Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Gray Mold Incidence (%)

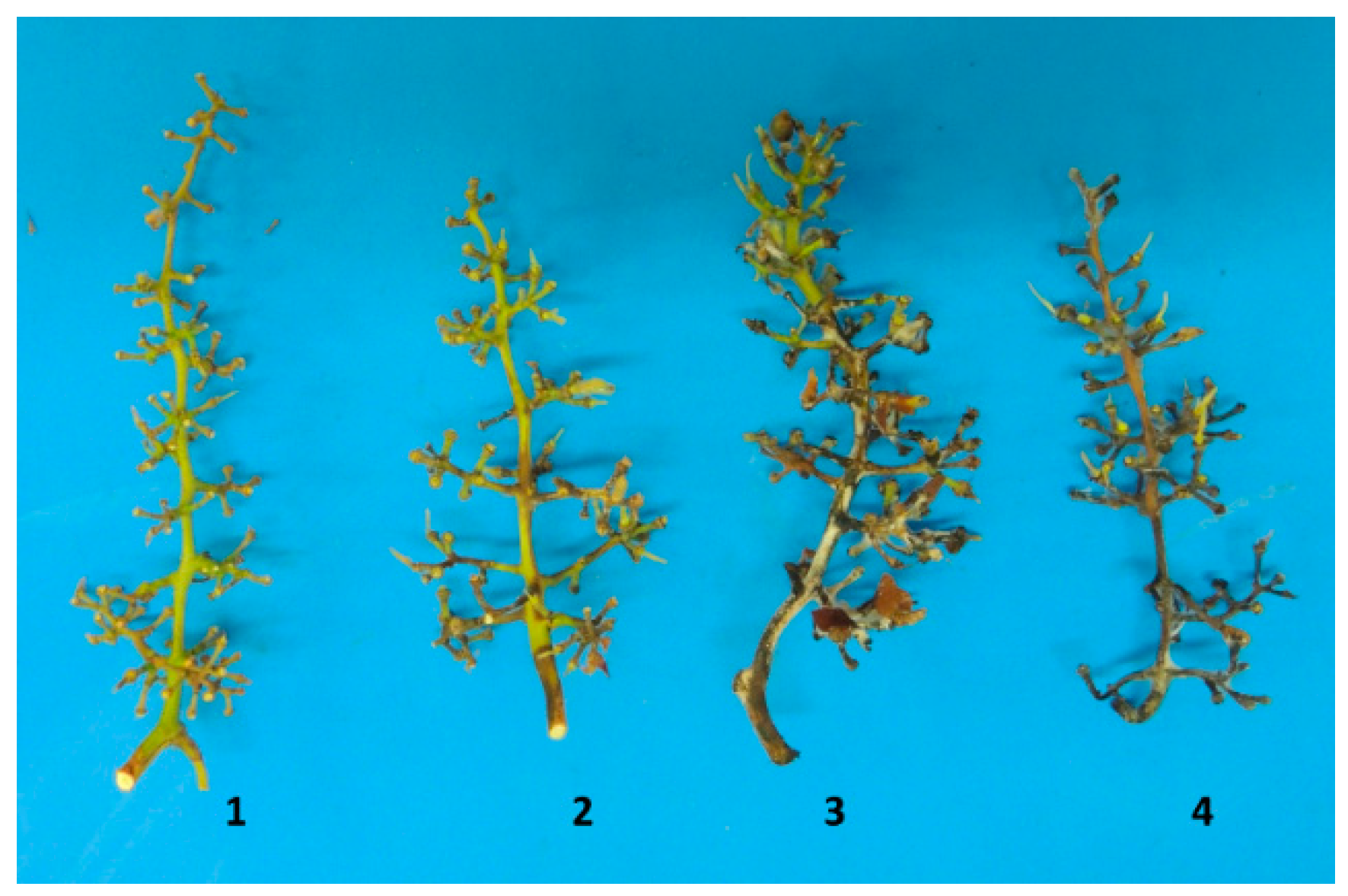

3.2. Shattered Berries and Stem Browning

3.3. Physical Properties for Quality Measurements

3.4. Chemical Properties for Quality Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Maia, J.D.G.; Ritschel, P.; Camargo, U.A.; Souza, R.T.; Fajardo, V.T.; Naves, R.L.; Girardi, C. ‘BRS Vitoria’—A novel seedless table grape cultivar exhibiting special flavor and tolerance to downy mildew (Plasmopara viticola). Crop Breed. Appl. Technol. 2014, 14, 204–206. [Google Scholar] [CrossRef] [Green Version]

- Bulit, J.; Dubos, B. Botrytis bunch rot and blight. In Compendium of Grape Diseases; APS Press: St. Paul, Rockville, MD, USA, 1990; pp. 13–15. [Google Scholar]

- Celik, M.; Kalpulov, T.; Zutahy, Y.; Ish-Shalom, B.; Lurie, S.; Lichter, A. Quantitative and qualitative analysis of Botrytis inoculated on table grapes by qPCR and antibodies. Postharvest Biol. Technol. 2009, 52, 235–239. [Google Scholar] [CrossRef]

- Oliveira, C.E.V.; Magnani, M.; de Sales, C.V.; Pontes, A.L.D.S.; Campos-Takaki, G.M.; Stamford, T.C.M. Effects of postharvest treatment using chitosan from Mucor circinelloides on fungal pathogenicity and quality of table grapes during storage. Food Microbiol. 2014, 44, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Crisosto, C.H.; Smilanick, J.L.; Dokoozlian, N.K.; Luvisi, D.A. Maintaining table grape postharvest quality for long distant markets. In Proceedings of the International Symposium on Table Grape Production, Anaheim, CA, USA, 28–29 June 1994; pp. 195–199. [Google Scholar]

- Karabulut, O.A.; Mlikota Gabler, F.; Mansour, M.; Smilanick, J.L. Postharvest ethanol and hot water treatments of table grapes to control gray mold. Postharvest Biol. Technol. 2004, 34, 169–177. [Google Scholar] [CrossRef]

- Lichter, A.; Gabler, F.M.; Smilanick, J.L. Control of spoilage in table grapes. Stewart Postharvest Rev. 2006. [Google Scholar] [CrossRef]

- Lichter, A.; Zutahy, Y.; Kaplunov, T.; Shacham, Z.; Aharoni, N.; Lurie, S. The benefits of modified atmosphere of ethanol treated grapes. Acta Hortic. 2005, 682, 1739–1744. [Google Scholar] [CrossRef]

- Fernandez-trujillo, J.P.; Obando-Ulloa, J.M.; Baró, R.; Martinez, J.A. Quality of two table grape cultivars treated with single or dual-phase release SO2 generators. J. Appl. Bot. Food Qual. 2008, 82, 1–8. [Google Scholar]

- Lichter, A.; Zutahy, Y.; Kaplunov, T.; Lurie, S. Evaluation of table grapes storage in boxes with sulfur dioxide-releasing pads with either an internal plastic liner or external wrap. HortTechnology 2008, 18, 206–214. [Google Scholar]

- Pires, J.C.M.; Sousa, S.I.V.; Pereira, A.M.C.; Alvim Ferraz, M.C.M.; Martins, F.G. Management of air quality monitoring using principal component and cluster analysis—Part I: SO2 and PM10. Atmos. Environ. 2008, 42, 1249–1260. [Google Scholar] [CrossRef]

- Youssef, K.; Roberto, S.R. Applications of salt solutions before and after harvest affect the quality and incidence of postharvest gray mold of ‘Italia’ table grapes. Postharvest Biol. Technol. 2014, 87, 95–102. [Google Scholar] [CrossRef]

- Mduduzi, E.K.N.; Mulugeta, A.D.; Umezuruik, L.O.; Chris, J.M. Performance of multi-packaging for table grapes based on airflow, cooling rates and fruit quality. J. Food Eng. 2012, 116, 613–621. [Google Scholar] [CrossRef]

- Mattiuz, B.; Miguel, A.C.A.; Galati, V.C.; Nachtigal, J.C. Efeito da temperatura no armazenamento de uvas apirênicas minimamente processadas. Rev. Bras. Frutic. 2009, 31, 44–52. [Google Scholar] [CrossRef] [Green Version]

- Lijavetzky, D.; Carbonell-Bejerano, P.; Grimplet, J.; Bravo, G.; Flores, P.; Fenoll, J.; Hellin, P.; Oliveros, J.C.; Martinez-Zapater, J.M. Berry flesh and skin ripening features in Vitis vinifera as assessed by transcriptional profiling. PLoS ONE 2012, 7, e39547. [Google Scholar] [CrossRef]

- Koyama, R.; Assis, A.M.; Yamamoto, L.Y.; Borges, W.S.; Prudencio, S.H.; Roberto, S.R. Exogenous abscisic acid increases the anthocyanin concentration of berry and juice from ‘Isabel’ grapes (Vitis labrusca L.). HortScience 2014, 49, 460–464. [Google Scholar]

- McGuire, R.G. Reporting of objective color measurements. HortScience 1992, 27, 1254–1255. [Google Scholar]

- Lancaster, J.E.; Lister, C.; Reay, P.F.; Triggs, C.M. Influence of pigment composition on skin color in a wide range of fruits and vegetables. J. Am. Soc. Hortic. Sci. 1997, 122, 594–598. [Google Scholar]

- Peppi, M.C.; Fidelibus, M.W.; Dokoozlian, N. Abscisic acid application timing and concentration affect firmness, pigmentation and color of ‘Flame Seedless’ grapes. HortScience 2006, 41, 1440–1445. [Google Scholar]

- Youssef, K.; Roberto, S.R. Salt strategies to control Botrytis mold of ‘Benitaka’ table grapes and to maintain fruit quality during storage. Postharvest Biol. Technol. 2014, 95, 95–102. [Google Scholar] [CrossRef]

- Youssef, K.; Roberto, S.; Chiarotti, F.; Koyama, R.; Hussain, I.; Souza, R. Control of Botrytis mold of the new seedless grape ‘BRS Vitoria’ during cold storage. Sci. Hortic. 2015, 193, 316–321. [Google Scholar] [CrossRef]

- Zutahy, Y.; Lichter, A.; Kaplunov, T.; Lurie, S. Extended storage of ‘Red Globe’ grapes in modified SO2 generating pads. Postharvest Biol. Technol. 2008, 12–17. [Google Scholar] [CrossRef]

- Zoffoli, J.P.; Latorre, B.; Naranjo, P. Hairline, a postharvest cracking disorder in table grapes induced by sulfur dioxide. Postharvest Biol. Technol. 2008, 47, 90–97. [Google Scholar] [CrossRef]

- Lurie, S.; Pesis, E.; Gadiyeva, O.; Feygenberg, O.; Ben-Arie, R.; Kaplunov, T.; Zutahy, Y.; Lichter, A. Modified ethanol atmosphere to control decay of table grapes during storage. Postharvest Biol. Pathol. 2006, 42, 222–227. [Google Scholar] [CrossRef]

- Zoffoli, J.P.; Latorre, B.A.; Naranjo, P. Preharvest applications of growth regulators and their effect on postharvest quality of table grapes during cold storage. Postharvest Biol. Technol. 2009, 51, 183–192. [Google Scholar] [CrossRef]

- Meng, X.; Tian, S. Effects of preharvest application of antagonistic yeast combined with chitosan on decay and quality of harvested table grape fruit. J. Sci. Food Agric. 2009, 89, 1838–1842. [Google Scholar] [CrossRef]

- Sölylemezoglu, G.; Agaoglu, Y.S. Research on the effect of grape guard during the cold storage of Thompson seedless cv. Acta Hortic. 1994, 368, 817–824. [Google Scholar] [CrossRef]

- Ozkaya, O.; Dundar, O.; Ozdemir, A.E.; Dilbaz, R. Effects of different postharvest applications on Red Globe grapes storage. Alatarım 2005, 4, 44–50, (In Turkish with English Abstract). [Google Scholar]

- Bleinroth, E.W. Determinação do ponto de colheita. In Uva Para Exportação: Procedimentos De Colheita E Pós-Colheita; EMBRAPA—SPI/FRUPEX: Brasília, Brazil, 1993; pp. 20–21. [Google Scholar]

| Treatments | Gray Mold Incidence (%) | |

|---|---|---|

| At 50 Days in Cold Storage | At 7 Days in Room Temperature | |

| Control | 7.9 ± 1.4 a z | 13.0 ± 3.0 a |

| SO2 slow release pad | 1.3 ± 1.3 b | 13.4 ± 8.4 a |

| SO2 dual release pad | 0.1 ± 0.2 c | 6.6 ± 2.3 b |

| SO2 dual release–fast reduced pad | 0.0 ± 0.0 c | 3.3 ± 2.0 b |

| SO2 slow release pad + Bo y | 1.9 ± 0.9 b | 17.2 ± 3.8 a |

| SO2 dual release pad + Bo | 0.3 ± 0.5 c | 4.7 ± 3.2 b |

| SO2 dual release–fast pad reduced + Bo | 0.0 ± 0.0 c | 2.5 ± 3.3 b |

| F value | 34.5 ** x | 5.6 ** |

| Treatments | Shattered Berries (%) | Stem Browning Scores z | Shattered Berries (%) | Stem Browning Scores z |

|---|---|---|---|---|

| At 50 Days in Cold Storage | At 7 Days in Room Temperature | |||

| Control | 6.1 ± 2.8 a y | 1.8 ± 0.1 | 4.9 ± 2.1 | 2.8 ± 0.5 |

| SO2 slow release pad | 2.9 ± 1.8 b | 1.3 ± 0.3 | 4.8 ± 2.2 | 2.5 ± 0.4 |

| SO2 dual release pad | 1.6 ± 1.3 b | 1.3 ± 0.3 | 3.7 ± 3.5 | 2.5 ± 0.2 |

| SO2 dual release–fast reduced pad | 1.6 ± 0.7 b | 1.5 ± 0.2 | 3.1 ± 0.6 | 2.3 ± 0.3 |

| SO2 slow release pad + Bo x | 3.3 ± 1.5 b | 1.6 ± 0.2 | 7.2 ± 1.3 | 2.8 ± 0.2 |

| SO2 dual release pad + Bo | 3.5 ± 0.9 b | 1.3 ± 0.2 | 5.0 ± 1.1 | 2.2 ± 0.2 |

| SO2 dual release–fast pad reduced + Bo | 1.5 ± 0.3 b | 1.4 ± 0.1 | 3.4 ± 0.6 | 2.7 ± 0.4 |

| F value | 3.4 * w | 2.14 NS | 1.6 NS | 1.40 NS |

| Treatments | Mass Loss (%) | Firmness (N) | Mass Loss (%) | Firmness (N) |

|---|---|---|---|---|

| At 50 Days in Cold Storage | At 7 Days in Room Temperature | |||

| Control | 1.9 ± 0.2 a z | 11.9 ± 1.2 | 1.7 ± 0.2 a | 12.0 ± 1.1 |

| SO2 slow release pad | 1.0 ± 0.2 b | 12.7 ± 0.4 | 1.9 ± 0.7 a | 12.5 ± 1.5 |

| SO2 dual release pad | 2.1 ± 0.3 a | 10.1 ± 0.6 | 1.1 ± 0.1 b | 11.3 ± 1.2 |

| SO2 dual release–fast reduced pad | 1.8 ± 0.3 a | 11.4 ± 1.2 | 0.9 ± 0.2 b | 11.5 ± 1.1 |

| SO2 slow release pad + Bo y | 2.2 ± 1.2 a | 12.5 ± 2.4 | 1.6 ± 0.2 a | 14.9 ± 1.7 |

| SO2 dual release pad + Bo | 2.1 ± 0.3 a | 13.4 ± 1.1 | 0.6 ± 0.3 c | 13.3 ± 1.1 |

| SO2 dual release–fast pad reduced + Bo | 2.4 ± 0.1 a | 11.1 ± 0.4 | 0.3 ± 0.1 c | 12.5 ± 1.6 |

| F value | 2.7 * x | 2.3 NS | 12.4 ** | 2.5 NS |

| Treatments | L* | C* | h° | L* | C* | h° |

|---|---|---|---|---|---|---|

| At 50 Days of Cold Storage | At 7 Days of Room Temperature | |||||

| Control | 20.0 ± 0.1 | 4.1 ± 0.8 | 117.6 ± 19.3 | 19.9 ± 0.5 b z | 2.8 ± 0.1 a | 101.1 ± 9.5 a |

| SO2 slow release pad | 20.0 ± 0.2 | 3.4 ± 0.4 | 124.8 ± 7.8 | 20.0 ± 0.6 b | 2.6 ± 0.1 a | 92.3 ± 4.2 a |

| SO2 dual release pad | 19.5 ± 0.3 | 3.2 ± 0.2 | 118.5 ± 7.6 | 20.0 ± 0.5 b | 2.7 ± 0.2 a | 92.4 ± 11.0 a |

| SO2 dual release–fast reduced pad | 20.2 ± 0.3 | 3.2 ± 0.1 | 110.0 ± 14.5 | 20.1 ± 0.3 b | 2.2 ± 0.2 b | 95.4 ± 15.5 a |

| SO2 slow release pad + Bo y | 19.9 ± 0.7 | 3.2 ± 0.3 | 111.3 ± 4.5 | 19.8 ± 0.4 b | 2.6 ± 0.4 a | 97.0 ± 16.1 a |

| SO2 dual release pad + Bo | 19.9 ± 0.5 | 3.2 ± 0.4 | 116.0 ± 7.4 | 20.2 ± 0.6 b | 3.0 ± 0.1 a | 57.3 ± 8.2 b |

| SO2 dual release–fast pad reduced + Bo | 19.9 ± 0.2 | 3.3 ± 0.4 | 124.7 ± 10.5 | 22.2 ± 0.4 a | 2.1 ± 0.4 b | 82.3 ± 1.4 a |

| F value | 0.9 NS x | 1.9 NS | 0.8 NS | 8.2 ** | 5.6 ** | 5.8 ** |

| Treatments | pH | Soluble Solids—SS (°Brix) | Titratable Acidity—TA (%) | SS/TA | pH | Soluble Solids—SS (°Brix) | Titratable Acidity—TA (%) | SS/TA |

|---|---|---|---|---|---|---|---|---|

| At 50 Days of Cold Storage | At 7 Days of Room Temperature | |||||||

| Control | 4.0 ± 0.1 | 17.2 ± 0.8 b z | 0.7 ± 0.0 b | 24.1 ± 1.7 a | 4.0 ± 0.1 | 16.8 ± 0.6 b | 0.7 ± 0.0 | 25.6 ± 1.5 b |

| SO2 slow release pad | 4.1 ± 0.2 | 17.6 ± 0.5 a | 0.7 ± 0.0 b | 24.7 ± 1.4 a | 4.0 ± 0.1 | 16.8 ± 0.8 b | 0.6 ± 0.0 | 28.9 ± 3.5 a |

| SO2 dual release pad | 3.9 ± 0.1 | 17.0 ± 0.4 b | 0.8 ± 0.0 b | 22.9 ± 1.5 b | 4.1 ± 0.2 | 16.1 ± 0.6 b | 0.6 ± 0.0 | 25.2 ± 0.6 b |

| SO2 dual release–fast reduced pad | 4.1 ± 0.1 | 17.4 ± 0.3 b | 0.8 ± 0.0 a | 22.1 ± 1.0 b | 4.1 ± 0.2 | 16.3 ± 0.9 b | 0.6 ± 0.0 | 25.8 ± 3.3 b |

| SO2 slow release pad + Bo y | 4.0 ± 0.1 | 16.8 ± 0.3 b | 0.8 ± 0 a | 20.7 ± 1.1 b | 4.1 ± 0.1 | 17.7 ± 0.3 a | 0.6 ± 0.0 | 28.8 ± 0.3 a |

| SO2 dual release pad + Bo | 4.1 ± 0.2 | 18.0 ± 0.4 a | 0.7 ± 0.0 b | 24.5 ± 1.4 a | 4.0 ± 0.1 | 17.5 ± 0.3 a | 0.6 ± 0.0 | 29.0 ± 1.9 a |

| SO2 dual release–fast pad reduced + Bo | 4.1 ± 0.2 | 17.9 ± 0.5 a | 0.8 ± 0.0 b | 23.5 ± 0.4 a | 4.2 ± 0.1 | 18.5 ± 1.2 a | 0.6 ± 0.0 | 29.9 ± 2.0 a |

| F value | 0.8 NS x | 2.7 * | 4.7 ** | 4.2 ** | 0.8 NS | 3.4 * | 1.1 NS | 2.4 * |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domingues, A.R.; Roberto, S.R.; Ahmed, S.; Shahab, M.; José Chaves Junior, O.; Sumida, C.H.; De Souza, R.T. Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage. Horticulturae 2018, 4, 17. https://doi.org/10.3390/horticulturae4030017

Domingues AR, Roberto SR, Ahmed S, Shahab M, José Chaves Junior O, Sumida CH, De Souza RT. Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage. Horticulturae. 2018; 4(3):17. https://doi.org/10.3390/horticulturae4030017

Chicago/Turabian StyleDomingues, Allan Ricardo, Sergio Ruffo Roberto, Saeed Ahmed, Muhammad Shahab, Osmar José Chaves Junior, Ciro Hideki Sumida, and Reginaldo Teodoro De Souza. 2018. "Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage" Horticulturae 4, no. 3: 17. https://doi.org/10.3390/horticulturae4030017

APA StyleDomingues, A. R., Roberto, S. R., Ahmed, S., Shahab, M., José Chaves Junior, O., Sumida, C. H., & De Souza, R. T. (2018). Postharvest Techniques to Prevent the Incidence of Botrytis Mold of ‘BRS Vitoria’ Seedless Grape under Cold Storage. Horticulturae, 4(3), 17. https://doi.org/10.3390/horticulturae4030017