1. Introduction

Intermetallic titanium aluminides (TiAl) are promising lightweight materials for high-performance components such as turbine blades in aircraft jet engines. These alloys are attractive due to the combination of low density, high strength and oxidation/corrosion resistance [

1,

2]. Recent work by Aguilar et al. [

3] describes the set-up of an investment casting facility for low-pressure turbine blades. In the jet engine of the Airbus A320Neo aircraft, the first series application of forged TiAl blades has recently been accomplished [

4]. To make forging of TiAl viable, alloys that solidify through the

-phase were developed. The

-phase acts like a lubricant between the hard phases (

-TiAl and

2-phase) during forging. Due to the high material cost and cost-intensive finishing operations of difficult-to-machine TiAl alloys [

5,

6], near-net shape forgings are desirable. However, the latest generation of alloys still exhibit poor workability and must therefore be shaped by isothermal forging processes [

7].

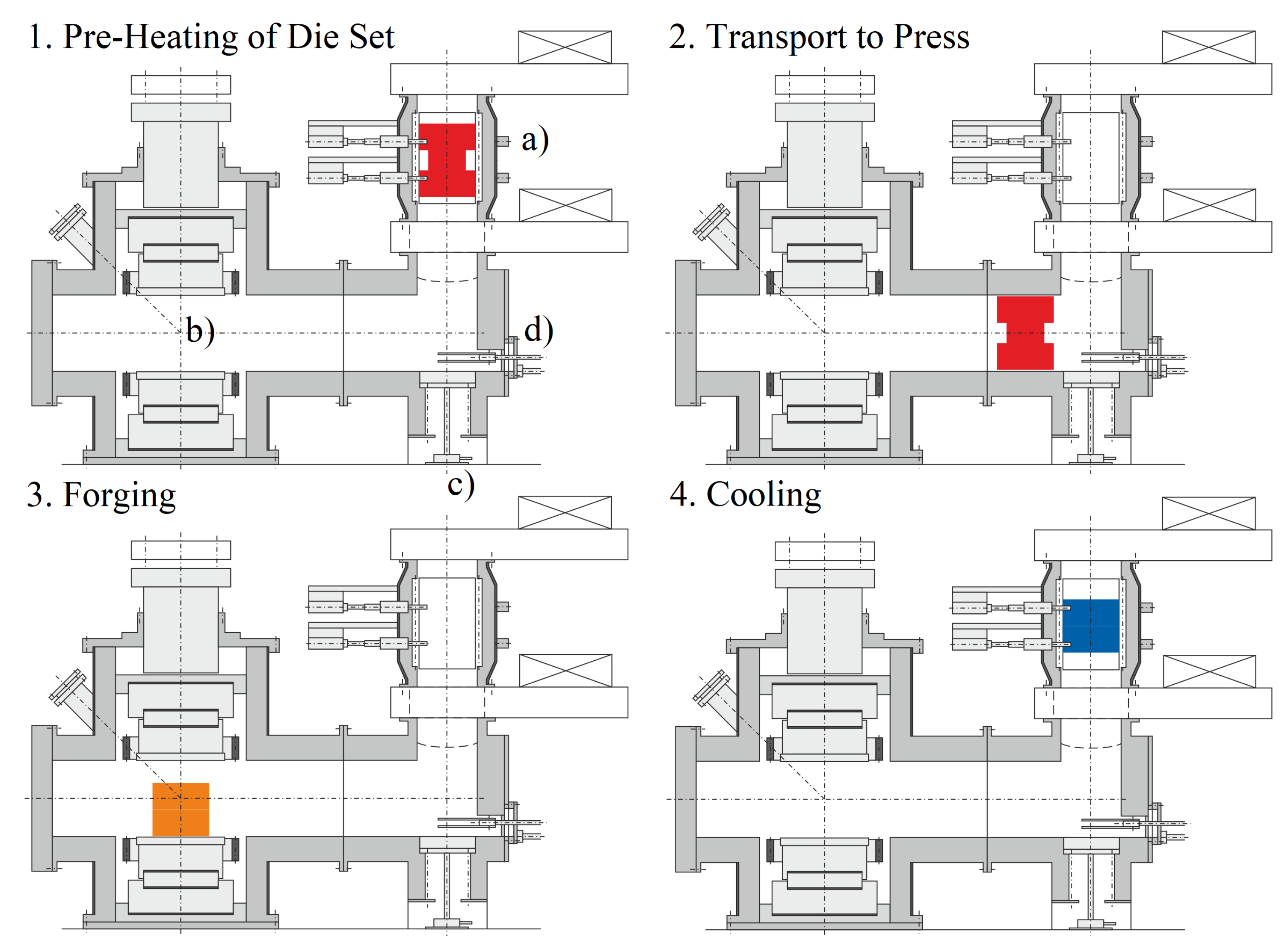

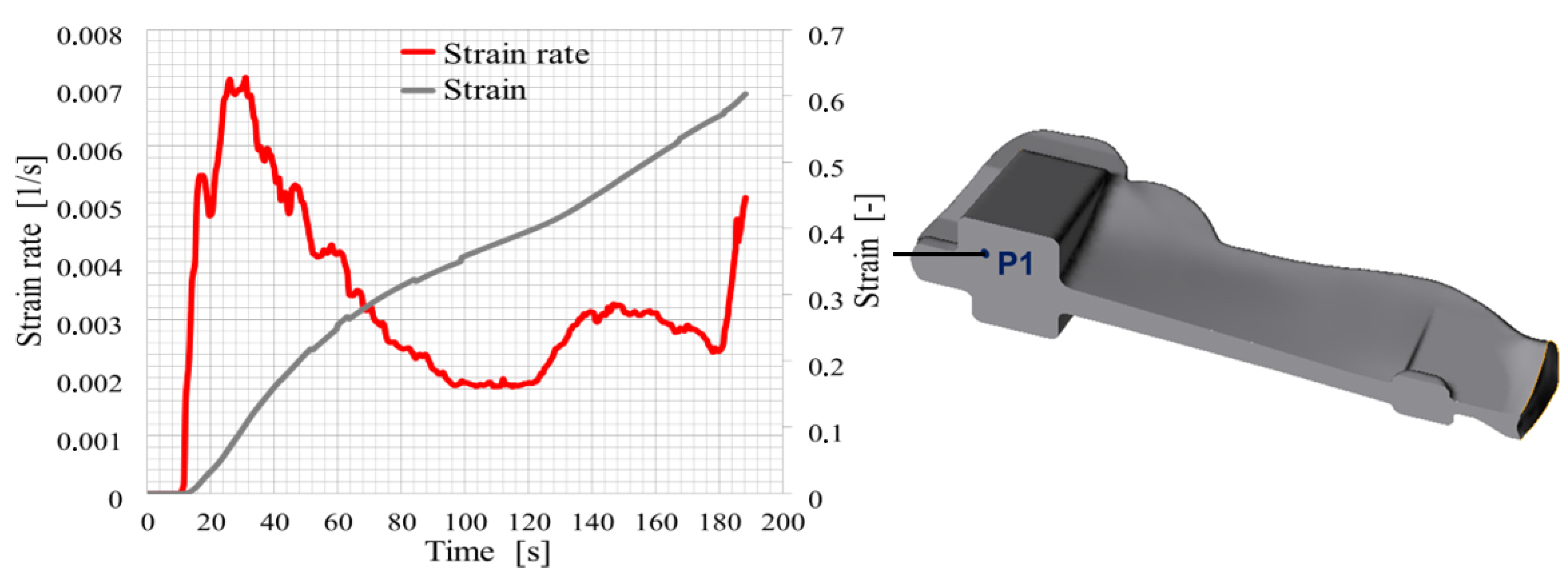

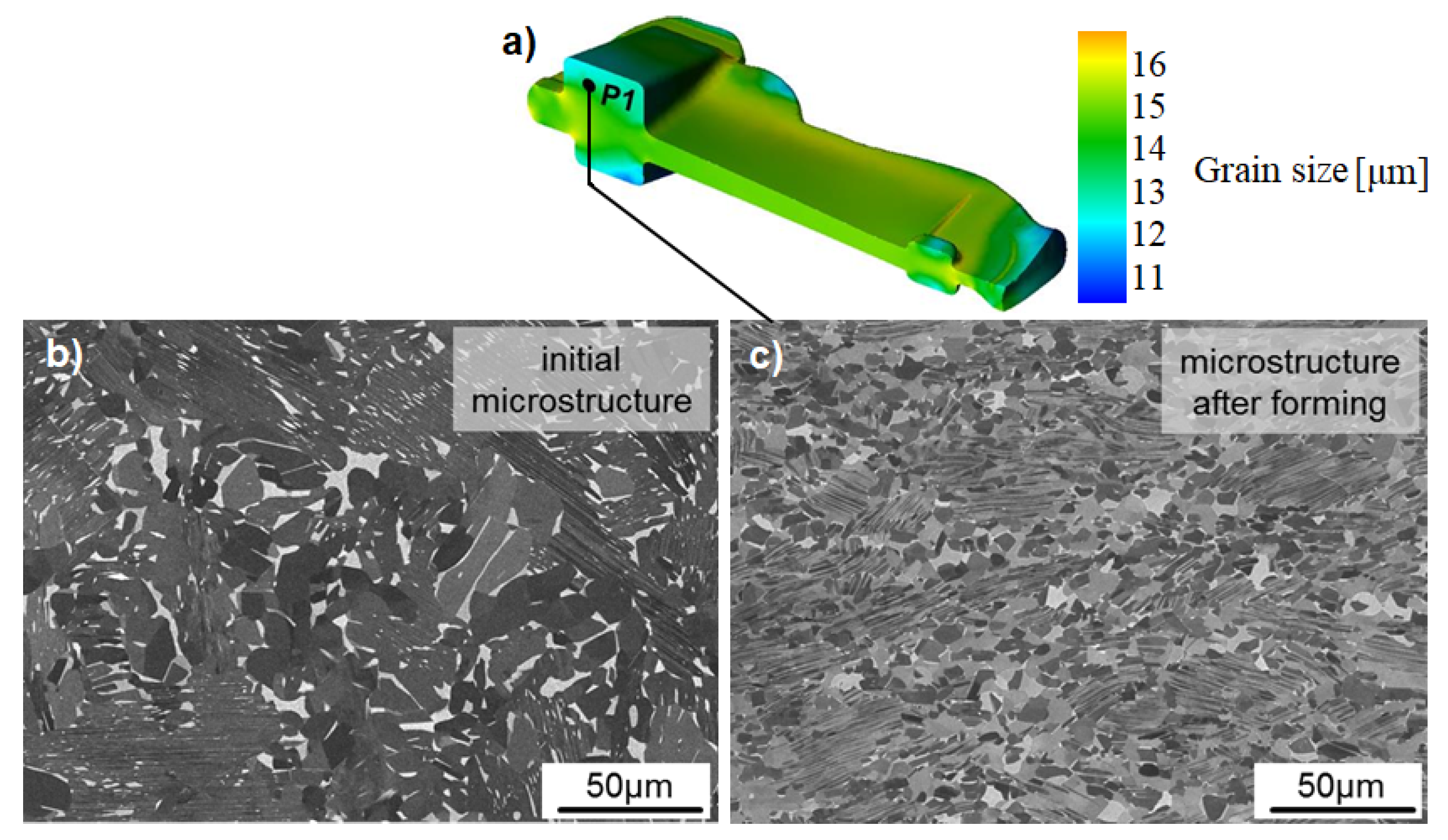

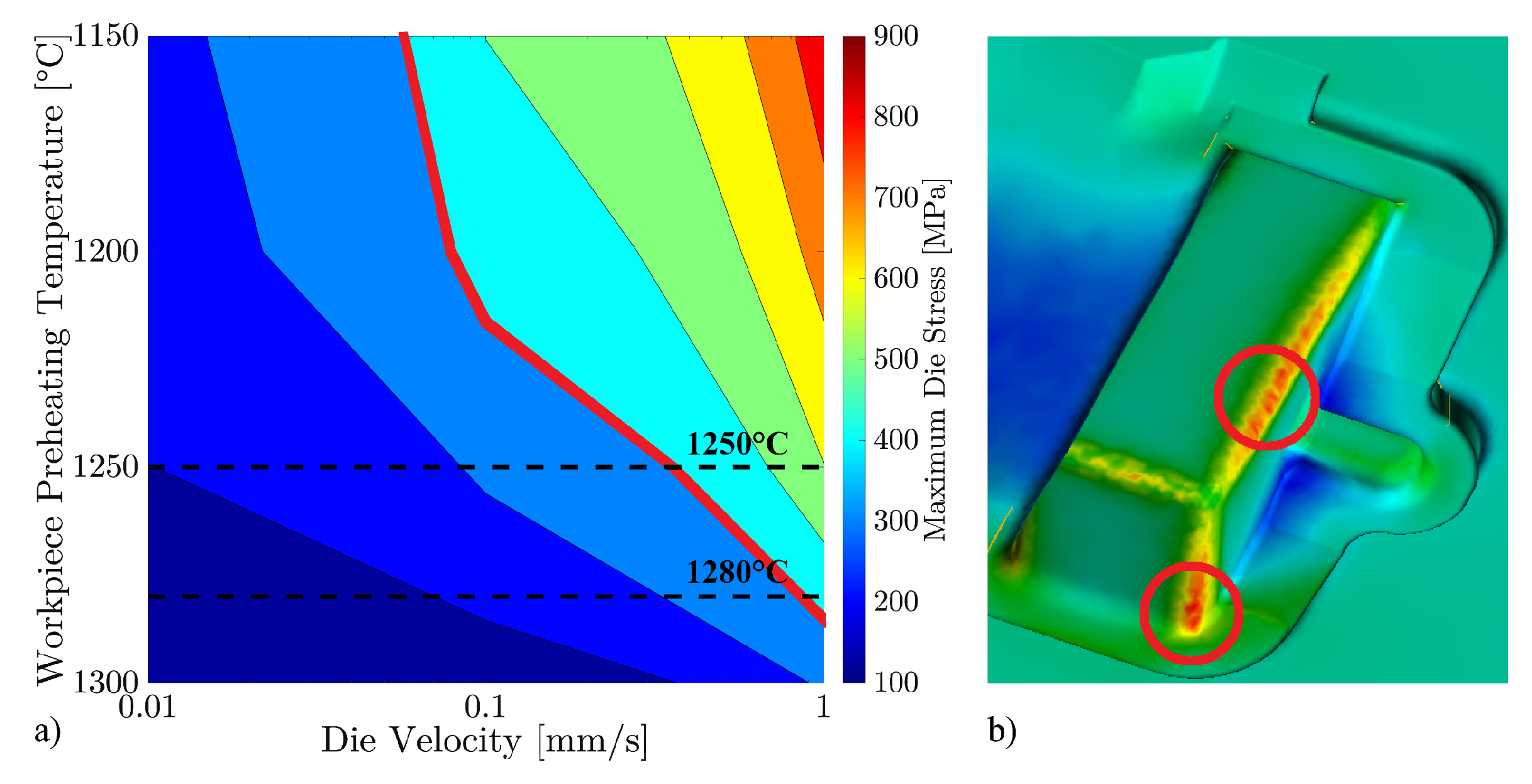

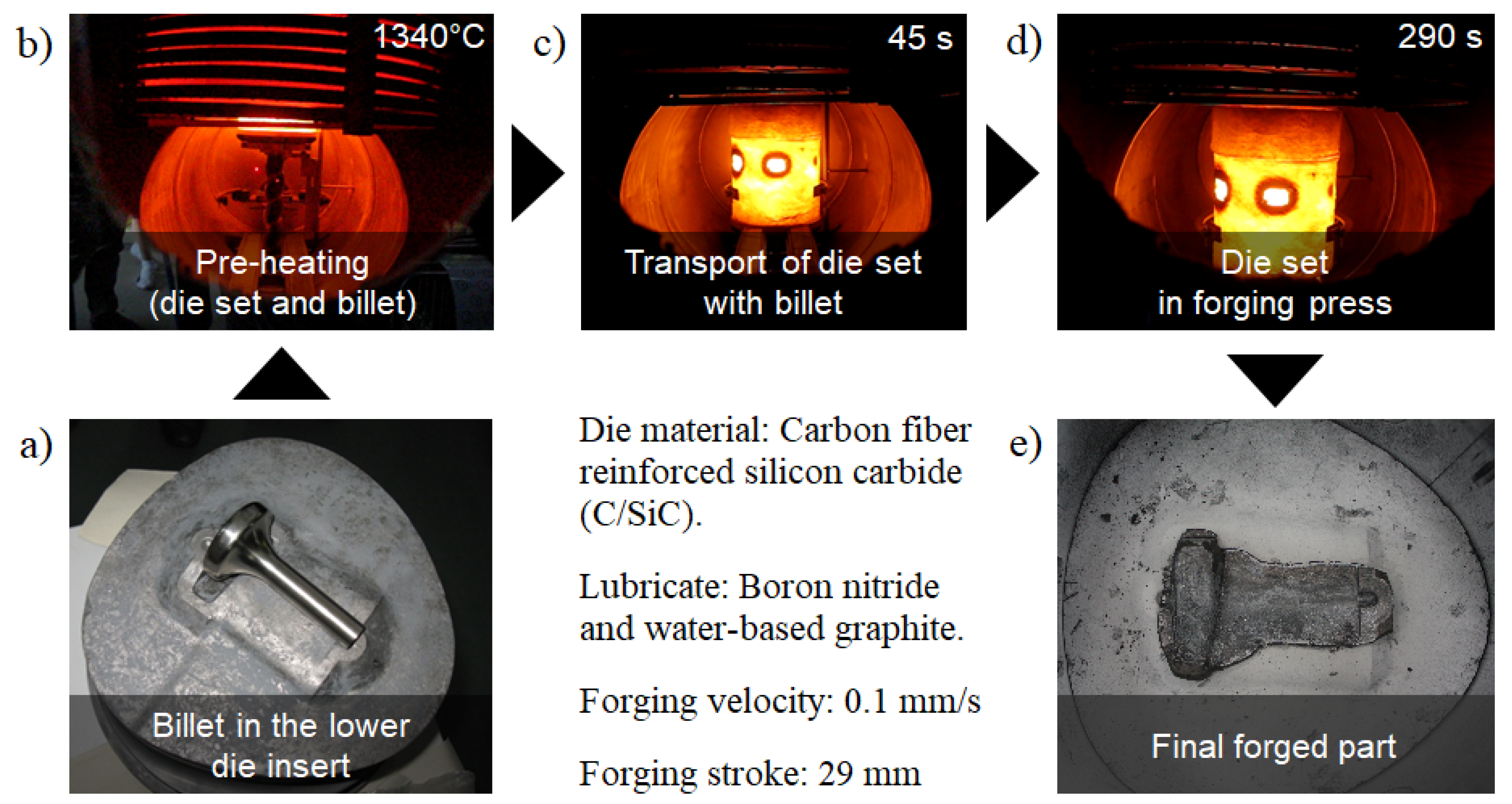

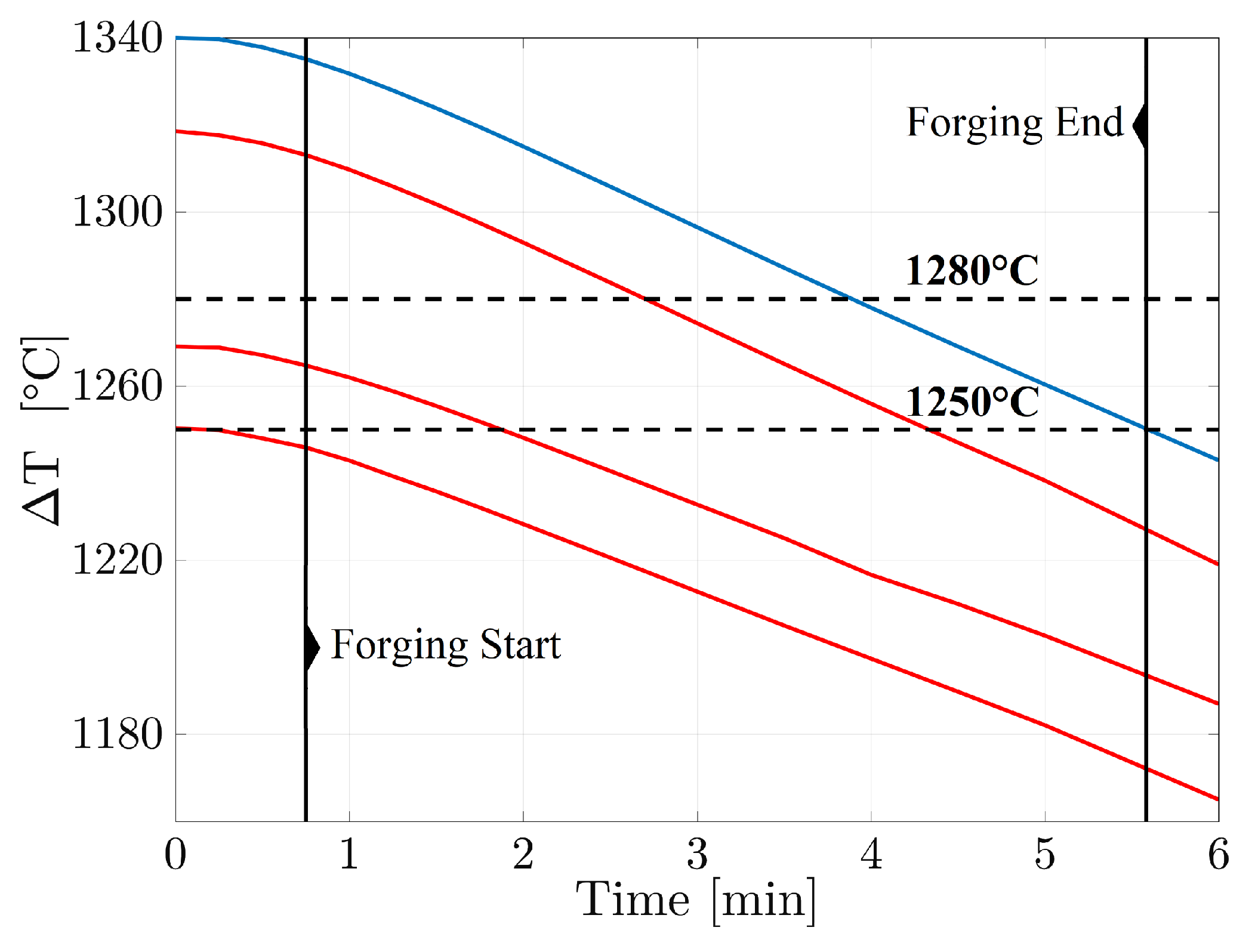

Isothermal forging at temperatures of roughly 1250 C with strain rates of ∼10 is time-consuming and demands for expensive molybdenum-based die materials, which are subject to heavy oxidation at temperatures above 625 C and require a protective atmosphere or even vacuum. In order to compensate for the high process and tooling costs, the forging process has to be optimized for productivity while maintaining the necessary quality. Forging of TiAl is typically carried out as a closed-die isothermal forging process with stationary dies, into which billets are inserted before forging and extracted after forging. Manipulation of parts causes idle time for the forging press. The idle time increases tremendously if a forged part sticks to the tool surface, which happens regularly due to long forging strokes (∼4–5 min) and relatively large glide distances between workpiece and tool.

The literature consists mostly of basic research on the isothermal forging of TiAl alloys. In addition, studies on the modeling of flow stress and dynamic recrystallization of austenitic steels were transferred to titanium aluminides. However, in-depth studies on the modelling and design of industrially viable forging processes of TiAl alloys are missing from the literature. Depending on part geometry and lot size, more cost-efficient production can be achieved by using innovative process designs. Small parts (e.g., compressor blades) require moderate forming forces and can therefore be grouped together and forged in a single die set as a batch. By preassembling and preheating the die set and billets outside the press, idle time due to handling of single parts can be avoided.

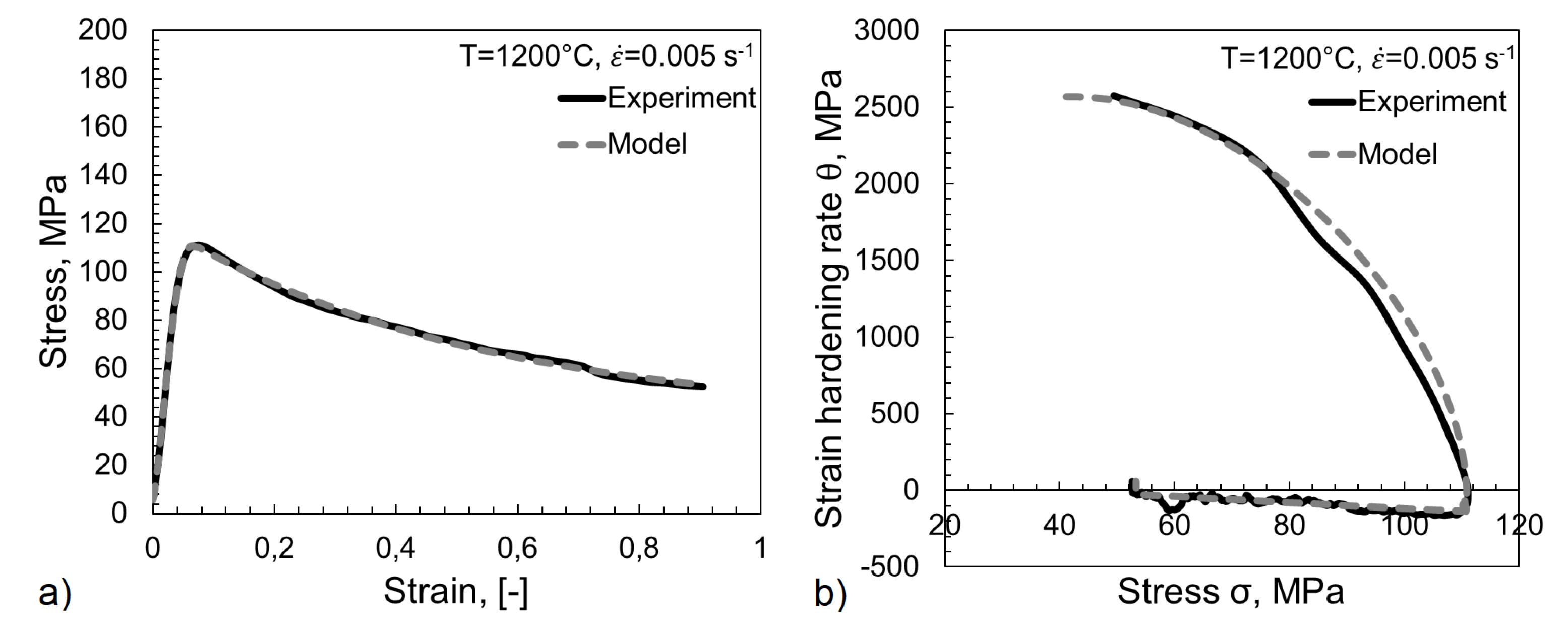

Designing such a batch process requires knowledge of the process window. Depletion temperatures of TiAl and the strength of the dies limit the lower temperature, while the two-phase region + and the thermal loads on the dies bound the process window towards higher temperatures. This results in a narrow temperature window, requiring precise temperature control and a priori process design in order to avoid damage to the dies. In addition, the transition from the incipient yield over the peak stress to the steady state is often not well represented in available material models.

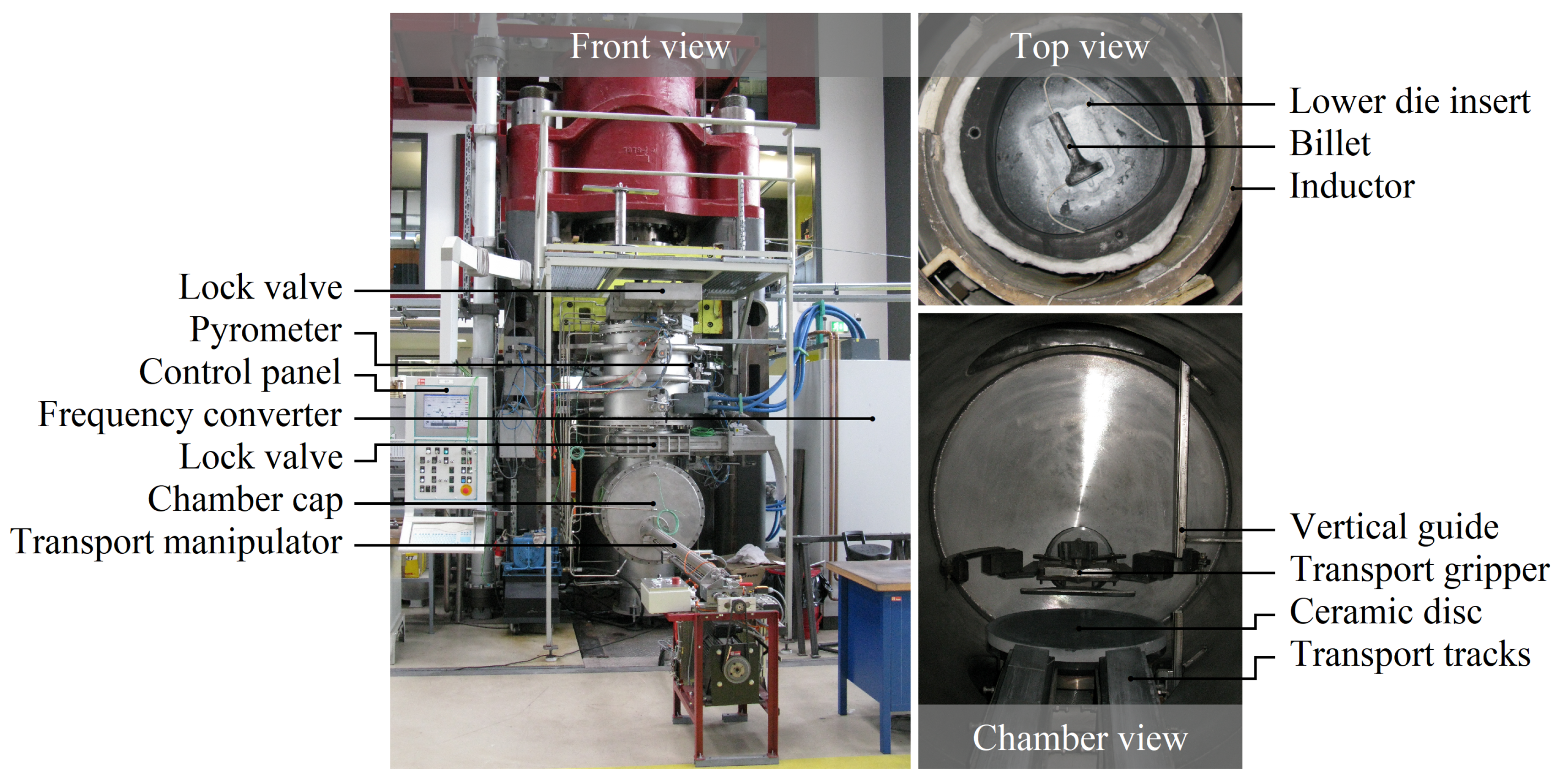

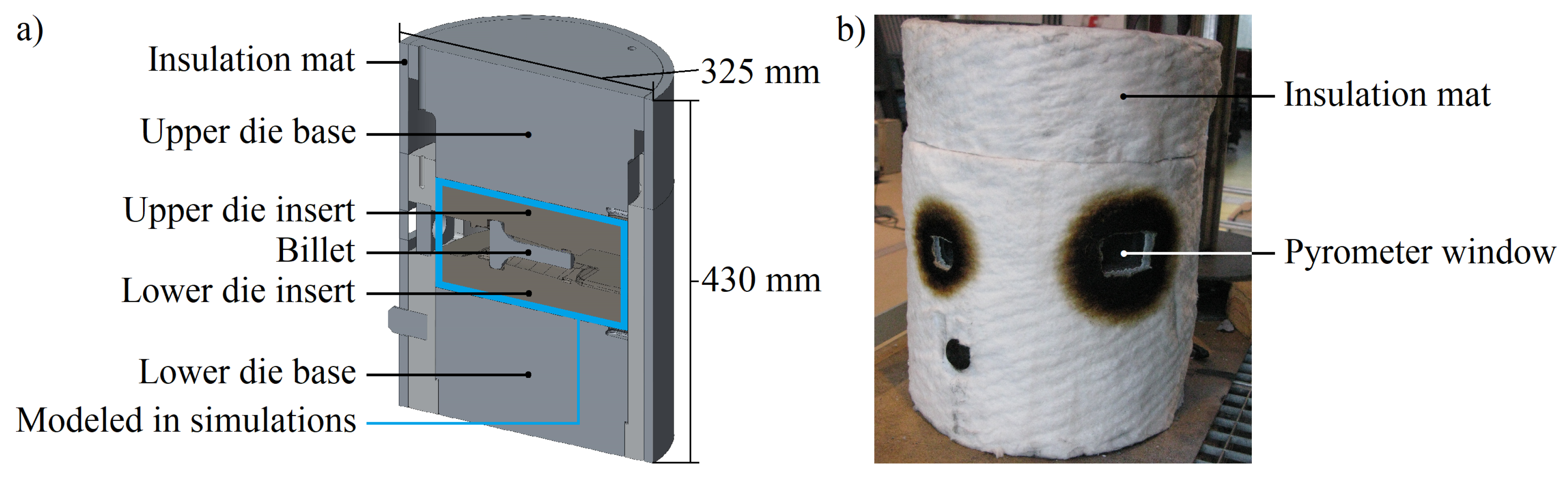

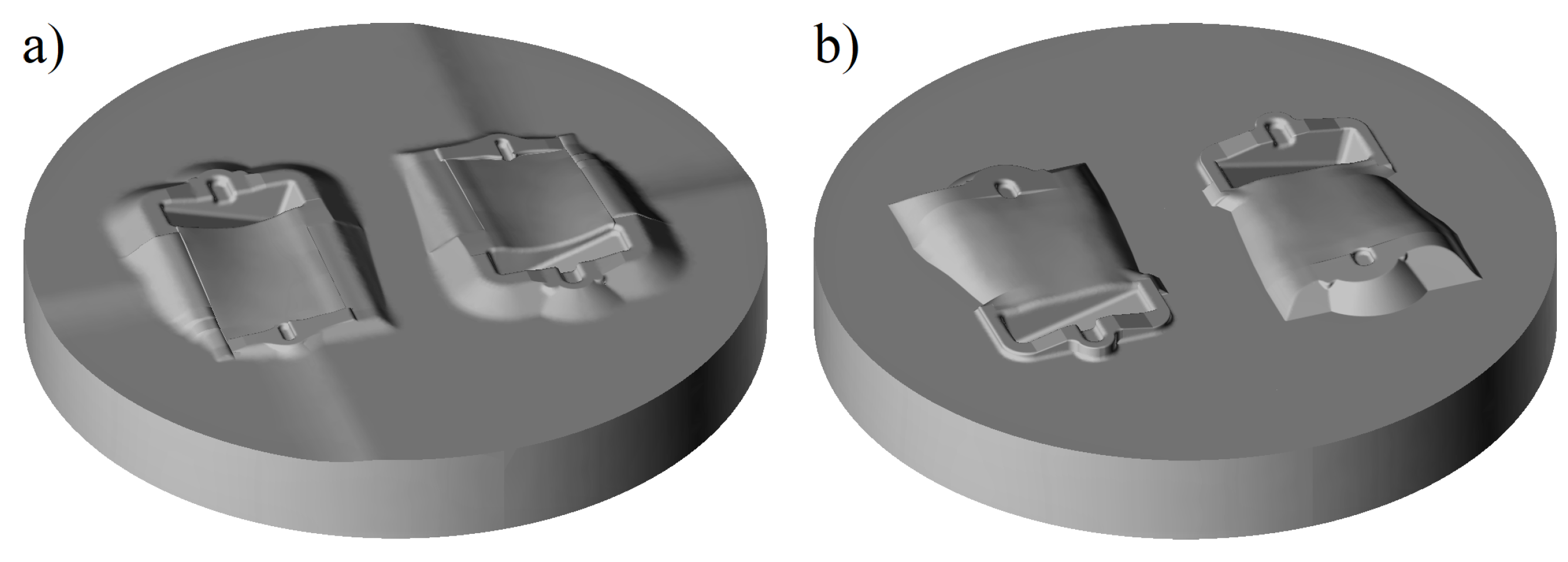

This paper aims at introducing and investigating the feasibility of a batch process design for the TiAl alloy TNB-V4. The batch process developed in this work consists of a transport system and a transportable die set, which is preassembled and preheated, fed into a hydraulic press to forge compressor blades, and finally extracted from the press. A previously developed material model, able to accurately predict the flow curve of TNB-V4, was implemented into the FE program Q-Form and validated using hot compression tests. Simulations based on the model and physical experiments were then performed to determine the forging parameters, and assess the feasibility of the developed transport and die design for batch processing. In addition, a cost analysis compares the economic viability of batch processing to stationary die forging. Due to cost restrictions, the authors were only able to produce dies able to forge 1 part per stroke. However, this investigation covers the ground work of material modelling, design of a transport system and a preassembled die set, and cost analysis for batch processing. Furthermore, scaling up of the process to forge 2 and 4 parts per batch is discussed.

2. Literature Review

Several studies on the forging process of TiAl-based alloys are reported in the literature. Millett et al. [

8] investigated a

-TiAl alloy with the nominal composition Ti-48Al-2Mn-2Nb. The authors found an increase in flow softening behavior with increasing temperature and decreasing strain rate (i.e., the opposite of the expected behavior), through examination of the produced stress-strain curves. In order to analyze the flow stress data the authors used the model developed by Blackwell et al. [

9]. The alloy was shown to deform via Dynamic Recrystallization (DRX), resulting in a nearly pure

-phase microstructure. This

structure has poor fracture toughness and creep resistance, making post-process heat treatment necessary, which can result in very large grain sizes, constraining the application of this alloy. Semiatin et al. [

10] reported on isothermal forging of a near

-titanium aluminide (Ti-46.6Al-2.7Nb-0.3Ta-0.2O) and found similar results. The investigation suggested that the flow softening was also a result of adiabatic heating. Tetsui et al. [

11] investigated hot forging and subsequent machining of a Ti-42Al-5Mn alloy with the aim of supplying large TiAl components with complex shapes and high dimensional precision, expanding the application variety of TiAl alloys. The authors verified that complex configurations were possible to fabricate using hot forging and machining. The presence of

-phase fractions was found to greatly improve both the hot forgeability and machinability in comparison to conventional TiAl alloys. However, the

-phase reduces the high-temperature strength of the alloy.

Furthermore, Finite Element (FE) analyses of the forging of TiAl alloys have been reported. Brooks et al. [

12] used two finite element codes (ABAQUS and FORGE 3) to model the forging of a two-phase TiAl (Ti-47.9Al-2.06Nb-1.93Cr-1.07B) turbine blade, with the aim of defining a forging window for isothermal deformation conditions, and comparing the results with isothermally forged parts. The model produced reasonable predictions for load and strain, and showed good agreement with the observed microstructure. The flow softening of the

-phase was found to be a function of the

grain size and the degree of recrystallization. There have been many investigations on the hot deformation behavior (Semiatin et al. [

13], Schmoelzer et al. [

14]) as well as on the constitutive modeling of TiAl-based alloys, as these models are needed for accurate FE simulations of isothermal forging processes. The flow behavior of TiAl-based alloys has been studied and a number of constitutive relationships and processing maps have been proposed in the literature. Cheng et al. [

15] investigated the flow behavior in hot forging of a high Nb containing TiAl-alloy (Ti-42Al-8Nb-0.2W-0.1Y) and applied the model proposed by Laasraoui and Jonas [

16], which was developed for hot working of steel in the austenitic range. The results revealed an easy onset of DRX, while the Dynamic Recovery (DRV) was impeded. In addition, a low DRX rate as compared to conventional alloys was found.

Werner et al. [

17] and Godor et al. [

18] applied two phenomenological constitutive models for the description of the hot deformation behavior of different TiAl-alloys, the Sellars-McTegart (ST) model and the Hensel-Spittel (HS) model. Werner et al. [

17] investigated the flow behavior of a

-solidifying TNM (TiAl with Nb and Mo as the main alloying elements) alloy with the nominal composition Ti-43.5Al-4Nb-1Mo-0.1B. Godor et al. [

18] investigated two

-TiAl alloys with the nominal compositions Ti-41Al-3Mo-0.5Si-0.1B and Ti-45Al-3Mo-0.5Si-0.1B. Both authors found that the ST model gave good predictions for flow stress, however the model is only valid in the experimental strain range from which the constitutive expression has been derived. The HS model was reported to reproduce the experimental flow stress curves well, in addition to being able to extrapolate stress data to strains outside the experimental range. In addition, both authors found that the calculated Zener-Hollomon parameter could be linked to the dynamically recrystallized grain size through a power law equation. Schwaighofer et al. [

19] studied a modified TNM alloy, with the nominal composition Ti-43Al-4Nb-1Mo-0.1B, which contains a small amount of C and Si (C + Si less than 1 at %). The authors also applied the Sellars–McTegar model and established processing maps with the demonstration of stable and unstable deformation regions.

The presently available literature on the modelling of TiAl-alloys, specifically the descriptions of the flow behavior, are based on empirical models which were derived originally for steels and do not consider the presence of a multiphase microstructure. Therefore, most of the present models are not able to predict the steep rise of flow stress from incipient yield to the peak stress, and the subsequent drop to the steady state. Modeling the entire course of the flow curve is crucial in predicting material flow in FE simulations, as only the points in the workpiece where local stress exceeds the flow stress will deform plastically. Thus, the state of the art leaves open questions regarding the FE modeling of titanium aluminides, and the design and implementation of new forging processes which make full use of the press capacity.

5. Cost Analysis

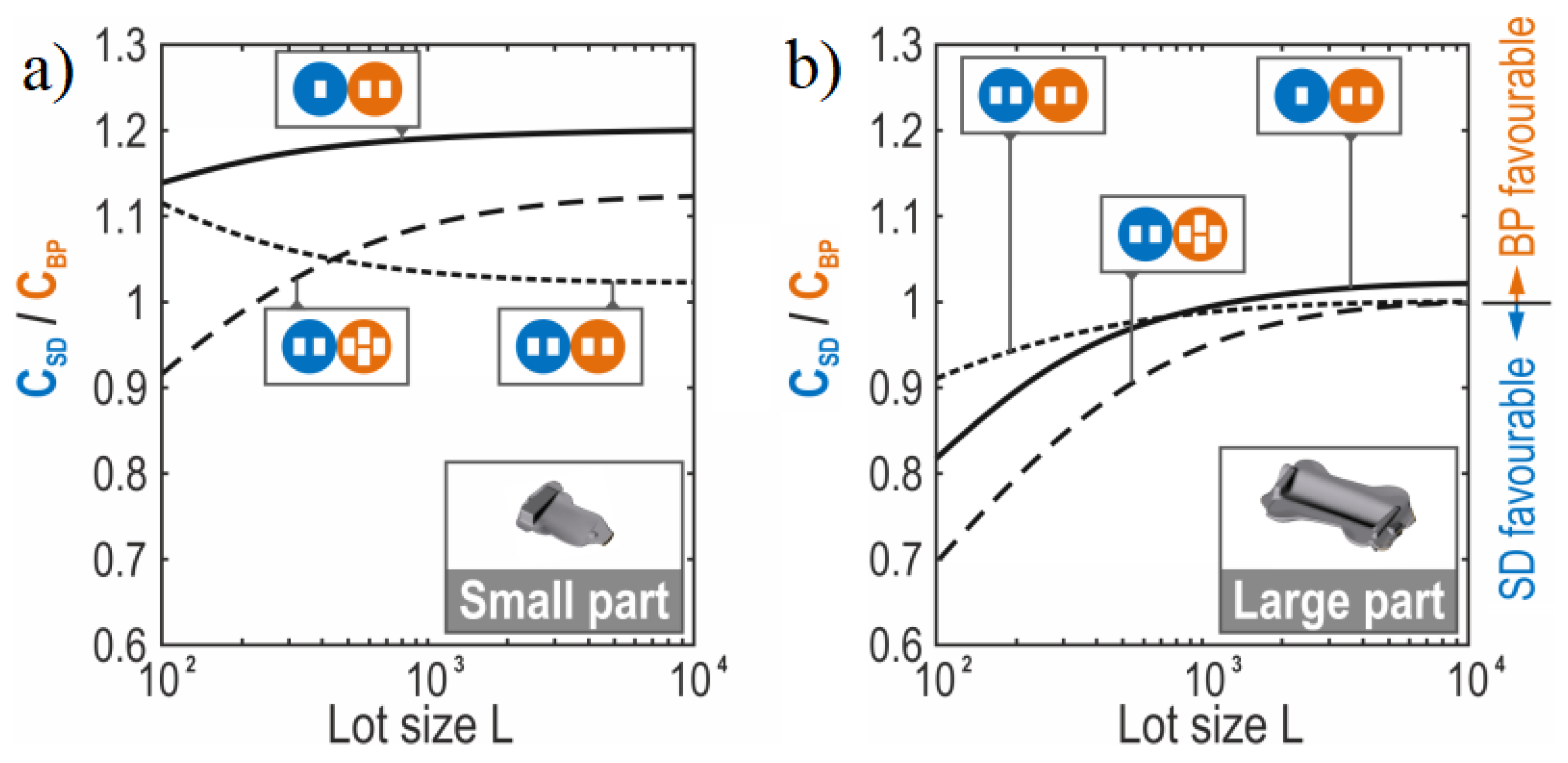

Economic considerations are of crucial importance for industrial production of TiAl forgings. In this section, a qualitative comparison of unit costs between isothermal forging of 1 and 2 parts with a stationary die, and isothermal forging of 2 and 4 parts using batch processing is presented. The equations and parameters used for the cost analysis model are given, as well as the produced results. For a lot size L, the unit costs C are

The costs for the dies (number

) are

For production with stationary dies, at least two dies are needed to avoid idle time during die maintenance. For batch processing, at least three die sets are needed which are circulated continuously, and a fourth die set would avoid idle time of the press during maintenance of a die set. It is assumed that the die engraving has to be re-machined after 1000 forgings. The process costs are

Finally, the material costs per billet are

The variables assumed for the cost model are given in

Table 4 and

Table 5, and are based on the experiences gained during the design of the press system and the forging experiments. They only allow for a qualitative comparison of the two process routes. The main difference between the routes are larger die investments for batch processing, and the long handling and setup times for die change (approximately one working day) with the stationary die. The die volumes are scaled up when more than one engraving is present.

Figure 11 shows the ratio of unit costs for the stationary die process (

) and batch processing (

) for small (a) and large (b) parts respectively. This diagram was created using the equations and parameters presented. For the stationary die, 1 and 2 engravings were used, as more engravings would increase the idle time of the press during part handling and increase the thermal load on the gripper. For batch processing, 2 and 4 engravings were used. The solid line represents the ratio of

/

for 1 part forged with the stationary die and 2 parts forged using batch processing, the dotted line represents 2 parts forged with the stationary die and 2 parts forged using batch processing, finally the dashed line represents 2 parts forged with the stationary die and 4 parts forged using batch processing. As indicated, forging with the stationary die provides a cost advantage when the value of

/

is below 1, while batch processing is favorable when the value exceeds 1. The comparison shows that for small parts and large lot sizes, batch processing of 2 and 4 parts always offer a cost advantage. If the number of engravings is equal, this advantage diminishes with increasing lot size. For large parts, the stationary die is more favorable for smaller lot sizes. Thus, batch processing requires a large lot size, which is a consequence of the fact that batch processing requires at least 3 die sets to avoid idle times. If the lot size is small so that no die change is necessary (low tool wear), stationary die forging with two engravings is still the most economical.