Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management

Abstract

:1. Introduction

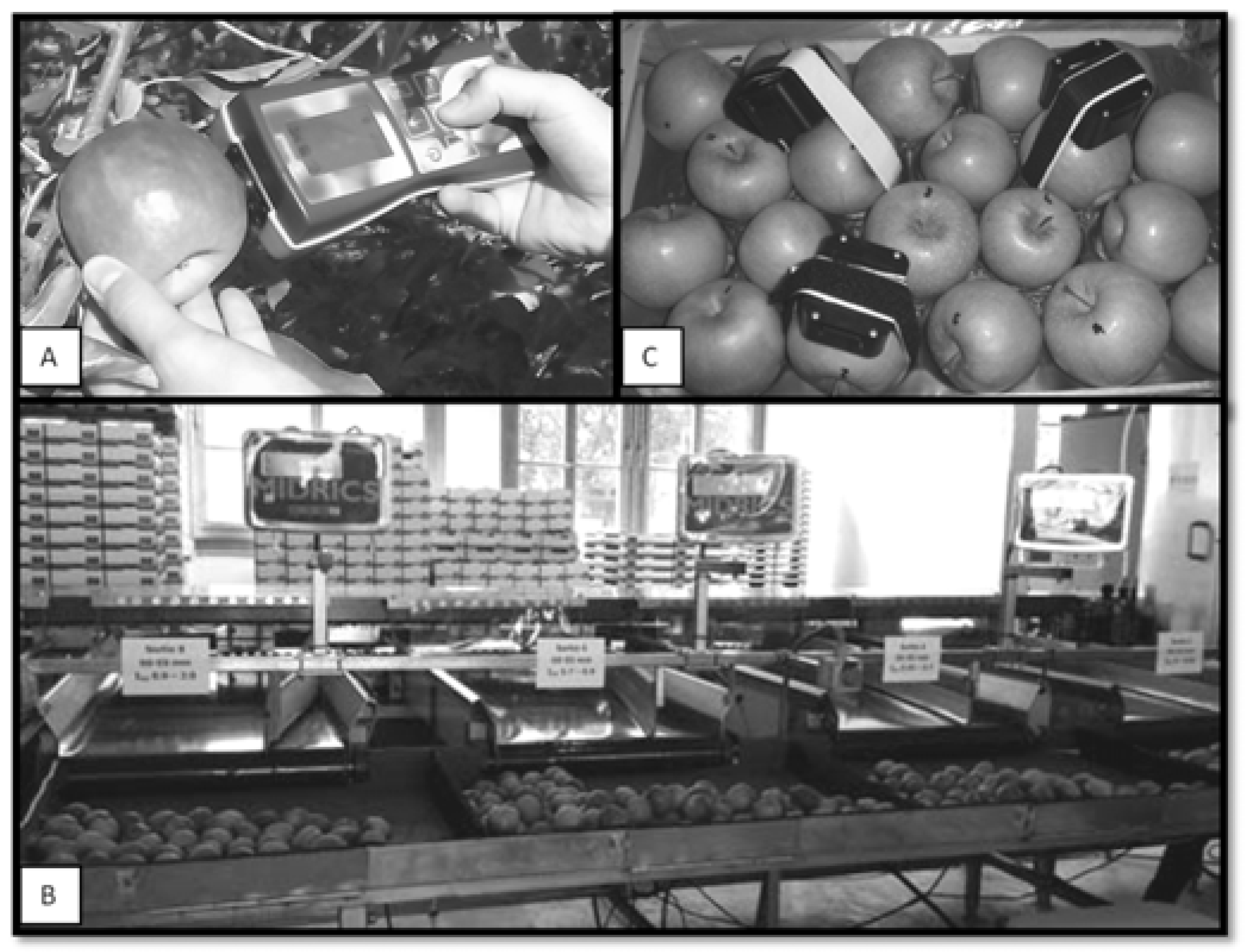

2. The VIS/NIR Devices Used in the Research

2.1. The DA-Meter

2.2. The DA-Head

2.3. The Difference Absorbance Fruit Logger (DAFL)

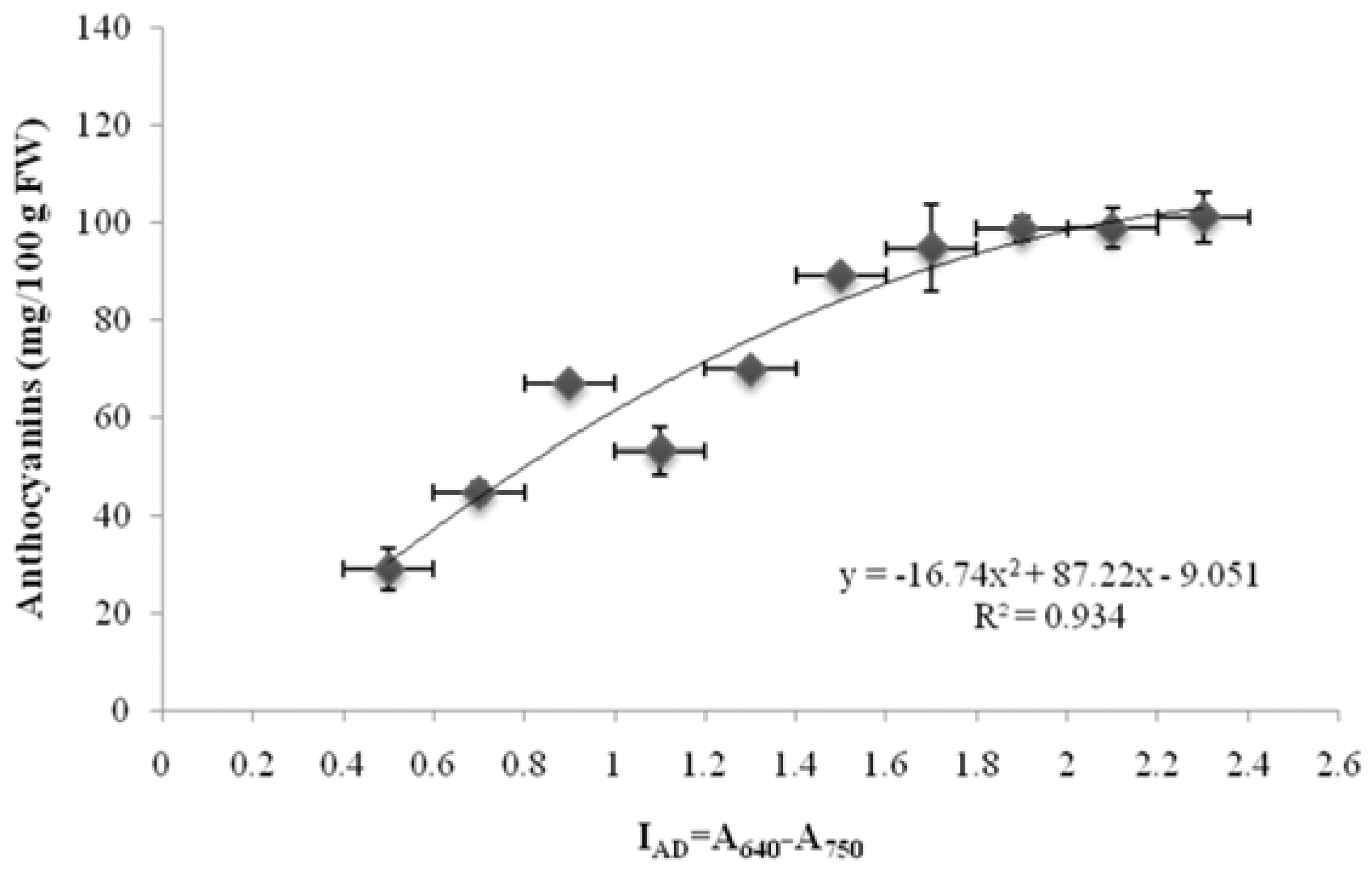

3. Major Accomplishments with the Use of the Devices

3.1. Assessing Proper Harvest Time

3.2. Grouping Fruit in Ripening Homogeneous Classes

3.3. Fruit Ripening Monitoring in Cold Storage

3.4. Reducing Postharvest Losses

4. Final Remarks

Acknowledgments

Conflicts of Interest

References

- Smith, G.S.; Gravett, I.M.; Edwards, C.M.; Curtis, J.P.; Buwalda, J.G. Spatial analysis of the canopy of kiwifruit vines as it relates to the physical, chemical and postharvest attributes of the fruit. Ann. Bot. 1994, 73, 99–111. [Google Scholar] [CrossRef]

- Dallabetta, N.; Costa, F.; Pasqualini, J.; Wehrens, R.; Noferini, M.; Costa, G. The influence of training system on apple fruit quality. Acta Hortic. 2013, 1058, 55–62. [Google Scholar] [CrossRef]

- Nagpala, E.G.L.; Noferini, M.; Farneti, B.; Piccinini, L.; Costa, G. Cherry-Meter: An innovative nondestructive (vis/NIR) device for cherry fruit ripening and quality assessment. In Proceedings of the 7th ISHS Internation Symposium on Cherry, Plasencia, Spain, 23–27 June 2013; ISHS: Leuven, Belgium in press.

- Bonora, E.; Noferini, M.; Vidoni, S.; Costa, G. Modeling fruit ripening for improving peach homogeneity in planta. Sci. Hortic. 2013, 159, 166–171. [Google Scholar] [CrossRef]

- Vidoni, S.; Rocchi, L.; Donati, I.; Spinelli, F.; Costa, G. Combined use of Planttoon® and IAD to characterize fruit ripening homogeneity in “Abbé Fétel” pears. Acta Hortic. 2015. [Google Scholar] [CrossRef]

- Vidoni, S.; Fiori, G.; Rocchi, L.; Spinelli, F.; Musacchi, S.; Costa, G. DAFL: New innovative device to monitor fruit ripening in storage. Acta Hortic. 2015, 1094, 549–554. [Google Scholar] [CrossRef]

- Harman, J.E. Kiwifruit maturity. Orchard. N. Z. 1981, 54, 126–127. [Google Scholar]

- Shewfelt, R.L. What is quality? Postharvest Biol. Technol. 1998, 15, 197–200. [Google Scholar] [CrossRef]

- Costa, G.; Fiori, G.; Torrigiani, P.; Noferini, M. Use of Vis/NIR spectroscopy to assess fruit ripening stage and improve management in post-harvest chain. In New Trends in Postharvest Management of Fresh Produce I, Fresh Produce 3 (Special Issue 1) ed.; Sivakumar, D., Ed.; Global Science Book: Ikenobe, Japan, 2009; pp. 1–6. [Google Scholar]

- Costa, G.; Bonora, E.; Fiori, G.; Noferini, M. Innovative nondestructive device for fruit quality assessment. Acta Hortic. 2011, 913, 575–581. [Google Scholar] [CrossRef]

- Costa, G.; Bonora, E.; Noferini, M. Modeling system and vis-NIR devices to improve pre- and post-harvest management. Acta Hortic. 2015, 1084, 809–821. [Google Scholar] [CrossRef]

- Costa, G.; Fiori, G.; Rocchi, L.; Vidoni, S.; Berthod, N.; Besse, S.; Knieling, S.; Rossier, J. A prototype of a stationary DA-device to group the apricots in classes of homogeneous ripening. In Proceedings of the ISHS XVI International Symposium on Apricot Breeding and Culture, Shenyang, China, 29 June–3 July 2015.

- Ziosi, V.; Noferini, M.; Fiori, G.; Tadiello, A.; Trainotti, L.; Casadoro, G.; Costa, G. A new index based on Vis spectroscopy to characterize the progression of ripening in peach fruit. Postharvest Biol. Technol. 2008, 49, 319–329. [Google Scholar] [CrossRef]

- Ruperti, B.; Cattivelli, L.; Pagni, S.; Ramina, A. Ethylene-responsive genes are differentially regulated during abscission, organ senescence and wounding in peach (Prunuspersica). J. Exp. Bot. 2002, 53, 429–437. [Google Scholar] [CrossRef] [PubMed]

- Trainotti, L.; Zanin, D.; Casadoro, G. A cell-oriented genomic approach reveals a new and unexpected complexity of the softening in peaches. J. Exp. Bot. 2003, 54, 1821–1832. [Google Scholar] [CrossRef] [PubMed]

- Tadiello, A.; Ziosi, V.; Negri, A.S.; Noferini, M.; Fiori, G.; Busatto, N.; Espen, L.; Costa, G.; Trainotti, L. On the role of ethylene, auxin and a GOLVEN-like peptide hormone in the regulation of peach ripening. BMC Plant Biol. 2016. [Google Scholar] [CrossRef] [PubMed]

- Bonora, E.; Noferini, M.; Stefanelli, D.; Costa, G. A new simple modeling approach for the early prediction of harvest date and yield in nectarines. Sci. Hortic. 2014, 172, 1–9. [Google Scholar] [CrossRef]

- Costa, G.; Noferini, M. Use of Nondestructive devices as a decision support system for fruit quality enhancement. Acta Hortic. 2013, 998, 103–115. [Google Scholar] [CrossRef]

- Costamagna, F.; Giordani, L.; Costa, G.; Noferini, M. Use of AD Index to define harvest time and characterize ripening variability at harvest in “Gala”apple. Acta Hortic. 2013, 998, 117–123. [Google Scholar] [CrossRef]

- Farneti, B.; Gutierrez, M.S.; Novak, B.; Busatto, N.; Ravaglia, D.; Spinelli, F.; Costa, G. Use of the index of absorbance difference (IAD) as a tool for tailoring post-harvest 1-MCP application to control apple superficial scald. Sci. Hortic. 2015, 16, 110–116. [Google Scholar] [CrossRef]

- Costa, G.; Rossi, D.; Tamburini, E.; Donegà, V.; Loberti, R. Innovazioni di processo per unapericoltura di qualità. L’Inf. Agrar. 2013, 36, 44–46. (In Italian) [Google Scholar]

- Pellegrino, S.; Costamagna, F.; Noferini, M.; Costa, G. Monitoring of “Hayward” (Actinidiadeliciosa) fruit ripening in North-West Italy. Acta Hortic. 2011, 913, 665–669. [Google Scholar] [CrossRef]

- Rocchi, L.; Vidoni, S.; Ceccarelli, A.; Fiori, G.; Costa, G. Use of the DA-indexTM for monitoring fruit ripening evolution in A. chinensis to precisely assess harvesting time “in planta”. J. Berry Sci. 2016. [Google Scholar] [CrossRef]

- Costa, G.; Vidoni, S.; Rocchi, L.; Cellini, A.; Buriani, G.; Donati, I.; Spinelli, F. Innovative nondestructive device for fruit quality assessment and early disease diagnosis. Acta Hortic. 2015, 1096, 69–78. [Google Scholar] [CrossRef]

- Costa, G.; Noferini, M.; Fiori, G.; Ziosi, V.; Berthod, N.; Rossier, J. Establishment of the optimal harvest time in Apricot (“Orangered” and “Bergarouge”) by means of a new Index based on Vis spectroscopy. Acta Hortic. 2010, 862, 533–539. [Google Scholar] [CrossRef]

- Salzman, R.A.; Tikhonova, I.; Bordelon, B.P.; Hasegawa, P.M.; Bressan, R.A. Coordinate accumulation of antifungal proteins and hexoses constitutes a developmentally controlled defense response during fruit ripening in grape. Plant Physiol. 1998, 117, 465–472. [Google Scholar] [CrossRef] [PubMed]

- Guillén, F.; Castillo, S.; Zapata, P.J.; Martínez-Romero, D.; Valero, D.; Serrano, M. Efficacy of 1-MCP treatment in tomato fruit: 2. Effect of cultivar and ripening stage at harvest. Postharvest Biol. Technol. 2006, 42, 235–242. [Google Scholar] [CrossRef]

- Cantu, D.; Vicente, A.R.; Greve, L.C.; Dewey, F.M.; Bennett, A.B.; Labavitch, J.M.; Powell, A.L.T. The intersection between cell wall disassembly, ripening, and fruit susceptibility to Botrytis cinerea. Proc. Natl. Acad. Sci. USA 2008, 105, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Spadoni, A.; Cameldi, I.; Noferini, M.; Bonora, E.; Costa, G.; Mari, M. An innovative use of DA-meter for peach fruit postharvest management. Sci. Hortic. 2016, 201, 140–144. [Google Scholar] [CrossRef]

| Class | IAD | Fruits (%) | Likelihood of Purchasing (%) | ||

|---|---|---|---|---|---|

| Yes | Maybe | No | |||

| 0 | 0–0.4 | 5.5 | 34.0 | 57.4 | 19.4 |

| 1 | 0.4–0.7 | 22.2 | 31.9 | 59.5 | 23.4 |

| 2 | 0.7–1 | 61.1 | 19.1 | 46.8 | 23.4 |

| 3 | >1 | 11.2 | 8.5 | 40.4 | 21.3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, G.; Rocchi, L.; Farneti, B.; Busatto, N.; Spinelli, F.; Vidoni, S. Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management. Horticulturae 2017, 3, 12. https://doi.org/10.3390/horticulturae3010012

Costa G, Rocchi L, Farneti B, Busatto N, Spinelli F, Vidoni S. Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management. Horticulturae. 2017; 3(1):12. https://doi.org/10.3390/horticulturae3010012

Chicago/Turabian StyleCosta, Guglielmo, Lorenzo Rocchi, Brian Farneti, Nicola Busatto, Francesco Spinelli, and Serena Vidoni. 2017. "Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management" Horticulturae 3, no. 1: 12. https://doi.org/10.3390/horticulturae3010012

APA StyleCosta, G., Rocchi, L., Farneti, B., Busatto, N., Spinelli, F., & Vidoni, S. (2017). Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management. Horticulturae, 3(1), 12. https://doi.org/10.3390/horticulturae3010012