The Evaluation of Microshear Bond Strength of Resin Cements to Titanium Using Different Surface Treatment Methods: An In Vitro Study

Abstract

:1. Introduction

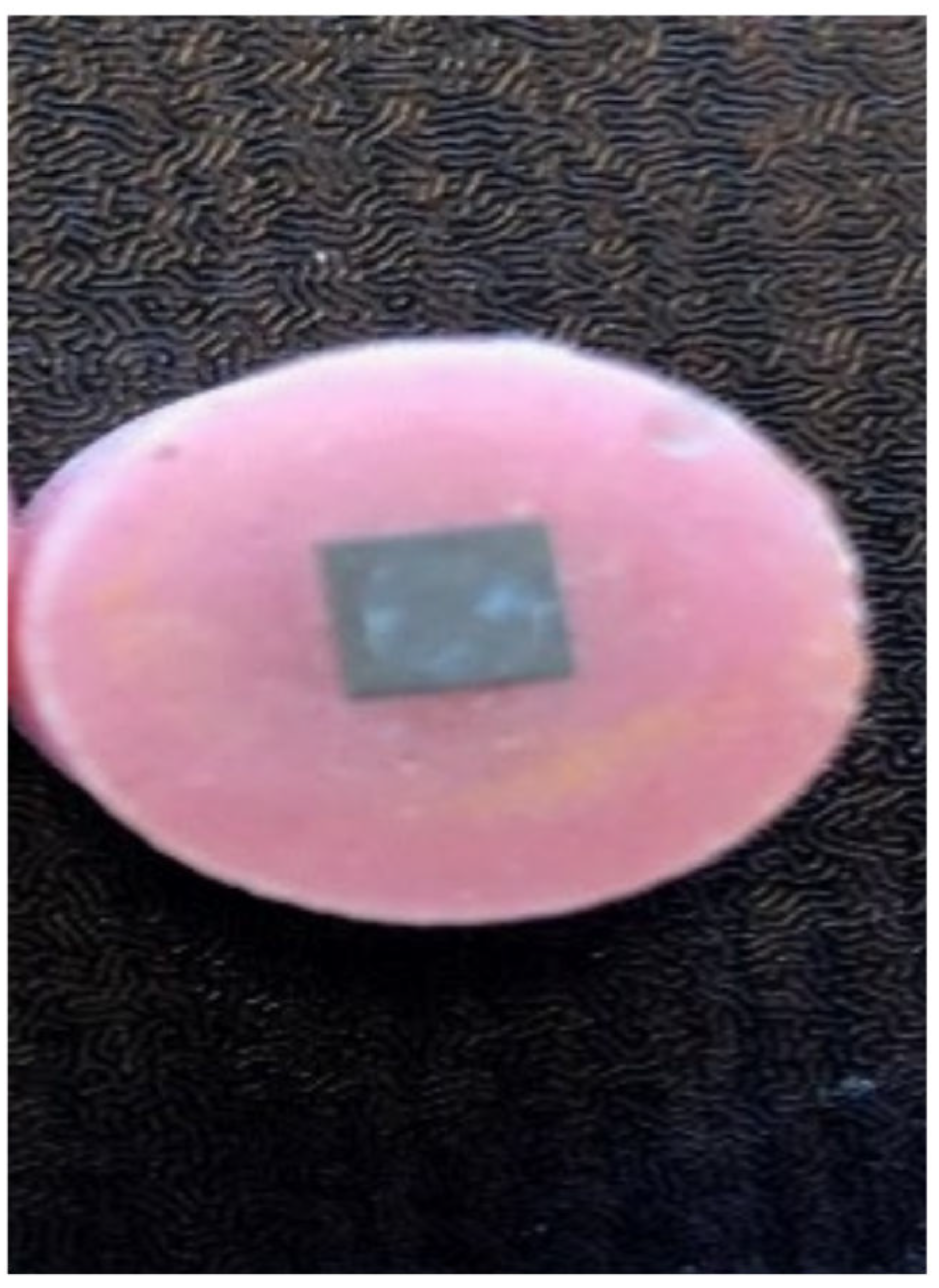

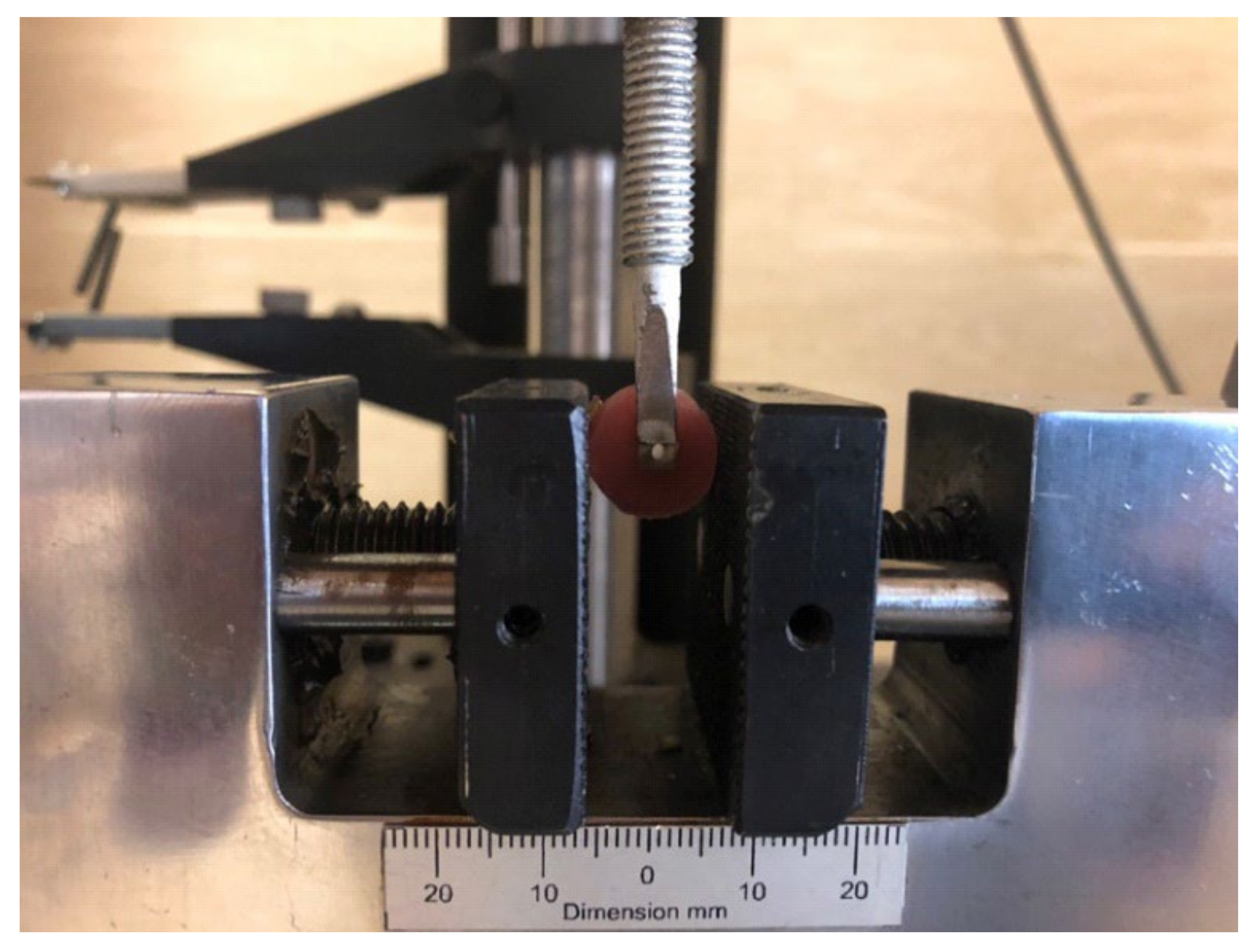

2. Materials and Methods

- Cohesive fracture: Fracture within the resin cement.

- Adhesive fracture: Fracture at resin cement–cp-Ti interface.

- Mixed fracture: A combination of adhesive and cohesive fractures.

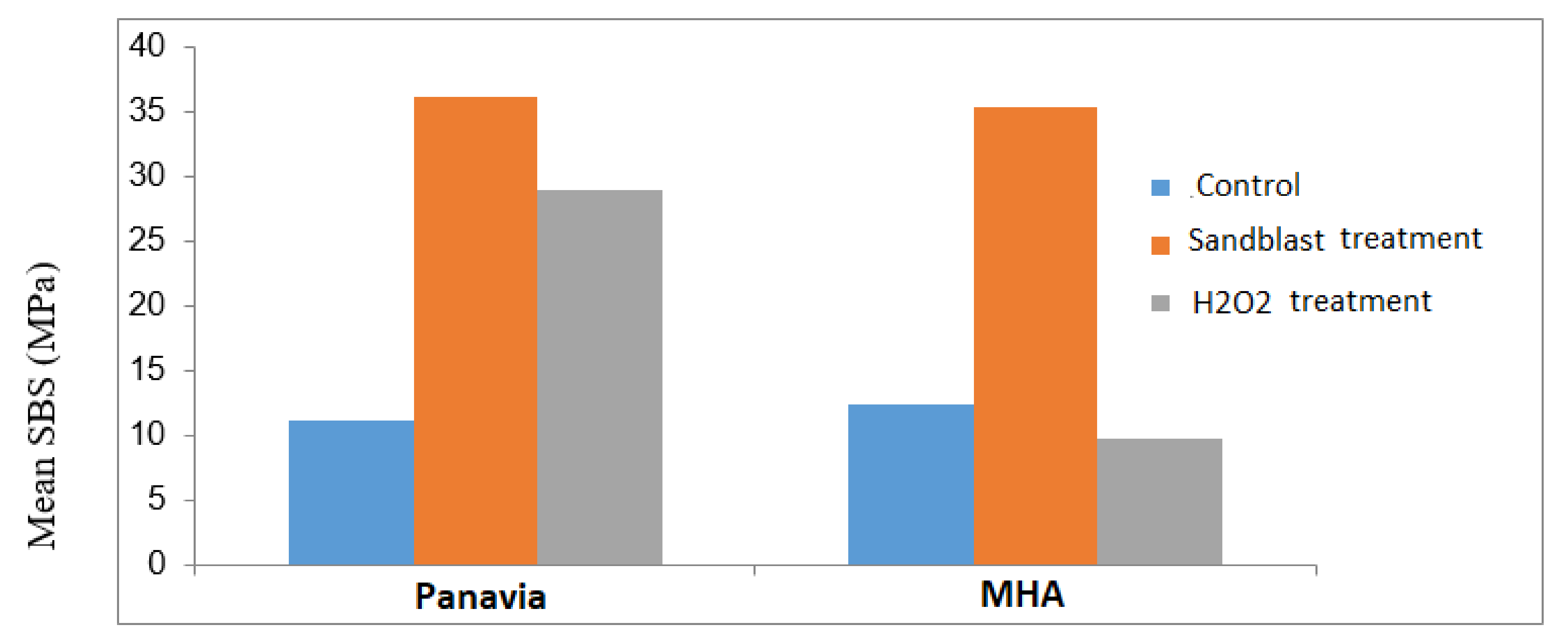

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alghamdi, H.S.; Jansen, J.A. The development and future of dental implants. Dent. Mater. J. 2020, 39, 167–172. [Google Scholar] [CrossRef] [Green Version]

- Eftekhar Ashtiani, R.; Alam, M.; Tavakolizadeh, S.; Abbasi, K. The Role of Biomaterials and Biocompatible Materials in Implant-Supported Dental Prosthesis. Evid.-Based Complementary Altern. Med. 2021, 2021, 3349433. [Google Scholar] [CrossRef] [PubMed]

- Alshehri, M.; Alghamdi, M.; Alayad, A.S. Anatomical Shaping for Zirconia Custom Implant Abutment to Enhance Anterior Esthetic: A Clinical Technique. Int. J. Dent. 2020, 2020, 8857410. [Google Scholar] [CrossRef]

- Totou, D.; Naka, O.; Mehta, S.B.; Banerji, S. Esthetic, mechanical, and biological outcomes of various implant abutments for single-tooth replacement in the anterior region: A systematic review of the literature. Int. J. Implant. Dent. 2021, 7, 1–17. [Google Scholar] [CrossRef]

- Bharate, V.; Kumar, Y.; Koli, D.; Pruthi, G.; Jain, V. Effect of different abutment materials (zirconia or titanium) on the crestal bone height in 1 year. J. Oral Biol. Craniofacial Res. 2020, 10, 372. [Google Scholar] [CrossRef] [PubMed]

- Cocchetto, R.; Canullo, L. The “hybrid abutment”: A new design for implant cemented restorations in the esthetic zones. Int. J. Esthet. Dent. 2015, 10, 186–208. [Google Scholar] [PubMed]

- Cao, Y.; Guo, Y.-y.; Chen, L.; Han, J.; Tong, H.; Zhang, B.; Zhang, Y. Effects of different surface treatments on bonding strength of resin cement to machined pure titanium. J. Adhes. Dent. 2019, 21, 401. [Google Scholar]

- Lee, S.-Y.; Vang, M.-S.; Yang, H.-S.; Park, S.-W.; Park, H.-O.; Lim, H.-P. Shear bond strength of composite resin to titanium according to various surface treatments. J. Adv. Prosthodont. 2009, 1, 68–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papageorgiou, S.N.; Pandis, N. Clinical evidence on orthodontic bond failure and associated factors. In Orthodontic Applications of Biomaterials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 191–206. [Google Scholar]

- Kamijo, K.; Yoshida, T.; Mizoguchi, T.; Nagasawa, S.; Ito, M. Evolution of H2O2 surface treatment for the adhesion between resin cements and titanium. J. Jpn. Soc. Dent. Mater. Devices 2002, 21, 121–124. [Google Scholar]

- Tengvall, P.; Lundström, I.; Sjöqvist, L.; Elwing, H.; Bjursten, L.M. Titanium-hydrogen peroxide interaction: Model studies of the influence of the inflammatory response on titanium implants. Biomaterials 1989, 10, 166–175. [Google Scholar] [CrossRef]

- Yoshida, T.; Terashima, N.; Niiro, T.; Nagasawa, S.; Ito, M.; Yagasaki, H.; Oshida, Y.; Agarwal, P. Bond strength of resin cements to H2O2-treated titanium plates. Dent. Mater. 2005, 21, 1087–1097. [Google Scholar] [CrossRef]

- Yap, A.U.J.; Wang, X.; Wu, X.; Chung, S.M. Comparative hardness and modulus of tooth-colored restoratives: A depth-sensing microindentation study. Biomaterials 2004, 25, 2179–2185. [Google Scholar] [CrossRef]

- Nakhaei, M.; Fendereski, Z.; Alavi, S.; Mohammadipour, H.-S. The Micro-Shear bond strength of different cements to commercially pure titanium. J. Clin. Exp. Dent. 2019, 11, e820. [Google Scholar] [CrossRef] [PubMed]

- Kern, M.; Thompson, V. Sandblasting and silica-coating of dental alloys: Volume loss, morphology and changes in the surface composition. Dent. Mater. 1993, 9, 155–161. [Google Scholar] [CrossRef]

- Kern, M.; Thompson, V. Effects of sandblasting and silica-coating procedures on pure titanium. J. Dent. 1994, 22, 300–306. [Google Scholar] [CrossRef]

- Bacchelli, B.; Giavaresi, G.; Franchi, M.; Martini, D.; De Pasquale, V.; Trirè, A.; Fini, M.; Giardino, R.; Ruggeri, A. Influence of a zirconia sandblasting treated surface on peri-implant bone healing: An experimental study in sheep. Acta Biomater. 2009, 5, 2246–2257. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira Abi-Rached, F.; Fonseca, R.G.; Haneda, I.G.; de Almeida-Júnior, A.A.; Adabo, G.L. The effect of different surface treatments on the shear bond strength of luting cements to titanium. J. Prosthet. Dent. 2012, 108, 370–376. [Google Scholar] [CrossRef]

- Almilhatti, H.J.; Giampaolo, E.T.; Vergani, C.E.; Machado, A.L.; Pavarina, A.C.; Betiol, É.Á.G. Adhesive bonding of resin composite to various Ni-Cr alloy surfaces using different metal conditioners and a surface modification system. J. Prosthodont. Implant. Esthet. Reconstr. Dent. 2009, 18, 663–669. [Google Scholar] [CrossRef]

- Nagassa, M.; Daw, A.; Rowe, W.G.; Carley, A.; Thomas, D.W.; Moseley, R. Optimisation of the hydrogen peroxide pre-treatment of titanium: Surface characterisation and protein adsorption. Clin. Oral Implant. Res. 2008, 19, 1317–1326. [Google Scholar] [CrossRef]

- Johansson, C.; Håkansson, A.; Papia, E. Bond strength between titanium and polymer-based materials adhesively cemented. Biomater. Investig. Dent. 2021, 8, 79–86. [Google Scholar] [CrossRef]

- Taira, Y.; Matsumura, H.; Yoshida, K.; Tanaka, T.; Atsuta, M. Adhesive bonding of titanium with a methacrylate–phosphate primer and self-curing adhesive resins. J. Oral Rehabil. 1995, 22, 409–412. [Google Scholar] [CrossRef] [PubMed]

- Freifrau von Maltzahn, N.; Bernard, S.; Kohorst, P. Two-part implant abutments with titanium and ceramic components: Surface modification affects retention forces—An in-vitro study. Clin. Oral Implant. Res. 2019, 30, 903–909. [Google Scholar] [CrossRef] [PubMed]

- Guilherme, N.; Wadhwani, C.; Zheng, C.; Chung, K.-H. Effect of surface treatments on titanium alloy bonding to lithium disilicate glass-ceramics. J. Prosthet. Dent. 2016, 116, 797–802. [Google Scholar] [CrossRef] [PubMed]

- Pitta, J.; Burkhardt, F.; Mekki, M.; Fehmer, V.; Mojon, P.; Sailer, I. Effect of airborne-particle abrasion of a titanium base abutment on the stability of the bonded interface and retention forces of crowns after artificial aging. J. Prosthet. Dent. 2020, 126, 214–221. [Google Scholar] [CrossRef] [PubMed]

- Nakhaei, M.; Taghvaei, F.; Mohammadipour, H.S. The Micro-Shear Bond Strength of Resin Cements to Commercially Pure Titanium Using Universal Adhesives and Alloy Primer. Int. J. Prosthodont. 2021. [Google Scholar] [CrossRef] [PubMed]

| Cement | Composition |

|---|---|

| Panavia V5 | Bisphenol A diglycidylmethacrylate (Bis-GMA), Triethyleneglycol dimethacrylate (TEGDMA), Hydrophobic aromatic dimethacrylate, Hydrophilic aliphatic dimethacrylate, Initiators Accelerators, Silanated barium glass filler, Silanated fluoroalminosilicate glass filler, Colloidal silica Bisphenol A, Silanated alminum oxide filler, dl-Camphorquinone, Pigments |

| MultiLink Hybrid-Abutment (MHA) | Dimethacrylate, HEMA, fillers (barium glass, ytterbium trifluoride, spheroid mixed oxides, titanium dioxide) |

| Subgroups | n | Mean (MPa) | Standard Deviation (MPa) |

|---|---|---|---|

| A | 15 | 11.06 | 2.99 |

| B | 15 | 36.13 | 5.54 |

| C | 15 | 28.86 | 7.37 |

| D | 15 | 18.55 | 3.30 |

| E | 15 | 35.28 | 4.33 |

| F | 15 | 9.7 | 5.37 |

| Subgroup | Subgroup | p-Value |

|---|---|---|

| A | B | p < 0.001 |

| A | C | p < 0.001 |

| B | C | p = 0.01 |

| D | E | p < 0.001 |

| D | F | 0.35 |

| E | F | p < 0.001 |

| Subgroups | Failure Mode | ||

|---|---|---|---|

| Adhesive (%) | Mixed (%) | Cohesive (%) | |

| A | 66.6 | 20 | 13.3 |

| B | 80 | 20 | 0 |

| C | 66.6 | 26.6 | 6.6 |

| D | 93.3 | 6.6 | 0 |

| F | 53.3 | 46.6 | 0 |

| F | 80 | 20 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakhaei, M.; Bozorgmehr, N.; Rajati Haghi, H.; Bagheri, H.; Rangrazi, A. The Evaluation of Microshear Bond Strength of Resin Cements to Titanium Using Different Surface Treatment Methods: An In Vitro Study. Biomimetics 2022, 7, 18. https://doi.org/10.3390/biomimetics7010018

Nakhaei M, Bozorgmehr N, Rajati Haghi H, Bagheri H, Rangrazi A. The Evaluation of Microshear Bond Strength of Resin Cements to Titanium Using Different Surface Treatment Methods: An In Vitro Study. Biomimetics. 2022; 7(1):18. https://doi.org/10.3390/biomimetics7010018

Chicago/Turabian StyleNakhaei, Mohammadreza, Neda Bozorgmehr, Hamidreza Rajati Haghi, Hossein Bagheri, and Abdolrasoul Rangrazi. 2022. "The Evaluation of Microshear Bond Strength of Resin Cements to Titanium Using Different Surface Treatment Methods: An In Vitro Study" Biomimetics 7, no. 1: 18. https://doi.org/10.3390/biomimetics7010018