High-Transmission Biomimetics Structural Surfaces Produced via Ultrafast Laser Manufacturing

Abstract

:1. Introduction

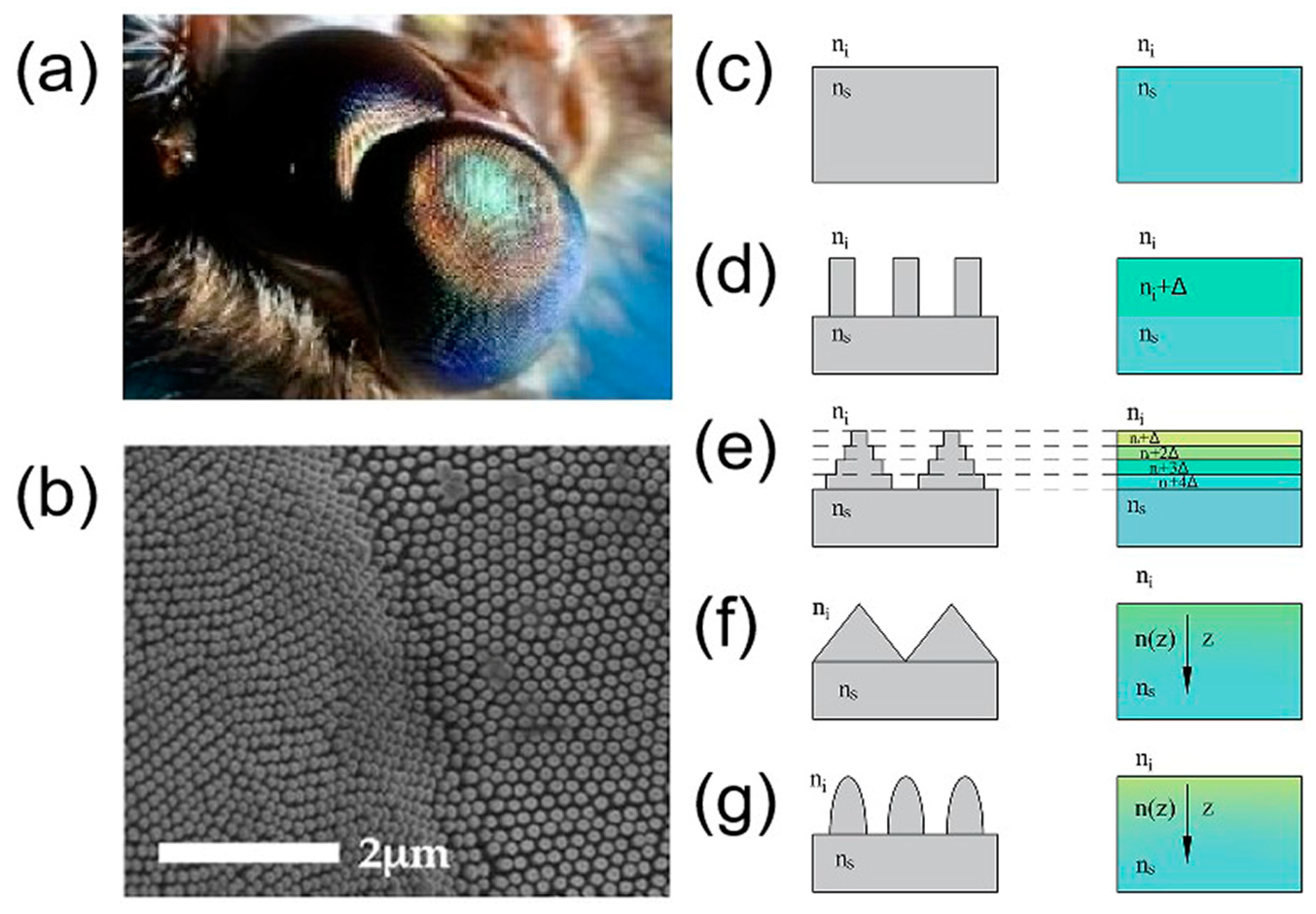

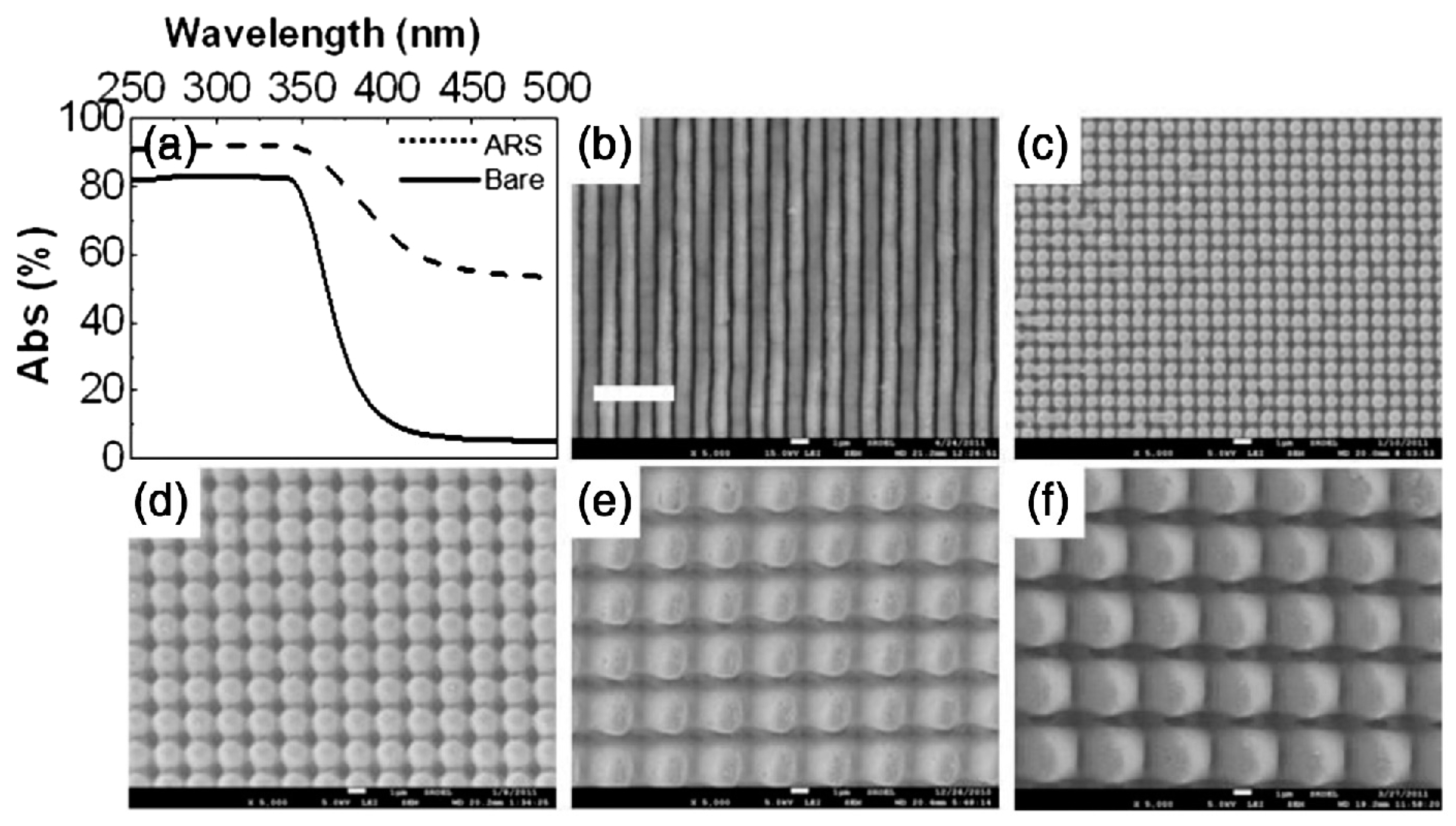

2. Mechanism of Antireflection for High-Transmission Structural Surfaces

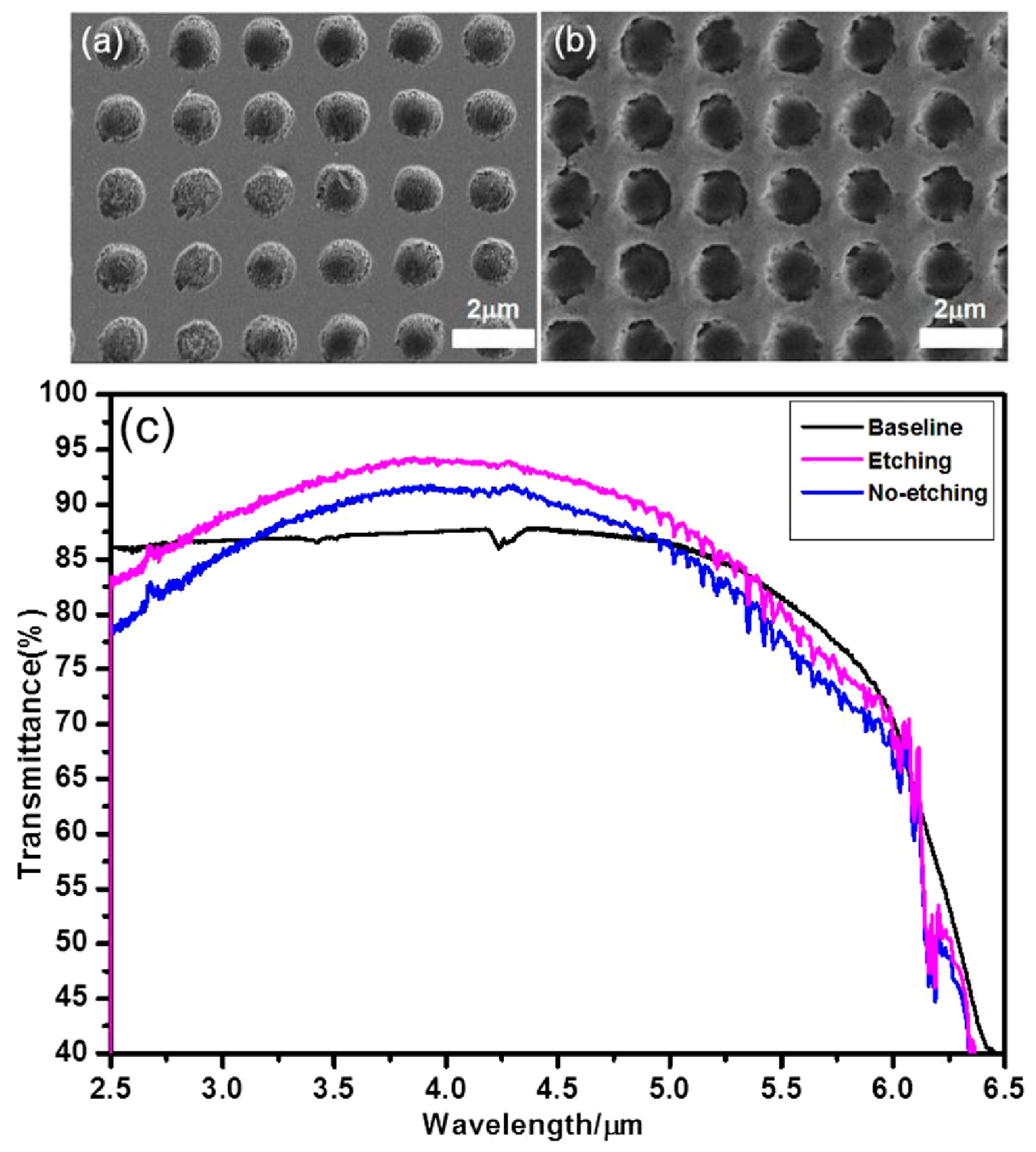

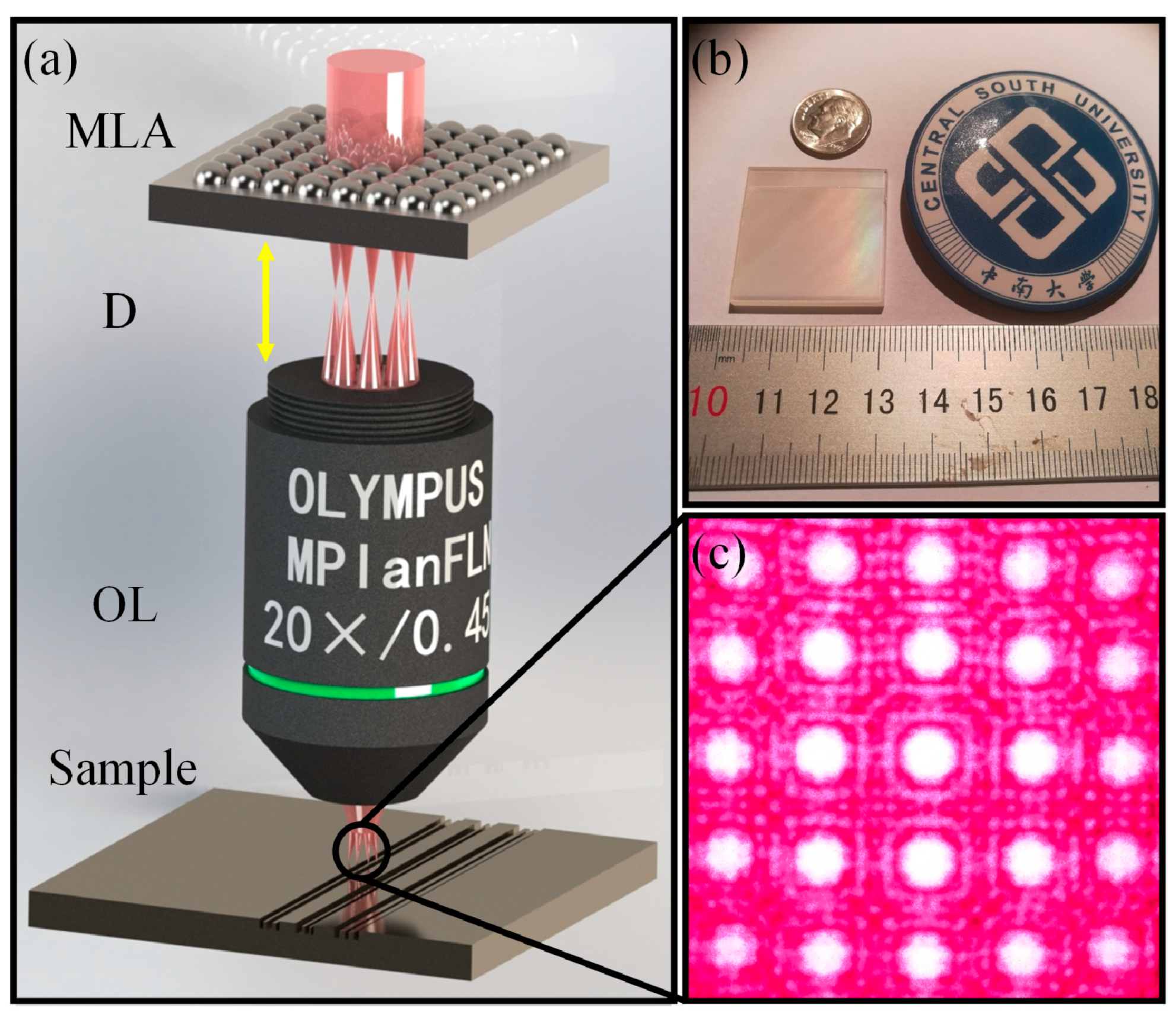

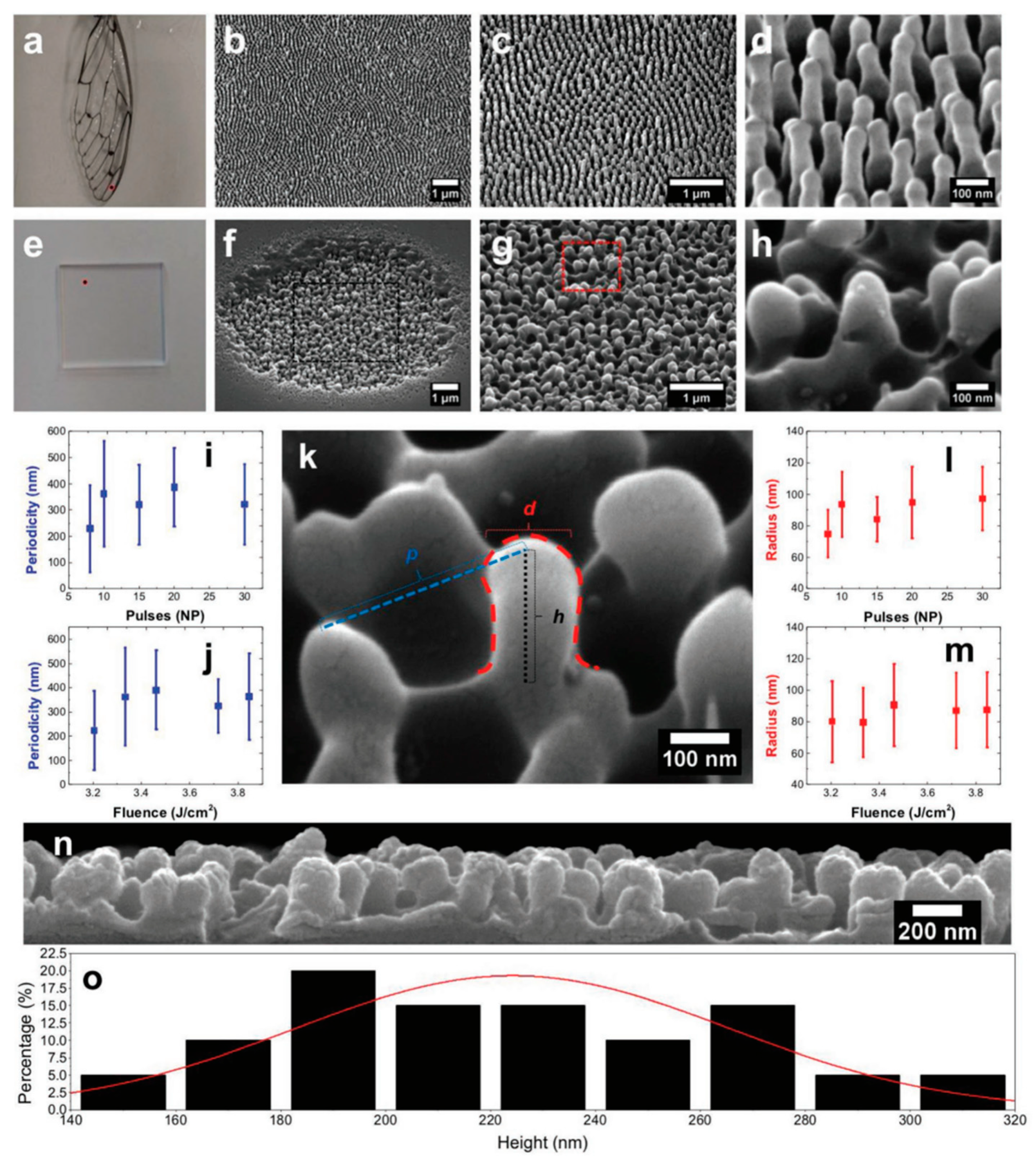

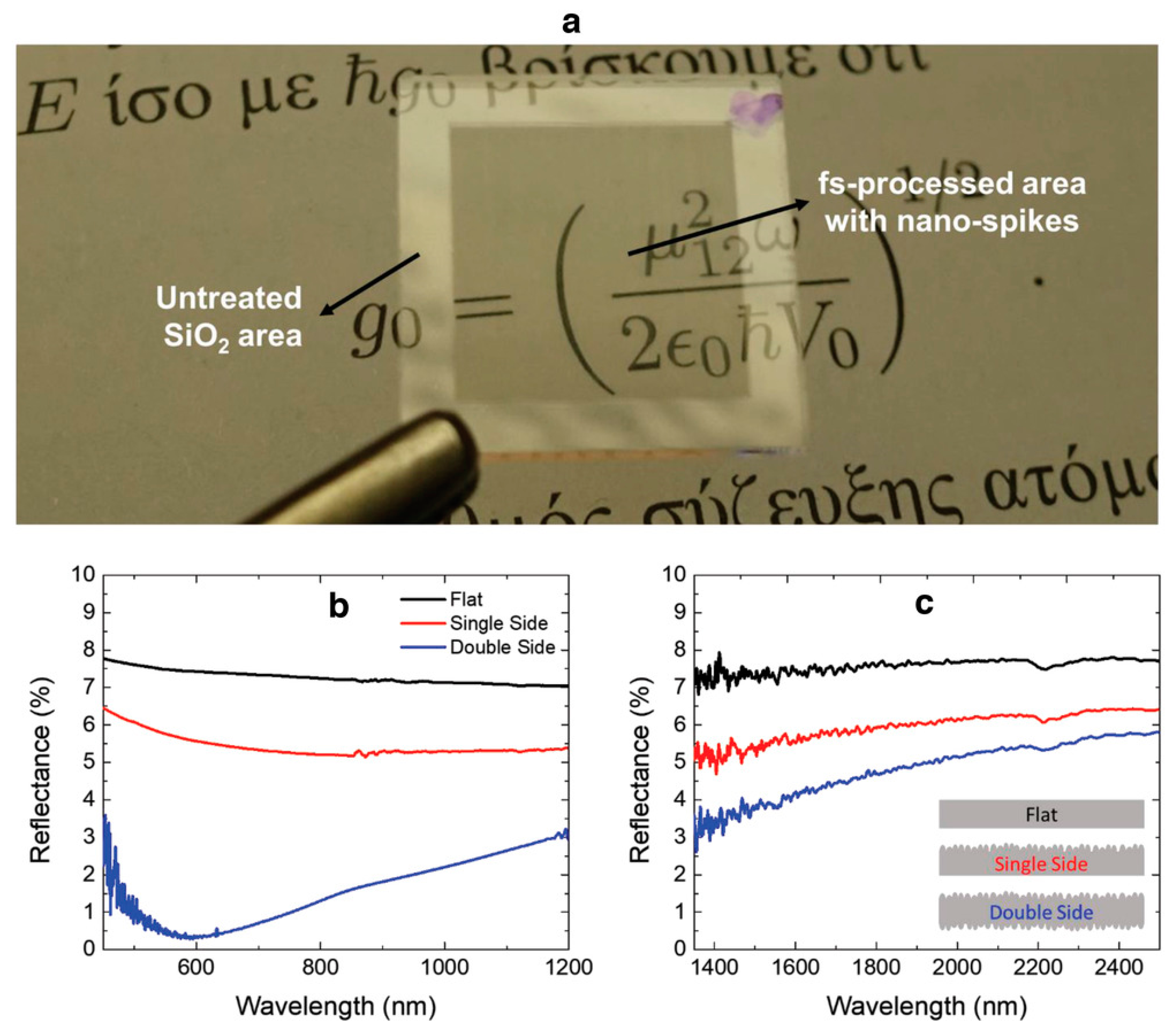

3. Ultrafast Laser Fabrication of ARSS

| Materials | ARSS | Methods | Laser Width | Advantages | Td; Eff | Waveband (μm) |

|---|---|---|---|---|---|---|

| ZnS [72] | Tall sinusoidal pillars | A multiple exposure of the two-beam interference | 10 ns | Maskless, rapid and simple; one-step approach for ARSS | >90% 20% | 4.32–6.85 |

| Sapphire [77] | Inverted cone and pyramid arrays | Femtosecond laser direct writing assisted with wet etching | 120 fs | An inexpensive, maskless and reproducible way to fabricate an ARSS on sapphire | 95% 9% | 3–5 |

| ZnS [82] | Nanogratings embedded in microgratings | Femtosecond laser parallel multibeam ablation | 120 fs | Improved efficiency through the utilization of laser energy in multibeam energy | >76.5% 12% | 4–10 |

| Sapphire [89] | Pyramidal structure array | Inside-out femtosecond laser deep-scribing technology | 290 fs | Effectively avoids uncontrollable damage; high-quality ARSS with an aspect ratio of 80 | 95% 10% | 2.5–6 |

| Fused silica [95] | Arrays of nanopillars | Laser-induced periodic surface structures | 170 fs | Novel single-step and chemical-free technique for ARSS | >99% 8% | 0.5–0.7 |

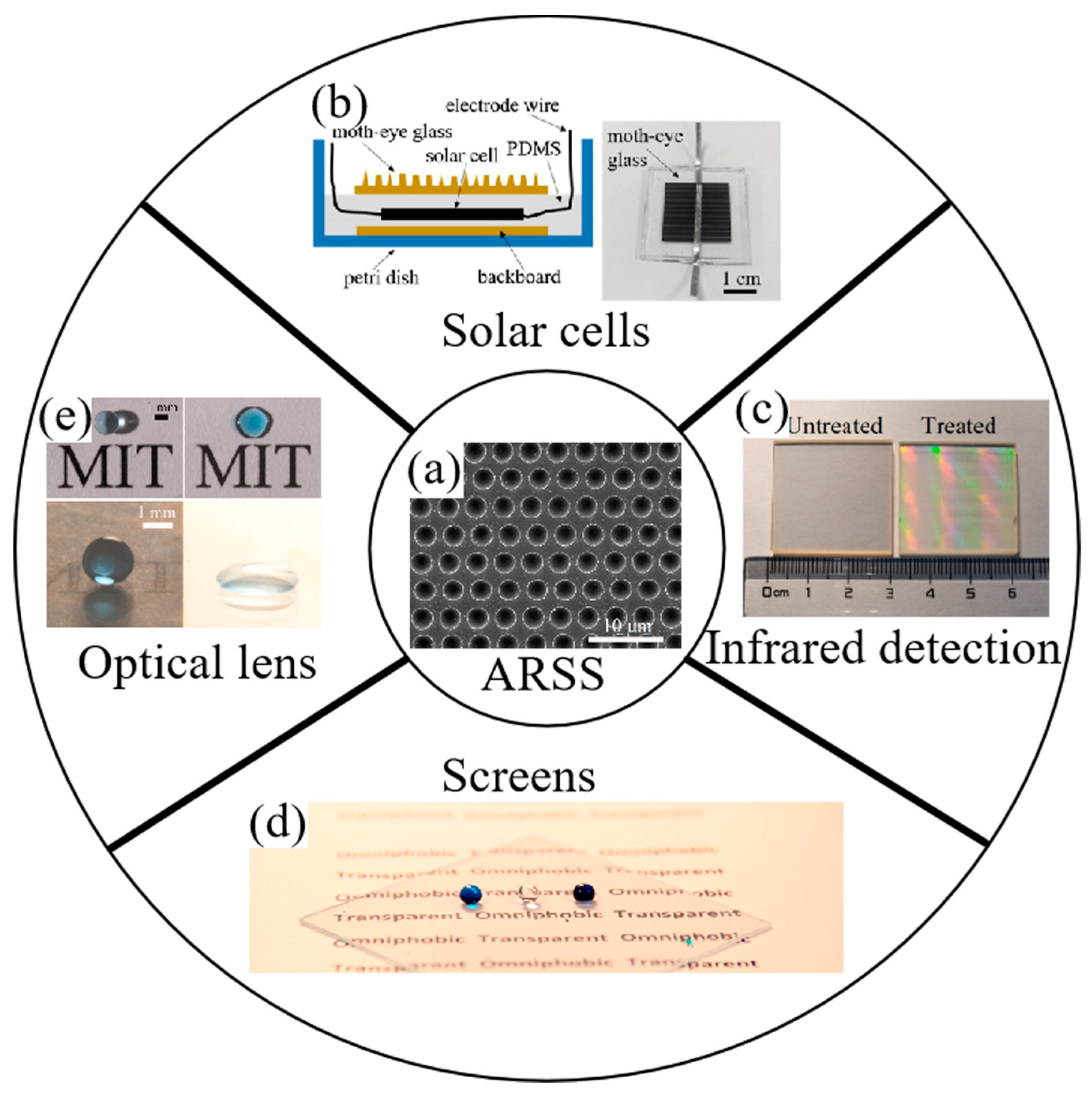

4. Application of ARSSs

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sullivan, T.; O’Callaghan, I. Recent Developments in Biomimetic Antifouling Materials: A Review. Biomimetics 2020, 5, 58. [Google Scholar] [CrossRef]

- Verbrugghe, N.; Rubinacci, E.; Khan, A.Z. Biomimicry in Architecture: A Review of Definitions, Case Studies, and Design Methods. Biomimetics 2023, 8, 107. [Google Scholar] [CrossRef]

- Wang, J.-N.; Shao, R.-Q.; Zhang, Y.-L.; Guo, L.; Jiang, H.-B.; Lu, D.-X.; Sun, H.-B. Biomimetic Graphene Surfaces with Superhydrophobicity and Iridescence. Chem.-Asian J. 2012, 7, 301–304. [Google Scholar] [CrossRef]

- Chan, L.W.; Morse, D.E.; Gordon, M.J. Moth eye-inspired anti-reflective surfaces for improved IR optical systems & visible LEDs fabricated with colloidal lithography and etching. Bioinspir. Biomim. 2018, 13, 041001. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Zhang, Y.L.; Pan, C.; Dou, J.Y.; Li, Z.Z.; Tian, Z.N.; Mao, J.W.; Chen, Q.D.; Sun, H.B. Miniature optoelectronic compound eye camera. Nat. Commun. 2022, 13, 5634. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-L.; Xia, H.; Kim, E.; Sun, H.-B. Recent developments in superhydrophobic surfaces with unique structural and functional properties. Soft Matter 2012, 8, 11217–11231. [Google Scholar] [CrossRef]

- Bonse, J.; Hohm, S.; Kirner, S.V.; Rosenfeld, A.; Kruger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Karlsson, M.; Nikolajeff, F. Diamond micro-optics: Microlenses and antireflection structured surfaces for the infrared spectral region. Opt. Express 2003, 11, 502–507. [Google Scholar] [CrossRef]

- Ma, Z.-C.; Zhang, Y.-L.; Han, B.; Hu, X.-Y.; Li, C.-H.; Chen, Q.-D.; Sun, H.-B. Femtosecond laser programmed artificial musculoskeletal systems. Nat. Commun. 2020, 11, 4536. [Google Scholar] [CrossRef]

- Addie, A.J.; Ismail, R.A.; Mohammed, M.A. Amorphous carbon nitride dual-function anti-reflection coating for crystalline silicon solar cells. Sci. Rep. 2022, 12, 9902. [Google Scholar] [CrossRef]

- Fazio, G.G.; Hora, J.L.; Allen, L.E.; Ashby, M.L.N.; Barmby, P.; Deutsch, L.K.; Huang, J.S.; Kleiner, S.; Marengo, M.; Megeath, S.T.; et al. The Infrared Array Camera (IRAC) for the Spitzer Space Telescope. Astrophys. J. Suppl. Ser. 2004, 154, 10–17. [Google Scholar] [CrossRef]

- Zhu, J.; Christensen, J.; Jung, J.; Martin-Moreno, L.; Yin, X.; Fok, L.; Zhang, X.; Garcia-Vidal, F.J. A holey-structured metamaterial for acoustic deep-subwavelength imaging. Nat. Phys. 2010, 7, 52–55. [Google Scholar] [CrossRef]

- Park, K.-C.; Choi, H.J.; Chang, C.-H.; Cohen, R.E.; McKinley, G.H.; Barbastathis, G. Nanotextured Silica Surfaces with Robust Superhydrophobicity and Omnidirectional Broadband Supertransmissivity. ACS Nano 2012, 6, 3789–3799. [Google Scholar] [CrossRef] [PubMed]

- Rahman, T.; Navarro-Cia, M.; Fobelets, K. High density micro-pyramids with silicon nanowire array for photovoltaic applications. Nanotechnology 2014, 25, 485202. [Google Scholar] [CrossRef]

- Min, W.-L.; Jiang, B.; Jiang, P. Bioinspired Self-Cleaning Antireflection Coatings. Adv. Mater. 2008, 20, 3914–3918. [Google Scholar] [CrossRef]

- Cai, J.; Qi, L. Recent advances in antireflective surfaces based on nanostructure arrays. Mater. Horiz. 2015, 2, 37–53. [Google Scholar] [CrossRef]

- Zhang, X.-L.; Song, J.-F.; Li, X.-B.; Feng, J.; Sun, H.-B. Anti-reflection resonance in distributed Bragg reflectors-based ultrathin highly absorbing dielectric and its application in solar cells. Appl. Phys. Lett. 2013, 102, 103901. [Google Scholar] [CrossRef]

- Kang, S.B.; Kim, J.H.; Jeong, M.H.; Sanger, A.; Kim, C.U.; Kim, C.M.; Choi, K.J. Stretchable and colorless freestanding microwire arrays for transparent solar cells with flexibility. Light Sci. Appl. 2019, 8, 121. [Google Scholar] [CrossRef]

- Fujii, T.; Gao, Y.; Sharma, R.; Hu, E.L.; DenBaars, S.P.; Nakamura, S. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl. Phys. Lett. 2004, 84, 855–857. [Google Scholar] [CrossRef]

- Pynn, C.D.; Chan, L.; Lora Gonzalez, F.; Berry, A.; Hwang, D.; Wu, H.; Margalith, T.; Morse, D.E.; DenBaars, S.P.; Gordon, M.J. Enhanced light extraction from free-standing InGaN/GaN light emitters using bio-inspired backside surface structuring. Opt. Express 2017, 25, 15778–15785. [Google Scholar] [CrossRef]

- Hossain, J.; Mondal, B.K.; Mostaque, S.K.; Ahmed, S.R.A.; Shirai, H. Optimization of multilayer anti-reflection coatings for efficient light management of PEDOT:PSS/c-Si heterojunction solar cells. Mater. Res. Express 2019, 7, 015502. [Google Scholar] [CrossRef]

- Xie, X.; Li, Y.; Wang, G.; Bai, Z.; Yu, Y.; Wang, Y.; Ding, Y.; Lu, Z. Femtosecond Laser Processing Technology for Anti-Reflection Surfaces of Hard Materials. Micromachines 2022, 13, 1084. [Google Scholar] [CrossRef]

- MacLeod, B.D.; Hobbs, D.S. Long life, high performance anti-reflection treatment for HgCdTe infrared focal plane arrays. In Proceedings of the 34th Conference on Infrared Technology and Applications, Orlando, FL, USA, 17–20 March 2008. [Google Scholar]

- Gonzalez, F.L.; Gordon, M.J. Bio-inspired, sub-wavelength surface structures for ultra-broadband, omni-directional anti-reflection in the mid and far IR. Opt. Express 2014, 22, 12808–12816. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Zhang, H.; Zhang, Y.; Peng, R.; Wang, M.; Hao, Y.; Lai, Y. Invisible surfaces enabled by the coalescence of anti-reflection and wavefront controllability in ultrathin metasurfaces. Nat. Commun. 2021, 12, 4523. [Google Scholar] [CrossRef]

- Siddique, R.H.; Gomard, G.; Holscher, H. The role of random nanostructures for the omnidirectional anti-reflection properties of the glasswing butterfly. Nat. Commun. 2015, 6, 6909. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Luo, F.; Kao, T.S.; Li, X.; Ho, G.W.; Teng, J.; Luo, X.; Hong, M. Design and fabrication of broadband ultralow reflectivity black Si surfaces by laser micro/nanoprocessing. Light Sci. Appl. 2014, 3, e185. [Google Scholar] [CrossRef]

- Lohmueller, T.; Helgert, M.; Sundermann, M.; Brunner, R.; Spatz, J.P. Biomimetic interfaces for high-performance optics in the deep-UV light range. Nano Lett. 2008, 8, 1429–1433. [Google Scholar] [CrossRef] [PubMed]

- Shu, Y.; Ye, H.; Chen, J. FDTD analysis of the optical properties of vertical ZnO nanorod array. Sci. China Technol. Sci. 2014, 57, 1147–1153. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Zhu, S.; Dong, H.; Jia, F.; Wang, Z.; Sun, Z.; Zhang, L.; Li, Y.; Li, H.; et al. Biomimetic Surfaces for High-Performance Optics. Adv. Mater. 2009, 21, 4731–4734. [Google Scholar] [CrossRef]

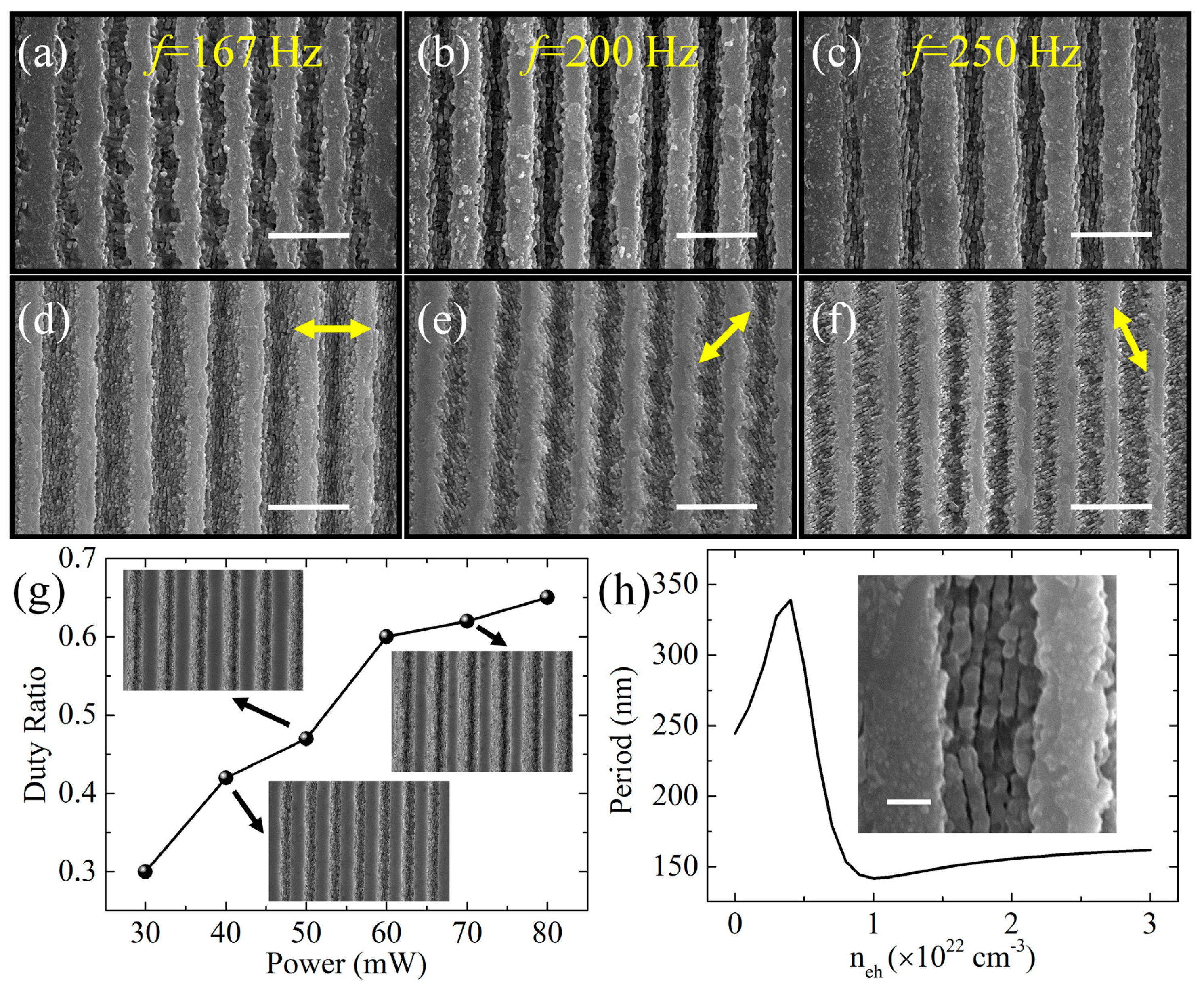

- Huang, L.; Xu, K.; Yuan, D.; Hu, J.; Wang, X.; Xu, S. Sub-wavelength patterned pulse laser lithography for efficient fabrication of large-area metasurfaces. Nat. Commun. 2022, 13, 5823. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Q.D.; Cao, X.W.; Buividas, R.; Wang, X.; Juodkazis, S.; Sun, H.B. Plasmonic nano-printing: Large-area nanoscale energy deposition for efficient surface texturing. Light Sci. Appl. 2017, 6, e17112. [Google Scholar] [CrossRef] [PubMed]

- Kanamori, Y.; Sasaki, M.; Hane, K. Broadband antireflection gratings fabricated upon silicon substrates. Opt. Lett. 1999, 24, 1422–1424. [Google Scholar] [CrossRef] [PubMed]

- Kanamori, Y.; Kikuta, H.; Hane, K. Broadband antireflection gratings for glass substrates fabricated by fast atom beam etching. Jpn. J. Appl. Phys. Part 2-Lett. Express Lett. 2000, 39, L735–L737. [Google Scholar] [CrossRef]

- Ye, X.; Huang, J.; Geng, F.; Liu, H.; Sun, L.; Yan, L.; Jiang, X.; Wu, W.; Zheng, W. High power laser antireflection subwavelength grating on fused silica by colloidal lithography. J. Phys. D-Appl. Phys. 2016, 49, 265104. [Google Scholar] [CrossRef]

- Geng, J.; Yan, W.; Shi, L.; Qiu, M. Surface plasmons interference nanogratings: Wafer-scale laser direct structuring in seconds. Light Sci. Appl. 2022, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Zhao, B.; Cheng, J.; Chamoli, S.K.; Zou, T.; Xin, W.; Yang, J. Super-regular femtosecond laser nanolithography based on dual-interface plasmons coupling. Nanophotonics 2021, 10, 3831–3842. [Google Scholar] [CrossRef]

- Kaless, A.; Schulz, U.; Munzert, P.; Kaiser, N. NANO-motheye antireflection pattern by plasma treatment of polymers. Surf. Coat. Technol. 2005, 200, 58–61. [Google Scholar] [CrossRef]

- Weatherspoon, M.R.; Cai, Y.; Crne, M.; Srinivasarao, M.; Sandhage, K.H. 3D rutile titania-based structures with Morpho butterfly wing scale morphologies. Angew. Chem.-Int. Ed. 2008, 47, 7921–7923. [Google Scholar] [CrossRef]

- Ting, C.-J.; Chen, C.-F.; Chou, C.P. Subwavelength structures for broadband antireflection application. Opt. Commun. 2009, 282, 434–438. [Google Scholar] [CrossRef]

- Ionin, A.A.; Klimachev, Y.M.; Kozlov, A.Y.; Kudryashov, S.I.; Ligachev, A.E.; Makarov, S.V.; Seleznev, L.V.; Sinitsyn, D.V.; Rudenko, A.A.; Khmelnitsky, R.A. Direct femtosecond laser fabrication of antireflective layer on GaAs surface. Appl. Phys. B 2013, 111, 419–423. [Google Scholar] [CrossRef]

- Cao, J.-J.; Li, Q.-K.; Yu, Y.-H.; Yu, Y.-S. Antireflection Microstructured Surface on ZnSe for Mid-infrared Spectral Region. J. Laser Micro Nanoeng. 2019, 14, 120–123. [Google Scholar] [CrossRef]

- Yelisseyev, A.; Fedyaj, V.; Simonov, V.; Isaenko, L.; Lobanov, S.; Shklyaev, A.; Simanchuk, A.; Babin, S.; Dostovalov, A. Femtosecond Laser Direct Writing of Antireflection Microstructures on the Front and Back Sides of a GaSe Crystal. Photonics 2022, 9, 774. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Liu, H.; Guo, Y. Fabrication of an Anti-Reflective Microstructure on ZnS by Femtosecond Laser Bessel Beams. Molecules 2021, 26, 4278. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Q.; Bai, B.-F.; Chen, Q.-D.; Sun, H.-B. Etching-assisted femtosecond laser modification of hard materials. Opto-Electron. Adv. 2019, 2, 19002101–19002114. [Google Scholar] [CrossRef]

- Hoerstmann-Jungemann, M.; Gottmann, J.; Keggenhoff, M. 3D-Microstructuring of Sapphire using fs-Laser Irradiation and Selective Etching. J. Laser Micro Nanoeng. 2010, 5, 145–149. [Google Scholar] [CrossRef]

- He, F.; Liao, Y.; Lin, J.; Song, J.; Qiao, L.; Cheng, Y.; Sugioka, K. Femtosecond laser fabrication of monolithically integrated microfluidic sensors in glass. Sensors 2014, 14, 19402–19440. [Google Scholar] [CrossRef] [PubMed]

- Muller, F.A.; Kunz, C.; Graf, S. Bio-Inspired Functional Surfaces Based on Laser-Induced Periodic Surface Structures. Materials 2016, 9, 476. [Google Scholar] [CrossRef]

- Farias, N.; Beckman, S.; Lee, A.T.; Suzuki, A. Simulated Performance of Laser-Machined Metamaterial Anti-reflection Coatings. J. Low Temp. Phys. 2022, 209, 1232–1241. [Google Scholar] [CrossRef]

- Yu, X.; Yasunaga, Y.; Goto, K.; Liu, D.; Ono, S. Profile control of femtosecond laser-fabricated moth-eye structures on Si substrate. Opt. Lasers Eng. 2021, 142, 106584. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Feng, G.; Zhu, B.; Xiao, S.; Zhou, L.; Zhao, L. Strong infrared absorber: Surface-microstructured Au film replicated from black silicon. Opt. Express 2011, 19, 20462–20467. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-reflecting and photonic nanostructures. Mater. Sci. Eng. R Rep. 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Visser, D.; Chen, D.Y.; Desieres, Y.; Ravishankar, A.P.; Anand, S. Embossed Mie resonator arrays composed of compacted TiO(2) nanoparticles for broadband anti-reflection in solar cells. Sci. Rep. 2020, 10, 12527. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Cong, H.; Huang, W.; Huang, Y.; Chen, L.; Pan, A.; Xue, C. Germanium/perovskite heterostructure for high-performance and broadband photodetector from visible to infrared telecommunication band. Light Sci. Appl. 2019, 8, 106. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.K.; Kumar, D.; Singh, P.K.; Kar, M.; Kumar, V.; Husain, M. Excellent antireflection properties of vertical silicon nanowire arrays. Sol. Energy Mater. Sol. Cells 2010, 94, 1506–1511. [Google Scholar] [CrossRef]

- Garnett, E.; Yang, P. Light trapping in silicon nanowire solar cells. Nano Lett. 2010, 10, 1082–1087. [Google Scholar] [CrossRef]

- Luo, X. Principles of electromagnetic waves in metasurfaces. Sci. China Phys. Mech. Astron. 2015, 58, 594201. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Z.; Liu, G.; Pan, P.; Liu, X.; Tang, C.; Liu, Z.; Wang, J. Ultra-broadband solar absorbers for high-efficiency thermophotovoltaics. Opt. Express 2020, 28, 36476–36486. [Google Scholar] [CrossRef]

- Zhan, X.; Xu, H.; Li, C.; Zang, H.; Liu, C.; Zhao, J.; Sun, H. Remote and rapid micromachining of broadband low-reflectivity black silicon surfaces by femtosecond laser filaments. Opt. Lett. 2017, 42, 510–513. [Google Scholar] [CrossRef]

- Fan, P.; Zhong, M.; Bai, B.; Jin, G.; Zhang, H. Tuning the optical reflection property of metal surfaces via micro–nano particle structures fabricated by ultrafast laser. Appl. Surf. Sci. 2015, 359, 7–13. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Antireflection effect of femtosecond laser-induced periodic surface structures on silicon. Opt. Express 2011, 19, A1031–A1036. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct creation of black silicon using femtosecond laser pulses. Appl. Surf. Sci. 2011, 257, 7291–7294. [Google Scholar] [CrossRef]

- Du, M.; Sun, Q.; Jiao, W.; Shen, L.; Chen, X.; Xiao, J.; Xu, J. Fabrication of Antireflection Micro/Nanostructures on the Surface of Aluminum Alloy by Femtosecond Laser. Micromachines 2021, 12, 1406. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Park, Q.H. Perfect anti-reflection from first principles. Sci. Rep. 2013, 3, 1062. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Wang, X.; Wu, J.; Jiang, C.; Shen, J.; Cooper, M.A.; Zheng, X.; Liu, Y.; Yang, Z.; Wu, D. Biomimetic Moth-eye Nanofabrication: Enhanced Antireflection with Superior Self-cleaning Characteristic. Sci. Rep. 2018, 8, 5438. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Jiao, Z.; Niu, S.; Ren, L. Ascendant bioinspired antireflective materials: Opportunities and challenges coexist. Prog. Mater. Sci. 2019, 103, 1–68. [Google Scholar] [CrossRef]

- Raguin, D.H.; Morris, G.M. Antireflection structured surfaces for the infrared spectral region. Appl. Opt. 1993, 32, 1154–1167. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, F.; Yin, K.; Duan, J.A. Bioinspired antireflective subwavelength nanostructures induced by femtosecond laser for high transparency glass. J. Non-Cryst. Solids 2023, 600, 122016. [Google Scholar] [CrossRef]

- Lin, Z.-Q.; Wang, G.-G.; Li, L.-H.; Wang, H.; Tian, J.-L.; Zhang, H.-Y.; Han, J.-C. Preparation and protection of ZnS surface sub-wavelength structure for infrared window. Appl. Surf. Sci. 2019, 470, 395–404. [Google Scholar] [CrossRef]

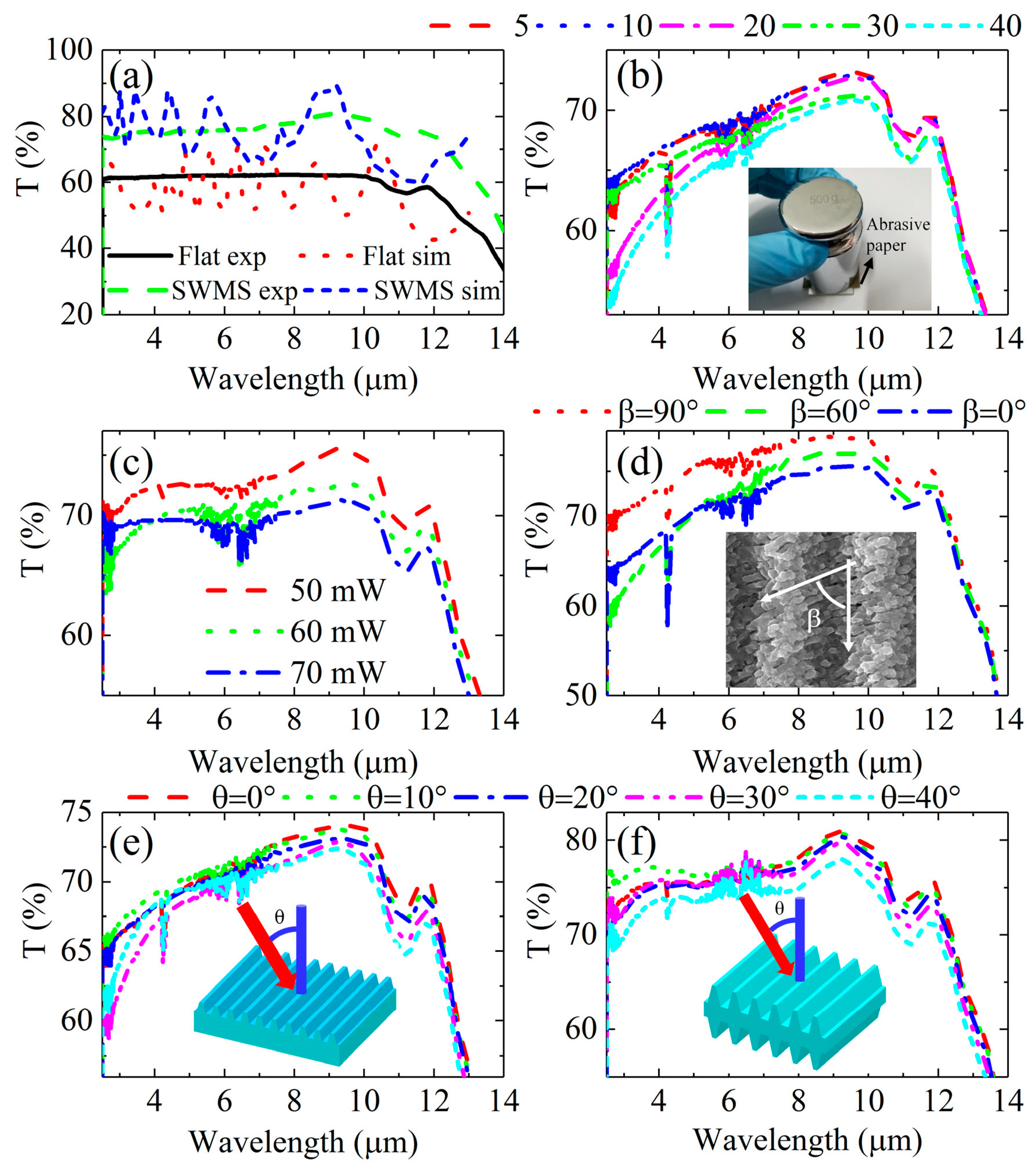

- Wang, H.; Zhang, F.; Wang, C.; Duan, J.A. Broadband antireflective subwavelength structures for infrared detection. Opt. Laser Technol. 2022, 149, 107931. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, F.; Duan, J. Subwavelength Quasi-Periodic Array for Infrared Antireflection. Nanomaterials 2022, 12, 3520. [Google Scholar] [CrossRef]

- Wang, L.; Xu, B.-B.; Chen, Q.-D.; Ma, Z.-C.; Zhang, R.; Liu, Q.-X.; Sun, H.-B. Maskless laser tailoring of conical pillar arrays for antireflective biomimetic surfaces. Opt. Lett. 2011, 36, 3305–3307. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, S.K.; Mazur, E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses. Nat. Mater. 2002, 1, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulk transparent materials induced by tightly focused femtosecond laser pulses. Meas. Sci. Technol. 2001, 12, 1784–1794. [Google Scholar] [CrossRef]

- Chen, J.; Lu, X.; Wen, Q.; Jiang, F.; Lu, J.; Lei, D.; Pan, Y. Review on laser-induced etching processing technology for transparent hard and brittle materials. Int. J. Adv. Manuf. Technol. 2021, 117, 2545–2564. [Google Scholar] [CrossRef]

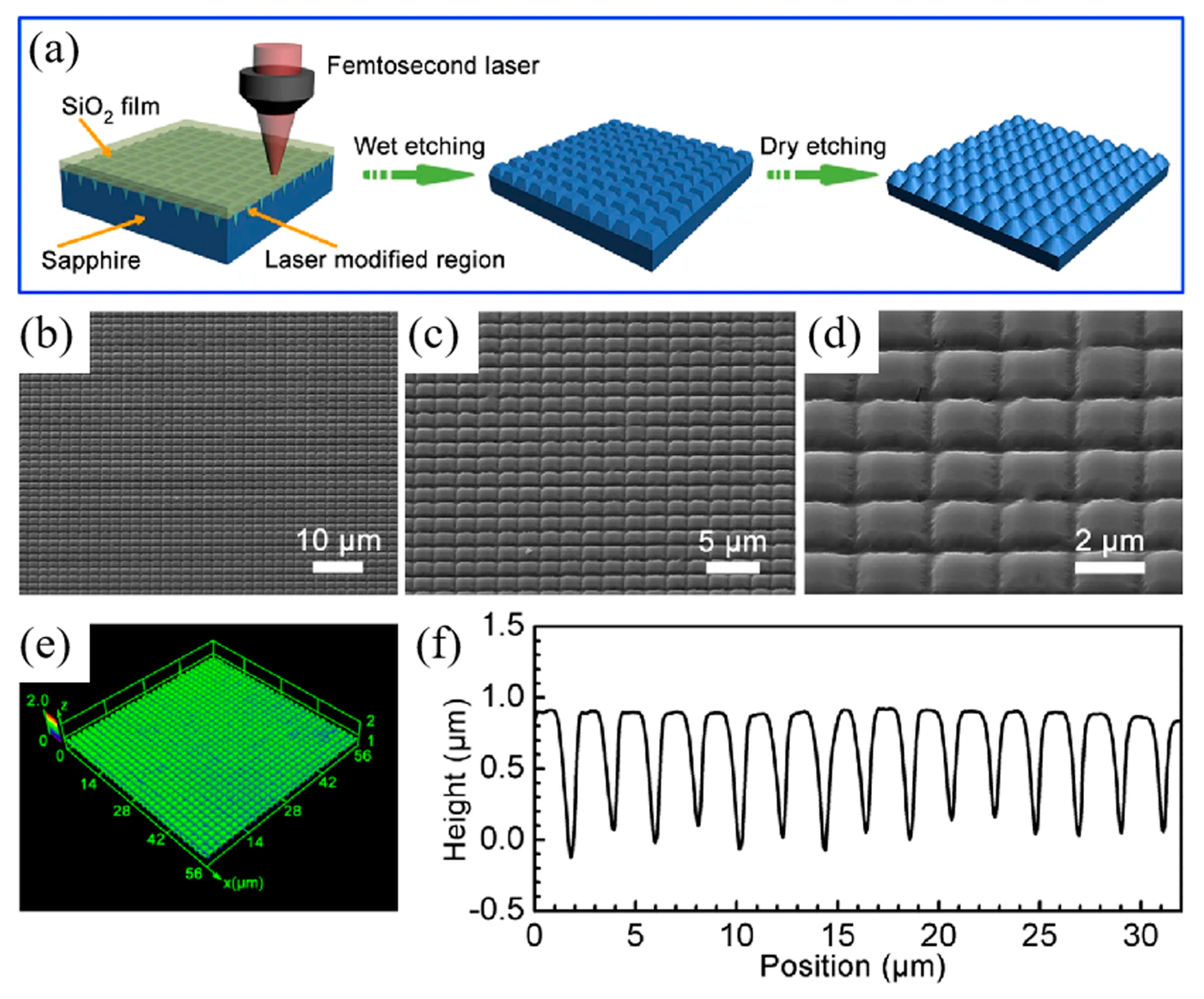

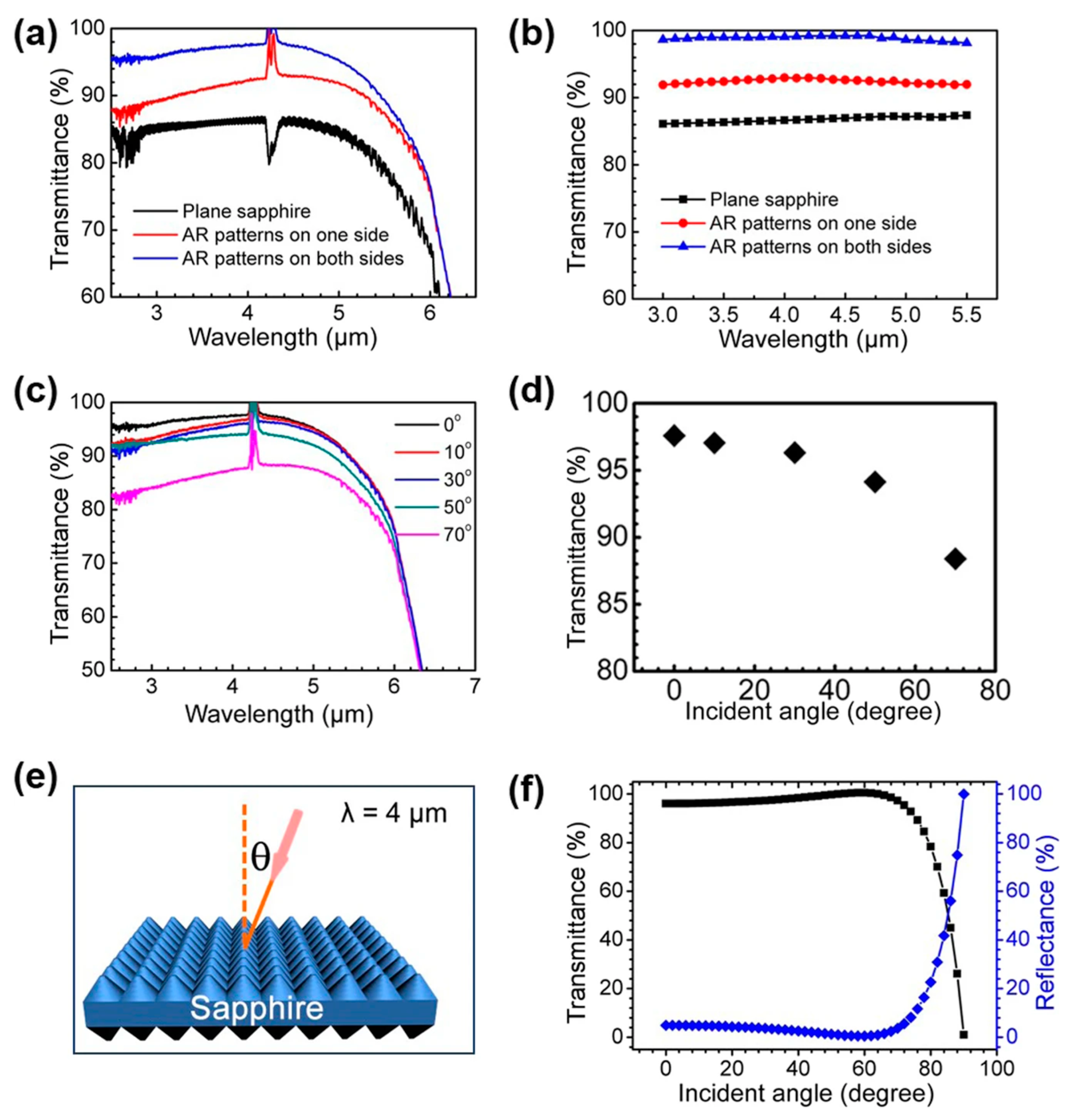

- Li, Q.K.; Cao, J.J.; Yu, Y.H.; Wang, L.; Sun, Y.L.; Chen, Q.D.; Sun, H.B. Fabrication of an anti-reflective microstructure on sapphire by femtosecond laser direct writing. Opt. Lett. 2017, 42, 543–546. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, Y.; Lin, W.; Hong, M. High-aspect-ratio crack-free microstructures fabrication on sapphire by femtosecond laser ablation. Opt. Laser Technol. 2020, 132, 106472. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, H.-B.; Shao, R.-Q.; Zhang, Y.-L.; Xie, S.-Y.; Wang, J.-N.; Li, X.-B.; Jiang, F.; Chen, Q.-D.; Zhang, T.; et al. Two-beam-laser interference mediated reduction, patterning and nanostructuring of graphene oxide for the production of a flexible humidity sensing device. Carbon 2012, 50, 1667–1673. [Google Scholar] [CrossRef]

- Zou, T.; Zhao, B.; Xin, W.; Wang, Y.; Wang, B.; Zheng, X.; Xie, H.; Zhang, Z.; Yang, J.; Guo, C.L. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse. Light Sci. Appl. 2020, 9, 69. [Google Scholar] [CrossRef]

- Pan, A.; Si, J.; Chen, T.; Li, C.; Hou, X. Fabrication of two-dimensional periodic structures on silicon after scanning irradiation with femtosecond laser multi-beams. Appl. Surf. Sci. 2016, 368, 443–448. [Google Scholar] [CrossRef]

- Zhang, F.; Duan, J.; Zhou, X.; Wang, C. Broadband and wide-angle antireflective subwavelength microstructures on zinc sulfide fabricated by femtosecond laser parallel multi-beam. Opt. Express 2018, 26, 34016–34030. [Google Scholar] [CrossRef]

- Chen, T.; Wang, W.; Tao, T.; Pan, A.; Mei, X. Multi-scale micro-nano structures prepared by laser cleaning assisted laser ablation for broadband ultralow reflectivity silicon surfaces in ambient air. Appl. Surf. Sci. 2020, 509, 145182. [Google Scholar] [CrossRef]

- Li, Z.Z.; Wang, L.; Fan, H.; Yu, Y.H.; Sun, H.B.; Juodkazis, S.; Chen, Q.D. O-FIB: Far-field-induced near-field breakdown for direct nanowriting in an atmospheric environment. Light Sci. Appl. 2020, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Balage, P.; Lopez, J.; Bonamis, G.; Hönninger, C.; Manek-Hönninger, I. Crack-free high-aspect ratio holes in glasses by top–down percussion drilling with infrared femtosecond laser GHz-bursts. Int. J. Extrem. Manuf. 2022, 5, 015002. [Google Scholar] [CrossRef]

- Bellouard, Y.; Said, A.; Dugan, M.; Bado, P. Fabrication of high-aspect ratio, micro-fluidic channels and tunnels using femtosecond laser pulses and chemical etching. Opt. Express 2004, 12, 2120–2129. [Google Scholar] [CrossRef] [PubMed]

- Tokel, O.; Turnali, A.; Makey, G.; Elahi, P.; Colakoglu, T.; Ergecen, E.; Yavuz, O.; Hubner, R.; Borra, M.Z.; Pavlov, I.; et al. In-chip microstructures and photonic devices fabricated by nonlinear laser lithography deep inside silicon. Nat. Photonics 2017, 11, 639–645. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.W.; Chen, Q.D.; Fan, H.; Zhang, L.; Juodkazis, S.; Sun, H.B. Liquid-Assisted Femtosecond Laser Precision-Machining of Silica. Nanomaterials 2018, 8, 287. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Q.; Zhang, Y.-L.; Li, Q.-K.; Zheng, J.-X.; Lu, Y.-M.; Juodkazis, S.; Chen, Q.-D.; Sun, H.-B. Biomimetic sapphire windows enabled by inside-out femtosecond laser deep-scribing. PhotoniX 2022, 3, 1. [Google Scholar] [CrossRef]

- Hnatovsky, C.; Taylor, R.S.; Simova, E.; Rajeev, P.P.; Rayner, D.M.; Bhardwaj, V.R.; Corkum, P.B. Fabrication of microchannels in glass using focused femtosecond laser radiation and selective chemical etching. Appl. Phys. A 2006, 84, 47–61. [Google Scholar] [CrossRef]

- Gottmann, J.; Wortmann, D.; Hörstmann-Jungemann, M. Fabrication of sub-wavelength surface ripples and in-volume nanostructures by fs-laser induced selective etching. Appl. Surf. Sci. 2009, 255, 5641–5646. [Google Scholar] [CrossRef]

- Bronnikov, K.; Dostovalov, A.; Terentyev, V.; Babin, S.; Kozlov, A.; Pustovalov, E.; Gurevich, E.L.; Zhizhchenko, A.; Kuchmizhak, A. Uniform subwavelength high-aspect ratio nanogratings on metal-protected bulk silicon produced by laser-induced periodic surface structuring. Appl. Phys. Lett. 2021, 119, 211106. [Google Scholar] [CrossRef]

- Sládek, J.; Levy, Y.; Derrien, T.J.Y.; Bryknar, Z.; Bulgakova, N.M. Silicon surface patterning by regular stripes of laser-induced periodic surface structures. Appl. Surf. Sci. 2022, 605, 154664. [Google Scholar] [CrossRef]

- Nakhoul, A.; Rudenko, A.; Maurice, C.; Reynaud, S.; Garrelie, F.; Pigeon, F.; Colombier, J.P. Boosted Spontaneous Formation of High-Aspect Ratio Nanopeaks on Ultrafast Laser-Irradiated Ni Surface. Adv. Sci. 2022, 9, e2200761. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Skoulas, E.; Mimidis, A.; Perrakis, G.; Kenanakis, G.; Tsibidis, G.D.; Stratakis, E. Biomimetic Omnidirectional Antireflective Glass via Direct Ultrafast Laser Nanostructuring. Adv. Mater. 2019, 31, e1901123. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Zhong, M.; Zhang, H.; Xie, Y.; Lin, C. Superhydrophobic and colorful copper surfaces fabricated by picosecond laser induced periodic nanostructures. Appl. Surf. Sci. 2014, 311, 461–467. [Google Scholar] [CrossRef]

- Sarnet, T.; Carey, J.E.; Mazur, E. From black silicon to photovoltaic cells, using short pulse lasers. AIP Conf. Proc. 2012, 1464, 219–228. [Google Scholar]

- Fan, P.; Wu, H.; Zhong, M.; Zhang, H.; Bai, B.; Jin, G. Large-scale cauliflower-shaped hierarchical copper nanostructures for efficient photothermal conversion. Nanoscale 2016, 8, 14617–14624. [Google Scholar] [CrossRef]

- Tan, G.; Lee, J.-H.; Lan, Y.-H.; Wei, M.-K.; Peng, L.-H.; Cheng, I.C.; Wu, S.-T. Broadband antireflection film with moth-eye-like structure for flexible display applications. Optica 2017, 4, 678–683. [Google Scholar] [CrossRef]

- Luo, X.; Lu, L.; Yin, M.; Fang, X.; Chen, X.; Li, D.; Yang, L.; Li, G.; Ma, J. Antireflective and self-cleaning glass with robust moth-eye surface nanostructures for photovoltaic utilization. Mater. Res. Bull. 2019, 109, 183–189. [Google Scholar] [CrossRef]

- Mazumder, P.; Jiang, Y.; Baker, D.; Carrilero, A.; Tulli, D.; Infante, D.; Hunt, A.T.; Pruneri, V. Superomniphobic, Transparent, and Antireflection Surfaces Based on Hierarchical Nanostructures. Nano Lett. 2014, 14, 4677–4681. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leng, R.-Z.; Yun, B.; Chen, Z.-H.; Chai, C.; Xu, W.-W.; Yu, Y.-H.; Wang, L. High-Transmission Biomimetics Structural Surfaces Produced via Ultrafast Laser Manufacturing. Biomimetics 2023, 8, 586. https://doi.org/10.3390/biomimetics8080586

Leng R-Z, Yun B, Chen Z-H, Chai C, Xu W-W, Yu Y-H, Wang L. High-Transmission Biomimetics Structural Surfaces Produced via Ultrafast Laser Manufacturing. Biomimetics. 2023; 8(8):586. https://doi.org/10.3390/biomimetics8080586

Chicago/Turabian StyleLeng, Rui-Zhe, Bi Yun, Zhi-Hao Chen, Chen Chai, Wei-Wei Xu, Yan-Hao Yu, and Lei Wang. 2023. "High-Transmission Biomimetics Structural Surfaces Produced via Ultrafast Laser Manufacturing" Biomimetics 8, no. 8: 586. https://doi.org/10.3390/biomimetics8080586