Study of Radiation Damage Kinetics in Dispersed Nuclear Fuel on Zirconium Dioxide Doped with Cerium Dioxide

Abstract

:1. Introduction

2. Experimental Part

3. Results and Discussion

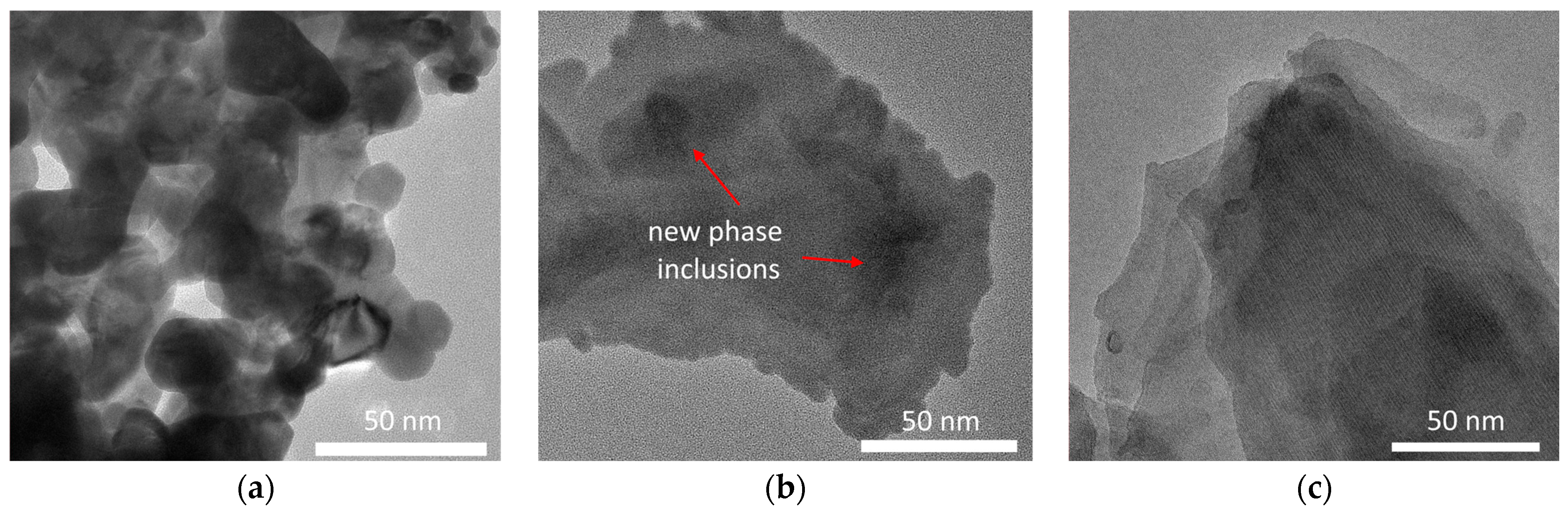

3.1. Characterization of Initial Samples as a Function of the Variation of CeO2 Dopant Concentration

3.2. Study of the Kinetics of Deformation Distortion of the Crystal Structure of Ceramics as a Function of Dopant Concentration under High-Dose Proton Irradiation

3.3. Influence of Structural Distortions and Radiation Damage Accumulation on the Alteration in the Strength Properties of Ceramics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Capps, N.; Schappel, D.; Nelson, A. Initial development of an RIA envelope for dispersed nuclear fuel. Ann. Nucl. Energy 2020, 148, 107719. [Google Scholar] [CrossRef]

- Ding, S.; Wang, Q.; Huo, Y. Mechanical behaviors of the dispersion nuclear fuel plates induced by fuel particle swelling and thermal effect II: Effects of variations of the fuel particle diameters. J. Nucl. Mater. 2010, 397, 80–91. [Google Scholar] [CrossRef]

- Song, T.; Wang, Y.; Chang, Z.; Guo, L. In-situ fabrication of dispersion nuclear fuel pellets with a core-shell structure. Ann. Nucl. Energy 2019, 134, 258–262. [Google Scholar] [CrossRef]

- Pillon, S.; Wallenius, J. Oxide and nitride TRU fuels: Lessons drawn from the CONFIRM and FUTURE projects of the 5th European Framework Program. Nucl. Sci. Eng. 2006, 153, 245–252. [Google Scholar] [CrossRef]

- Frieß, F.; Liebert, W. Inert-matrix fuel for transmutation: Selected mid-and long-term effects on reprocessing, fuel fabrication and inventory sent to final disposal. Prog. Nucl. Energy 2022, 145, 104106. [Google Scholar] [CrossRef]

- Saoudi, M.; Barry, A.; Lang, J.; Boyer, C.; Rogge, R.B.; Corbett, S.; Wang, X. Post-irradiation examination of U-7Mo/Mg and U-10Mo/Mg dispersion fuels irradiated in the NRU reactor. J. Nucl. Mater. 2022, 558, 153343. [Google Scholar] [CrossRef]

- Terricabras, A.J.; Wang, L.; Raftery, A.M.; Nelson, A.T.; Zinkle, S.J. Properties and microstructure evolution of silicon nitride and zirconium nitride following Ni ion irradiation. J. Nucl. Mater. 2022, 563, 153643. [Google Scholar] [CrossRef]

- Chen, J.; Liu, H.; Zhang, R.; Li, G.; Yi, D.; Lin, G.; Guo, Z.; Liu, S. High-temperature deformation and processing maps of Zr-4 metal matrix with dispersed coated surrogate nuclear fuel particles. Results Phys. 2018, 9, 1057–1066. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Q.; Cui, Y.; Huo, Y.; Ding, S. Simulation of irradiation hardening of Zircaloy within plate-type dispersion nuclear fuel elements. J. Nucl. Mater. 2011, 413, 76–89. [Google Scholar] [CrossRef]

- Osaka, M.; Miwa, S.; Tachi, Y. Simple fabrication process for CeO2–MgO composite as surrogate for actinide-containing target for use in nuclear fuel. Ceram. Int. 2006, 32, 659–663. [Google Scholar] [CrossRef]

- Monge, M.A.; González, R.; Muñoz Santiuste, J.E.; Pareja, R.; Chen, Y.; Kotomin, E.A.; Popov, A.I. Photoconversion and dynamic hole recycling process in anion vacancies in neutron-irradiated MgO crystals. Phys. Rev. B 1999, 60, 3787–3791. [Google Scholar] [CrossRef]

- Savoini, B.; Cáceres, D.; Vergara, I.; González, R.; Muñoz Santiuste, J.E. Radiation damage in neutron-irradiated yttria-stabilized-zirconia single crystals. J. Nucl. Mater. 2000, 277, 199–203. [Google Scholar] [CrossRef]

- Konings, R.J.M.; Bakker, K.; Boshoven, J.G.; Conrad, R.; Hein, H. The influence of neutron irradiation on the microstructure of Al2O3, MgAl2O4, Y3Al5O12 and CeO2. J. Nucl. Mater. 1998, 254, 135–142. [Google Scholar] [CrossRef]

- Monge, M.A.; Gonzalez, R.; Muñoz Santiuste, J.E.; Pareja, R.; Chen, Y.; Kotomin, E.A.; Popov, A.I. Photoconversion of F+ centers in neutron-irradiated MgO. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2000, 166, 220–224. [Google Scholar] [CrossRef]

- Ehrhart, P.; Averback, R.S.; Popov, A.I.; Sambeek, A.V. Defects in ion implanted and electron irradiated MgO and Al203. Radiat. Eff. Defects Solids 1995, 136, 169–173. [Google Scholar] [CrossRef]

- Seeman, V.; Feldbach, E.; Kärner, T.; Maaroos, A.; Mironova-Ulmane, N.; Popov, A.I.; Shablonin, E.; Vasil’chenko, E.; Lushchik, A. Fast-neutron-induced and as-grown structural defects in magnesium aluminate spinel crystals with different stoichiometry. Opt. Mater. 2019, 91, 42–49. [Google Scholar] [CrossRef]

- Lushchik, A.; Dolgov, S.; Feldbach, E.; Pareja, R.; Popov, A.I.; Shablonin, E.; Seeman, V. Creation and thermal annealing of structural defects in neutron-irradiated MgAl2O4 single crystals. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 435, 31–37. [Google Scholar] [CrossRef]

- Lee, Y.W.; Lee, S.C.; Kim, H.S.; Young, C.Y.; Degueldre, C. Study on the mechanical properties and thermal conductivity of silicon carbide-, zirconia-and magnesia aluminate-based simulated inert matrix nuclear fuel materials after cyclic thermal shock. J. Nucl. Mater. 2003, 319, 15–23. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Zdorovets, M.V.; Shlimas, D.I. Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics. Metals 2022, 12, 1687. [Google Scholar] [CrossRef]

- Angle, J.P.; Nelson, A.T.; Men, D.; Mecartney, M.L. Thermal measurements and computational simulations of three-phase (CeO2–MgAl2O4–CeMgAl11O19) and four-phase (3Y-TZP–Al2O3–MgAl2O4–LaPO4) composites as surrogate inert matrix nuclear fuel. J. Nucl. Mater. 2014, 454, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Yun, D.; Lu, C.; Zhou, Z.; Wu, Y.; Liu, W.; Guo, S.; Shi, T.; Stubbins, J.F. Current state and prospect on the development of advanced nuclear fuel system materials: A review. Mater. Rep. Energy 2021, 1, 100007. [Google Scholar] [CrossRef]

- Meyer, M.K.; Hofman, G.L.; Hayes, S.L.; Clark, C.R.; Wiencek, T.C.; Snelgrove, J.L.; Strain, R.V.; Kim, K.-H. Low-temperature irradiation behavior of uranium–molybdenum alloy dispersion fuel. J. Nucl. Mater. 2002, 304, 221–236. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Wei, H.; Tang, C.; Lu, C.; Huang, C.; Ding, S.; Li, Y. Modelling of effective irradiation swelling for inert matrix fuels. Nucl. Eng. Technol. 2021, 53, 2616–2628. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, X.; Ding, S.; Huo, Y. A numerical method for simulating the non-homogeneous irradiation effects in full-sized dispersion nuclear fuel plates. Int. J. Mech. Sci. 2014, 81, 174–183. [Google Scholar] [CrossRef]

- Dong, Y.; Lv, J.; Zuo, H.; Li, Q. Explicit Analysis of Nonuniform Irradiation Swelling Pressure Exerting on Dispersion Fuel Matrix Based on the Equivalent Inclusion Method. Materials 2022, 15, 3231. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhao, L.; Yao, C.; Li, P.; Huang, F.; Meng, F. Improved thermal stability and irradiation tolerance of oxide dispersion strengthened chromium coatings. J. Nucl. Mater. 2023, 577, 154328. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, Z.; Tu, J.; Zhao, Y.; Dong, Y. Application of LSTM Approach for Predicting the Fission Swelling Behavior within a CERCER Composite Fuel. Energies 2022, 15, 9053. [Google Scholar] [CrossRef]

- Polovnikov, P.V.; Tarasov, V.I.; Veshchunov, M. Modelling of breakaway swelling in intermetallic fuels during low-temperature irradiation. J. Nucl. Mater. 2022, 558, 153362. [Google Scholar] [CrossRef]

- Matzke, H. Radiation effects in nuclear fuels. In Radiation Effects in Solids; Sickafus, K.E., Kotomin, E.A., Uberuaga, B.P., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 401–420. [Google Scholar] [CrossRef]

- Castin, N.; Terentyev, D.; Bakaev, A.; Stankovskiy, A.; Bonny, G. On the equivalence of irradiation conditions on present and future facilities for fusion materials research and qualification: A computational study. J. Nucl. Mater. 2022, 562, 153589. [Google Scholar] [CrossRef]

- Neto, I.; Roberto, R.; Kardoulaki, E.; Valdez, J.A. The influence of the processing parameters on the reactive flash sintering of ZrO2-CeO2. J. Am. Ceram. Soc. 2022, 105, 3937–3948. [Google Scholar] [CrossRef]

- Giniyatova, S.G.; Sailaukhanov, N.A.; Nesterov, E.; Zdorovets, M.V.; Kozlovskiy, A.L.; Shlimas, D.I. Research of Structural, Strength and Thermal Properties of ZrO2—CeO2 Ceramics Doped with Yttrium. Crystals 2022, 12, 242. [Google Scholar] [CrossRef]

- Koike, M.; Kodaira, A.; Tokunaga, T.; Yamamoto, T. Shrinkage-rate controlled flash sintering for 3–10 mol% Y2O3-doped ZrO2 polycrystals. J. Ceram. Soc. Jpn. 2022, 130, 906–912. [Google Scholar] [CrossRef]

- Clark, D.; Zinkle, S.; Patel, M.; Parish, C. High temperature ion irradiation effects in MAX phase ceramics. Acta Mater. 2016, 105, 130–146. [Google Scholar] [CrossRef] [Green Version]

- Casalegno, V.; Kondo, S.; Hinoki, T.; Salvo, M.; Czyrska-Filemonowicz, A.; Moskalewicz, T.; Katoh, Y.; Ferraris, M. CaO-Al2O3 glass-ceramic as a joining material for SiC based components: A microstructural study of the effect of Si-ion irradiation. J. Nucl. Mater. 2018, 501, 172–180. [Google Scholar] [CrossRef]

- Zhumazhanova, A.; Mutali, A.; Ibrayeva, A.; Skuratov, V.; Dauletbekova, A.; Korneeva, E.; Akilbekov, A.; Zdorovets, M. Raman Study of Polycrystalline Si3N4 Irradiated with Swift Heavy Ions. Crystals 2021, 11, 1313. [Google Scholar] [CrossRef]

- van Vuuren, A.J.; Ibrayeva, A.D.; Skuratov, V.A.; Zdorovets, M.V. Analysis of the microstructural evolution of silicon nitride irradiated with swift Xe ions. Ceram. Int. 2020, 46, 7155–7160. [Google Scholar] [CrossRef]

- Thomé, L.; Moll, S.; Sattonnay, G.; Vincent, L.; Garrido, F.; Jagielski, J. Radiation effects in cubic zirconia: A model system for ceramic oxides. J. Nucl. Mater. 2009, 389, 297–302. [Google Scholar] [CrossRef]

- Florez, R.; Crespillo, M.L.; He, X.; White, T.A.; Hilmas, G.; Fahrenholtz, W.; Graham, J. The irradiation response of ZrC ceramics under 10 MeV Au3+ ion irradiation at 800 °C. J. Eur. Ceram. Soc. 2020, 40, 1791–1800. [Google Scholar] [CrossRef]

- Beck, H.; Kaliba, C. On the solubility of Fe, Cr and Nb in ZrO2 and its effect on thermal dilatation and polymorphic transition. Mater. Res. Bull. 1990, 25, 1161–1168. [Google Scholar] [CrossRef]

- Manik, S.K.; Dutta, H.; Pradhan, S.K. Microstructure characterization and phase transformation kinetics of polymorphic transformed ball milled a-TiO2–10 mol% m-ZrO2 mixture by Rietveld method. Mater. Chem. Phys. 2003, 82, 848–859. [Google Scholar] [CrossRef]

- Dippel, A.-C.; Jensen, K.M.; Tyrsted, C.; Bremholm, M.; Bøjesen, E.D.; Saha, D.; Birgisson, S.; Christensen, M.; Billinge, S.J.L.; Iversen, B.B. Towards atomistic understanding of polymorphism in the solvothermal synthesis of ZrO2 nanoparticles. Acta Crystallogr. Sect. A Found. Adv. 2016, 72, 645–650. [Google Scholar] [CrossRef]

- Yashima, M.; Takashina, H.; Kakihana, M.; Yoshimura, M. Low-Temperature Phase Equilibria by the Flux Method and the Metastable–Stable Phase Diagram in the ZrO2–CeO2 System. J. Am. Ceram. Soc. 1994, 77, 1869–1874. [Google Scholar] [CrossRef]

- Li, L.; Van Der Biest, O.; Wang, P.L.; Vleugels, J.; Chen, W.W.; Huang, S.G. Estimation of the phase diagram for the ZrO2–Y2O3–CeO2 system. J. Eur. Ceram. Soc. 2001, 21, 2903–2910. [Google Scholar] [CrossRef]

- Li, J.; Peng, J.; Guo, S.; Qv, W.; Chen, G.; Li, W.; Zhang, L. Martensitic transformation thermodynamic calculation of ZrO2–MgO system. Phase Transit. 2012, 85, 1022–1029. [Google Scholar] [CrossRef]

- Wen, T.; Yuan, L.; Tian, C.; Yan, Z.; Liu, Z.; Yu, J. Electrical conductivity behavior of ZrO2-MgO-Y2O3 ceramic: Effect of heat treatment temperature. J. Aust. Ceram. Soc. 2022, 58, 421–427. [Google Scholar] [CrossRef]

- Li, J.; Peng, J.; Guo, S.; Qv, W.; Li, W.; Zhang, L.; Chen, G. Thermodynamic calculations of t to m martenstic transformation of ZrO2–CaO binary system. Ceram. Int. 2012, 38, 2743–2747. [Google Scholar] [CrossRef]

- Bruni, Y.L.; Garrido, L.B.; Aglietti, E.F. Properties of CaO-ZrO2 Based Composites. Procedia Mater. Sci. 2015, 8, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Neetu; Singh, D.; Kumar, N.; Gangwar, J. Comparative study of crystallographic representation on the three ZrO2 polymorphs: Structural models, lattice planes, model electron and nuclear densities. Mater. Res. Express 2019, 6, 1150f8. [Google Scholar] [CrossRef]

- Kurakhmedov, A.E.; Morzabayev, A.K.; Tleubay, I.; Berguzinov, A.; Kozlovskiy, A.L. Study of the Mechanisms of Polymorphic Transformations in Zirconium Dioxide upon Doping with Magnesium Oxide, as Well as Establishing the Relationship between Structural Changes and Strength Properties. Ceramics 2023, 6, 1164–1178. [Google Scholar] [CrossRef]

- Schwartz, K.; Volkov, A.E.; Sorokin, M.V.; Trautmann, C.; Voss, K.-O.; Neumann, R.; Lang, M. Effect of electronic energy loss and irradiation temperature on color-center creation in LiF and NaCl crystals irradiated with swift heavy ions. Phys. Rev. B 2008, 78, 024120. [Google Scholar] [CrossRef]

- Medvedev, N.A.; Rymzhanov, R.A.; Volkov, A.E. Time-resolved electron kinetics in swift heavy ion irradiated solids. J. Phys. D Appl. Phys. 2015, 48, 355303. [Google Scholar] [CrossRef]

- Luo, P.; Sun, X.Y.; Li, Y.; Yang, L.; Shao, W.Z.; Zhen, L.; Xu, C.Y. Correlation between Structural Evolution and Device Performance of CH3NH3PbI3 Solar Cells under Proton Irradiation. ACS Appl. Energy Mater. 2021, 4, 13504–13515. [Google Scholar] [CrossRef]

- Reali, L.; Boleininger, M.; Gilbert, M.R.; Dudarev, S.L. Macroscopic elastic stress and strain produced by irradiation. Nucl. Fusion 2022, 62, 016002. [Google Scholar] [CrossRef]

- Alin, M.; Kozlovskiy, A.L.; Zdorovets, M.V.; Uglov, V.V. Study of the mechanisms of the t-ZrO2→c-ZrO2 type polymorphic transformations in ceramics as a result of irradiation with heavy Xe22+ ions. Solid State Sci. 2022, 123, 106791. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Alin, M.; Borgekov, D.B. Study of Polymorphic Transformation Processes and Their Influence in Polycrystalline ZrO2 Ceramics upon Irradiation with Heavy Ions. Ceramics 2023, 6, 686–706. [Google Scholar] [CrossRef]

- Ghyngazov, S.A.; Boltueva, V.A.; O’Connell, J.H.; Vershinina, T.N.; Kirilkin, N.S.; Rymzhanov, R.A.; Skuratov, V.A.; Surzhikov, A.P. Swift heavy ion induced phase transformations in partially stabilized ZrO2. Radiat. Phys. Chem. 2022, 192, 109917. [Google Scholar] [CrossRef]

- Palomares, R.I.; Shamblin, J.; Tracy, C.L.; Neuefeind, J.; Ewing, R.C.; Trautmann, C.; Lang, M. Defect accumulation in swift heavy ion-irradiated CeO2 and ThO2. J. Mater. Chem. A 2017, 5, 12193–12201. [Google Scholar] [CrossRef]

- Cureton, W.F.; Palomares, R.I.; Walters, J.; Tracy, C.L.; Chen, C.-H.; Ewing, R.C.; Baldinozzi, G.; Lian, J.; Trautmann, C.; Lang, M. Grain size effects on irradiated CeO2, ThO2, and UO2. Acta Mater. 2018, 160, 47–56. [Google Scholar] [CrossRef]

- Cureton, W.F.; Tracy, C.L.; Lang, M. Review of swift heavy ion irradiation effects in CeO2. Quantum Beam Sci. 2021, 5, 19. [Google Scholar] [CrossRef]

- Evans, T.; Norris, S. Swelling as a stabilizing mechanism in irradiated thin films: II. Effect of swelling rate. J. Phys. Condens. Matter 2022, 34, 325302. [Google Scholar] [CrossRef]

| Parameter | CeO2 Concentration, mol | |||

|---|---|---|---|---|

| 0.05 | 0.10 | 0.15 | 0.25 | |

| Degree of structural ordering (crystallinity degree *), % | 88.4 ± 0.3 | 89.3 ± 0.2 | 92.2 ± 0.7 | 94.7 ± 0.5 |

| Deformation factor of crystal lattice distortion ** | 0.023 ± 0.005 | 0.021 ± 0.005 | 0.028 ± 0.006 | 0.019 ± 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlovskiy, A.L.; Borgekov, D.B.; Zdorovets, M.V.; Kenzhina, I.E.; Shlimas, D.I. Study of Radiation Damage Kinetics in Dispersed Nuclear Fuel on Zirconium Dioxide Doped with Cerium Dioxide. J. Compos. Sci. 2023, 7, 277. https://doi.org/10.3390/jcs7070277

Kozlovskiy AL, Borgekov DB, Zdorovets MV, Kenzhina IE, Shlimas DI. Study of Radiation Damage Kinetics in Dispersed Nuclear Fuel on Zirconium Dioxide Doped with Cerium Dioxide. Journal of Composites Science. 2023; 7(7):277. https://doi.org/10.3390/jcs7070277

Chicago/Turabian StyleKozlovskiy, Artem L., Daryn B. Borgekov, Maxim V. Zdorovets, Inesh E. Kenzhina, and Dmitriy I. Shlimas. 2023. "Study of Radiation Damage Kinetics in Dispersed Nuclear Fuel on Zirconium Dioxide Doped with Cerium Dioxide" Journal of Composites Science 7, no. 7: 277. https://doi.org/10.3390/jcs7070277