Fabrication of Magnetically Driven Microvalve Arrays Using a Photosensitive Composite

Abstract

:1. Introduction

2. Material and Methods

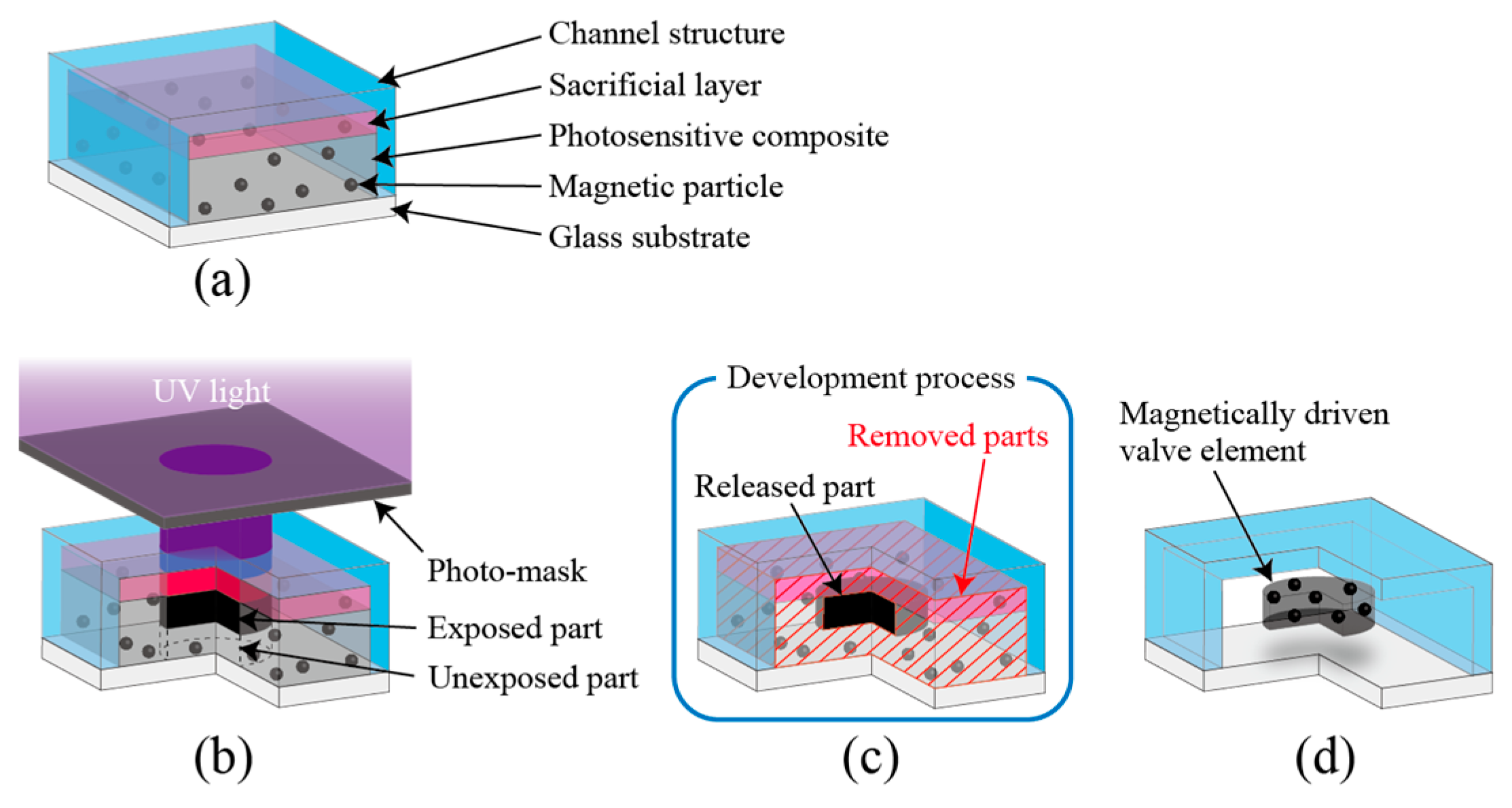

2.1. Principle of the Fabrication Process

2.2. Mixing Method of Photosensitive Composite

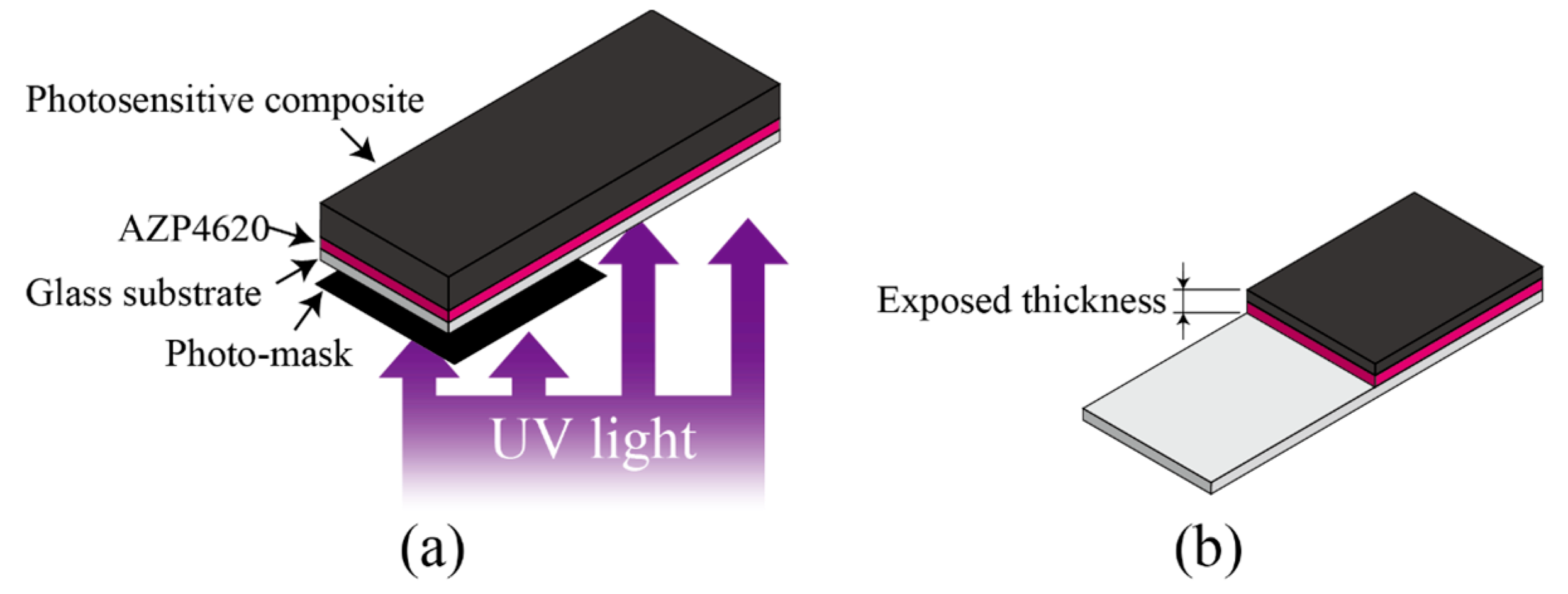

2.3. Optimization of Process Conditions

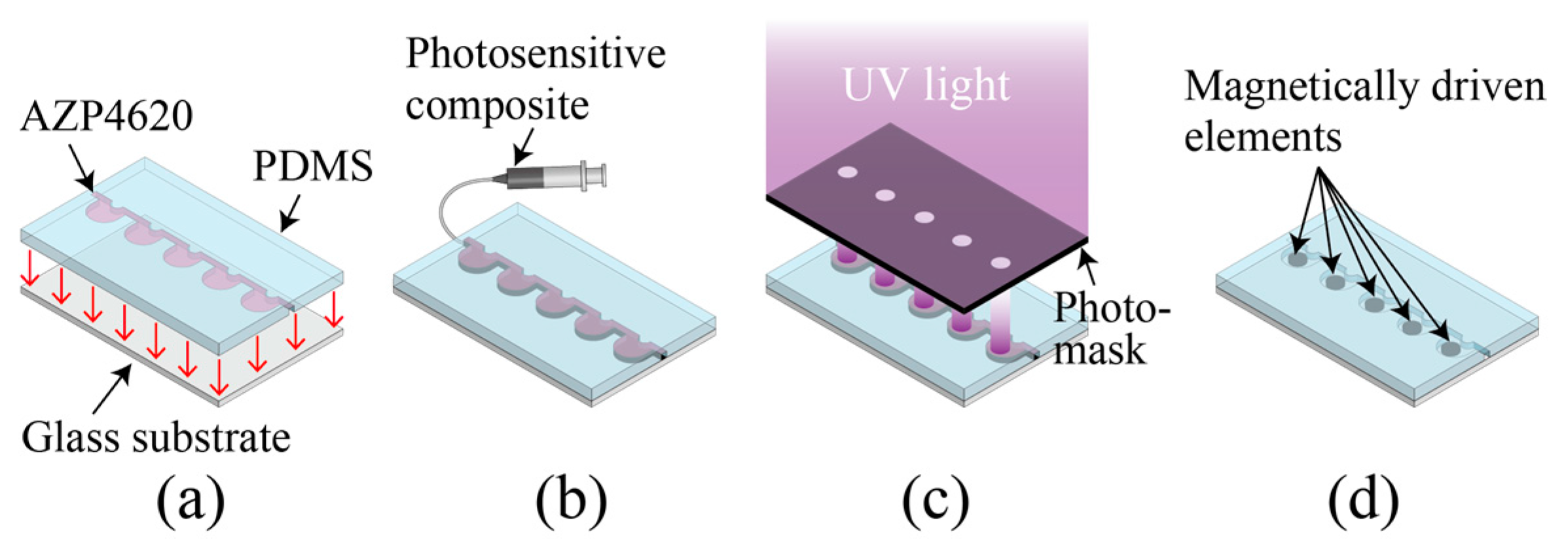

2.4. Fabrication Process of Microvalve Array Device

2.5. Evaluation Method of Microvalve Properties

3. Results and Discussion

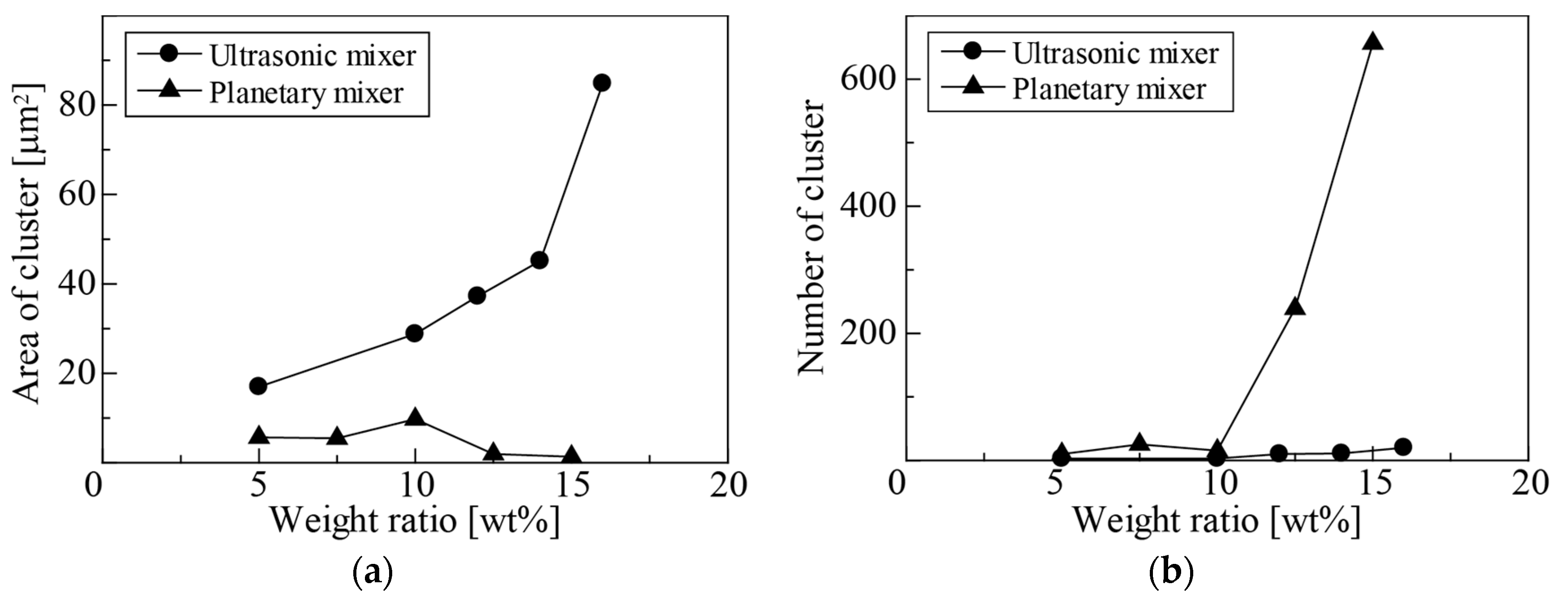

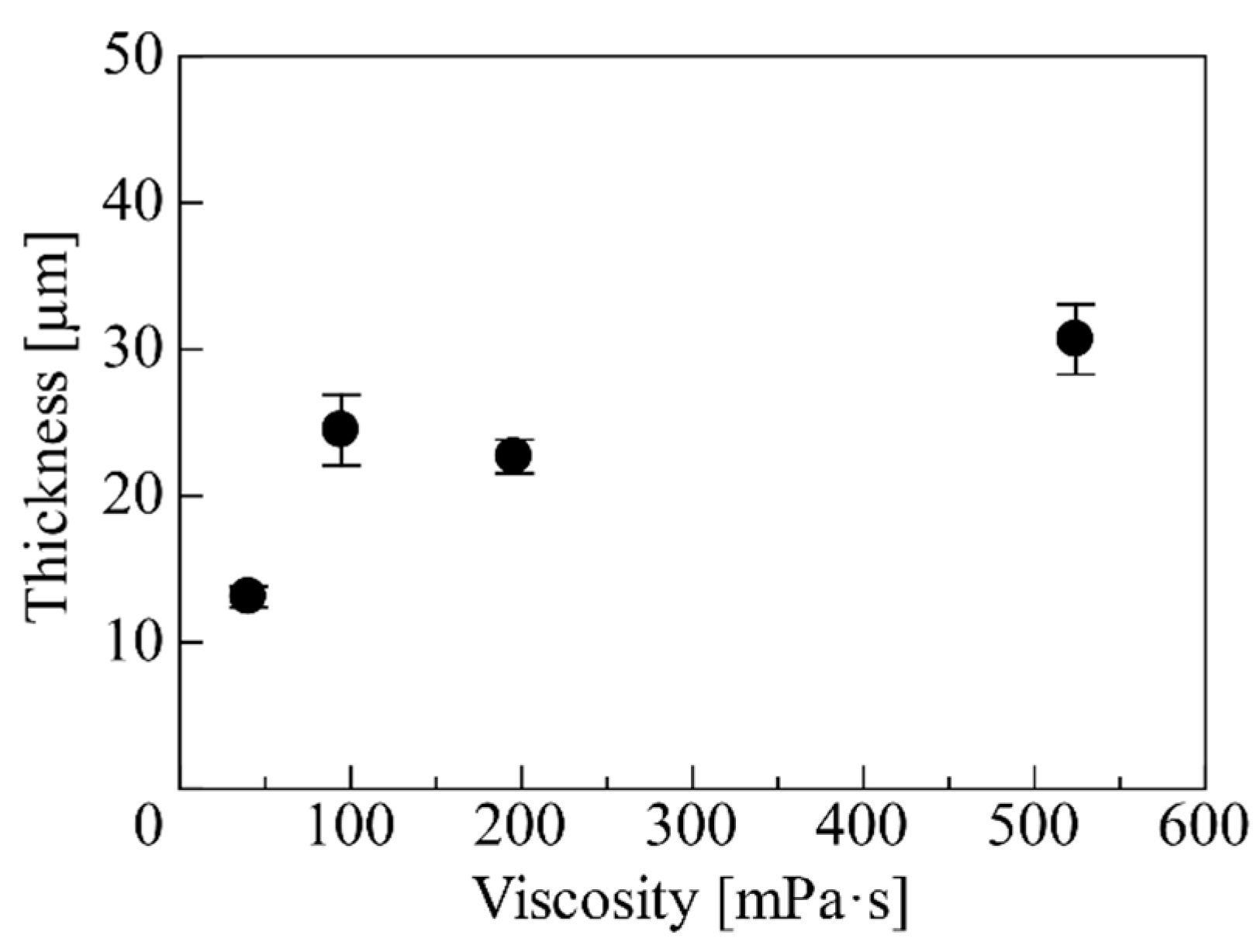

3.1. Characteristics of Photosensitive Composite

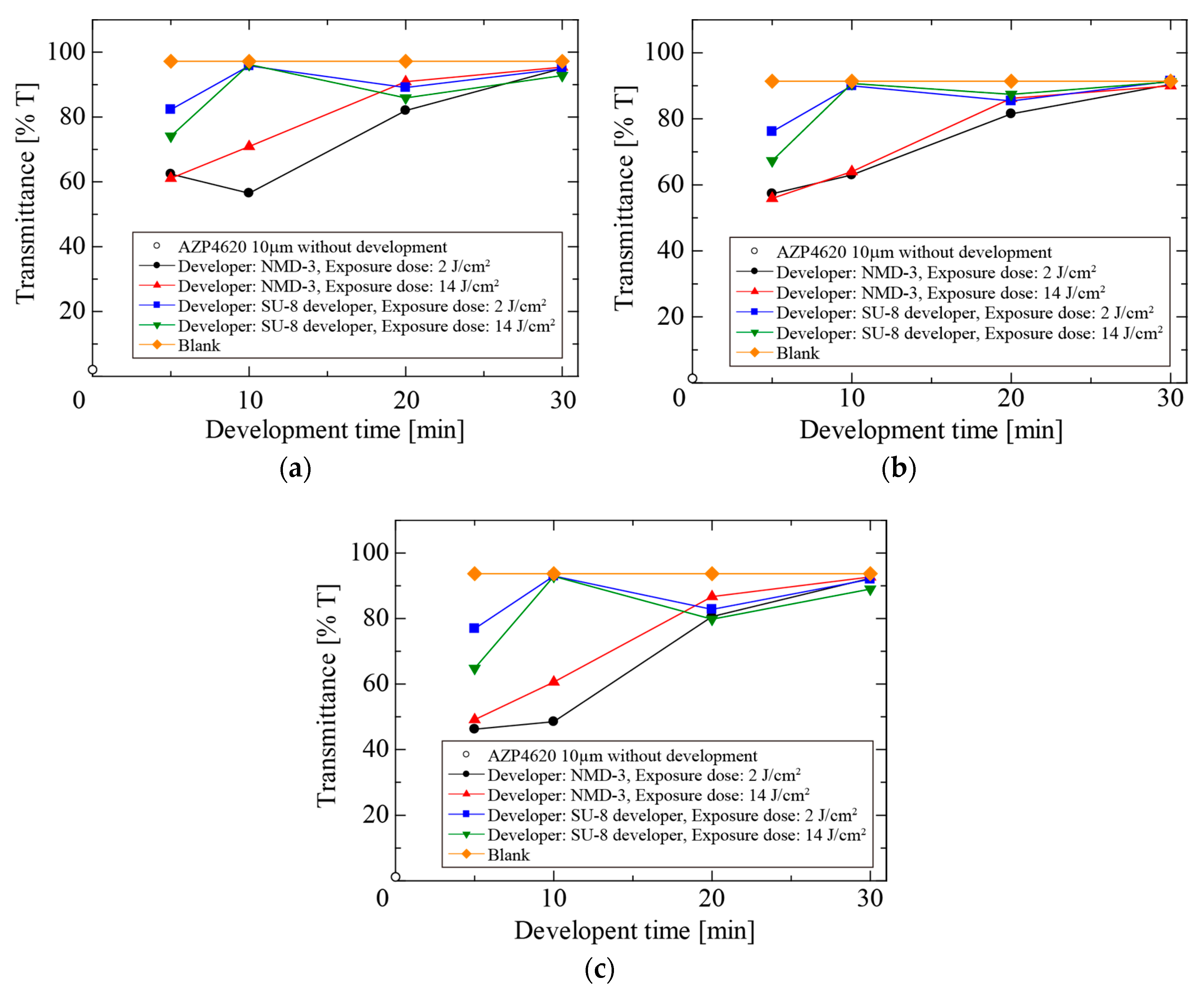

3.2. Evaluation of Process Condition

3.3. Fabrication Result of Microvalve Array Device

3.4. Valve Properties in Applied Magnetic Field

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, C.J.; Sheen, H.J.; Tu, Z.K.; Lei, U.; Yang, C.Y. A study of PZT valveless micropump with asymmetric obstacles. Microsyst. Technol. 2009, 15, 993–1000. [Google Scholar] [CrossRef]

- Yang, K.-S.; Chao, T.-F.; Chen, I.Y.; Wang, C.-C.; Shyu, J.-C. A comparative study of nozzle/diffuser micropumps with novel valves. Molecules 2012, 17, 2178–2187. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.T.; Wu, Z. Micromixers—A review. J. Micromech. Microeng. 2005, 15, R1–R16. [Google Scholar] [CrossRef]

- Yang, S.Y.; Lin, J.L.; Lee, G.B. A vortex-type micromixer utilizing pneumatically driven membranes. J. Micromech. Microeng. 2009, 19, 035020. [Google Scholar] [CrossRef]

- Au, A.K.; Lai, H.; Utela, B.R.; Folch, A. Microvalves and micropumps for BioMEMS. Micromachines 2011, 2, 179–220. [Google Scholar] [CrossRef]

- Oh, K.W.; Ahn, C.H. A review of microvalves. J. Micromech. Microeng. 2006, 16, R13–R39. [Google Scholar] [CrossRef]

- Casals-Terré, J.; Duch, M.; Plaza, J.A.; Esteve, J.; Pérez-Castillejos, R.; Vallés, E.; Gómez, E. Design, fabrication and characterization of an externally actuated on/off microvalve. Sens. Actuators A Phys. 2008, 147, 600–606. [Google Scholar] [CrossRef]

- Groen, M.S.; Brouwer, D.M.; Wiegerink, R.J.; Lötters, J.C. Design considerations for a micromachined proportional control valve. Micromachines 2012, 3, 396–412. [Google Scholar] [CrossRef]

- Gholizadeh, A.; Javanmard, M. Magnetically actuated microfluidic transistors: Miniaturized micro-valves using magnetorheological fluids integrated with elastomeric membranes. J. Microelectromech. Syst. 2016, 25, 922–928. [Google Scholar] [CrossRef]

- Harper, J.C.; Andrews, J.M.; Ben, C.; Hunt, A.C.; Murton, J.K.; Carson, B.D.; Bachand, G.D.; Lovchik, J.A.; Arndt, W.D.; Finley, M.R.; et al. Magnetic-adhesive based valves for microfluidic devices used in low-resource settings. Lab Chip 2016, 16, 4142–4151. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.E.; Soper, S.; Wang, W. Design and fabrication of an electrochemically actuated microvalve. Microsyst. Technol. 2008, 14, 1751–1756. [Google Scholar] [CrossRef]

- Ezkerra, A.; Fernández, L.J.; Mayora, K.; Ruano-López, J.M. A microvalve for lab-on-a-chip applications based on electrochemically actuated SU8 cantilevers. Sens. Actuators B Chem. 2011, 155, 505–511. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B.; Bestetti, M. Microvalve actuation with wettability conversion through darkness/UV application. J. Micromech. Microeng. 2011, 21, 025019. [Google Scholar] [CrossRef]

- Huang, C.; Tsou, C. The implementation of a thermal bubble actuated microfluidic chip with microvalve, micropump and micromixer. Sens. Actuators A Phys. 2014, 210, 147–156. [Google Scholar] [CrossRef]

- Suter, M.; Ergeneman, O.; Zürcher, J.; Moitzi, C.; Pané, S.; Rudin, T.; Pratsinis, S.E.; Nelson, B.J.; Hierold, C. A photopatternable superparamagnetic nanocomposite: Material characterization and fabrication of microstructures. Sens. Actuators B Chem. 2011, 156, 433–443. [Google Scholar] [CrossRef]

- Suter, M.; Ergeneman, O.; Zürcher, J.; Schmid, S.; Camenzind, A.; Nelson, B.J.; Hierold, C. Superparamagnetic photocurable nanocomposite for the fabrication of microcantilevers. J. Micromech. Microeng. 2011, 21, 025023. [Google Scholar] [CrossRef]

- Suter, M.; Zhang, L.; Siringil, E.C.; Peters, C.; Luehmann, T.; Ergeneman, O.; Peyer, K.E.; Nelson, B.J.; Hierold, C. Superparamagnetic microrobots: Fabrication by two-photon polymerization and biocompatibility. Biomed. Microdevices 2013, 15, 997–1003. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Flynn, T.J.; Nation, J.C.; Kershaw, J.; Scott Stephens, L.; Trinkle, C.A. Photopatternable NdFeB polymer micromagnets for microfluidics and microrobotics applications. J. Micromech. Microeng. 2013, 23, 065002. [Google Scholar] [CrossRef]

- Suzuki, J.; Onishi, Y.; Terao, K.; Takao, H.; Shimokawa, F.; Oohira, F.; Miyagawa, H.; Namazu, T.; Suzuki, T. Development of a two-dimensional scanning micro-mirror utilizing magnetic polymer composite. Jpn. J. Appl. Phys. 2016, 55, 06GP01. [Google Scholar] [CrossRef]

- Damean, N.; Parviz, B.A.; Lee, J.N.; Odom, T.; Whitesides, G.M. Composite ferromagnetic photoresist for the fabrication of microelectromechanical systems. J. Micromech. Microeng. 2005, 15, 29–34. [Google Scholar] [CrossRef]

- Kandpal, M.; Sharan, C.; Palaparthy, V.; Tiwary, N.; Poddar, P.; Rao, V.R. Spin-coatable, photopatternable magnetic nanocomposite thin films for mems device applications. RSC Adv. 2015, 5, 85741–85747. [Google Scholar] [CrossRef]

- Suzuki, T.; Suzuki, J.; Terao, K.; Takao, H.; Shimokawa, F.; Oohira, F.; Miyagawa, H. Development of magnetically driven microvalve using photosensitive SU-8/Fe composite. Int. J. Appl. Electrom. 2016, 52, 1585–1590. [Google Scholar] [CrossRef]

- Nakahara, T.; Hosokawa, Y.; Terao, K.; Takao, H.; Shimokawa, F.; Oohira, F.; Namazu, T.; Kotera, H.; Suzuki, T. Self-aligned fabrication process for active membrane made of photosensitive nanocomposite. In Proceedings of the Technical digest of 25th IEEE International Conference on Micro Electro Mechanical Systems, Paris, France, 29 January–2 February 2012; pp. 1181–1184. [Google Scholar]

- Nayek, C.; Manna, K.; Bhattacharjee, G.; Murugavel, P.; Obaidat, I. Investigating size- and temperature-dependent coercivity and saturation magnetization in PEG coated Fe3O4 nanoparticles. Magnetochemistry 2017, 3, 19. [Google Scholar] [CrossRef]

- Moulet, L.; Daro, N.; Etrillard, C.; Létard, J.F.; Grosjean, A.; Guionneau, P. Rational control spin-crossover particle size: From nano- to micro-rods of [Fe(Htrz)2(trz)] (BF4). Magnetochemistry 2016, 2, 10. [Google Scholar] [CrossRef]

- Friend, J.; Yeo, L. Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 2010, 4, 026502. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakahara, T.; Suzuki, J.; Hosokawa, Y.; Shimokawa, F.; Kotera, H.; Suzuki, T. Fabrication of Magnetically Driven Microvalve Arrays Using a Photosensitive Composite. Magnetochemistry 2018, 4, 7. https://doi.org/10.3390/magnetochemistry4010007

Nakahara T, Suzuki J, Hosokawa Y, Shimokawa F, Kotera H, Suzuki T. Fabrication of Magnetically Driven Microvalve Arrays Using a Photosensitive Composite. Magnetochemistry. 2018; 4(1):7. https://doi.org/10.3390/magnetochemistry4010007

Chicago/Turabian StyleNakahara, Tasuku, Junya Suzuki, Yuki Hosokawa, Fusao Shimokawa, Hidetoshi Kotera, and Takaaki Suzuki. 2018. "Fabrication of Magnetically Driven Microvalve Arrays Using a Photosensitive Composite" Magnetochemistry 4, no. 1: 7. https://doi.org/10.3390/magnetochemistry4010007