The Use of 3D Printing in the Fabrication of Nasal Stents

Abstract

:1. Introduction

2. Materials

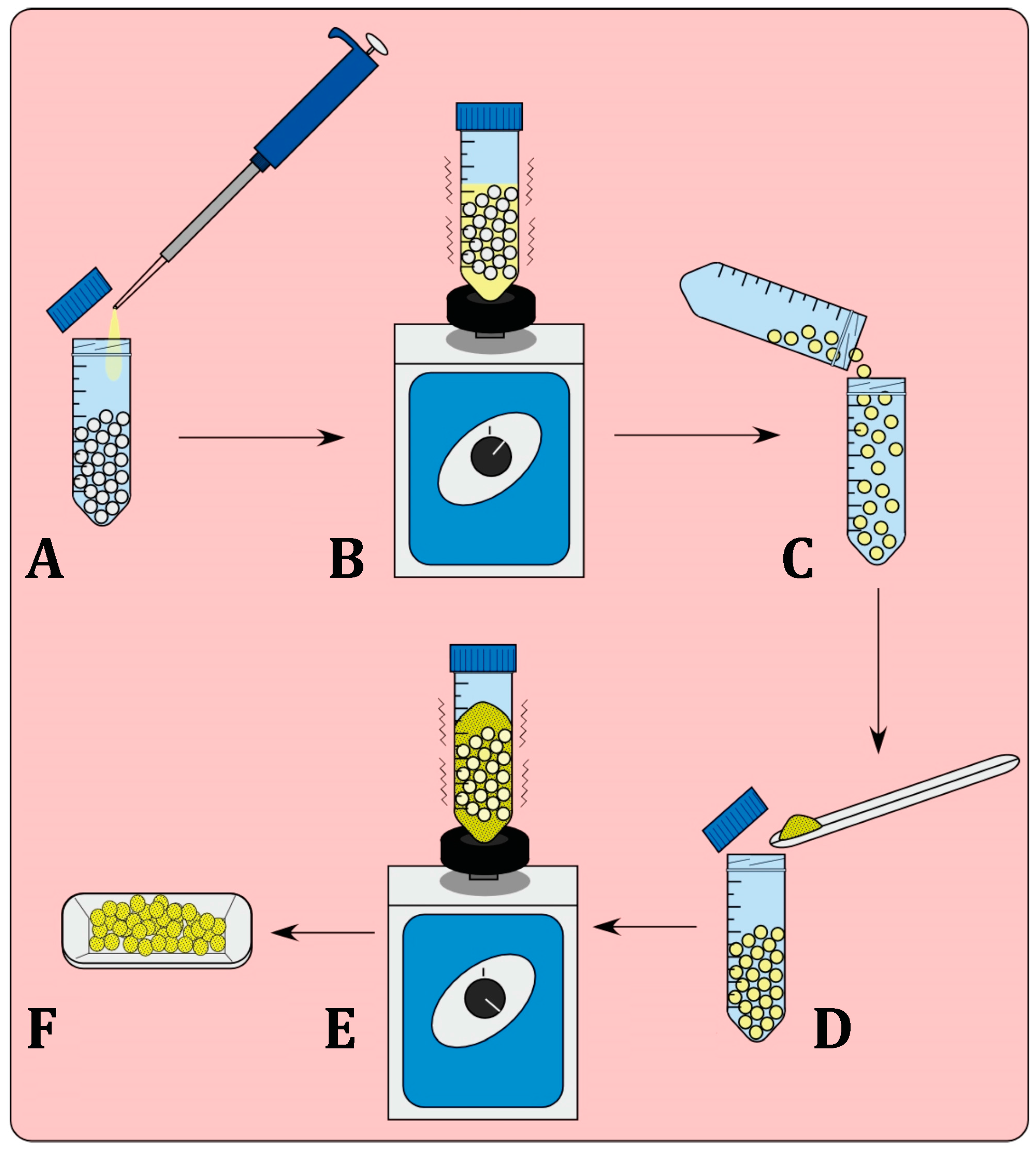

2.1. Polylactic Acid (PLA) Pellet Preparation

2.2. Filament Extrusion

2.3. 3D Printing

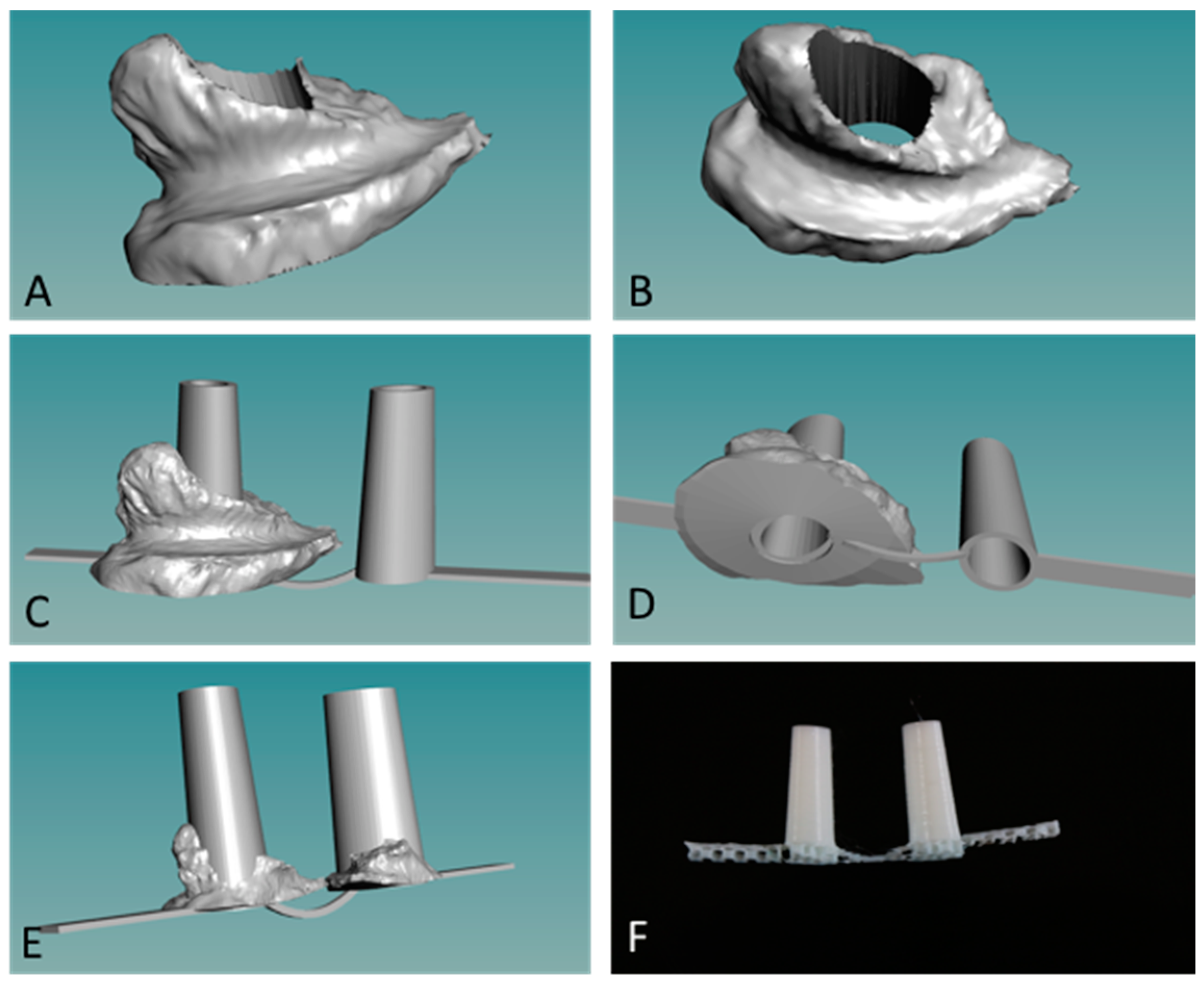

2.4. Imaging

2.5. Bacterial Cultures

3. Results

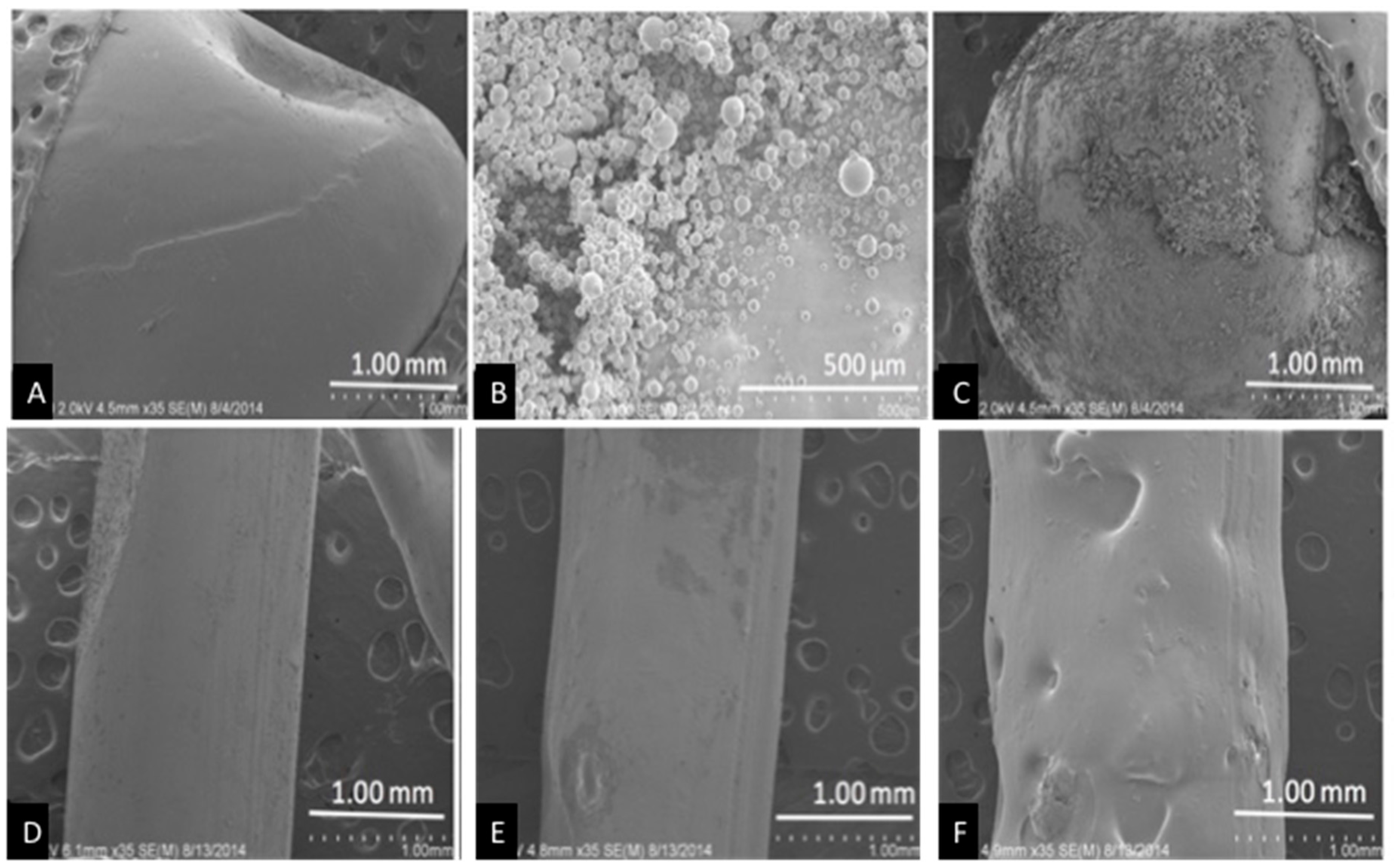

3.1. Scanning Emission Microscope (SEM) Analysis

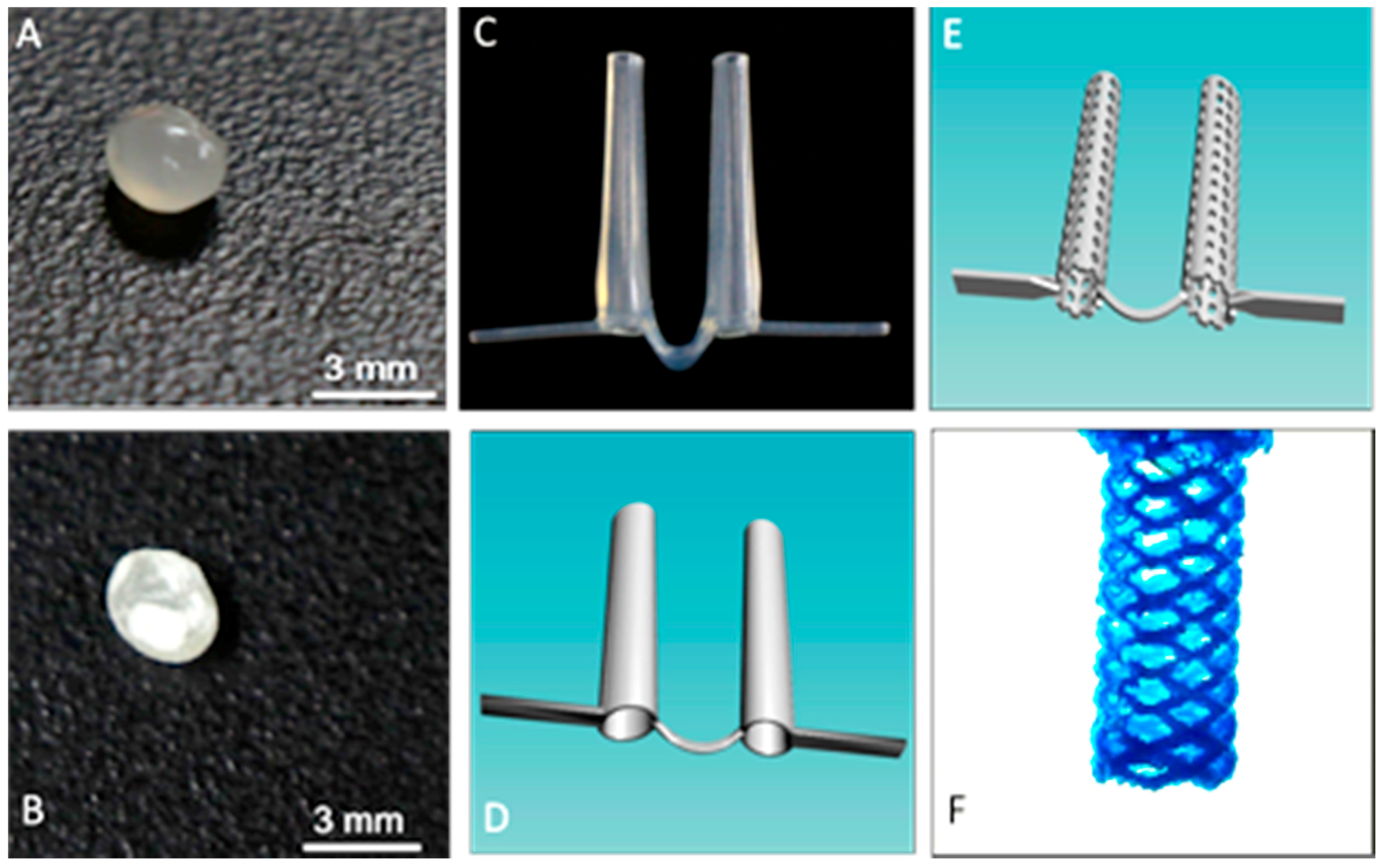

3.2. Device Fabrication

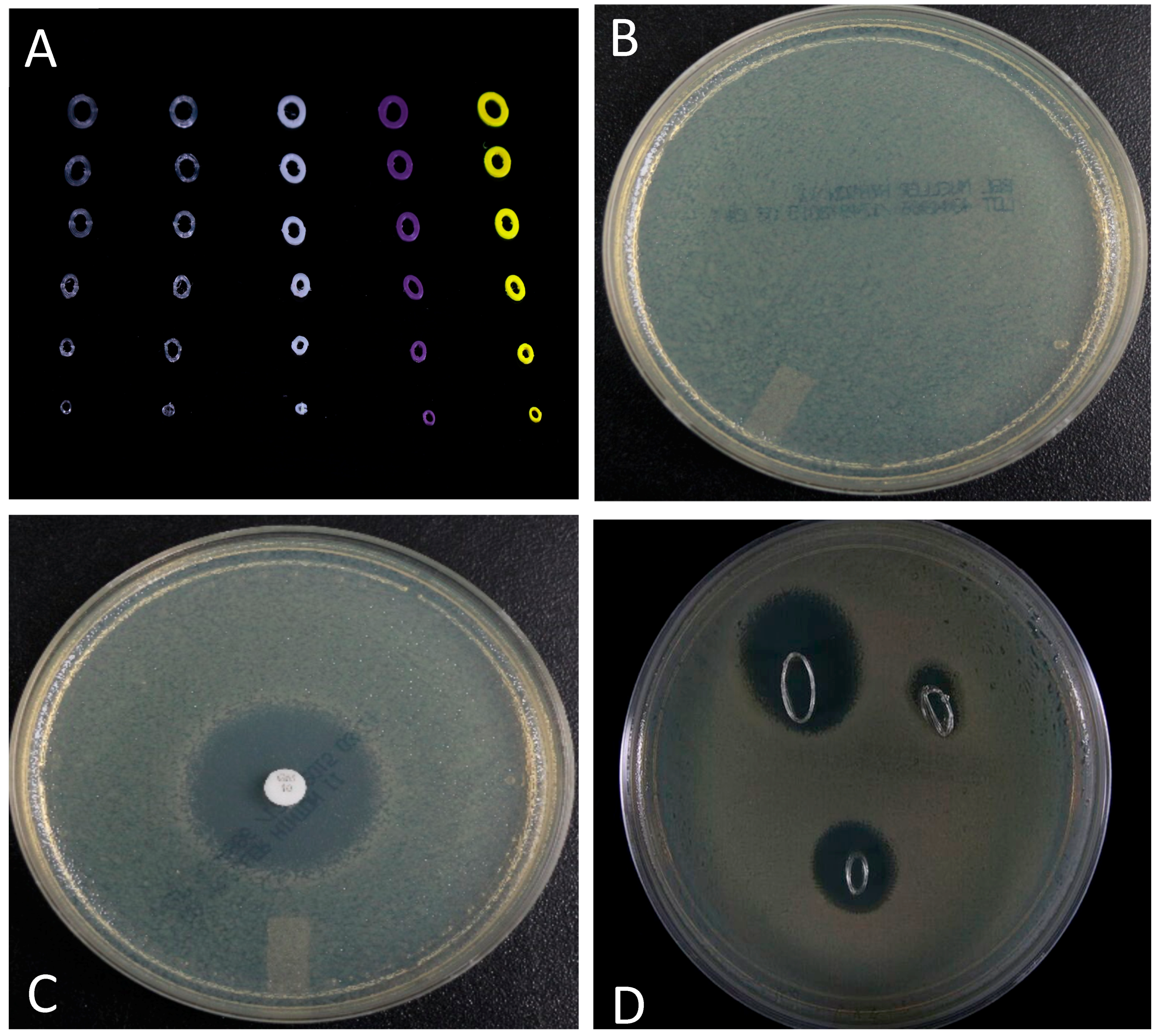

3.3. Growth Inhibition Studies

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-dimensional printing techniques. Patent US5340656 A, 1994. [Google Scholar]

- Jijotiya, D.; Verma, P.L. A survey of performance based advanced rapid prototyping techniques. Sch. J. Eng. Tech. 2013, 1, 4–12. [Google Scholar]

- Derby, B. Printing and prototyping of tissues and scaffolds. Science 2012, 338, 921–926. [Google Scholar] [CrossRef] [PubMed]

- Jeffrey, W.; Stansbury, J.W.; Idacavageca, M.J. 3D printing with polymers, challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar]

- Shafiee, A.; Atala, A. Printing technologies for medical applications. Trends Mol. Med. 2016, 22, 254–265. [Google Scholar] [CrossRef] [PubMed]

- Hayhurst, C. 3D printing and medical devices. Biomed. Instrum. Tech. 2014, 14–24. [Google Scholar] [CrossRef] [PubMed]

- Vijayavenkataraman, S.; Fuh, J.T.H.; Wen, F.; Lu, W.F. 3D printing and 3D bioprinting in pediatrics. Bioengineering 2017, 4. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Montgomery, M.; Chamberlain, M.D.; Ogawa, S.; Korolj, A.; Pahnke, A.; Wells, L.A.; Masse, S.; Kim, J.; Reis, L.; et al. Biodegradable scaffold with built-in vasculature for organ-n-a-chip engineering and direct surgical anastomosis. Nat. Mater. 2016, 15, 669–678. [Google Scholar] [CrossRef] [PubMed]

- Ozbolat, I.T.; Yu, Y. Bioprinting towards organ fabrication, challenges and future trends. IEEE Trans. Biomed. Eng. 2013, 60, 691–699. [Google Scholar] [CrossRef] [PubMed]

- Duan, B.; Hockaday, L.A.; Kang, K.H.; Butcher, J.T. 3D bioprinting of heterogeneous aortic valve conduits with alginate/gelatin hydrogels. J. Biomed. Mater. Res. A 2013, 101, 1255–1264. [Google Scholar] [CrossRef] [PubMed]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 497–504. [Google Scholar] [CrossRef]

- Zhang, A.P.; Qu, X.; Soman, P.; Hribar, K.; Lee, J.W.; Chen, S.; He, S. Rapid fabrication of complex 3D extracellular microenvironments by dynamic optical projection stereolithography. Adv. Mater. 2012, 24, 4266–4270. [Google Scholar] [CrossRef] [PubMed]

- Weisman, J.; Nicholson, C.; Tappa, K.; Jammalamadaka, U.; Wilson, C.; Mills, D.K. Antibiotic and chemotherapeutic enhanced 3D printer filaments and constructs for biomedical applications. Inter. J. Nanomed. 2014, 10, 357–370. [Google Scholar]

- Landers, R.; Mülhaupt, R. Desktop manufacturing of complex objects, prototypes and biomedical scaffolds by means of computer-assisted design combined with computer-guided 3D plotting of polymers and reactive oligomers. Macromol. Mater. Eng. 2000, 282, 17–21. [Google Scholar] [CrossRef]

- Ballard, D.H.; Weisman, J.A.; Jammalamadaka, U.; Tappa, K.; Alexander, S.; Griffen, F. Three-dimensional printing of bioactive hernia meshes, in vitro proof of principle. Surgery 2017, 161, 1479–1481. [Google Scholar] [CrossRef] [PubMed]

- Parker, S.E.; Mai, C.T.; Canfield, M.A.; Richard, R.; Yang, Y.; Meyer, M. Updated national birth estimates prevalence for selected birth defects in the US. Birth Defect Res. 2010, 88, 1008–1016. [Google Scholar] [CrossRef] [PubMed]

- Shkoukani, M.A.; Chen, M.; Vong, A. Cleft lip—A comprehensive review. Front. Pediatr. 2013, 1. [Google Scholar] [CrossRef] [PubMed]

- Mossey, P.A.; Little, J.; Munger, R.G.; Dixon, M.J.; Shaw, W.C. Cleft lip and palate. Lancet 2009, 374, 1773–1785. [Google Scholar] [CrossRef]

- Enlow, D.H. Facial Growth, 3rd ed.; WB Saunders: Philadelphia, PA, USA, 1990. [Google Scholar]

- McCarthy, J.G. Plastic Surgery, Cleft Lip and Palate and Craniofacial Anomalies; WB Saunders: Philadelphia, PA, USA, 1990. [Google Scholar]

- Dixon, M.J.; Marazita, M.L.; Beaty, T.H.; Murray, J.C. Cleft lip and palate, synthesizing genetic and environmental influences. Nat. Rev. Genet 2011, 12, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Soares, P.R.; Alonso, N. Protocols in cleft lip and palate treatment, systematic review. Plast. Surg. Int. 2012. [Google Scholar] [CrossRef]

- Wehby, G.L.; Cassell, C.H. The impact of orofacial clefts on quality of life and healthcare use and costs. Oral Dis. 2010, 16, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Eshraghi, S.; Das, S. Mechanical and microstructural properties of polycaprolactone scaffolds with one-dimensional, two-dimensional and three-dimensional orthogonally oriented porous architectures produced by selective laser sintering. Acta Biomater. 2010, 6, 2467–2476. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Wang, B.; Yang, G.; Gauthier, M. Poly(lactic acid)-based biomaterials, synthesis, modification and applications. In Biomedical Science, Engineering and Technology; Ghista, D.N., Ed.; InTech: London, UK, 2012; ISBN 978-953-307-471-9. [Google Scholar]

- Farahani, R.D.; Dubé, R.; Therriault, D. Three-dimensional printing of multifunctional nanocomposites, manufacturing techniques and applications. Adv. Mater. 2016, 28, 5794–5821. [Google Scholar] [CrossRef] [PubMed]

- Sanders, C.W. Presurgical orthopedics. Facial Plast. Surg. Clin. 1996, 4, 333–342. [Google Scholar]

- Herbert, N.; Simpson, D.; Spence, W.D.; Ion, W. A preliminary investigation into the development of 3—D printing of prosthetic sockets. J. Rehabil. Res. Dev. 2015, 42, 141–146. [Google Scholar] [CrossRef]

- Zopf, D.A.; Hollister, S.J.; Nelson, M.E.; Ohye, R.G.; Green, G.E. Bioresorbable airway splint created with a three—Dimensional printer. N. Eng. J. Med. 2013, 368, 2043–2045. [Google Scholar] [CrossRef] [PubMed]

- Di Luca, A.; Longoni, A.; Criscenti, G.; Lorenzo-Moldero, I.; Klein-Gunnewiek, M.; Vancso, J.; van Blitterswijk, C.; Mota, C.; Moroni, L. Surface energy and stiffness discrete gradients in additive manufactured scaffolds for osteochondral regeneration. Biofabrication 2016, 8, 015014. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, S.H.; Lewis, G.S.; Bushman, Z.J.; Adair, J.H.; Donahue, H.J. 3D printing of personalized artificial bone scaffolds. 3D Print Addit. Manuf. 2015, 1, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Rahoma, A. Complete cleft palate, A new scheme of treatment. Indian J. Plast. Surg. 2006, 4, 1–9. [Google Scholar]

- Grayson, B.H.; Shetye, P.R. Presurgical nasoalveolar moulding treatment in cleft lip and palate patients. Indian J. Plast. Surg. 2009, 42, S56–S61. [Google Scholar] [CrossRef] [PubMed]

- Kung, T.A.; Bueno, R.A.; Alkhalefah, G.K.; Langhals, N.B.; Urbanchek, M.G.; Cederna, P.S. Innovations in prosthetic interfaces for the upper extremity. Plast. Reconstr. Surg. 2013, 132, 1515–1523. [Google Scholar] [CrossRef] [PubMed]

- Zein, I.; Hutmacher, D.W.; Tan, K.C.; Teoh, S.H. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.; Vacant, J. Advances in tissue engineering. J. Pediatr. Surg. 2016, 51, 8–12. [Google Scholar] [CrossRef] [PubMed]

- Abdllayev, E.; Lvov, L. Functional polymer clay nanotube composites with sustained release of chemical agents. Prog. Polym. Sci. 2013, 38, 1690–1719. [Google Scholar]

- Weisman, J.; Jammalamadaka, U.; Tappa, K.; Mills, D.K. Doped halloysite nanotubes for use in the 3D printing of medical devices. Bioengineering 2017, 4, 96. [Google Scholar] [CrossRef] [PubMed]

- Karnik, S.; Mills, D.K. Nanoenhanced hydrogel system with sustained release capabilities. J. BioMed Mater. Res. 2015, 103, 2416–2426. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mills, D.; Tappa, K.; Jammalamadaka, U.; Weisman, J.; Woerner, J. The Use of 3D Printing in the Fabrication of Nasal Stents. Inventions 2018, 3, 1. https://doi.org/10.3390/inventions3010001

Mills D, Tappa K, Jammalamadaka U, Weisman J, Woerner J. The Use of 3D Printing in the Fabrication of Nasal Stents. Inventions. 2018; 3(1):1. https://doi.org/10.3390/inventions3010001

Chicago/Turabian StyleMills, David, Karthik Tappa, Uday Jammalamadaka, Jeffery Weisman, and Jennifer Woerner. 2018. "The Use of 3D Printing in the Fabrication of Nasal Stents" Inventions 3, no. 1: 1. https://doi.org/10.3390/inventions3010001