Development of a Cavitation Generator Mimicking Pistol Shrimp

Abstract

:1. Introduction

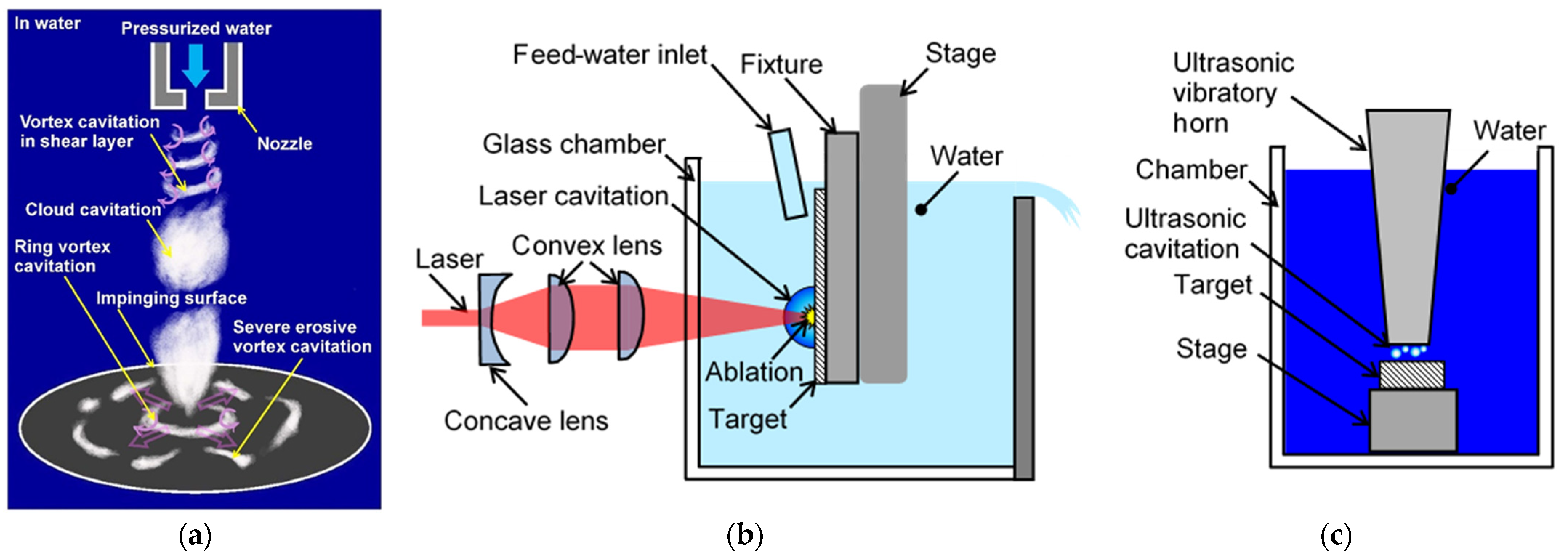

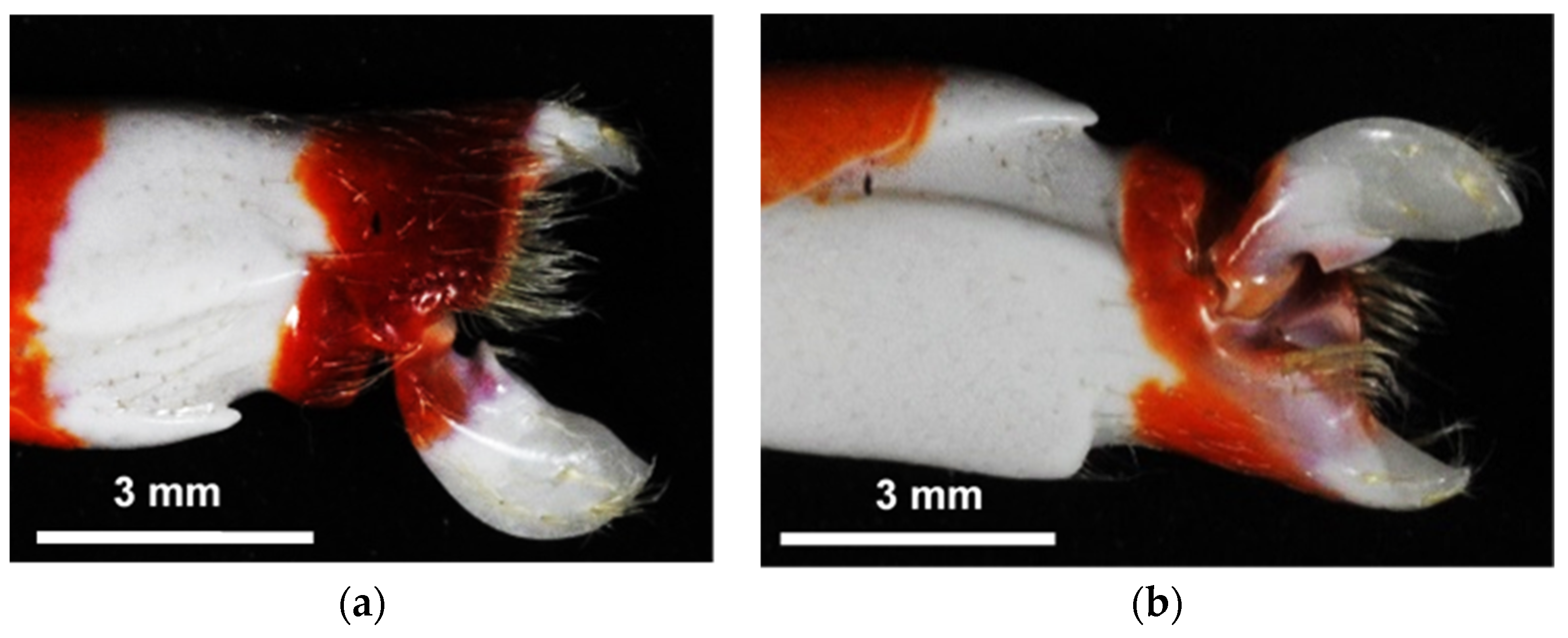

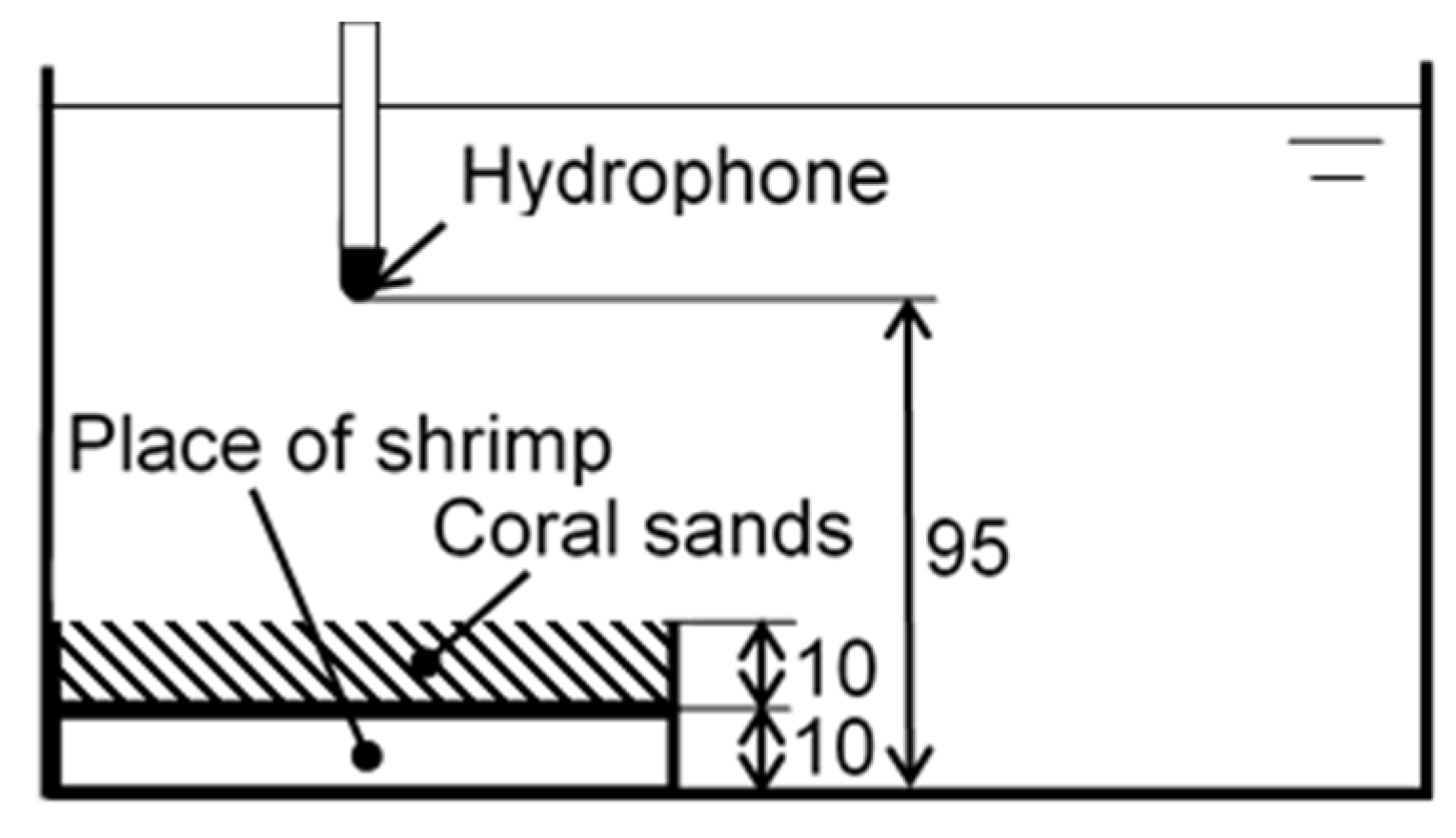

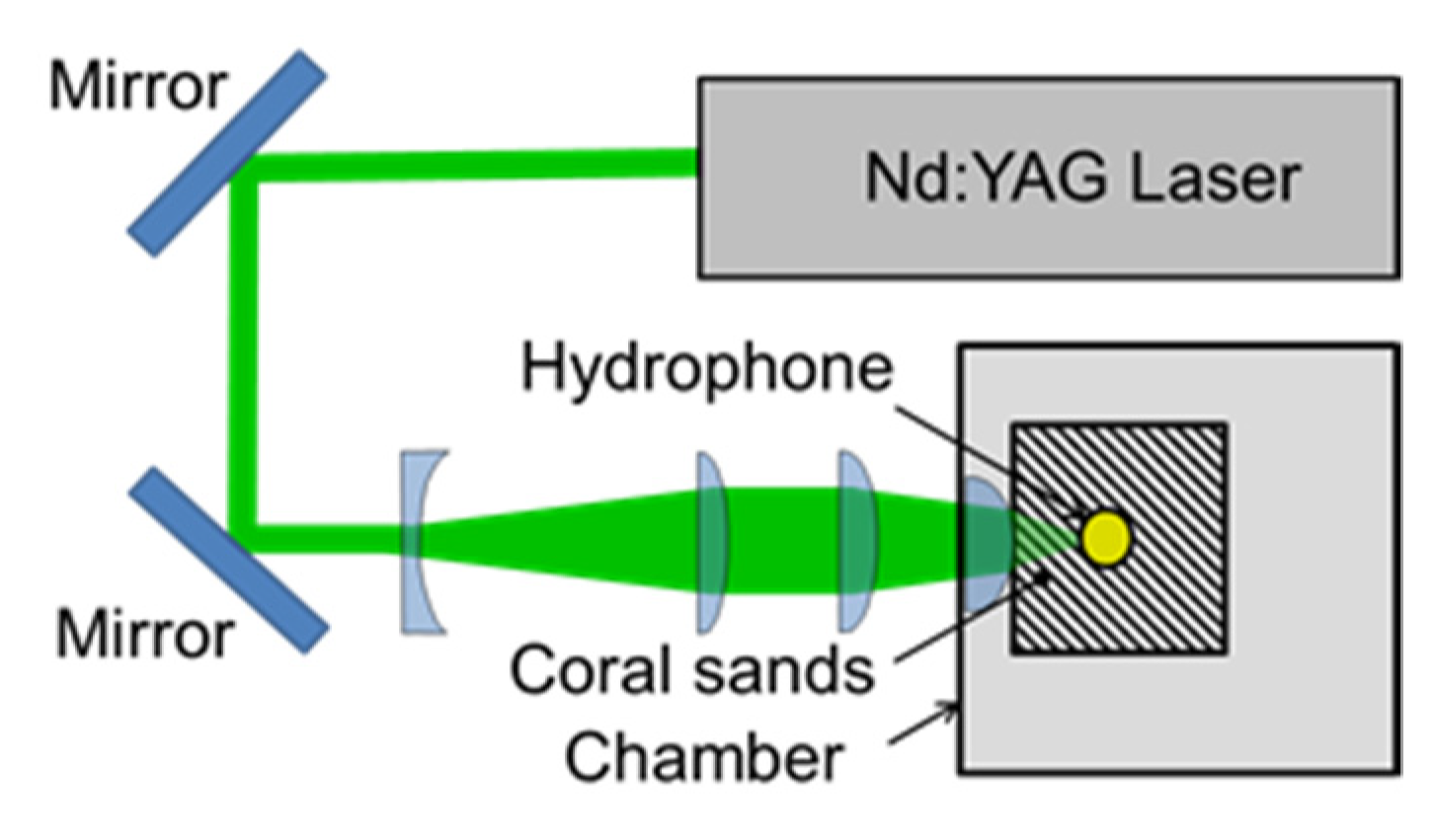

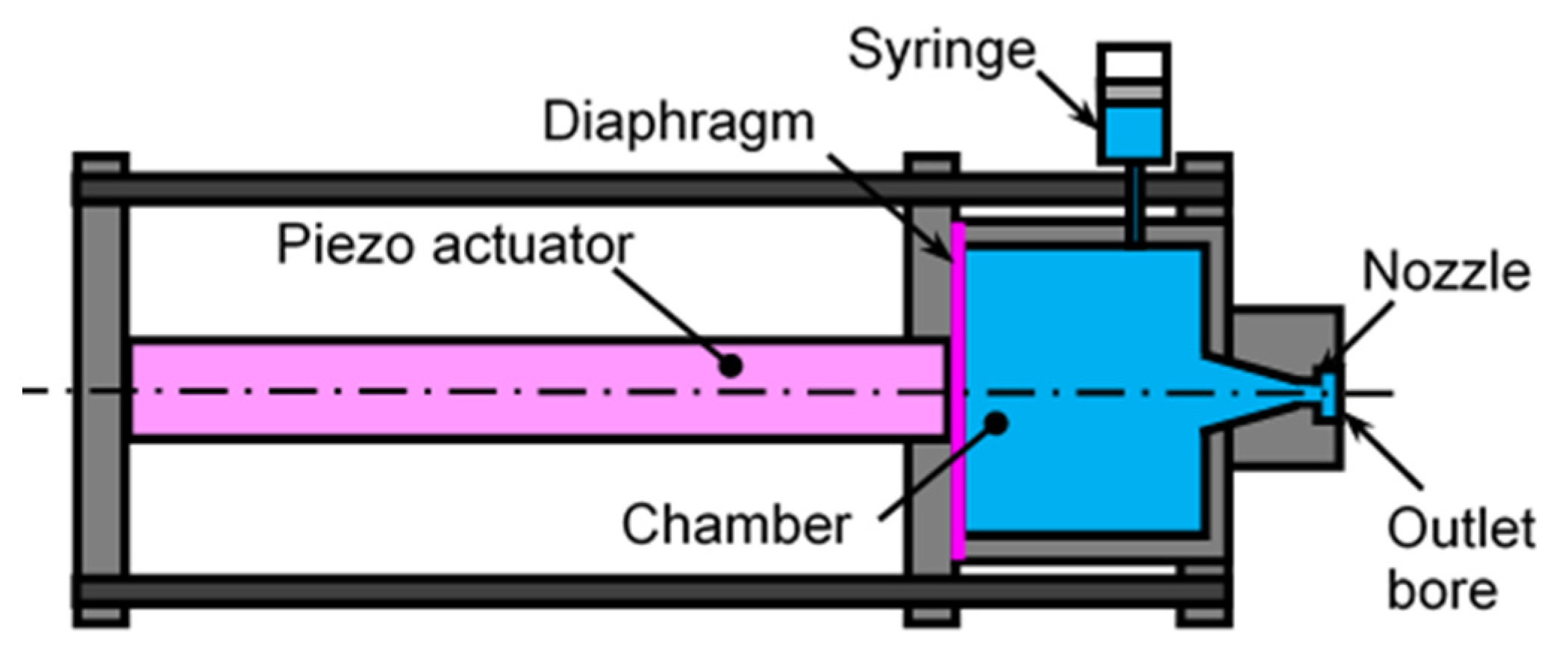

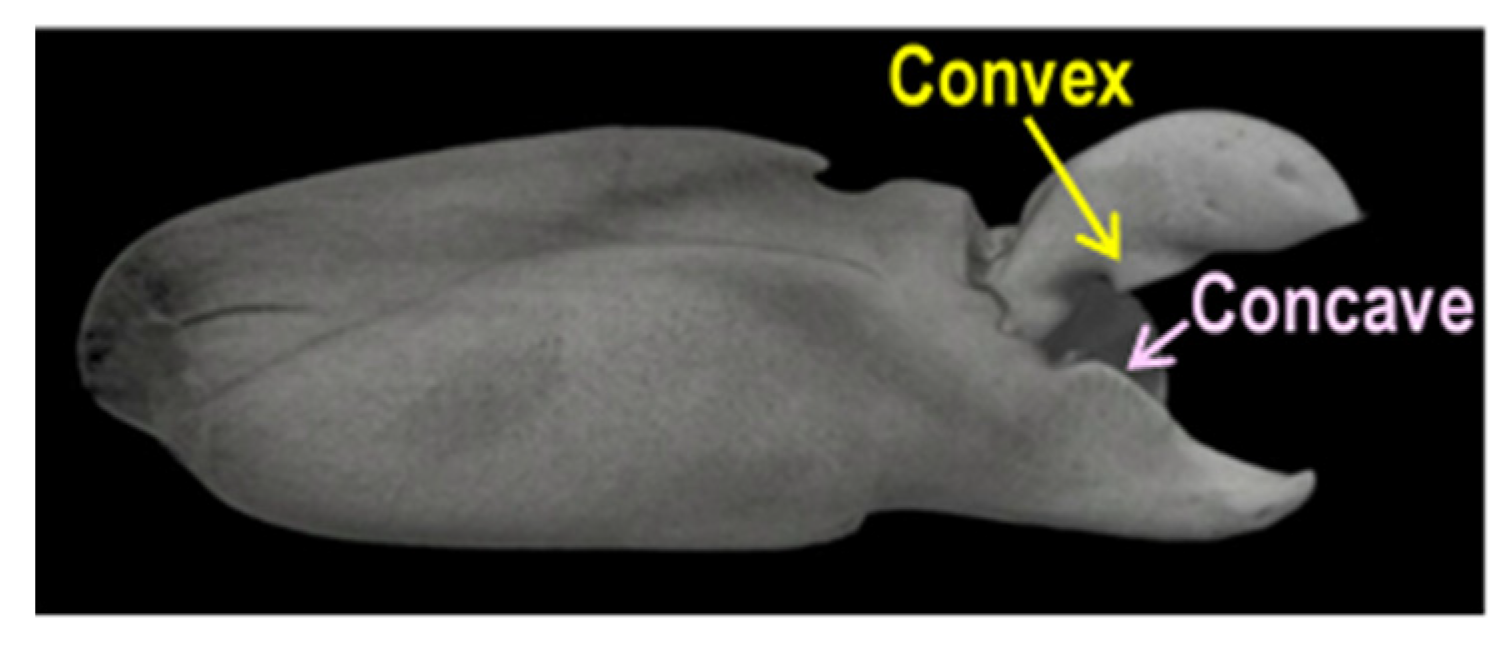

2. Materials and Methods

3. Results

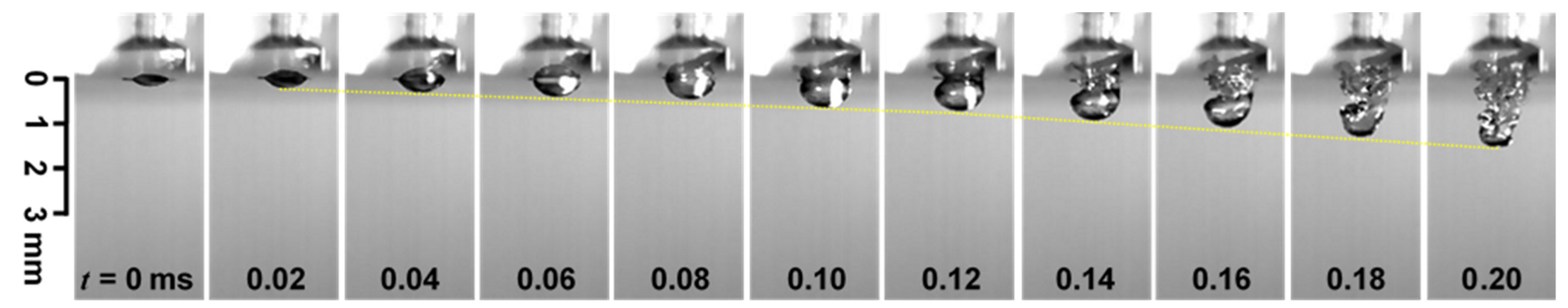

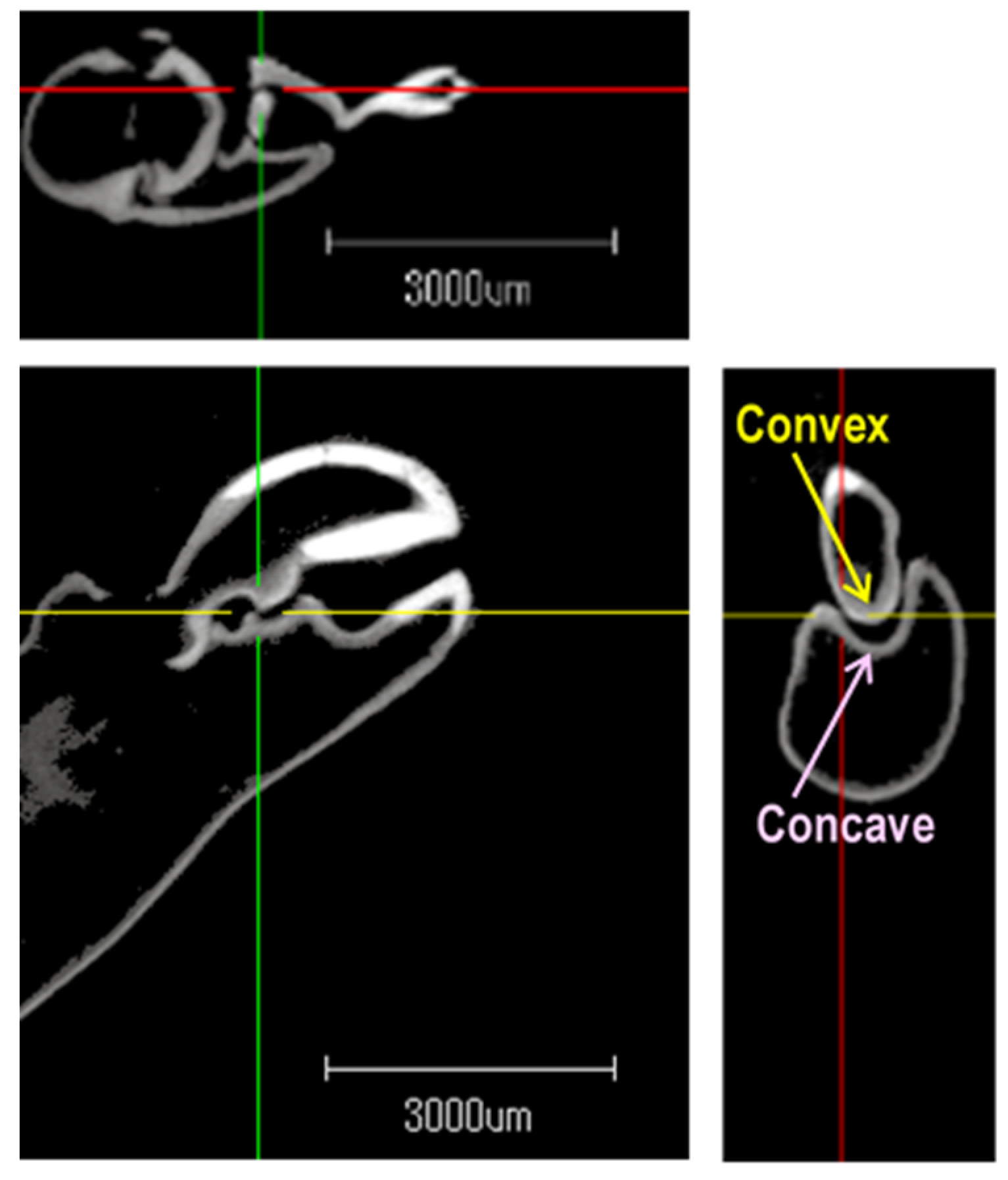

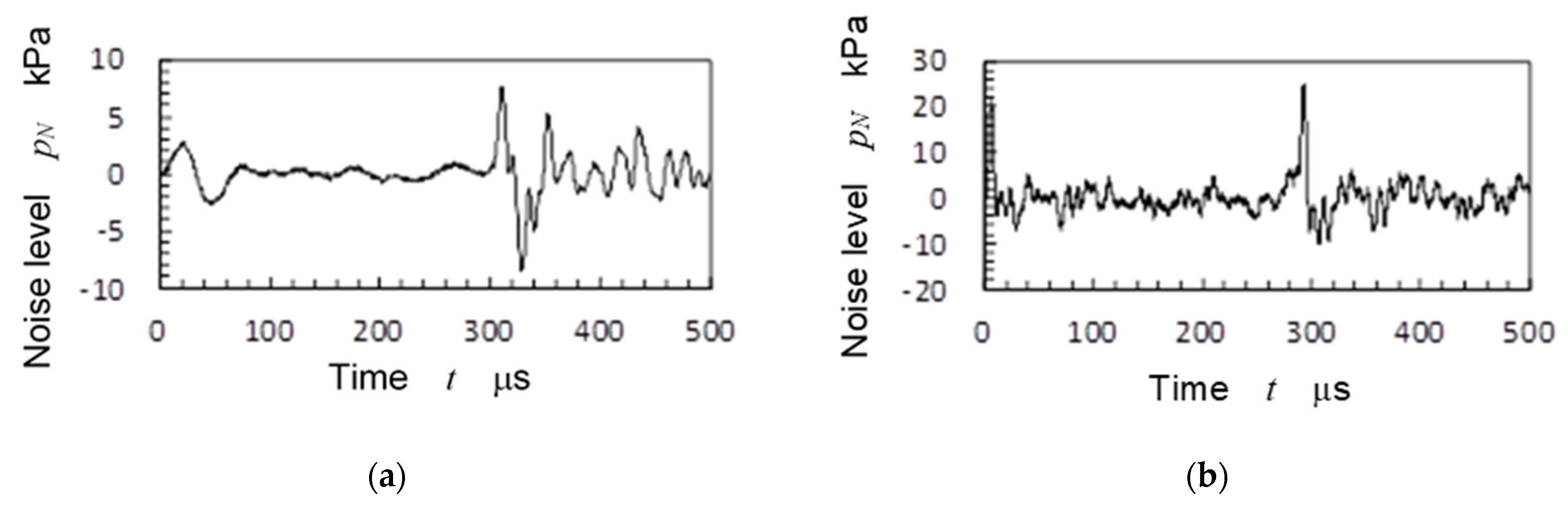

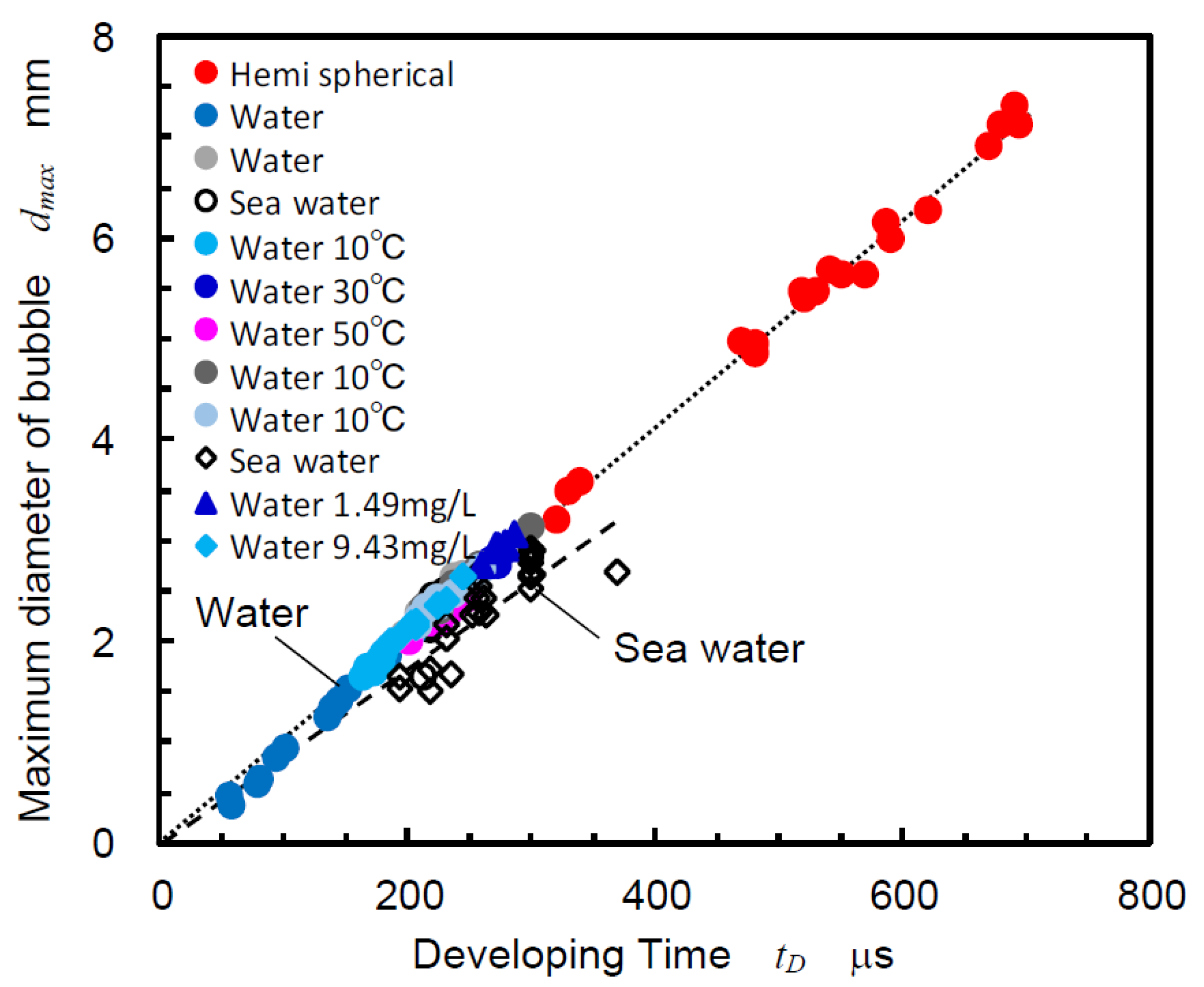

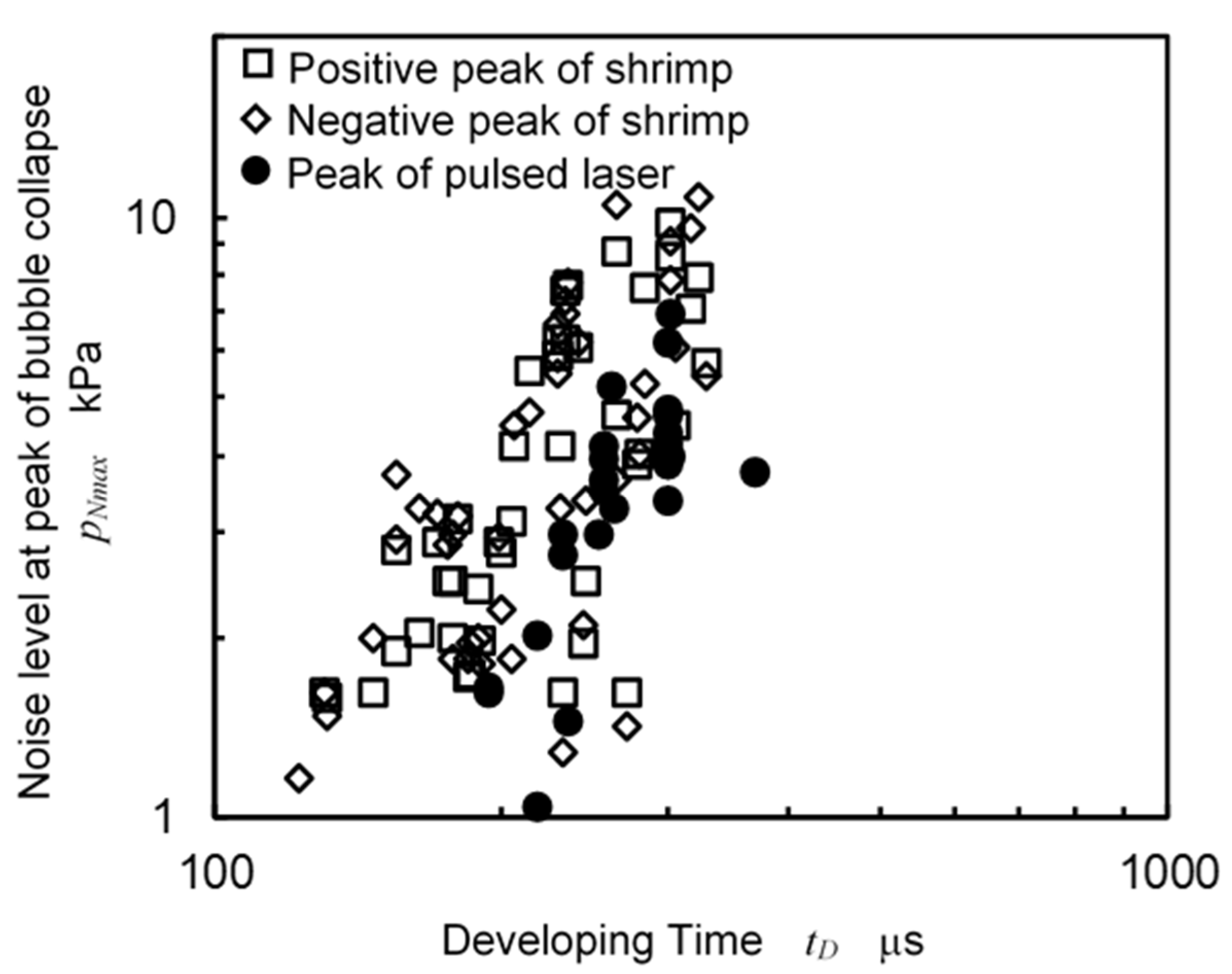

3.1. Cavitation Induced by Pistol Shrimp Compared with a Pulsed Laser

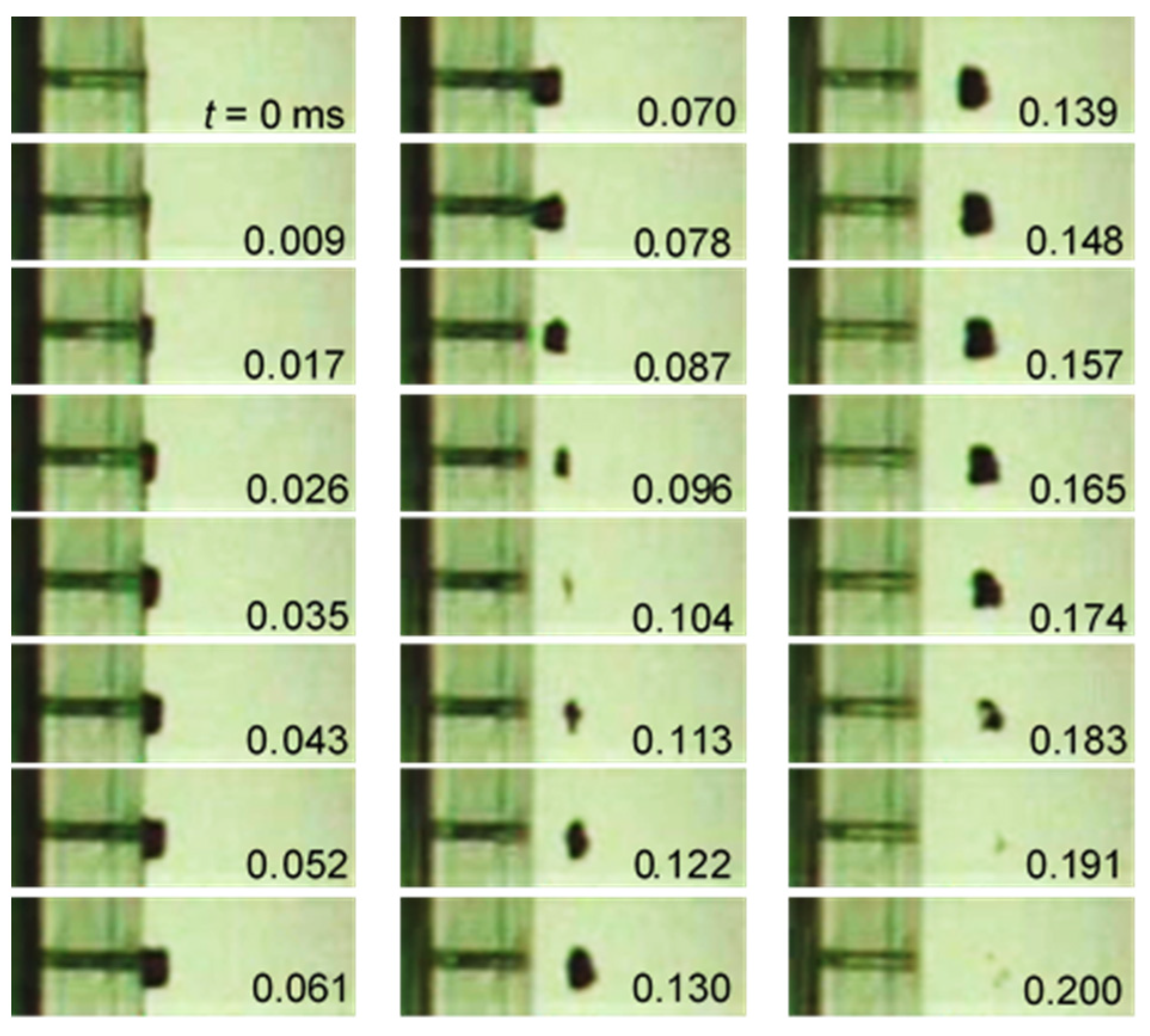

3.2. Development of Cavitation Generator Mimicking Pistol Shrimp

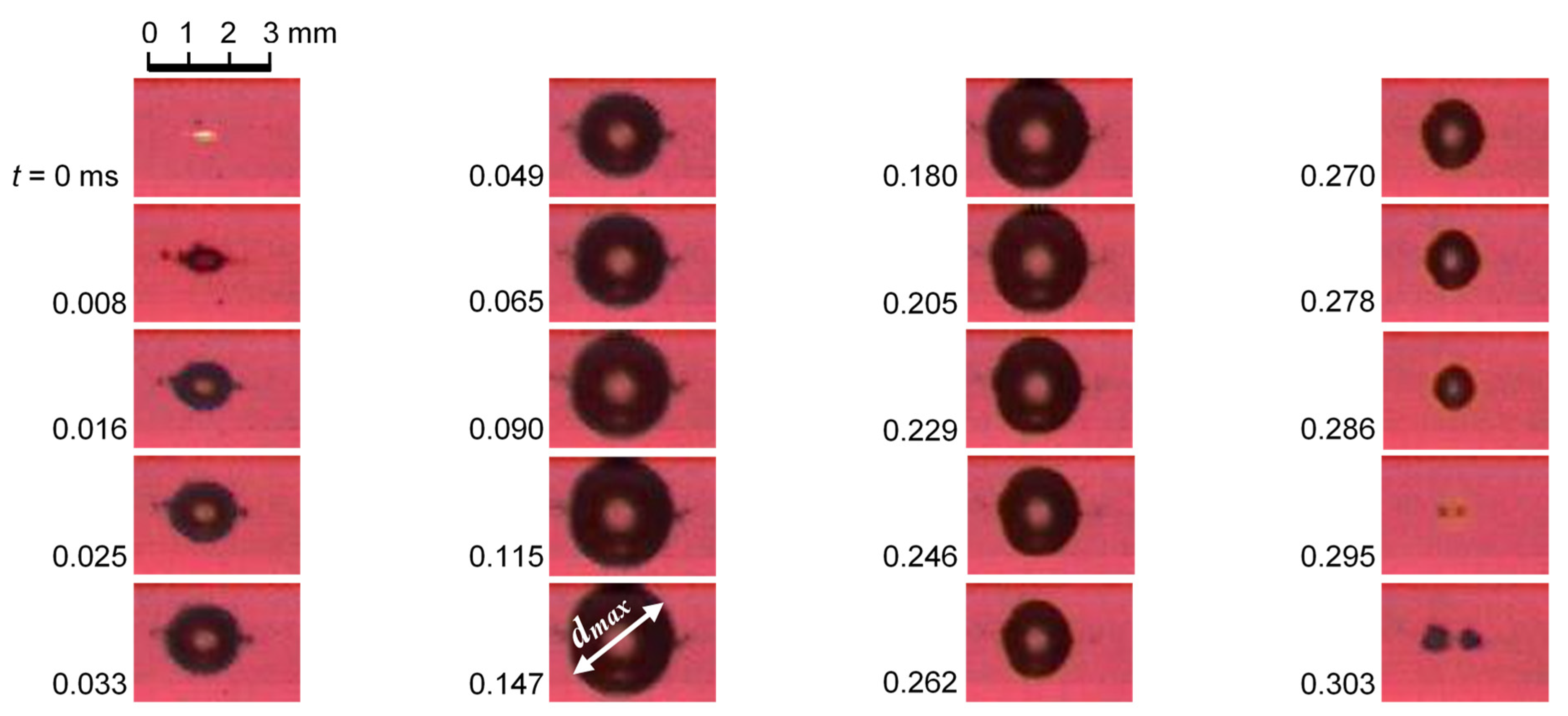

3.2.1. Cavitation Generator Using Pulsed Laser

3.2.2. A Cavitation Generator Using a Piezo Actuator

4. Conclusions

- Pistol shrimp create a cavitation bubble by producing a pulsed water jet, which is generated by the closing of their claws. With respect to the sample pistol shrimp, the volume of the concavo-convex mating area that was required to generate the pulse jet was about 0.35 mm3.

- The size of the cavitation bubble, which was estimated by monitoring the noise, was about 3 mm in diameter, and the volume was 30 times larger than that of the pulsed water jet.

- The required speed for the pulsed water jet to create a cavitation bubble was found to be about 10 m/s.

- The aggressive intensity of the cavitation collapse caused by the pistol shrimp was larger than that of the pulsed laser, even when at an equivalent cavitation volume. This is due to the cushion effect of the pistol shrimp being lesser than that of the pulsed laser.

- A pulsed laser can generate a pulsed water jet, which can thus create cavitations.

- The cavitation generator was realized by using a piezo actuator, which was designed to mimic the mechanism of a pistol shrimp. The ring vortex cavitation around the pulsed water jet was also observed.

- If the cavitation generator using the piezo actuator generate cavitation bubbles that are three mm in diameter, it would be applicable for cavitation peening.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Brennen, C.E. Cavitation and Bubble Dynamics; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Knapp, R.T.; Daily, J.W.; Hammitt, F.G. Cavitation; McGraw-Hill: New York, NY, USA, 1970. [Google Scholar]

- ASTM G32 (2021); Standard Test Method for Cavitation Erosion Using Vibratory Apparatus. ASTM Standard: West Conshohocken, PA, USA, 2023; Volume 03.20, pp. 1–20.

- ASTM G134 (2023); Standard Test Method for Erosion of Solid Materials by a Cavitating Liquid Jet. ASTM Standard: West Conshohocken, PA, USA, 2023; Volume 03.02, pp. 1–17.

- Soyama, H.; Korsunsky, A.M. A critical comparative review of cavitation peening and other surface peening methods. J. Mater. Process. Technol. 2022, 305, 117586. [Google Scholar] [CrossRef]

- Delosrios, E.R.; Walley, A.; Milan, M.T.; Hammersley, G. Fatigue-crack initiation and propagation on shot-peened surfaces in A316 stainless-steel. Int. J. Fatigue 1995, 17, 493–499. [Google Scholar] [CrossRef]

- Wang, S.P.; Li, Y.J.; Yao, M.; Wang, R.Z. Compressive residual stress introduced by shot peening. J. Mater. Process. Technol. 1998, 73, 64–73. [Google Scholar] [CrossRef]

- Wagner, L. Mechanical surface treatments on titanium, aluminum and magnesium alloys. Mater. Sci. Eng. A 1999, 263, 210–216. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- McClung, R.C. A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 173–205. [Google Scholar] [CrossRef]

- Harada, Y.; Fukauara, K.; Kohamada, S. Effects of microshot peening on surface characteristics of high-speed tool steel. J. Mater. Process. Technol. 2008, 201, 319–324. [Google Scholar] [CrossRef]

- John, M.; Kalvala, P.R.; Misra, M.; Menezes, P.L. Peening techniques for surface modification: Processes, properties, and applications. Materials 2021, 14, 3841. [Google Scholar] [CrossRef]

- Kikuchi, S.; Minamizawa, K.; Arakawa, J.; Akebono, H.; Takesue, S.; Hayakawa, M. Combined effect of surface morphology and residual stress induced by fine particle and shot peening on the fatigue limit for carburized steels. Int. J. Fatigue 2023, 168, 107441. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue behavior of a low-alloy steel with nanostructured surface obtained by severe shot peening. Eng. Fract. Mech. 2012, 81, 56–68. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured alsi10mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Bag, A.; Delbergue, D.; Ajaja, J.; Bocher, P.; Levesque, M.; Brochu, M. Effect of different shot peening conditions on the fatigue life of 300 M steel submitted to high stress amplitudes. Int. J. Fatigue 2020, 130, 12. [Google Scholar] [CrossRef]

- Kumar, C.S.; Chattopadhyay, K.; Singh, V.; Mahobia, G.S. Enhancement of low-cycle fatigue life of high-nitrogen austenitic stainless steel at low strain amplitude through ultrasonic shot peening. Mater. Today Commun. 2020, 25, 101576. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Miao, H.Y.; Demers, D.; Larose, S.; Perron, C.; Levesque, M. Experimental study of shot peening and stress peen forming. J. Mater. Process. Technol. 2010, 210, 2089–2102. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. Numerical and experimental analysis of surface roughness generated by shot peening. Appl. Surf. Sci. 2012, 258, 6831–6840. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Zhou, J.; Retraint, D.; Sun, Z.; Kanoute, P. Comparative study of the effects of surface mechanical attrition treatment and conventional shot peening on low cycle fatigue of a 316L stainless steel. Surf. Coat. Technol. 2018, 349, 556–566. [Google Scholar] [CrossRef]

- Soyama, H.; Chighizola, C.R.; Hill, M.R. Effect of compressive residual stress introduced by cavitation peening and shot peening on the improvement of fatigue strength of stainless steel. J. Mater. Process. Technol. 2021, 288, 116877. [Google Scholar] [CrossRef]

- Langdon, G.S.; Schleyer, G.K. Unusual strain rate sensitive behaviour of aisi 316L austenitic stainless steel. J. Strain Anal. Eng. Des. 2004, 39, 71–86. [Google Scholar] [CrossRef]

- Clarke, K.D.; Comstock, R.J.; Mataya, M.C.; van Tyne, C.J.; Matlock, D.K. Effect of strain rate on the yield stress of ferritic stainless steels. Metall. Mater. Trans. A 2008, 39, 752–762. [Google Scholar] [CrossRef]

- Jiao, Y.F.; Hou, Y.L. Dynamic mechanical properties of austenitic 304L stainless steel with different strain rates. Funct. Mater. 2020, 27, 93–99. [Google Scholar]

- Husain, A.; La, P.; Hongzheng, Y.; Jie, S. Molecular dynamics as a means to investigate grain size and strain rate effect on plastic deformation of 316 L nanocrystalline stainless-steel. Materials 2020, 13, 3223. [Google Scholar] [CrossRef] [PubMed]

- Soyama, H. Cavitating jet: A review. Appl. Sci. 2020, 10, 7280. [Google Scholar] [CrossRef]

- Soyama, H. Luminescence intensity of vortex cavitation in a venturi tube changing with cavitation number. Ultrason. Sonochem. 2021, 71, 105389. [Google Scholar] [CrossRef]

- Soyama, H.; Liang, X.; Yashiro, W.; Kajiwara, K.; Asimakopoulou, E.M.; Bellucci, V.; Birnsteinova, S.; Giovanetti, G.; Kim, C.; Kirkwood, H.J.; et al. Revealing the origins of vortex cavitation in a venturi tube by high speed X-ray imaging. Ultrason. Sonochem. 2023, 101, 106715. [Google Scholar] [CrossRef]

- Kawanami, Y.; Kato, H.; Yamaguchi, H.; Maeda, M.; Nakasumi, S. Inner structure of cloud cavity on a foil section. JSME Int. J. Ser. B 2002, 45, 655–661. [Google Scholar] [CrossRef]

- Dular, M.; Petkovšek, M. On the mechanisms of cavitation erosion—Coupling high speed videos to damage patterns. Exp. Therm. Fluid Sci. 2015, 68, 359–370. [Google Scholar] [CrossRef]

- Soyama, H.; Iga, Y. Laser cavitation peening: A review. Appl. Sci. 2023, 13, 6702. [Google Scholar] [CrossRef]

- Soyama, H. Laser cavitation peening and its application for improving the fatigue strength of welded parts. Metals 2021, 11, 531. [Google Scholar] [CrossRef]

- Gu, J.Y.; Luo, C.H.; Ma, P.C.A.; Xu, X.C.; Wu, Y.; Ren, X.D. Study on processing and strengthening mechanisms of mild steel subjected to laser cavitation peening. Appl. Surf. Sci. 2021, 562, 13. [Google Scholar] [CrossRef]

- Soyama, H.; Kuji, C.; Liao, Y. Comparison of the effects of submerged laser peening, cavitation peening and shot peening on the improvement of the fatigue strength of magnesium alloy AZ31. J. Magnes. Alloys 2023, 11, 1592–1607. [Google Scholar] [CrossRef]

- Soyama, H.; Takeo, F. Effect of various peening methods on the fatigue properties of titanium alloy Ti6Al4V manufactured by direct metal laser sintering and electron beam melting. Materials 2020, 13, 2216. [Google Scholar] [CrossRef] [PubMed]

- Soyama, H.; Kuji, C. Improving effects of cavitation peening, using a pulsed laser or a cavitating jet, and shot peening on the fatigue properties of additively manufactured titanium alloy Ti6Al4V. Surf. Coat. Technol. 2022, 451, 129047. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H.P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-T7351 aluminum alloy joints. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Telang, A.; Gnaupel-Herold, T.; Gill, A.; Vasudevan, V.K. Effect of applied stress and temperature on residual stresses induced by peening surface treatments in alloy 600. J. Mater. Eng. Perform. 2018, 27, 2796–2804. [Google Scholar] [CrossRef]

- Mao, B.; Liao, Y.L.; Li, L. Abnormal twin-twin interaction in an Mg-3Al-1Zn magnesium alloy processed by laser shock peening. Scr. Mater. 2019, 165, 89–93. [Google Scholar] [CrossRef]

- Yang, F.; Liu, P.; Zhou, L.; He, W.; Pan, X.; An, Z. Review on anti-fatigue performance of gradient microstructures in metallic components by laser shock peening. Metals 2023, 13, 979. [Google Scholar] [CrossRef]

- Li, Y.; Geng, J.; Wang, Z.; Shao, Z.; Zhang, C.; Chen, D.; Wang, H. Thermal evolutions of residual stress and strain hardening of GH4169 Ni-based superalloy treated by laser shock peening. Surf. Coat. Technol. 2023, 467, 129690. [Google Scholar] [CrossRef]

- Ye, Y.; Zhang, Y.; Huang, T.; Zou, S.; Dong, Y.; Ding, H.; Vasudevan, V.K.; Ye, C. A critical review of laser shock peening of aircraft engine components. Adv. Eng. Mater. 2023, 25, 2201451. [Google Scholar] [CrossRef]

- Sano, Y.; Obata, M.; Kubo, T.; Mukai, N.; Yoda, M.; Masaki, K.; Ochi, Y. Retardation of crack initiation and growth in austenitic stainless steels by laser peening without protective coating. Mater. Sci. Eng. A 2006, 417, 334–340. [Google Scholar] [CrossRef]

- Yoda, M.; Chida, I.; Okada, S.; Ochiai, M.; Sano, Y.; Mukai, N.; Komotori, G.; Saeki, R.; Takagi, T.; Sugihara, M.; et al. Development and application of laser peening system for pwr power plants. In Proceedings of the 14th International Conference on Nuclear Engineering, Miami, FL, USA, 17–20 July 2006; pp. 419–424. [Google Scholar]

- Sano, Y. Quarter century development of laser peening without coating. Metals 2020, 10, 152. [Google Scholar] [CrossRef]

- Sano, Y.; Akita, K.; Sano, T. A mechanism for inducing compressive residual stresses on a surface by laser peening without coating. Metals 2020, 10, 816. [Google Scholar] [CrossRef]

- Kaufman, J.; Špirit, Z.; Vasudevan, V.K.; Steiner, M.A.; Mannava, S.R.; Brajer, J.; Pína, L.; Mocek, T. Effect of laser shock peening parameters on residual stresses and corrosion fatigue of AA5083. Metals 2021, 11, 1635. [Google Scholar] [CrossRef]

- Sasoh, A.; Watanabe, K.; Sano, Y.; Mukai, N. Behavior of bubbles induced by the interaction of a laser pulse with a metal plate in water. Appl. Phys. A 2005, 80, 1497–1500. [Google Scholar] [CrossRef]

- Sano, Y.; Kato, T.; Mizuta, Y.; Tamaki, S.; Yokofujita, K.; Taira, T.; Hosokai, T.; Sakino, Y. Development of a portable laser peening device and its effect on the fatigue properties of HT780 butt-welded joints. Forces Mech. 2022, 7, 100080. [Google Scholar] [CrossRef]

- Soyama, H. Development of laser cavitation peening using a normal-oscillation Nd:YAG laser. Coatings 2023, 13, 1395. [Google Scholar] [CrossRef]

- Takahashi, N.; Kugimiya, T.; Seki, T.; Terao, K.; Kunoh, T.; Mizuno, M. Application of ultrasonic cavitation to metal working and surface-treatment of mild-steel. JSME Int. J. 1987, 30, 1229–1236. [Google Scholar] [CrossRef]

- Rawers, J.C.; McCune, R.A.; Dunning, J.S. Ultrasound treatment of centrifugally atomized 316 stainless steel powders. Metall. Trans. A 1991, 22A, 3025–3033. [Google Scholar] [CrossRef]

- Nakagawa, M.; Watanabe, T. Introducing compressive residual stress on metal surfaces by irradiating ultrasonic wave with a horn in water: Surface modification by irradiating ultrasonic wave in liquid (report 1). Q. J. Jpn. Weld. Soc. 2004, 22, 587–594. [Google Scholar] [CrossRef]

- Toh, C.K. The use of ultrasonic cavitation peening to improve micro-burr-free surfaces. Int. J. Adv. Manuf. Technol. 2007, 31, 688–693. [Google Scholar] [CrossRef]

- Gao, Y.B.; Wu, B.X.; Liu, Z.; Zhou, Y.; Shen, N.G.; Ding, H.T. Ultrasonic cavitation peening of stainless steel and nickel alloy. J. Manuf. Sci. Eng. 2014, 136, 014502. [Google Scholar] [CrossRef]

- Okada, T.; Iwai, Y.; Hattori, S.; Tanimura, N. Relation between impact load and the damage produced by cavitation bubble collapse. Wear 1995, 184, 231–239. [Google Scholar] [CrossRef]

- Versluis, M.; Schmitz, B.; von der Heydt, A.; Lohse, D. How snapping shrimp snap: Through cavitating bubbles. Science 2000, 289, 2114–2117. [Google Scholar] [CrossRef] [PubMed]

- Lohse, D.; Schmitz, B.; Versluis, M. Snapping shrimp make flashing bubbles. Nature 2001, 413, 477–478. [Google Scholar] [CrossRef] [PubMed]

- Lillis, A.; Perelman, J.N.; Panyi, A.; Aran Mooney, T. Sound production patterns of big-clawed snapping shrimp (Alpheus spp.) are influenced by time-of-day and social context. J. Acoust. Soc. Am. 2017, 142, 3311. [Google Scholar] [CrossRef]

- Yang, Y.; Qin, S.; Di, C.; Qin, J.; Wu, D.; Zhao, J. Research on claw motion characteristics and cavitation bubbles of snapping shrimp. Appl. Bionics Biomech. 2020, 2020, 6585729. [Google Scholar] [CrossRef]

- Larsen, O.N.; Reichmuth, C. Walruses produce intense impulse sounds by clap-induced cavitation during breeding displays. R. Soc. Open Sci. 2021, 8, 210197. [Google Scholar] [CrossRef]

- Song, Z.; Salas, A.K.; Montie, E.W.; Laferriere, A.; Zhang, Y.; Aran Mooney, T. Sound pressure and particle motion components of the snaps produced by two snapping shrimp species (Alpheus heterochaelis and Alpheus angulosus). J. Acoust. Soc. Am. 2021, 150, 3288. [Google Scholar] [CrossRef]

- Kingston, A.C.N.; Woodin, S.A.; Wethey, D.S.; Speiser, D.I. Snapping shrimp have helmets that protect their brains by dampening shock waves. Curr. Biol. 2022, 32, 3576–3583.e3. [Google Scholar] [CrossRef] [PubMed]

- Dinh, J.P.; Patek, S.N. Weapon performance and contest assessment strategies of the cavitating snaps in snapping shrimp. Funct. Ecol. 2022, 37, 327–342. [Google Scholar] [CrossRef]

- Patek, S.N.; Korff, W.L.; Caldwell, R.L. Biomechanics: Deadly strike mechanism of a mantis shrimp—This shrimp packs a punch powerful enough to smash its prey's shell underwater. Nature 2004, 428, 819–820. [Google Scholar] [CrossRef] [PubMed]

- Patek, S.N.; Caldwell, R.L. Extreme impact and cavitation forces of a biological hammer: Strike forces of the peacock mantis shrimp odontodactylus scyllarus. J. Exp. Biol. 2005, 208, 3655–3664. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, X.; Hou, X.; Li, Y.; Meng, Y.; Ma, L.; Tian, Y. Mantis shrimp-inspired underwater striking device generates cavitation. J. Bionic Eng. 2022, 19, 1758–1770. [Google Scholar] [CrossRef]

- Amini, S.; Tadayon, M.; Chua, J.Q.I.; Miserez, A. Multi-scale structural design and biomechanics of the pistol shrimp snapper claw. Acta Biomater. 2018, 73, 449–457. [Google Scholar] [CrossRef] [PubMed]

- Au, W.W.L.; Banks, K. The acoustics of the snapping shrimp synalpheus parneomeris in kaneohe bay. J. Acoust. Soc. Am. 1998, 103, 41–47. [Google Scholar] [CrossRef]

- Herberholz, J.; Schmitz, B. Flow visualisation and high speed video analysis of water jets in the snapping shrimp (Alpheus heterochaelis). J. Comp. Physiol. A 1999, 185, 41–49. [Google Scholar] [CrossRef]

- Anker, A.; Ahyong, S.T.; Noël, P.Y.; Palmer, A.R. Morphological phylogeny of alpheid shrimps: Parallel preadaptation and the origin of a key morphological innovation, the snapping claw. Evolution 2006, 60, 2507–2528. [Google Scholar] [CrossRef]

- Koukouvinis, P.; Bruecker, C.; Gavaises, M. Unveiling the physical mechanism behind pistol shrimp cavitation. Sci. Rep. 2017, 7, 13994. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, C.; Xu, Y.; Heng, J. Structural design and jet-cavitation mechanism of bioinspired snapping-claw apparatus. J. Vib. Eng. Technol. 2021, 10, 649–666. [Google Scholar] [CrossRef]

- Salinas-Vázquez, M.; Godínez, F.A.; Vicente, W.; Guzmán, J.E.V.; Valdés, R.; Palacios-Morales, C.A. Numerical simulation of a flow induced by the high-speed closure of a bioinspired claw. J. Fluids Struct. 2022, 113, 103654. [Google Scholar] [CrossRef]

- Tang, X.; Staack, D. Bioinspired mechanical device generates plasma in water via cavitation. Sci. Adv. 2019, 5, eaau7765. [Google Scholar] [CrossRef]

- Tajima, K.; Yagi, K.; Mori, Y. Development of an impulsive motion generator inspired by cocking slip joint of snapping shrimp. Bioinspiration Biomim. 2023, 18, 066002. [Google Scholar] [CrossRef] [PubMed]

- Rayleigh, L. On the pressure developed in a liquid during the collapse of a spherical cavity. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1917, 34, 94–98. [Google Scholar] [CrossRef]

- Ohl, C.D.; Lindau, O.; Lauterborn, W. Luminescence from spherically and aspherically collapsing laser induced bubbles. Phys. Rev. Lett. 1998, 80, 393–396. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soyama, H.; Tanaka, M.; Takiguchi, T.; Yamamoto, M. Development of a Cavitation Generator Mimicking Pistol Shrimp. Biomimetics 2024, 9, 47. https://doi.org/10.3390/biomimetics9010047

Soyama H, Tanaka M, Takiguchi T, Yamamoto M. Development of a Cavitation Generator Mimicking Pistol Shrimp. Biomimetics. 2024; 9(1):47. https://doi.org/10.3390/biomimetics9010047

Chicago/Turabian StyleSoyama, Hitoshi, Mayu Tanaka, Takashi Takiguchi, and Matsuo Yamamoto. 2024. "Development of a Cavitation Generator Mimicking Pistol Shrimp" Biomimetics 9, no. 1: 47. https://doi.org/10.3390/biomimetics9010047