Identification Methodology for Chemical Warehouses Dealing with Flammable Substances Capable of Causing Firewater Pollution

Abstract

:1. Introduction

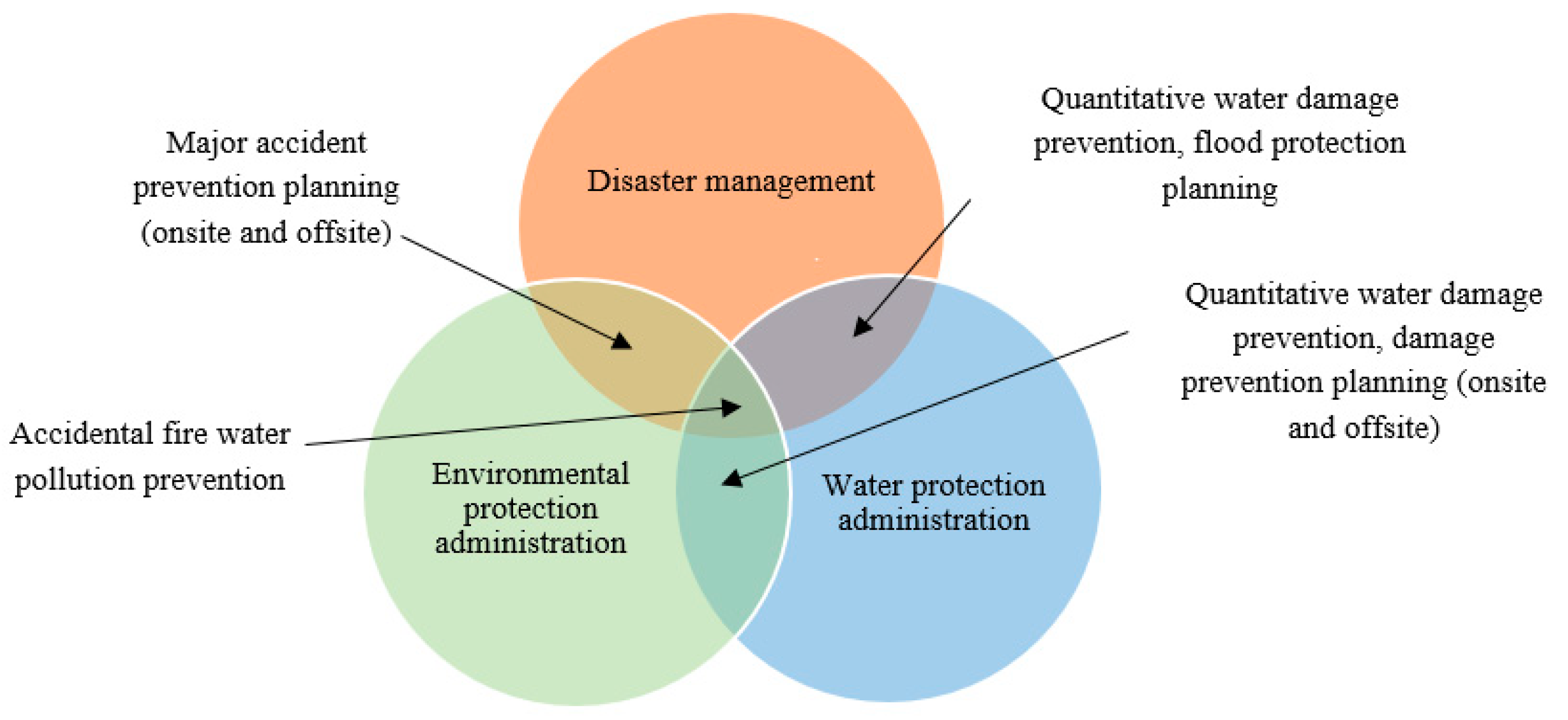

1.1. Environmental Impacts of Major Accidents Involving Dangerous Substances

1.2. Determination and Limitation of the Scope of the Research

1.3. Introduction of Research Problem and Objectives of the Present Study

- Examination of the consequences and impacts of major accident scenarios causing firewater pollution.

- Development of the identification procedure and methodology for the existing chemical warehouses requiring the introduction of FPP measures.

- Assessment of the operator’s FPP measures implementation practice of Hungarian chemical warehouses and testing the applicability of the identification procedure and methodology.

2. Literature Review

2.1. In the Field of FPP Policies and Safety Measures

2.2. In the Field of Risk Assessment of Major Accidents Involving Dangerous Substances

3. Materials and Methods

3.1. Environmental Pollution Consequences and Impacts of Dangerous Substances Released into the Environment

- Toxic effects caused by the release of toxic, dangerous substances.

- The fire following the release of flammable substances and a subsequent release of contaminated firewater.

- The effect of the toxic combustion products produced during the fire, which can have both air and water pollution environmental impacts.

- —amount of percolating water,

- ΔH—hydraulic pressure difference,

- A—cross-section of the soil column,

- t—the time,

- ΔL—length of soil column,

- KS—the leakage factor.

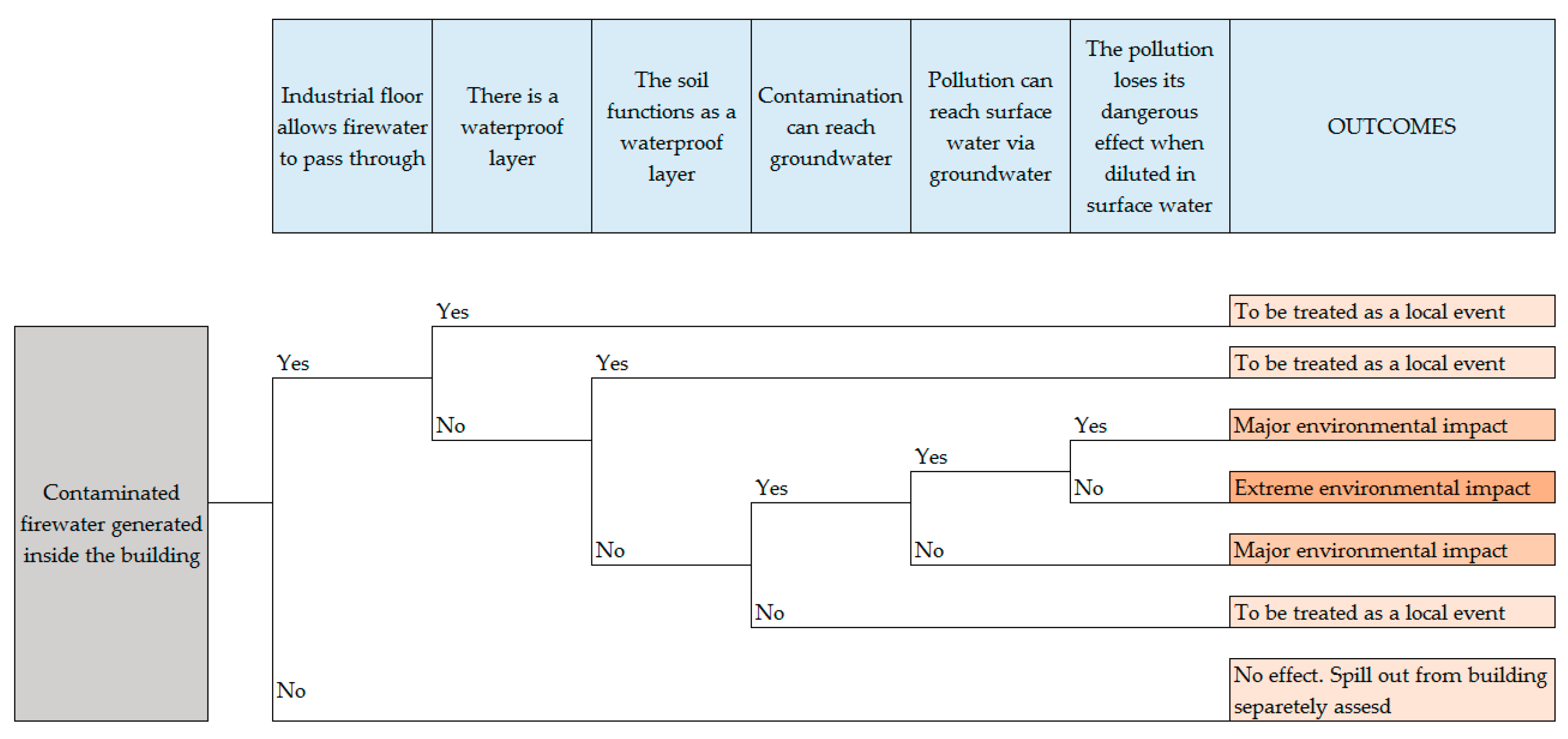

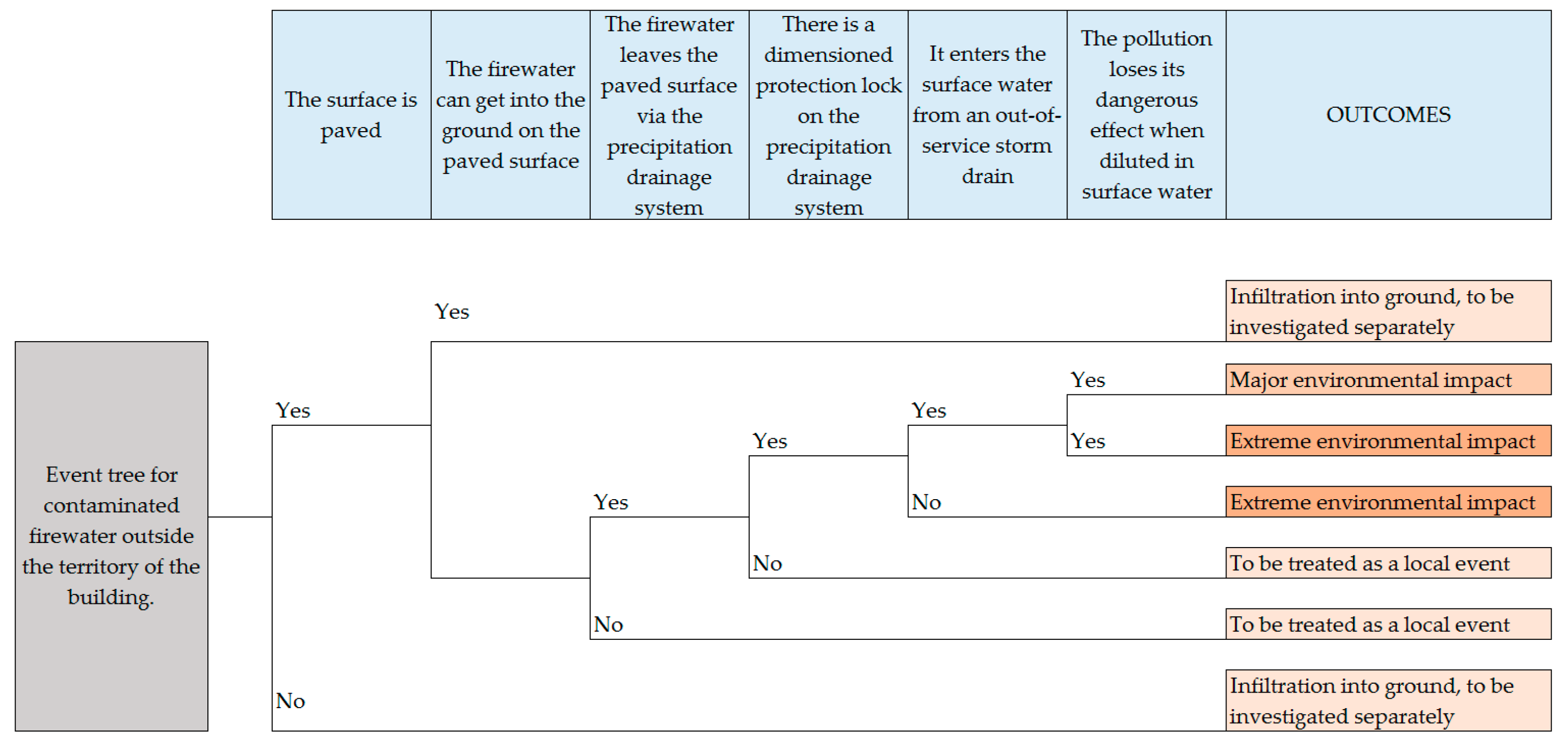

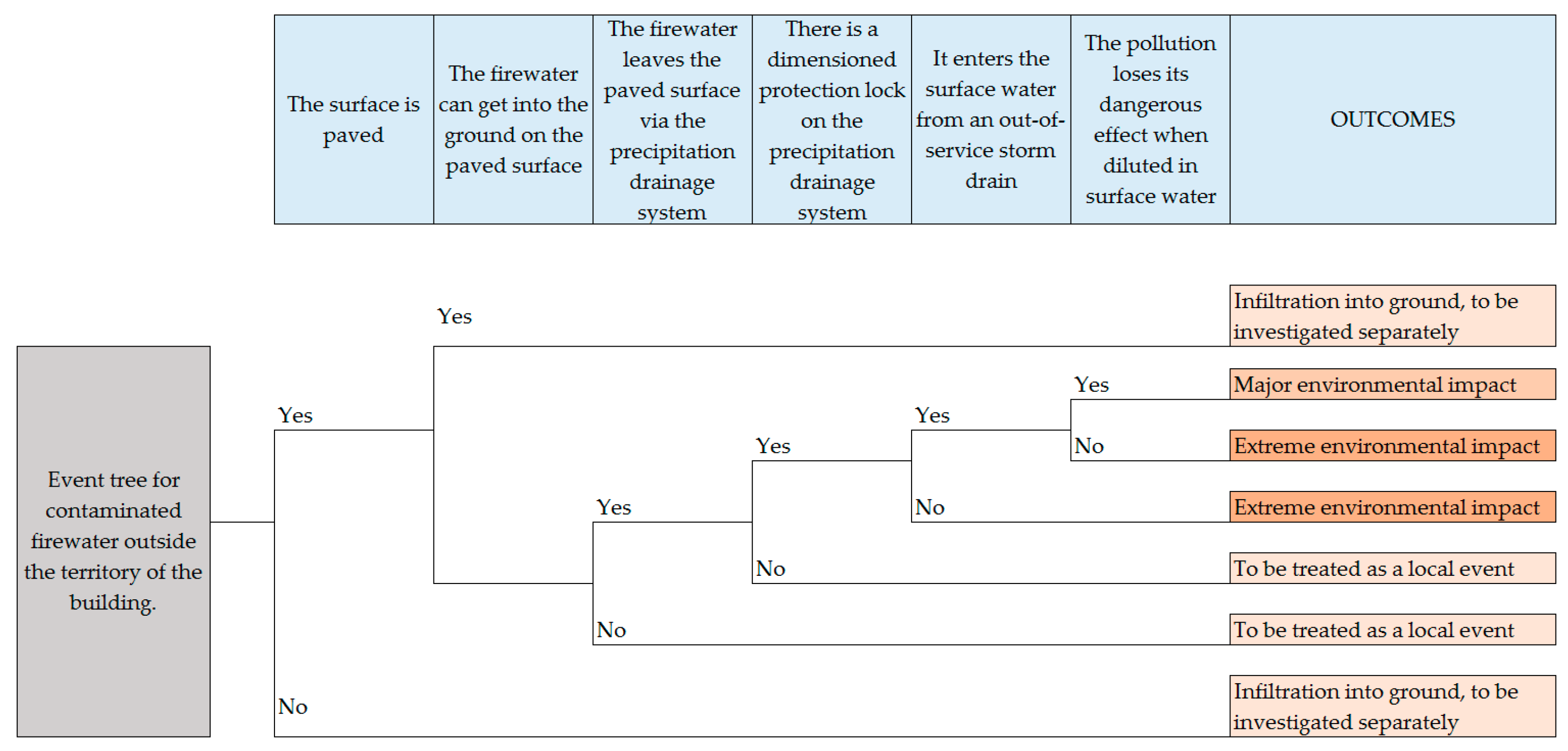

3.2. Consequence Assessment of Firewater Run-Off Scenarios

- A detailed understanding of the operation of the tested system, including safety barriers, as well as their breakdown into technological elements.

- Investigation of the possible failures of technological elements and analysis of the consequences of these failures.

- On the occasion of a “local event”, no actual catastrophic impact or permanent damage to the state of the environment should be expected.

- In the case of an output with a “major environment impact”, a catastrophic effect may develop, or permanent damage to the state of the environment may occur. However, there is no need to count on an impact beyond the national borders.

- In the event of an output with an “extreme impact”, a catastrophic effect may develop, and there may also be permanent damage to the state of the environment, which may also cause an impact beyond national borders.

3.2.1. Event Tree Related to Contaminated Firewater Generated Inside the Building

3.2.2. Event Tree for Firewater Run-Off Outside the Territory of the Building

3.2.3. Event Tree for Contaminated Firewater Falling on the Ground Outside of the Building

3.3. Development of Identification Procedure for Existing Chemical Warehouses

3.3.1. Determination of Index Components and Validation of their Values and Ranges

- Amount and type of stored dangerous substances.

- Fire prevention device of the chemical warehouse.

- Firewater retention device installed inside the storage building.

- Firewater retention device installed outside of the storage building.

- Sensitivity of the pathways and receiving environment.

3.3.2. K1 Index Component—Amount and Type of Stored Dangerous Substances

3.3.3. K2 Index Component—Fire Protection Device of Chemical Warehouse

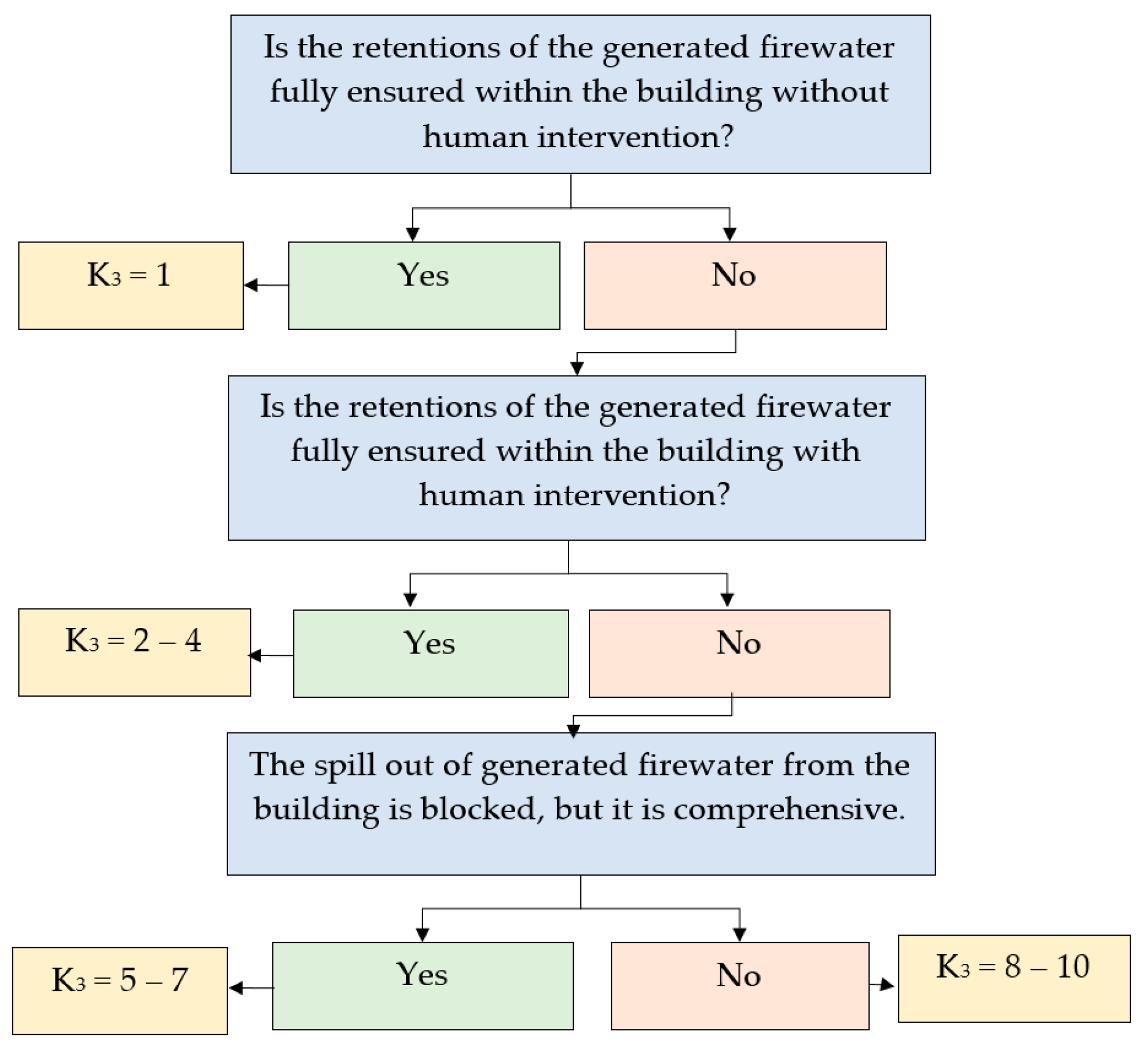

3.3.4. K3 Index Component—Firewater Retention Device Installed Inside of Storage Building

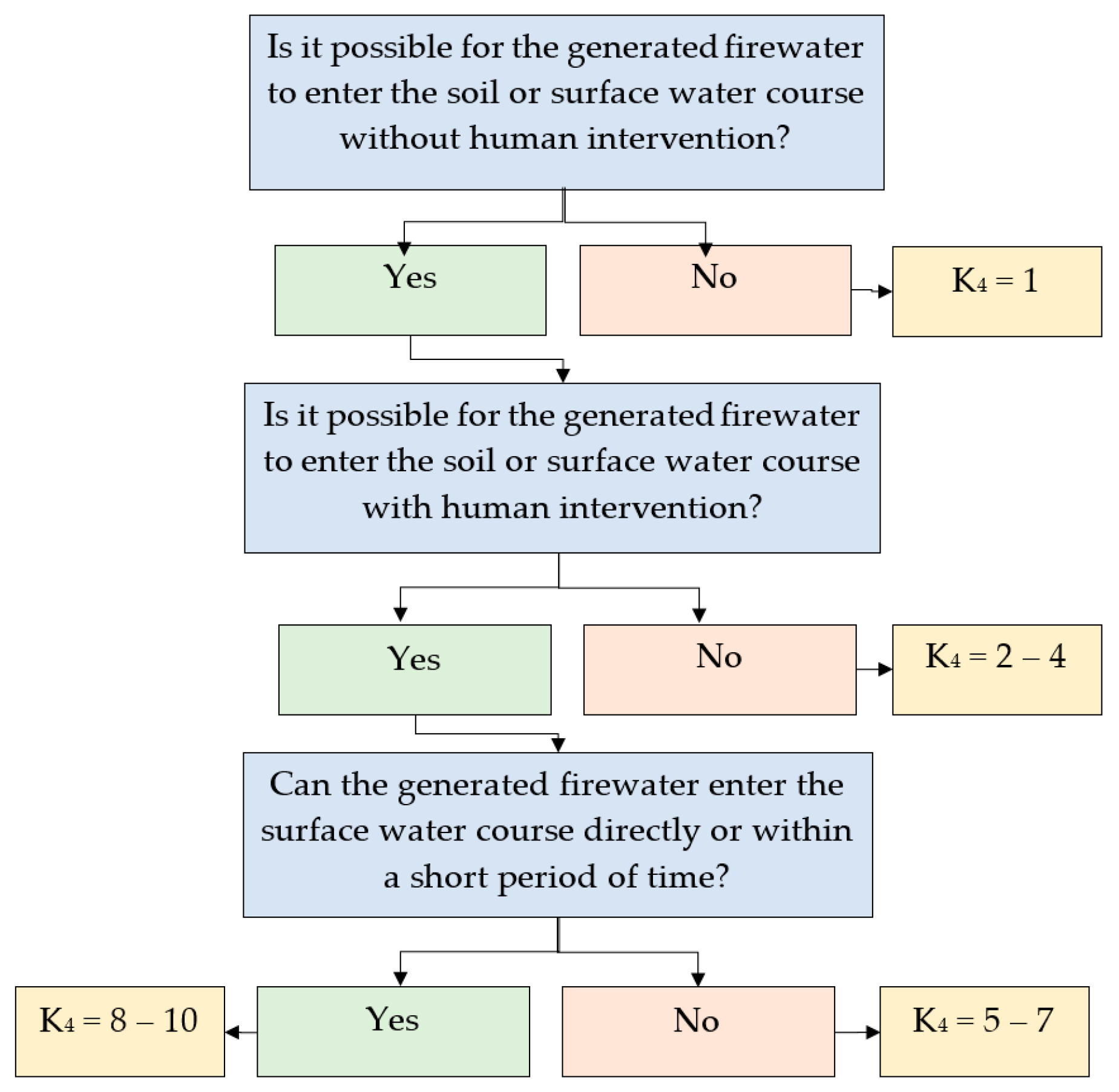

3.3.5. K4 Index Component—Firewater Retention Devise Installed Outside of the Storage Building

3.3.6. K5 Index Component—Sensitivity of the Pathways and Receiving Environment

3.3.7. Definition of the Summary Evaluation Criteria for the Identification Procedure

- The authors assume that the contaminated firewater directly enters the surface water course, in which case K5 = 10.

- On this occasion, the maximum protection criterion must be met in order to retain the contaminated firewater inside the building or discharge outside of the building. In this case, at least one of the component values of K3 or K4 should be 1.

- Furthermore, If K2 = 4, then significant environmental pollution does not occur, and, in that case, any dangerous substances can be present in the area of the chemical storage facility; that is, K1 = 10.

3.4. Inspection of the Enforcement Level of FPP Measures for Existing Chemical Warehouses

4. Results and Discussion

4.1. Assessment of the Operator’s FPP Measures Implementation Practice for Existing Chemical Warehouses in Hungary

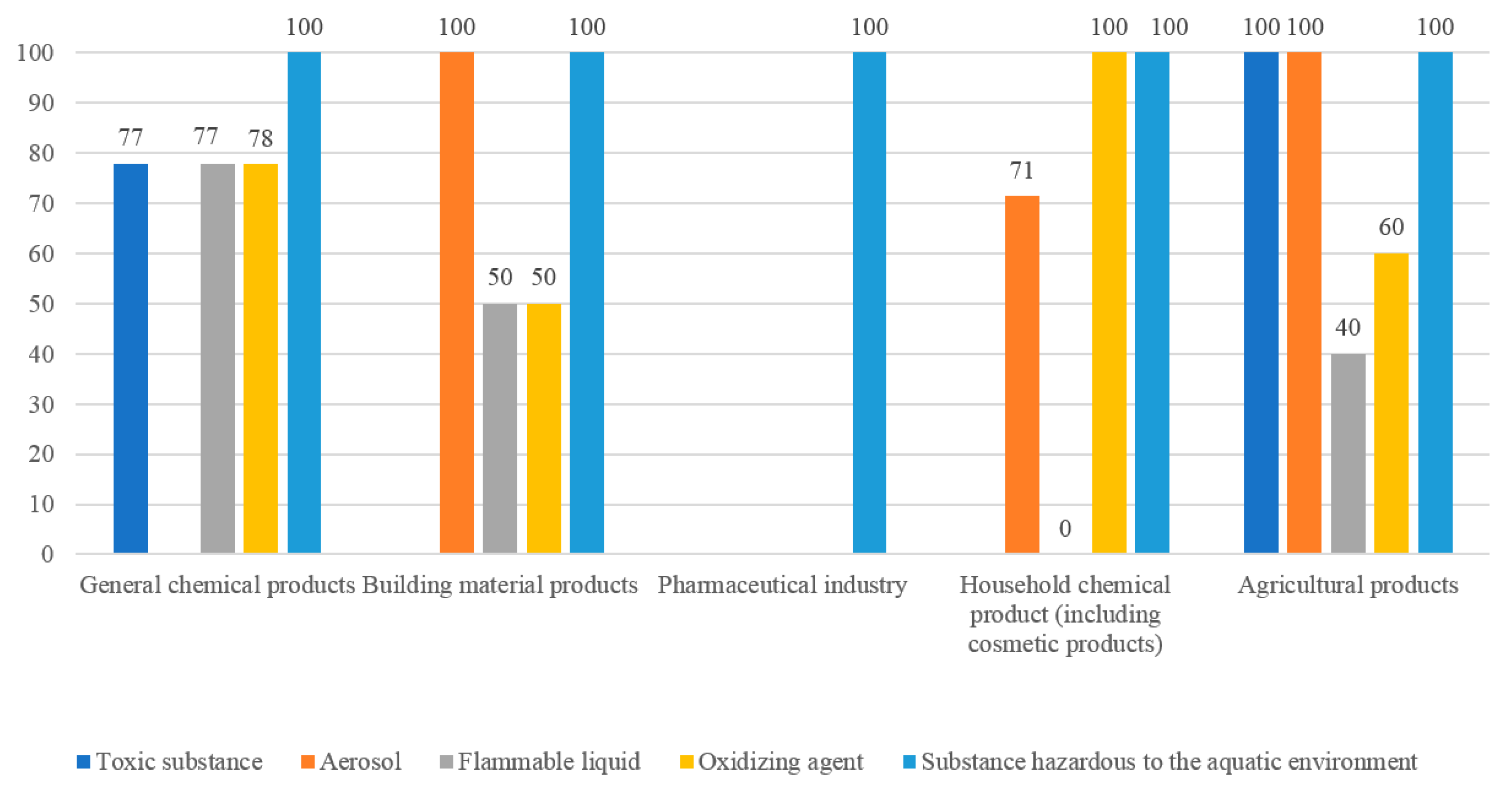

- In 38% of the examined chemical warehouses, general chemical products are typically stored in liquid or solid state. The IBC (intermediate bulk container) is typically the largest packaging unit in storage facilities, but products can also be stored in barrels, cans, bags and smaller packages.

- Liquid, solid products and aerosols are stored in the chemical warehouses of household chemical products, including cosmetic products, in 29% of the examined chemical warehouses. It is typical for storage that the size of the packaging units usually does not exceed 10 litres.

- Liquid or solid products are stored in agricultural product chemical warehouses, which is 21% of the examined chemical warehouses. The largest packaging unit is the big-bag packaging, but the entire spectrum of packaging equipment from IBC to smaller packaging units can be found in these chemical warehouses.

- The storage of building material products (8% of all warehouses) is mainly present in liquid, solid and aerosol form. The largest packaging unit is typically the IBC, but similar to other chemical warehouses, the entire spectrum of packaging devices can be used during storage.

- In the case of pharmaceutical product’s chemical warehouses (4% of all warehouses), the main objective was the examination of the chemical warehouses storing the finished product.

- The FPP obligations of the chemical warehouses existing and under planning must be dealt with separately. Theoretically, the best solution is to introduce FPP measures during the design and construction activities of the storage facilities, but the author’s experience does not show this operator practice. A total of 34% of the examined chemical warehouses were originally built for the storage of conventional products, not for storing and handling flammable, dangerous substances. Due to various market demands, the function of the warehouse during the operation of these facilities changes, and consequently, the storage of dangerous substances or dangerous goods also begins.

- In line with Annex 1 (point 21.) of the European Union directive on environmental impact assessment, the assessment should be performed if the storage capacity of the storage is site more than 200,000 t of total chemical products and in accordance with Annex 3 for the storage capacity of over 30,000 m3. In the case of the present study, the total storage capacity condition was met in four cases of 200,000 tons and in two cases of 30,000 m3. At the same time, an environmental impact assessment was carried out for only one chemical warehouse since the function of the chemical warehouse did not yet extend to the storage of dangerous substances during the installation period of the chemical warehouses. The storage function was changed only during operation activities.

- Looking at the technical design of the chemical warehouses, it can be established that they comply with the fire prevention legal obligations. A fire alarm system was installed in 92%, and an automatic fire extinguishing system was installed in 37.5% of the chemical warehouses. There was automatic gas extinguishing in one chemical warehouse, automatic foam extinguishing in two chemical warehouses and water sprinkler fire extinguishing systems in the other chemical warehouses in operation.

- In each of the examined chemical warehouses, an industrial floor was installed, and the appropriate waterproofing was ensured. Therefore, in the case of contaminated firewater being generated and remaining inside the facility, a significant amount of seepage should not be expected. A total of 21% of the chemical warehouses were designed as scaled-up retention basins.

- During the environmental hazard analysis procedure, none of the investigated chemical warehouses identified the possibility of the generation of contaminated firewater scenarios. At the same time, the operators, implementing major accident prevention regulations, introduced FPP measures in their safety documentation.

- It can also be stated that the contaminated firewater cannot enter the surface watercourse directly from any of the investigated chemical warehouses since the sectioning of the precipitation drainage system has been solved. At the same time, the exclusion of contaminated firewater from entering the soil and the minimisation of released pollutants can be realised only in the case of one chemical warehouse.

- It can also be concluded that the safety level of some of the facilities (41.7%) meets the requirements of international standards and guidelines, as these facilities were designed and built recently based on these safety instructions.

- In the case of existing chemical warehouses, it is difficult to enforce FPP measures from the authorities’ point of view. In the case of existing chemical warehouses, either the range of products to be stored must be limited with a subsequent obligation of a competent authority, or technical measures must be taken to limit the run-off of contaminated firewater.

4.2. Auditing, Testing and Discussing the Applicability of Identification Procedure and Methodology

4.2.1. Results of the Validation of Evaluation Criteria

4.2.2. Testing and Discussing the Applicability of the Identification Procedure and Methodology

- Example 1.

- K1 = 10, the value was determined by the fact that the examined chemical warehouse falls under the scope of the Seveso III Directive’s regulation on the prevention of major accidents; thus, hazardous substances are present in the given chemical warehouse based on their quantitative and qualitative properties.

- K2 = 4, based on the safety documentation, it was determined that the chemical warehouse has a built-in automatic water extinguishing system.

- K3 = 6, the examined storage building does not fully function as a fire retention boundary; the contaminated extinguishing water from it can reach the area outside the building, although to a limited extent.

- K4 = 10, there was no firewater retention system designed and installed outside the chemical warehouse building territory to eliminate the further flow of contaminated firewater.

- K5 = 8, the spread of the polluted firewater is not significantly hindered by the soil conditions because it is a sandy soil. The entry of polluted firewater into the surface watercourse and the endangering of sensitive environmental habitats, such as drinking water base, exist due to the soil conditions.

- Example 2.

- It has been proven that the index components can represent the degree of firewater run-off risk caused by the affected chemical warehouse sites. Of course, the preliminary risk analysis technique proposed by the authors can be followed by the application of detailed and more sophisticated risk analyses, but only for a preselected group of operators.

- The application of the site identification process and methodology can be extended to all hazardous activities, but they require the definition of additional special risk assessment components.

4.3. Limitation of the Applicability of Identification Procedure and Methodology

- The procedure and methodology proposed by the authors can be applied at sites serving as the chemical storage facility of dangerous substances and goods; most of the sites are regulated by major accident prevention regulations.

- The applicability of the approach can also be extended to dangerous establishments producing or processing dangerous substances, where the identification procedure can be carried out at their own chemical warehouse installations operating inside of these facilities.

- The modified approach can be applicable to facilities that use special storage procedures, such as waste disposal sites, inter- and multimodal terminals and other facilities for storing and handling electronic, battery, plastic or household waste. In the latter case, the already discussed (Section 2.1) more complex and punctual calculation procedures and methods can be used.

5. Conclusions

- One of the main conclusions of this publication is that there are significant differences in the design of chemical warehouses, both in terms of built-in modern fire prevention and firewater retention systems, in the implementation of FPP measures.

- The scientific examination and systematisation of the processes that cause firewater pollution in major accident events can technically lay the foundation for the legal, organisational and institutional system to be established in the case of dangerous activities, such as existing chemical warehouses capable of endangering the surrounding environment.

- The authors—using the event tree hazard analyses method—investigated the possible environmental pollution effects of the contaminated firewater that may be released in the event of a major accident, and then they proposed an identification procedure and methodology—based on the indexing method—for existing chemical warehouses involved in the implementation of the FPP measures.

- In accordance with the calculation test and an assessment of the implementation level of FPP measures carried out among the Hungarian chemical warehouse operators, the applicability of the proposed facility identification procedure and methodology was proven. The inspected operators agreed with the results and conclusions of the authors, and in many cases, FPP measures had to be introduced based on the results of the present study. The limitation of the applicability of the approach is described in the discussion part of the article.

- In the opinion of the authors, safety problems related to commercial and logistics warehouses dealing with dangerous goods, such as inter- and multimodal terminals, may be a future research task.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UN Office for Disaster Risk Reduction. Words into Action Guidelines. Implementation Guide for Man-made and Technological Hazards. Available online: https://www.undrr.org/publication/words-action-guideline-man-made/technological-hazards (accessed on 1 August 2023).

- Vince, I. Major Accidents to the Environment: A Practical Guide to the Seveso II Directive and COMAH Regulations; Butterworth-Heinemann: Oxford, UK; Elsevier: Oxford, UK, 2008. [Google Scholar]

- Bureau for Analysis of Industrial Risks and Pollutions. Analysis, Research and Information on Accidents (ARIA) Database. Available online: https://www.aria.developpement-durable.gouv.fr/the-barpi/the-aria-database/?lang=en (accessed on 1 August 2023).

- Zema Major Accidents and Incidents. Available online: https://www.infosis.uba.de/index.php/en/site/13947/zema/index.html (accessed on 1 August 2023).

- Directorate-General Joint Research Centre of the European Commission. The Minerva Portal of the Major Accident Hazards Bureau. Available online: https://emars.jrc.ec.europa.eu/en/emars/statistics/statistics (accessed on 1 August 2023).

- Nivolianitou, Z.; Konstandinidou, M.; Michalis, C. Statistical analysis of major accidents in petrochemical industry notified to the major accident reporting system (MARS). J. Hazard. Mater. 2006, 137, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Institution of Chemical Engineers. Loss Prevention Bulletin: Environment Agency (Special Issue). Available online: https://www.icheme.org/knowledge/loss-prevention-bulletin/free-downloads/issues/issues/ (accessed on 1 August 2023).

- USA. Chemical Safety and Hazard Investigation Board. Final Investigation Report: Caribbean Petroleum Tank Terminal Explosion and Multiple. Tank Fires. Report No. 2010.02.I.PR. Available online: https://www.csb.gov/caribbean-petroleum-refining-tank-explosion-and-fire (accessed on 1 August 2023).

- Health and Safety Executive. Buncefield: Why Did It Happen? The Underlying Causes of the Explosion and Fire at the Buncefield Oil Storage Depot, Hemel Hempstead, Hertfordshire on 11 December 2005. Available online: https://www.hse.gov.uk/comah/investigation-reports.htm (accessed on 1 August 2023).

- Kátai-Urbán, I.; Vass, G. Hazardous Activities in Hungary—In Terms of Industrial Safety. AARMS 2014, 13, 141–154. [Google Scholar] [CrossRef]

- Kátai-Urbán, L.; Cséplő, Z. Disaster in the Ajka Red Sludge Reservoir on 4 October 2010. In Proceedings of the UN Economic Commission for Europe, Sixth Meeting of the Conference of the Parties to the Convention on the Transboundary Effects of Industrial Accidents, Hague, The Netherlands, 8–10 November 2010. [Google Scholar]

- Kovac, C. Cyanide Spill Could Have Long Term Impact. BMJ 2000, 320, 1294. [Google Scholar]

- Kátai-Urbán, M. Safety of Storage of Dangerous Substances and Goods, with Particular Regard to Accidental Water Pollution. Hadmérnök 2023, 18, 29–41. [Google Scholar] [CrossRef]

- UN Economic Commission for Europe (UN ECE). Convention on the Transboundary Effects of Industrial Accidents—As Amended on 15 December 2015. Available online: https://unece.org/info/Environment-Policy/Industrial-accidents/pub/21645 (accessed on 1 August 2023).

- Official Journal of the European Union. Directive 2012/18/EU of the European Parliament and of the Council of 4-th of July 2012 on the Control of Major-Accident Hazards Involving Dangerous Substances, Amending and Subsequently Repealing Council Directive 96/82/EC. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2012:197:0001:0037:EN:PDF (accessed on 1 August 2023).

- Major Accident Hazards. Available online: https://ec.europa.eu/environment/seveso/legislation.htm (accessed on 1 August 2023).

- 219/2011. (X. 20.) Government Decree on the Protection against Major Accidents Involving Dangerous Substances. Available online: https://net.jogtar.hu/jogszabaly?docid=a1100219.kor (accessed on 1 August 2023).

- Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on Classification, Labelling and Packaging of Substances and Mixtures, Amending and Repealing Directives 67/548/EEC and 1999/45/EC, and Amending Regulation (EC) No 1907/2006. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32008R1272 (accessed on 1 August 2023).

- Agreement Concerning the International Carriage of Dangerous Goods by Road ADR. Available online: https://unece.org/transport/standards/transport/dangerous-goods/adr-2023-agreement-concerning-international-carriage (accessed on 1 August 2023).

- Cimer, Z.; Varga, F. Application of Special Risk Reduction Protective Measures in Combiterminals for Dangerous Goods. AARMS 2015, 14, 209–218. [Google Scholar] [CrossRef]

- Santhi, R.; Muthuswamy, A.P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics 2022, 6, 81. [Google Scholar] [CrossRef]

- Campbell, R. Warehouse Structure Fires; National Fire Protection Association: Quincy, MA, USA, 2022; Available online: https://www.nfpa.org/News-and-Research/Data-research-and-tools/Building-and-Life-Safety/Warehouse-Structure-Fires (accessed on 1 August 2023).

- CRBE. European XXL Logistics Deals. Available online: https://www.cbre.co.uk/insights/viewpoints/european-xxl-logistics-deals (accessed on 1 August 2023).

- Kátai-Urbán, L.; Cimer, Z.; Lublóy, É.E. Examination of the Fire Resistance of Construction Materials from Beams in Chemical Warehouses Dealing with Flammable Dangerous Substances. Fire 2023, 6, 293. [Google Scholar] [CrossRef]

- Kirchsteiger, C. Absolute and relative ranking approaches for comparing and communicating industrial accidents. J. Hazard. Mater. 1998, 59, 31–54. [Google Scholar] [CrossRef]

- International Commission for the Protection of the Danube River. Inventory of Potential Accidental Risk Spots in the Danube River Basin. 2001. Available online: https://www.icpdr.org/main/sites/default/files/ARS%20Inventory.pdf (accessed on 1 August 2023).

- UN Economic Commission for Europe. Safety Guidelines and Good Practices for the Management and Retention of Firefighting Water; UN Economic Commission for Europe: Geneva, Switzerland, 2019; Available online: https://unece.org/fileadmin/DAM/env/documents/2019/TEIA/Publication/1914406E_web_high_res.pdf (accessed on 1 August 2023).

- ISO/TR 26368:2012; Environmental Damage Limitation from Fire-Fighting Water Run-Off. International Organization for Standardization: Geneva, Switzerland, 2012.

- VdS 2557. Planning and Installation of Facilities for Retention of Extinguishing Water. In Guidelines for Loss Prevention by the German Insurers; VdS Schadenverhütung GmbH.: Koln, Germany, 2013; Available online: https://shop.vds.de/publikation/vds-2557en (accessed on 1 August 2023).

- Kanton St. Gallen Amt für Umwelt. Beurteilungshilfe zur Löschwasser-Rückhaltung. St. Gallen. 2017. Available online: https://www.zh.ch/content/dam/zhweb/bilder-dokumente/themen/umwelt-tiere/umweltschutz/betrieblicher-umweltschutz/fachbereiche/leitfaden_loeschwasserrueckhaltung (accessed on 1 August 2023).

- Environment Protection Agency. Environmental Protection Handbook for the Fire and Rescue Service; Environment Protection Agency: Norwich, UK, 2011. Available online: https://www.ukfrs.com/sites/default/files/2017-09/Environment%20Agency%20and%20DCLG%20environmental%20handbook.pdf (accessed on 1 August 2023).

- Environment Agency. United Kingdom PPG18-Managing Fire Water and Major Spillages. Available online: https://www.netregs.org.uk/media/1674/ppg-18.pdf (accessed on 1 August 2023).

- GMBI. TRGS 510-Technical Rules for Hazardous Substances. Storage of Hazardous Substances in Nonstationary Containers. 2013. Available online: https://www.baua.de/EN/Service/Legislative-texts-and-technical-rules/Rules/TRGS/pdf/TRGS-510.pdf?__blob=publicationFile&v=2 (accessed on 1 August 2023).

- BG RCI. Storage of Hazardous Substances. 2013. Available online: https://www.vci.de/vci/downloads-vci/m062e-code-of-practice-storage-of-hazardous-substances.pdf (accessed on 1 August 2023).

- Scholz, M. Firewater Storage, Treatment, Recycling and Management: New Perspectives Based on Experiences from the United Kingdom. Water 2014, 6, 367–380. [Google Scholar] [CrossRef]

- Sikorova, K.; Bernatik, A. Analysis of Firewater Runoff in SEVESO Chemical Plant. Chem. Eng. Trans. 2018, 67, 241–246. [Google Scholar] [CrossRef]

- Meel, A.; O’Neill, L.M.; Levin, J.H.; Seider, W.D.; Oktem, U.; Keren, N. Operational Risk Assessment of Chemical Industries by Exploiting Accident Databases. J. Loss Prev. Process Ind. 2007, 20, 113–127. [Google Scholar] [CrossRef]

- Ansaldi, S.M.; Agnello, P.; Pirone, A.; Vallerotonda, M.R. Near Miss Archive: A Challenge to Share Knowledge among Inspectors and Improve Seveso Inspections. Sustainability 2021, 13, 8456. [Google Scholar] [CrossRef]

- IMPEL, Seminar Series on ‘Lessons Learnt from Industrial Accidents’. Available online: https://www.impel.eu/en/projects/seminar-series-on-lessons-learnt-from-industrial-accidents (accessed on 1 August 2023).

- Buncefield Major Incident Investigation Board. Recommendations on the Emergency Preparedness for, Response to and Recovery from Incidents. Available online: https://www.icheme.org/media/13708/buncefield-miib-final-report-volume-2b.pdf (accessed on 1 August 2023).

- Hybská, H.; Makovicka Osvaldova, L.; Horváthová, M.; Hýrošová, T.; Restas, A. Firewater Toxicity after Extinguishing Natural-Based Insulation Materials. BioResources 2022, 17, 1988–2002. [Google Scholar] [CrossRef]

- Erazo-Chamorro, V.C.; Arciniega-Rocha, R.P.; Nagy, R.; Babos, T.; Szabó, G. Safety Workplace: The Prevention of Industrial Security Risk Factors. Appl. Sci. 2022, 12, 10726. [Google Scholar] [CrossRef]

- Kátai-Urbán, M.; Hoffmann, I.; Bíró, T. Planning and Establishment of Fire-Water Retention and Storage Facilities Based on German Guidelines. Hadmérnök 2019, 14, 111–122. (In Hungarian) [Google Scholar] [CrossRef]

- National Institute of Public Health and the Environment. Guidelines for Quantitative Risk Assessment. CPR 18E. Available online: https://content.publicatiereeksgevaarlijkestoffen.nl/documents/PGS3/PGS3-1999-v0.1-quantitative-risk-assessment.pdf (accessed on 1 August 2023).

- VROM Ministry of Housing, Spatial Planning and the Environment. PGS-Programmaraad. PGS 15. Opslag van Verpakte Gevaarlijke Stoffen. Hague. 2016. Available online: https://content.publicatiereeksgevaarlijkestoffen.nl/documents/PGS15/PGS_15_2016_versie_1_0_sept_2016_definitief.pdf (accessed on 1 August 2023).

- Mannan, S. Lees’ Loss Prevention in the Process Industries: Hazard Identification, Management and Control; Butterworth-Heinemann: Oxford, UK, 2012; p. 3776. [Google Scholar]

- Török, Z.; Ozunu, A. Chemical Risk Assessment for Storage of Hazardous Materials in The Context of Land Use Planning. AES Bioflux 2010, 2, 33–56. [Google Scholar]

- Carter, D.A.; Hirst, I.L.; Maddison, T.E.; Porter, S.R. Appropriate Risk Assessment Methods for Major Accident Establishments. Process Saf. Environ. Prot. 2003, 8, 12–18. [Google Scholar] [CrossRef]

- Tixiera, J.; Dusserre, G.; Salvi, O.; Gaston, D. Review of 62 Risk Analysis Methodologies of Industrial Plants. J. Loss Prev. Process Ind. 2002, 15, 291–303. [Google Scholar] [CrossRef]

- Delvosalle, C.; Fievez, C.; Pipart, A. ARAMIS Accidental Risk Assessment Methodology for Industries; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–60. [Google Scholar]

- Duijm, N.J. Safety-barrier Diagrams as a Safety Management Tool. Reliab. Eng. Syst. Saf. 2009, 94, 332–341. [Google Scholar] [CrossRef]

- Landucci, G.; Antonioni, G.; Tugnoli, A.; Bonvicini, S.; Molag, M.; Cozzani, V. HazMat Transportation Risk Assessment: A revisitation in the perspective of the Viareggio LPG accident. J. Loss Prev. Process Ind. 2017, 49, 36–46. [Google Scholar] [CrossRef]

- Szakál, B.; Cimer, Z.; Kátai-Urbán, L.; Sárosi, G.; Vass, G. Methodological Manual for Experts Involved in the Prevention of Major-Accident Hazards Involving Dangerous Substances; HVESZ: Budapest, Hungary, 2020; p. 78. (In Hungarian) [Google Scholar]

- Cimer, Z.; Vass, G.; Zsitnyányi, A.; Kátai-Urbán, L. Application of Chemical Monitoring and Public Alarm Systems to Reduce Public Vulnerability to Major Accidents Involving Dangerous Substances. Symmetry 2021, 13, 1528. [Google Scholar] [CrossRef]

- Song, D.; Yoon, E.S.; Jang, N. A Framework and Method for the Assessment of Inherent Safety to Enhance Sustainability in Conceptual Chemical Process Design. J. Loss Prev. Process Ind. 2018, 54, 10–17. [Google Scholar] [CrossRef]

- Darbra, R.M.; Palacios, A.; Casal, J. Domino Effect in Chemical Accidents: Main features and accident sequences. J. Hazard. Mater. 2010, 183, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Bottelberghs, P.H. Risk Analysis and Safety Policy Developments in the Netherlands. J. Hazard. Mater. 2000, 71, 59–84. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0304389499000722?via%3Dihub (accessed on 1 August 2023). [CrossRef] [PubMed]

- Stam, G.J.; Bottelberghs, P.H.; Post, J.G.; Bos, H.G. Proteus, a Technical and Management at Model for Aquatic Risk Assessment of Industrial Spills. J. Hazard. Mater. 2000, 71, 439–448. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0304389499000928?via%3Dihub (accessed on 5 August 2023). [CrossRef]

- Szalai, Z.; Jakab, G. Introduction to Soil Science; Typotex Kiadó: Budapest, Hungary, 2011; (In Hungarian). Available online: http://etananyag.ttk.elte.hu/FiLeS/downloads/EJ-Szalai_Jakab_Talajtan.pdf (accessed on 5 August 2023).

- Szekrényi, B. Changes in the Water Permeability of the Soil as a Function of the time of Water Exposure. Agrokémia És Talajt. 1961, 10, 207–216. (In Hungarian) [Google Scholar]

- Det Norske Veritas, QRA Software–Safety. Available online: https://www.dnv.com/services/qra-software-safeti-1715 (accessed on 1 August 2023).

- Delvosalle, C.; Fievez, C.; Pipart, A.; Debray, B. ARAMIS project: A Comprehensive Methodology for the Identification of Reference Accident Scenarios in Process Industries. J. Hazard. Mater. 2006, 130, 200–219. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Directive 2011/92/EU of the European Parliament and of the Council of 13 December 2011 on the Assessment of the Effects of Certain Public and Private Projects on the Environment. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02011L0092-20140515 (accessed on 1 August 2023).

- Christou, M.; Gyenes, Z.; Struckl, M. Risk assessment in support to land-use planning in Europe: Towards more consistent decisions? J. Loss Prev. Process Ind. 2011, 24, 219–226. [Google Scholar] [CrossRef]

- Federal Environmental Agency. Checklists for Surveying and Assessing Industrial Plant Handling Materials and Substances, Which Are Hazardous to Water № 8 Fire Prevention Strategy; Federal Environment Agency: Dessau, Germany, 2015. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/check08_fireprevention_en_2014.pdf (accessed on 5 August 2023).

- Almási, C.; Christián, L.; Kátai-Urbán, L.; Vass, G. Security Planning in Transport of Dangerous Goods by Road in Hungary. In Proceedings of the 25. Medzinárodná Vedecká Konferencia, Riešenie Krízových Situácií v Špecifickom Prostredí, Žilina, Slovakia, 18–19 May 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kátai-Urbán, M.; Bíró, T.; Kátai-Urbán, L.; Varga, F.; Cimer, Z. Identification Methodology for Chemical Warehouses Dealing with Flammable Substances Capable of Causing Firewater Pollution. Fire 2023, 6, 345. https://doi.org/10.3390/fire6090345

Kátai-Urbán M, Bíró T, Kátai-Urbán L, Varga F, Cimer Z. Identification Methodology for Chemical Warehouses Dealing with Flammable Substances Capable of Causing Firewater Pollution. Fire. 2023; 6(9):345. https://doi.org/10.3390/fire6090345

Chicago/Turabian StyleKátai-Urbán, Maxim, Tibor Bíró, Lajos Kátai-Urbán, Ferenc Varga, and Zsolt Cimer. 2023. "Identification Methodology for Chemical Warehouses Dealing with Flammable Substances Capable of Causing Firewater Pollution" Fire 6, no. 9: 345. https://doi.org/10.3390/fire6090345