PubMed]

- Dirksen, J.; Clemens, L.R. Probabilistic modeling of sewer deterioration using inspection data inspection data. Water Sci. Technol. 2008, 57, 1635–1641. [Google Scholar] [CrossRef] [PubMed]

- Laakso, T.; Kokkonen, T.; Mellin, I.; Vahala, R. Sewer Life Span Prediction: Comparison of Methods and Assessment of the Sample Impact on the Results. Water 2019, 11, 2657. [Google Scholar] [CrossRef] [Green Version]

- Caradot, N. The Use of Deterioration Modelling to Simulate Sewer Asset Management Strategies; INSA Université de Lyon: Lyon, France, 2019. [Google Scholar]

- Hernández, N.R. Methodology for Identifying the Key and Enough Factors for Achieving Objectives in Sewer Asset Management; Pontificia Universidad Javeriana: Bogota, Columbia, 2020. [Google Scholar]

- Fugledalen, T.; Rokstad, M.M.; Tscheikner-Gratl, F. On the influence of input data uncertainty on sewer deterioration models—A case study. Struct. Infrastruct. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Jin, Y.; Mukherjee, A.; Asce, A.M. Modeling Blockage Failures in Sewer Systems to Support Maintenance Decision Making. J. Perform. Constr. Facil. 2010, 24, 622–633. [Google Scholar] [CrossRef]

- Korving, H.; van Noortwijk, J.M.; van Gelder, P.H.A.J.M.; Clemens, H.L.R.; Korving, H.; van Noortwijk, J.M.; van Gelder, P.H.A.J.M. Risk-based design of sewer system rehabilitation. Struct. Infrastruct. Eng. 2009, 5, 215–227. [Google Scholar] [CrossRef]

- ACPA. Highway Live Loads on Concrete Pipe; ACPA: St. Louis, MI, USA, 2009; Volume 1, pp. 1–10. [Google Scholar]

- Zamanian, S.; Hur, J.; Shafieezadeh, A. Significant variables for leakage and collapse of buried concrete sewer pipes: A global sensitivity analysis via Bayesian additive regression trees and Sobol’ indices. Struct. Infrastruct. Eng. 2021, 17, 676–688. [Google Scholar] [CrossRef]

- Qiu, L.; Dong, S.; Ashour, A.; Han, B. Antimicrobial concrete for smart and durable infrastructures: A review. Constr. Build. Mater. 2020, 260, 1–15. [Google Scholar] [CrossRef]

- Jamshidi, M.; Alizadeh, M.; Salar, M.; Hashemi, A. Durability of Polyester Resin Concrete in Different Chemical Solutions. Adv. Mater. Res. 2013, 687, 150–154. [Google Scholar] [CrossRef]

- Meyer-Policrete. POLYCRETE Catalog; Meyer: Stendal: Germany, 2020; pp. 1–16. [Google Scholar]

- Resin, N.P.G.P.; Relining, P. CRYSTIC PD10098T. Ortho—NPG Polyester Resin for Pipe Relining; Scott Bader SAS: Amiens, France, 2018; pp. 1–2. [Google Scholar]

- TPP Manufacturing. Polyester resin concrete jacking pipe. In Product Type Specification; TPP Manufacturing: Singapore, 2016; pp. 1–2. [Google Scholar]

- DIN 16946-2; Cured Casting Resins: Types. German Institute for Standardisation (DIN): Berlin, Germany, 1989; 8p.

| Exposure Time (Days) | Weight Loss | Thickness Loss (mm/Year) | Environment | Experimental Conditions | Ref. |

|---|---|---|---|---|---|

| 20 | N.A. | 3.50 | 1100 ppm H2S, 21.5 °C | Pilot-scale sewer pipe | [66] |

| 40 | N.A. | 10 | 89 ppm H2S, 17 °C | In situ (real env.) | [13] |

| 68 | N.A. | 5.37 | 250 ppm H2S | Experimental apparatus | [67] |

| 81 | N.A. | 2.59 | N.A. | Experimental apparatus | [68] |

| 120 | 1.6% | 0.16a | 100–200 ppm H2S, 25–30 °C | In situ (real env.) | [14] |

| 180 | N.A. | 20 | 700–1000 ppm H2S, 20–35 °C | Pilot scale system | [17] |

| 227 | N.A. | 0.21 | 300–600 ppm H2S, 23 °C | Reactor in laboratory | [69] |

| 270 | 5.8% | 0.20 a | 12–18 ppm H2S | Simulation chamber | [53] |

| 300 | 6.8% | 0.30 a | 8–15 ppm H2S, 30 °C | Experimental apparatus | [6] |

| 350 | 100% | 20 | 5–15 ppm H2S, 30 °C | Simulation chamber | [70] |

| 360 | 37.0% | 10 | 10–50 ppm H2S | In situ (real env.) | [12] |

| 930 | N.A. | 12 | 79 ppm H2S | In situ (real env.) | [11] |

| 960 | N.A. | 8.9 | 50 ppm H2S, 30 °C | Corrosion Chamber | [27] |

| 1350 | N.A. | 1.0 | 5–50 ppm H2S, | Corrosion Chamber | [18] |

| 1460 | N.A. | 1.0 | 5 ppm H2S, 21 °C | In situ (real env.) | [10] |

| 1460 | N.A. | 0.5 | 68 ppm H2S, 27 °C | In situ (real env.) | [10] |

| 1460 | N.A. | 0.1 | 650 ppm H2S, 27 °C | In situ (real env.) | [10] |

| 1620 | N.A. | 0.19 | 5–50 ppm H2S, 25 °C | Corrosion Chamber | [19] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marquez-Peñaranda, J.F.; Sanchez-Silva, M.; Bastidas-Arteaga, E. Probabilistic Assessment of Biodeterioration Effects on Reinforced Concrete Sewers. Corros. Mater. Degrad. 2022, 3, 333-348. https://doi.org/10.3390/cmd3030020

Marquez-Peñaranda JF, Sanchez-Silva M, Bastidas-Arteaga E. Probabilistic Assessment of Biodeterioration Effects on Reinforced Concrete Sewers. Corrosion and Materials Degradation. 2022; 3(3):333-348. https://doi.org/10.3390/cmd3030020

Chicago/Turabian StyleMarquez-Peñaranda, Jorge Fernando, Mauricio Sanchez-Silva, and Emilio Bastidas-Arteaga. 2022. "Probabilistic Assessment of Biodeterioration Effects on Reinforced Concrete Sewers" Corrosion and Materials Degradation 3, no. 3: 333-348. https://doi.org/10.3390/cmd3030020