Enhanced Mechanical Properties in ED-Machinable Zirconia-Tungsten Carbide Composites with Yttria-Neodymia Co-Stabilized Zirconia Matrix

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Density, Electrical Conductivity, and Mechanical Properties

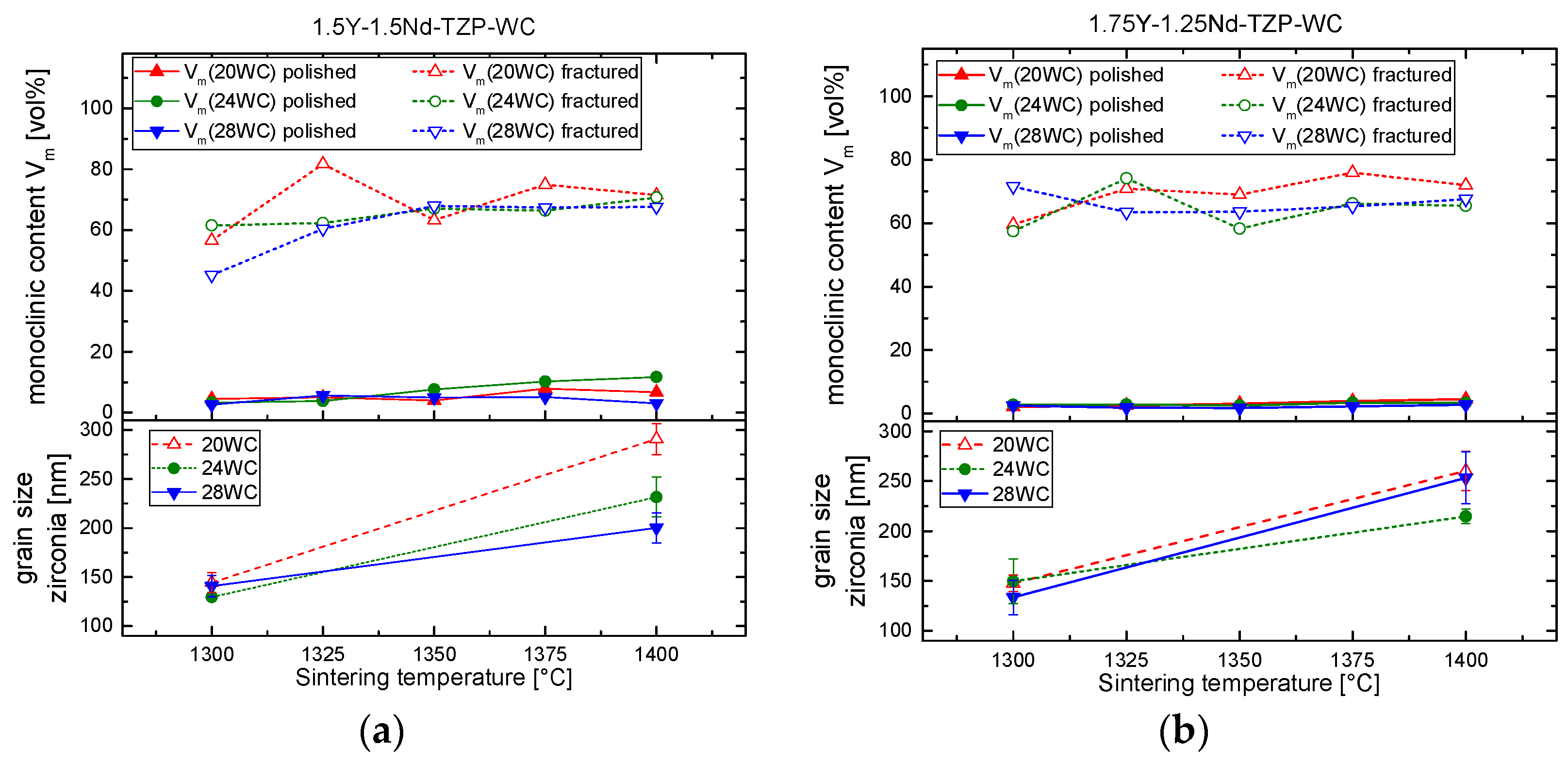

3.2. Phase Analysis

3.3. Microstructure

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation Toughening in Zirconia-Containing Ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Kelly, P.M.; Francis Rose, L.R. The martensitic transformation in ceramics—Its role in transformation toughening. Prog. Mater. Sci. 2002, 47, 463–557. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G.; Muratori, F.; Brach del Prever, E. Alumina and zirconia ceramics in joint replacements. J. Appl. Biomater. Biomech. 2003, 1, 19–32. [Google Scholar] [PubMed]

- Harrer, W.; Deluca, M.; Morrell, R. Failure analysis of a ceramic ball race bearing made of Y-TZP zirconia. Eng. Fail. Anal. 2014, 36, 262–268. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization—An X-ray Absorption Study: I, Trivalent Dopants. J. Am. Ceram. Soc. 1994, 77, 118–128. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization—An X-ray Absorption Study: II, Tetravalent Dopants. J. Am. Ceram. Soc. 1994, 77, 1281–1288. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization—An X-ray Absorption Study: III, Charge-Compensating Dopants. J. Am. Ceram. Soc. 1994, 77, 1289–1295. [Google Scholar] [CrossRef]

- Swain, M.V.; Rose, L.R.F. Strength Limitations of Transformation-Toughened Zirconia Alloys. J. Am. Ceram. Soc. 1986, 69, 511–518. [Google Scholar] [CrossRef]

- Xu, T.; Vleugels, J.; van der Biest, O.; Wang, P. Mechanical properties of Nd2O3/Y2O3-coated zirconia ceramics. Mater. Sci. Eng. A 2004, 374, 239–243. [Google Scholar] [CrossRef]

- Vleugels, J.; Xu, T.; Huang, S.; Kan, Y.; Wang, P.; Li, L.; van der Biest, O. Characterization of (Nd,Y)-TZP ceramics prepared by a colloidal suspension coating technique. J. Eur. Ceram. Soc. 2007, 27, 1339–1343. [Google Scholar] [CrossRef]

- Kern, F. High toughness and strength in yttria–neodymia costabilized zirconia ceramics. Scr. Mater. 2012, 67, 301–304. [Google Scholar] [CrossRef]

- Kern, F. Ytterbia–neodymia–costabilized TZP—Breaking the limits of strength–toughness correlations for zirconia? J. Eur. Ceram. Soc. 2013, 33, 965–973. [Google Scholar] [CrossRef]

- Yuan, Z.X.; Vleugels, J.; van der Biest, O. Preparation of Y2O3-coated ZrO2 powder by suspension drying. J. Mater. Sci. Lett. 2000, 19, 359–361. [Google Scholar] [CrossRef]

- Ohnishi, H.; Naka, H.; Sekino, T.; Niihara, K. Mechanical properties of 2.0–3.5 mol% Y2O3-stabilized zirconia polycrystals fabricated by the solid phase mixing and sintering method. J. Ceram. Soc. Jpn. 2008, 116, 1270–1277. [Google Scholar] [CrossRef]

- Wang, C.; Zinkevich, M.; Aldinger, F. Phase diagrams and thermodynamics of rare-earth-doped zirconia ceramics. Pure Appl. Chem. 2007, 79. [Google Scholar] [CrossRef]

- Chen, M.; Hallstedt, B.; Gauckler, L.J. Thermodynamic modeling of the ZrO2–YO1.5 system. Solid State Ion. 2004, 170, 255–274. [Google Scholar] [CrossRef]

- Tsukuma, K.; Ueda, K.; Shimada, M. Strength and Fracture Toughness of Isostatically Hot-Pressed Composites of Al2O3 and Y2O3-Partially-Stabilized ZrO2. J. Am. Ceram. Soc. 1985, 68, C4–C5. [Google Scholar] [CrossRef]

- Pȩdzich, Z.; Haberko, K.; Piekarczyk, J.; Faryna, M.; Lityńska, L. Zirconia matrix–tungsten carbide particulate composites manufactured by hot-pressing technique. Mater. Lett. 1998, 36, 70–75. [Google Scholar] [CrossRef]

- Jiang, D.; van der Biest, O.; Vleugels, J. ZrO2–WC nanocomposites with superior properties. J. Eur. Ceram. Soc. 2007, 27, 1247–1251. [Google Scholar] [CrossRef]

- Huang, S.G.; Vanmeensel, K.; van der Biest, O.; Vleugels, J. Development of ZrO2–WC composites by pulsed electric current sintering. J. Eur. Ceram. Soc. 2007, 27, 3269–3275. [Google Scholar] [CrossRef]

- Salehi, S.; van der Biest, O.; Vleugels, J. Y2O3 and Nd2O3 co-stabilized ZrO2-WC composites. J. Mater. Sci. 2008, 43, 5784–5789. [Google Scholar] [CrossRef]

- Lazarenko, B.R.; Lazarenko, N.I. Elektrische Erosion von Metallen; Cosenergoidat: Moscow, Russia, 1944. [Google Scholar]

- Zolotych, B.N.; Proffen, G. Physikalische Grundlagen der Elektrofunkenbearbeitung von Metallen; VEB Technik: Berlin, Germany, 1955. [Google Scholar]

- Bonny, K.; de Baets, P.; Vleugels, J.; van der Biest, O.; Lauwers, B.; Liu, W. EDM machinability and dry sliding friction of WC-Co cemented carbides. IJMR 2009, 4, 375–394. [Google Scholar] [CrossRef]

- König, W.; Dauw, D.F.; Levy, G.; Panten, U. EDM-Future Steps towards the Machining of Ceramics. CIRP Ann. Manuf. Technol. 1988, 37, 623–631. [Google Scholar] [CrossRef]

- Schmitt-Radloff, U.; Gommeringer, A.; Assmuth, P.; Kern, F.; Klocke, F.; Holsten, M.; Schneider, S. Effects of Composition on Mechanical and ED-machining Characteristics of Zirconia toughened Alumina—Titanium Carbide (ZTA-TiC) Composite Ceramics. Procedia CIRP 2018, 68, 17–21. [Google Scholar] [CrossRef]

- Schmitt-Radloff, U.; Kern, F.; Gadow, R. Wire EDM of ZTA-NbC Dispersion Ceramics—The Influence of ED Machining on Mechanical Properties. Procedia CIRP 2018, 68, 91–95. [Google Scholar] [CrossRef]

- Gommeringer, A.; Schmitt-Radloff, U.; Ninz, P.; Kern, F.; Klocke, F.; Schneider, S.; Holsten, M.; Klink, A. ED-machinable Ceramics with Oxide Matrix: Influence of Particle Size and Volume Fraction of the Electrical Conductive Phase on the Mechanical and Electrical Properties and the EDM Characteristics. Procedia CIRP 2018, 68, 22–27. [Google Scholar] [CrossRef]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-Ray Diffraction. J. Am. Ceram. Soc. 1984, 67, C119–C121. [Google Scholar] [CrossRef]

- Panten, U. Funkenerosive Bearbeitung von Elektrisch Leitfähigen Keramiken. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1990. [Google Scholar]

- McMurdie, H.F.; Morris, M.C.; Evans, E.H.; Paretzkin, B.; Wong-NG, W.; Hubbard, C.R. Methods of Producing Standard X-Ray Diffraction Powder Patterns. Powder Diffr. 1986, 1, 40–43. [Google Scholar] [CrossRef]

- Nakayama, S.; Maekawa, S.; Sato, T.; Masuda, Y.; Imai, S.; Sakamoto, M. Mechanical properties of ytterbia stabilized zirconia ceramics (Yb-TZP) fabricated from powders prepared by co-precipitation method. Ceram. Int. 2000, 26, 207–211. [Google Scholar] [CrossRef]

- McMeeking, R.M.; Evans, A.G. Mechanics of Transformation-Toughening in Brittle Materials. J. Am. Ceram. Soc. 1982, 65, 242–246. [Google Scholar] [CrossRef]

- Balberg, I.; Azulay, D.; Toker, D.; Millo, O. Percolation and Tunneling in Composite Materials. Int. J. Mod. Phys. B 2004, 18, 2091–2121. [Google Scholar] [CrossRef]

- Swain, M.V. Limitation of Maximum Strength of Zirconia-Toughened Ceramics by Transformation Toughening Increment. J. Am. Ceram. Soc. 1985, 68, C–97. [Google Scholar] [CrossRef]

- Kern, F. Mechanical properties and microstructure of 1Y2Nd-TZP/20 vol % alumina nanocomposites. Ceram. Mater. 2012, 64, 168–171. [Google Scholar] [CrossRef]

- Kern, F.; Gadow, R. Alumina toughened zirconia from yttria coated powders. J. Eur. Ceram. Soc. 2012, 32, 3911–3918. [Google Scholar] [CrossRef]

- Gregori, G.; Burger, W.; Sergo, V. Piezo-spectroscopic analysis of the residual stresses in zirconia-toughened alumina ceramics: The influence of the tetragonal-to-monoclinic transformation. Mater. Sci. Eng. 1999, A271, 401–406. [Google Scholar] [CrossRef]

- Kern, F.; Kabir, A.; Gadow, R. Mechanical properties and low temperature degradation resistance of alumina-doped 3Y-TZP fabricated from stabilizer coated powders. Ceram. Mater. 2017, 69, 279–285. [Google Scholar]

- Danilenko, I.; Konstantinova, T.; Volkova, G.; Burkhovetski, V.; Glazunova, V. The Role of Powder Preparation Method in Enhancing Fracture Toughness of Zirconia Ceramics with Low Alumina Amount. J. Ceram. Sci. Technol. 2015, 6, 191–200. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gommeringer, A.; Kern, F.; Gadow, R. Enhanced Mechanical Properties in ED-Machinable Zirconia-Tungsten Carbide Composites with Yttria-Neodymia Co-Stabilized Zirconia Matrix. Ceramics 2018, 1, 26-37. https://doi.org/10.3390/ceramics1010004

Gommeringer A, Kern F, Gadow R. Enhanced Mechanical Properties in ED-Machinable Zirconia-Tungsten Carbide Composites with Yttria-Neodymia Co-Stabilized Zirconia Matrix. Ceramics. 2018; 1(1):26-37. https://doi.org/10.3390/ceramics1010004

Chicago/Turabian StyleGommeringer, Andrea, Frank Kern, and Rainer Gadow. 2018. "Enhanced Mechanical Properties in ED-Machinable Zirconia-Tungsten Carbide Composites with Yttria-Neodymia Co-Stabilized Zirconia Matrix" Ceramics 1, no. 1: 26-37. https://doi.org/10.3390/ceramics1010004