Exploring Microbial Diversity of Non-Dairy Fermented Beverages with a Focus on Functional Probiotic Microorganisms

Abstract

:1. Introduction

2. Fermented Products

2.1. Chhang and Jau Chhang

2.2. Tarubá

2.3. Chicha

2.4. Apple Cider

2.5. Water Kefir

2.6. Kombucha

3. Microbial Diversity

3.1. Lactic Acid Bacteria

3.2. Other Bacterial Groups

| Beverage | Microorganisms | Substrate | Identification Method | Country | References |

|---|---|---|---|---|---|

| Jau Chhang | L. plantarum SAA 595; P. pentosaceus SAA 599; Serratia sp. SAA 601 | Barley/grape | rDNA gene sequencing CD | India | [29] |

| Chhang | P. pentosaceus SAA 599; B. amyloliquefaciens SAA 610 | Rice/wheat | rDNA gene sequencing CD | India | [29] |

| Chicha | L. mesenteroides; L. fermentum; S. mutans; L. lactis; S. salivarius | Chewed cassava | Next-generation sequencing | Ecuador | [73] |

| L. fermentum; S. salivarius; | Mushed cassava | ||||

| L. casei; L. mesenteroides; L. plantarum; L. parabuchneri; L. paracasei; L. pantheris | Corn | ||||

| Chicha | E. asburiae; E. cancerogenus; K. ascorbate; L. brevis *; L. camelliae *; L. delbrueckii; L. fermentum; L. manihotivorans; L. plantarum; Lactobacillus sp.; P. vaccinostercus; L. lactis; Lactococcus sp.; L. lactis; Serratia sp.; S. oralis; S. parasanguinis; S. pneumoniae; S. salivarius; S. thermophilus; S. vestibularis; W. cibaria; W. confusa; W. paramesenteroides; Weissella sp. | Chewed cassava | Next-generation sequencing | Ecuador | [73] |

| Chicha | B. amyloliquefaciens; L. brevis; L. fermentum; Lactococcus sp.; L. citreum; L. lactis; S. gallolyticus; S. oralis; S. parasanguinis; S. pasteurianus; S. pneumoniae; S. salivarius; S. thermophilus; S. vestibularis; W. confusa | Mushed cassava | Next-generation sequencing | Ecuador | [73] |

| Chicha | C. maltaromaticum; Fructobacillus sp., G. intermedius; L. brevis; L. camelliae; L. casei; S. harbinensis *; L. parabuchneri; L. paracasei; S. paracollinoides; L. plantarum; Lactococcus sp.; L. lactis; Leuconostoc sp.; O. kitaharae; W. cibaria; W. confuse; Weissella sp. | Corn | Next-generation sequencing | Ecuador | [73] |

| Tarubá | L. plantarum; L. brevis; L. mesenteroides; L. lactis; P. pentosaceus; B. subtilis; B. amyloliquefaciens; B. licheniformis; Bacillus sp.; A. orientalis; C. terrae; O. intermedium | Cassava | rDNA gene sequencing CD PCR–DGGE analysis | Brazil | [34] |

| Apple cider | Leuconostoc sp.; L. pseudomesenteroides; Gluconobacter sp.; Rahnella; A. malorum; G. oxydans; Gluconobacter cerinus; K. saccharivorans; R. inusitata | Apple | rDNA gene sequencing CD | China | [45] |

| Kombucha | Gluconobacter sp.; Lyngbya sp.; Bifidobacterium sp.; Enterobacter sp.; Weissella sp.; Lactobacillus sp. Leuconostoc sp. | black tea | Next-generation sequencing | India | [55] |

| Water kefir grains | L. ruminis; B. methanolicus; Lactococcus sp. 1JSPR7; A. persici; A. amylophilus; Lactococcus sp. 1JSPR7; Marinilactibacillus sp. 15R; A. xylosoxidans; L. buchneri; P.pentosaceus; M. plutonius; E. faecium; M. plutonius; K. accharivorans; S. aureus; Marinilactibacillus sp. 15R; S. sobrinus; P. synxantha; Marinilactibacillus sp. 15R; L. sakei *; E. faecium; B. amyloliquefaciens; B. thuringiensis; L. backii; A. persici; L. agilis *; L. fermentum | Sugar | Next-generation sequencing | Turkiye | [74] |

3.3. Yeasts and Filamentous Fungi

| Beverage | Microorganisms | Substrate | Identification Method | Country | References |

|---|---|---|---|---|---|

| Jau Chhang | C. tropicalis SAA 613; S. cerevisiae SAA 620 | Barley/grape | rDNA gene sequencing CD | India | [29] |

| Chhang | S. cerevisiae SAA 616 | Rice/wheat | rDNA gene sequencing CD | India | [29] |

| Chicha | S. cerevisiae; P. citrinum; D. hansenii; H. uvarum; W. muriae; Wallemia sp.; Aspergillus sp.; P. kudriavzevii; A. versicolor; P. burtonii; H. burtonii; Cyberlindneras; Pichia sp.; S. bayanus; Galactomyces sp.; P. fermentans | Chewed cassava/Mushed cassava | Next-generation sequencing | Ecuador | [55] |

| Chicha | H. guilliermondii; H. opuntiae; H. uvarum; Hanseniaspora sp.; T. delbrueckii; Candida sp.; S. cerevisiae; P. kluyveri; P. kudriavzevii; R. mucilaginosa; R. slooffiae; Cryptococcus sp.; Y. lipolytica; W. anomalus | Rice/oat/grape/mixture of seven corn varieties | rDNA gene sequencing CD | Ecuador | [80] |

| Chicha | Acremonium sp.; Cladosporium sp.; Fusarium sp.; Mucor sp.; Penicillium sp.; Peyronellaea sp.; C. oleophila; C. zeylanoides; C. magnus; D. hansenii; G. candidum; H. uvarum; K. lactis; K. marxianus; M. caribbica; M. guilliermondii; P. fermentans; Pichia sp. NRRL Y-17803; R. mucilaginosa; S. cerevisiae; T. domesticum; W. anomalus | Corn | rDNA gene sequencing CD Next-generation sequencing | Argentina | [41] |

| Tarubá | P. exigua; H. uvarum; C. rugosa; T. delbrueckii; C. tropicalis; P. kudriavzevii; W. anomalus; C. ethanolica; P. manshurica | Cassava | rDNA gene sequencing CD PCR–DGGE analysis | Brazil | [34] |

| Apple cider | Saccharomyces sp.; Hanseniaspora sp.; Torulaspora sp. | Apple | rDNA gene sequencing CD | China | [45] |

| Apple cider | H. valbyensis; H. uvarum; H. osmophila; M. pulcherrima; P. guilliermondii; S. bayanus; S. cerevisiae | Apple | PCR-RFLP | Spain | [46] |

| Pineapple wine | H. guilliermondii; P. anomala; M. guilliermondii; H. uvarum; W. anomalus; M. guilliermondii; H. opuntiae; H. uvarum; | Pineapple | rDNA gene sequencing CD | Angola | [81] |

| Kombucha | C. stellimalicola; C. tropicalis; C. parapsilosis; L. thermotolerans; L. fermentati; L. kluyveri; E. cymbalariae; E. ashbyi; K. marxianus; D. hansenii; P. mexicana; M.caribbica; M. guilliermondii; Z. californica; S. cerevisiae; S. fibuligera; H. uvarum; H. meyeri; H. vineae; M. ingelheimense; S. lactativora; K. telluris; K. exigua; S. amethionina; S. caribaea | black tea | Next-generation sequencing | India | [55] |

| Water kefir grains | P. kudriavzevii; S. cerevisiae; E. cymbalariae; C. glabrata; O. parapolymorpha; T. terrestris; T. phaffii; F. oxysporum; S. lignohabitans | Sugar | Next-generation sequencing | Turkiye | [74] |

4. Beneficial Effects

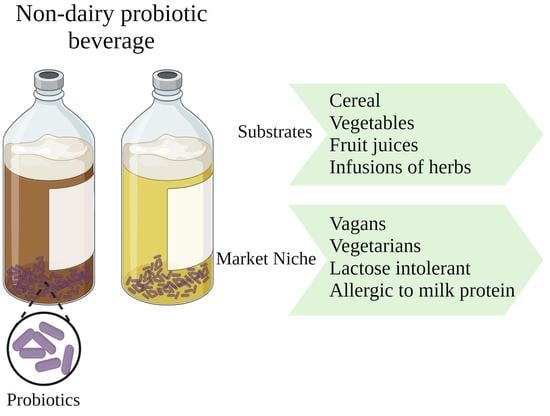

5. Novel Non-Dairy Probiotic Beverages

| Microorganism | Fermentation | Study Proposal | Main Results | Beverage/Substrate | Reference |

|---|---|---|---|---|---|

| L. paracasei; L. plantarum and L. rhamnosus | 37 °C/ 48 h | Impact of different LAB strains on the taste, chemical profile and bioactivities of goji juice. | Increased organic acid levels, reduced sugar level, and improved sensory quality. | Goji berry juice | [120] |

| L. plantarum, L. acidophilus, L. helveticus, F. fructosus and W. cibaria | 30 °C/24 h | Characterization of flavor profiles, volatile compounds, non-volatile organic acids, reducing sugars, and sensory quality. | Decreased acetic acid levels and improved “goji berry” note in final products. | Goji berry juice | [107] |

| L. plantarum, P. kluyveri, P. guilliermondii and D. hansenii | 30 °C/24 h | Performance of potential probiotic yeasts and bacteria in co-cultivation for the elaboration of a non-dairy fermented beverage. | Fermentation with co-culture of LAB and yeasts showed a minor reduction in antioxidant activity. | Sunflower seeds, oats, and almonds | [119] |

| L. plantarum and L. fermentum | 37 °C/48 h | Kinetics and variations in the profile of organic acids, anthocyanins, and non-anthocyanin phenolic acid by isolated LAB. | Increased antioxidant capacity of fermented blueberry juice. | Blueberry juice | [105] |

| L. plantarum | 37 °C/24 h | Antioxidant functional characteristics of blueberry juice fermented by L. plantarum. | Increased phenolic compound levels, antioxidant activity, and inhibition of α-glucosidase and α-amylase. | Blueberry juice | [127] |

| P. pentosaceus and P. acidilactici | 37 °C/72 h | Determination of cell viability, antimicrobial potential, physicochemical, and sensory properties of a probiotic juice. | Increased production of organic acid and mineral (Fe, Ca, Na) levels. | Mango juice | [109] |

| L. acidophilus, L. plantarum and L. fermentum | 37 °C/24 h | Influence of the cultivar on the fermentative properties of the fermented beverage regarding the levels of sugars, organic acids, volatile compounds, and sensory quality. | Higher consumption of total sugars and improved sensory quality. | Apple juice | [21] |

| P. pentosaceus | 37 °C/18 h | Aroma and flavor of a juice fermented by LAB regarding the profile of non-volatile metabolites. | Improvement of sensory quality. | Broccoli juice | [110] |

| L. rhamnosus and S. cerevisiae | 30 °C/24 h | Growth and survival of probiotics in co-culture with yeast. | Co-cultivation with probiotic yeast increases LAB survival in coffee varieties. | Coffee | [117] |

| L. rhamnosus, L. paracasei, L. plantarum, L. acidophilus and B. animalis | 37 °C/24 h | Production of a probiotic juice fermented by LAB and Bifidobacterium. | The mixture provides a suitable medium for the growth and viability of LAB and Bifidobacterium in a bioreactor. | Mixture of fruits and vegetables | [114] |

| P. acidilactici | 37 °C/24 h | Orange juice-based probiotic drink with antimicrobial properties. | Probiotic and antimicrobial effect against L. monocytogenes. | Orange juice | [108] |

| P. kudriavzevii, S. cerevisiae and W. subpelliculosus | 37 °C/36 h | Fermentation protocol for a functional fermented beverage with profiles of bioactive compounds and effect on gut microbiota. | Higher content of alcohols and esters and lower levels of aldehydes and alkanes, with modulation of gut microbiota. | Cherry | [118] |

| L. brevis, L. plantarum, L. rhamnosus and F. tropaeoli | 30 °C/48 h | Ability of LAB to extend shelf life and improve biochemical and functional properties of fermented juice. | Preservation of antioxidant activity after long fermentation and shelf life. | Cherimoya juice | [128] |

| L. acidophilus, L. plantarum, L. rhamnosus and L.casei | 37 °C/72 h | Changes in cell viability, acidifying activities of LAB and production of volatile compounds and organic acids. | Production of flavor compounds such as acetaldehyde and ketones. | Apple juice | [106] |

| B. lactis, L. plantarum and L. acidophilus | 37 °C/24 h | Effects of prebiotics on probiotic viability and stability of BAL-fermented juice. | Supplementation with prebiotic fructooligosaccharides increased lactic acid production by bifidobacteria and improved stability of probiotics. | Pineapple juice | [124] |

| S. cerevisiae | 25 °C | Physicochemical, antioxidant and sensory characteristics of fermented pomegranate juice. | Decreased antioxidant activity, total phenolic compounds, flavonoids, and anthocyanins. | Pomegranate juice | [116] |

| B. animalis | - | Non-dairy probiotic product, incorporated with microencapsulated B. animalis by spray drying. | The presence of inulin increases the survival of bifidobacteria during spray drying. | Passion fruit juice | [112] |

| L. casei | 37 °C/48 h | Development of vegetal probiotic beverage of passion fruit, yam and Lacticaseibacillus casei. | The drinks were considered good sources of fiber and had good acceptance in terms of aroma, color, and appearance. | Passion fruit juice and yam flour | [122] |

| L. casei and L. acidophilus | 37 °C/10 h | Development and sensory profile of a probiotic beverage from apple fermented by Lactobacillus casei. | The fermented probiotic apple drink was characterized by a thick texture and sweet taste. The drink was tested by potential consumers, with an acceptance rate of 96%. | Apple juice | [20] |

| L. casei | 31 °C/24 h | Development of probiotic drink: process optimization and product stability. | The color was maintained throughout the shelf life. Sonicated pineapple juice proved to be a suitable substrate for the cultivation of L. casei. | Pineapple juice | [129] |

| L. plantarum | 37 °C/6–10 h | Development of a new oat-based probiotic drink. | The beta-glucan content in the beverage remained unchanged during beverage fermentation and storage. The shelf life of the oat drink was estimated to be 21 days under refrigeration. | Oat | [123] |

| L. acidophilus and L. plantarum | 30 °C/48 h | Development of a probiotic beverage using breadfruit flour as a substrate. | This study successfully demonstrated the development of a new breadfruit-based fermented beverage with acceptable sensory characteristics and cell viability. | Breadfruit flour | [130] |

| L. casei | 37 °C/72 h | Chemical and sensory properties of probiotic drink based on rice bran extract and honey. | Bacterial bioavailability decreased during refrigerator storage. The results of the sensorial evaluation showed that the sample with 10% of rice bran extract was more acceptable than the others. | Bran extract of rice and honey | [131] |

| L. acidophilus | 30 °C/8 h | Development of a non-dairy probiotic drink utilizing sprouted cereals, legume, and soymilk. | Acidity, pH and probiotic counts in samples of wheat, barley, millet and green grass-based probiotic drink were found to be dependent on the level of sprouted cereal flour and soy milk. | Cereal sprouts, legumes and soy milk | [22] |

| L. rhamnnosus, L. plantarum and L. delbrueckii | 37 °C/24 h | Development of a beetroot probiotic drink. | Total phenols, flavonoids and antioxidant activity were increased in the probiotic drink compared to the fresh juice sample. | Beet juice | [132] |

| L. acidophilus | 30 °C/8 h | Development of a non-dairy fermented probiotic drink based on germinated and ungerminated cereals and legume. | Fermentation improved the overall acceptability and functional properties of the drink. | Sprouted and non-sprouted cereals and legumes | [133] |

| L. bulgaricus and S. thermophilus | Room temperature/8 h | Nutritional composition of non-dairy yogurt from sprouted tigernut tubers. | Increased value of protein, ash, crude fiber and energy. It improved amino acid content and sensory attributes, but decreased fat and antinutritional content of yogurt samples. | Chufa “tigernut” | [134] |

| L. paracasei | 37 °C/24 h | Probiotic Gac fruit beverage fermented with Lactobacillus paracasei. | Fermentation increased β-carotene content, antioxidant activity, binding to bile acids and increased inhibition of cholesterol micellization. Furthermore, it altered the volatile compounds in Gac juice. | Melon | [135] |

| L. casei, L. fermentum and L. plantarum | 30 °C/72 h | Probiotic drink of mangosteen juice fermented with Lactobacillus strains. | The fermented juice showed good antioxidant activity compared to the control (without lactic acid bacteria). | Mangosteen juice | [136] |

| L. plantarum, L. acidophilus and L. delbrueckiiem | 37 °C/24 and 48 h | Evaluation of probiotics in vegetable juices: tomato, carrot, and beet juice. | Increase in the amount of vitamin C. | Tomato juice, carrot and beet | [137] |

6. Market Perspectives and Challenges in the Production of Non-Dairy Probiotic Beverages

7. Safety of Probiotics Beverage and Relevant Concerns

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereira, G.V.; de Oliveira Coelho, B.; Magalhães Júnior, A.I.; Thomaz-Soccol, V.; Soccol, C.R. How to Select a Probiotic? A Review and Update of Methods and Criteria. Biotechnol. Adv. 2018, 36, 2060–2076. [Google Scholar] [CrossRef]

- Daliri, E.B.M.; Lee, B.H. New Perspectives on Probiotics in Health and Disease. Food Sci. Hum. Wellness 2015, 4, 56–65. [Google Scholar] [CrossRef]

- Aspri, M.; Papademas, P.; Tsaltas, D. Review on Non-Dairy Probiotics and Their Use in Non-Dairy Based Products. Fermentation 2020, 6, 30. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Giri, S.K. Probiotic Functional Foods: Survival of Probiotics during Processing and Storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Mohammadi, R.; Mortazavian, A.M. Review Article: Technological Aspects of Prebiotics in Probiotic Fermented Milks. Food Rev. Int. 2011, 27, 192–212. [Google Scholar] [CrossRef]

- Tangyu, M.; Muller, J.; Bolten, C.J.; Wittmann, C. Fermentation of Plant-Based Milk Alternatives for Improved Flavour and Nutritional Value. Appl. Microbiol. Biotechnol. 2019, 103, 9263–9275. [Google Scholar] [CrossRef] [PubMed]

- Vilela, A.; Cosme, F.; Inês, A. Wine and Non-Dairy Fermented Beverages: A Novel Source of Pro-and Prebiotics. Fermentation 2020, 6, 113. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Khartad, A.; Chakraborty, S. The Potential of Non-Dairy Synbiotic Instant Beverage Powder: Review on a New Generation of Healthy Ready-to-Reconstitute Drinks. Food Biosci. 2021, 42, 101195. [Google Scholar] [CrossRef]

- Catanzaro, R.; Sciuto, M.; Marotta, F. Lactose Intolerance: An Update on Its Pathogenesis, Diagnosis, and Treatment. Nutr. Res. 2021, 89, 23–34. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Chakraborty, S. Review on Potential Non-dairy Synbiotic Beverages: A Preliminary Approach Using Legumes. Int. J. Food Sci. Technol. 2021, 56, 2068–2077. [Google Scholar] [CrossRef]

- Shori, A.B. Influence of Food Matrix on the Viability of Probiotic Bacteria: A Review Based on Dairy and Non-Dairy Beverages. Food Biosci. 2016, 13, 1–8. [Google Scholar] [CrossRef]

- Roberts, D.; Reyes, V.; Bonilla, F.; Dzandu, B.; Liu, C.; Chouljenko, A.; Sathivel, S. Viability of Lactobacillus Plantarum NCIMB 8826 in Fermented Apple Juice under Simulated Gastric and Intestinal Conditions. LWT 2018, 97, 144–150. [Google Scholar] [CrossRef]

- Xu, X.; Bao, Y.; Wu, B.; Lao, F.; Hu, X.; Wu, J. Chemical Analysis and Flavor Properties of Blended Orange, Carrot, Apple and Chinese Jujube Juice Fermented by Selenium-Enriched Probiotics. Food Chem. 2019, 289, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Kandylis, P.; Pissaridi, K.; Bekatorou, A.; Kanellaki, M.; Koutinas, A.A. Dairy and Non-Dairy Probiotic Beverages. Curr. Opin. Food Sci. 2016, 7, 58–63. [Google Scholar] [CrossRef]

- Rasika, D.M.D.; Vidanarachchi, J.K.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ranadheera, C.S. Probiotic Delivery through Non-Dairy Plant-Based Food Matrices. Agriculture 2021, 11, 599. [Google Scholar] [CrossRef]

- Lima, T.T.M.; de Oliveira Hosken, B.; Venturim, B.C.; Lopes, I.L.; Martin, J.G.P. Traditional Brazilian Fermented Foods: Cultural and Technological Aspects. J. Ethn. Foods 2022, 9, 35. [Google Scholar] [CrossRef]

- Grujović, M.Ž.; Mladenović, K.G.; Semedo-Lemsaddek, T.; Laranjo, M.; Stefanović, O.D.; Kocić-Tanackov, S.D. Advantages and Disadvantages of Non-starter Lactic Acid Bacteria from Traditional Fermented Foods: Potential Use as Starters or Probiotics. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1537–1567. [Google Scholar] [CrossRef]

- da Silva Vale, A.; de Melo Pereira, G.V.; Santana, L.M.; de Carvalho Neto, D.P.; Colonia, B.S.O.; Soccol, V.T.; Maske, B.L.; Soccol, C.R. Perspective on the Use of Synthetic Biology in Rudimentary Food Fermentations. Syst. Microbiol. Biomanuf. 2022, 3, 150–165. [Google Scholar] [CrossRef]

- Granato, D.; Branco, G.F.; Nazzaro, F.; Cruz, A.G.; Faria, J.A.F. Functional Foods and Nondairy Probiotic Food Development: Trends, Concepts, and Products. Compr. Rev. Food Sci. Food Saf. 2010, 9, 292–302. [Google Scholar] [CrossRef]

- De Souza Neves Ellendersen, L.; Granato, D.; Bigetti Guergoletto, K.; Wosiacki, G. Development and Sensory Profile of a Probiotic Beverage from Apple Fermented with Lactobacillus Casei. Eng. Life Sci. 2012, 12, 475–485. [Google Scholar] [CrossRef]

- Peng, W.; Meng, D.; Yue, T.; Wang, Z.; Gao, Z. Effect of the Apple Cultivar on Cloudy Apple Juice Fermented by a Mixture of Lactobacillus Acidophilus, Lactobacillus Plantarum, and Lactobacillus Fermentum. Food Chem. 2021, 340, 127922. [Google Scholar] [CrossRef] [PubMed]

- Mridula, D.; Sharma, M. Development of Non-Dairy Probiotic Drink Utilizing Sprouted Cereals, Legume and Soymilk. LWT 2015, 62, 482–487. [Google Scholar] [CrossRef]

- McGovern, P.E.; Zhang, J.; Tang, J.; Zhang, Z.; Hall, G.R.; Moreau, R.A.; Nuñez, A.; Butrym, E.D.; Richards, M.P.; Wang, C.; et al. Fermented Beverages of Pre-and Proto-Historic China. Anthropology 2004, 51, 17593–17598. [Google Scholar] [CrossRef] [PubMed]

- Chan, S.T.; Padam, B.S.; Chye, F.Y. Effect of Fermentation on the Antioxidant Properties and Phenolic Compounds of Bambangan (Mangifera pajang) Fruit. J. Food Sci. Technol. 2023, 60, 303–314. [Google Scholar] [CrossRef] [PubMed]

- Prado, F.C.; Parada, J.L.; Pandey, A.; Soccol, C.R. Trends in Non-Dairy Probiotic Beverages. Food Res. Int. 2008, 41, 111–123. [Google Scholar] [CrossRef]

- da Silva Vale, A.; de Melo Pereira, G.V.; de Oliveira, A.C.; de Carvalho Neto, D.P.; Herrmann, L.W.; Karp, S.G.; Soccol, V.T.; Soccol, C.R. Production, Formulation, and Application of Postbiotics in the Treatment of Skin Conditions. Fermentation 2023, 9, 264. [Google Scholar] [CrossRef]

- Davani-Davari, D.; Negahdaripour, M.; Karimzadeh, I.; Seifan, M.; Mohkam, M.; Masoumi, S.J.; Berenjian, A.; Ghasemi, Y. Prebiotics: Definition, Types, Sources, Mechanisms, and Clinical Applications. Foods 2019, 8, 92. [Google Scholar] [CrossRef]

- Thakur, N.; Chand Bhalla, T. Characterization of Some Traditional Fermented Foods and Beverages of Himachal Pradesh. Indian J. Tradit. Knowl. 2004, 3, 325–335. [Google Scholar]

- Thakur, N.; Saris, P.E.J.; Bhalla, T.C. Microorganisms Associated with Amylolytic Starters and Traditional Fermented Alcoholic Beverages of North Western Himalayas in India. Food Biosci. 2015, 11, 92–96. [Google Scholar] [CrossRef]

- Kumari, A.; Swain, M.R.; Pandey, A.; Gupta, A.; Raj, A.; Sharma, A.; Kumar, A.; Chauhan, A.; Ann, A.; Neopany, B.; et al. Indigenous Alcoholic Beverages of South Asia. In Indigenous Fermented Foods of South Asia; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Targais, K.; Stobdan, T.; Mundra, S.; Ali, Z.; Yadav, A.; Korekar, G.; Singh, S.B. Chhang-A Barley Based Alcoholic Beverage of Ladakh, India. Indian J. Tradit. Knowl. 2012, 11, 190–193. [Google Scholar]

- Savitri, S.; Thakur, N.; Bhalla, T.C. Present Status and Future Prospects of Traditional Fermented Beverages of Himachal Pradesh, India. Int. J. Food Ferment. Technol. 2019, 9, 67–72. [Google Scholar] [CrossRef]

- Mayorga, G.A.C.; Arias Palma, G.B.; Sandoval-Cañas, G.J.; Ordoñez-Araque, R.H. Ancestral Fermented Indigenous Beverages from South America Made from Cassava (Manihot esculenta). Food Sci. Technol. 2021, 41, 360–367. [Google Scholar] [CrossRef]

- Ramos, C.L.; de Sousa, E.S.; Ribeiro, J.; Almeida, T.M.; Santos CC AD, A.; Abegg, M.A.; Schwan, R.F. Microbiological and Chemical Characteristics of Tarubá, an Indigenous Beverage Produced from Solid Cassava Fermentation. Food Microbiol. 2015, 49, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Faria-Oliveira, F.; Diniz, R.H.S.; Godoy-Santos, F.; Piló, F.B.; Mezadri, H.; Castro, I.M.; Brandão, R.L. The Role of Yeast and Lactic Acid Bacteria in the Production of Fermented Beverages in South America. In Food Production and Industry; InTech: Rijeka, Croatia, 2015. [Google Scholar]

- Guerra, L.S.; Cevallos-Cevallos, J.M.; Weckx, S.; Ruales, J. Traditional Fermented Foods from Ecuador: A Review with a Focus on Microbial Diversity. Foods 2022, 11, 1854. [Google Scholar] [CrossRef] [PubMed]

- Grijalva-Vallejos, N.; Krogerus, K.; Nikulin, J.; Magalhães, F.; Aranda, A.; Matallana, E.; Gibson, B. Potential Application of Yeasts from Ecuadorian Chichas in Controlled Beer and Chicha Production. Food Microbiol. 2021, 98, 103644. [Google Scholar] [CrossRef]

- Freire, A.L.; Ramos, C.L.; Schwan, R.F. Microbiological and Chemical Parameters during Cassava Based-Substrate Fermentation Using Potential Starter Cultures of Lactic Acid Bacteria and Yeast. Food Res. Int. 2015, 76, 787–795. [Google Scholar] [CrossRef] [PubMed]

- Piló, F.B.; Carvajal-Barriga, E.J.; Guamán-Burneo, M.C.; Portero-Barahona, P.; Dias, A.M.M.; Freitas, L.F.D.d.; Gomes, F.d.C.O.; Rosa, C.A. Saccharomyces Cerevisiae Populations and Other Yeasts Associated with Indigenous Beers (Chicha) of Ecuador. Br. J. Microbiol. 2018, 49, 808–815. [Google Scholar] [CrossRef]

- Colehour, A.M.; Meadow, J.F.; Liebert, M.A.; Cepon-Robins, T.J.; Gildner, T.E.; Urlacher, S.S.; Bohannan, B.J.M.; Snodgrass, J.J.; Sugiyama, L.S. Local Domestication of Lactic Acid Bacteria via Cassava Beer Fermentation. PeerJ 2014, 2014, e479. [Google Scholar] [CrossRef]

- Mendoza, L.M.; Neef, A.; Vignolo, G.; Belloch, C. Yeast Diversity during the Fermentation of Andean Chicha: A Comparison of High-Throughput Sequencing and Culture-Dependent Approaches. Food Microbiol. 2017, 67, 1–10. [Google Scholar] [CrossRef]

- Resende, L.V.; Pinheiro, L.K.; Miguel, M.G.C.P.; Ramos, C.L.; Vilela, D.M.; Schwan, R.F. Microbial Community and Physicochemical Dynamics during the Production of ‘Chicha’, A Traditional Beverage of Indigenous People of Brazil. World J. Microbiol. Biotechnol. 2018, 34, 34–46. [Google Scholar] [CrossRef]

- Bassi, D.; Orrù, L.; Vasquez, J.C.; Cocconcelli, P.S.; Fontana, C. Peruvian Chicha: A Focus on the Microbial Populations of This Ancient Maize-Based Fermented Beverage. Microorganisms 2020, 8, 93. [Google Scholar] [CrossRef]

- Al Daccache, M.; Koubaa, M.; Maroun, R.G.; Salameh, D.; Louka, N.; Vorobiev, E. Impact of the Physicochemical Composition and Microbial Diversity in Apple Juice Fermentation Process: A Review. Molecules 2020, 25, 3698. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Du, J. A Comparative Study of the Effect of Bacteria and Yeasts Communities on Inoculated and Spontaneously Fermented Apple Cider. Food Microbiol. 2023, 111, 104195. [Google Scholar] [CrossRef] [PubMed]

- Valles, B.S.; Bedriñana, R.P.; Tascón, N.F.; Simón, A.Q.; Madrera, R.R. Yeast Species Associated with the Spontaneous Fermentation of Cider. Food Microbiol. 2007, 24, 25–31. [Google Scholar] [CrossRef]

- Schneedorf, J.M. Kefir D’Aqua and Its Probiotic Properties. In Probiotic in Animals; InTech: Rijeka, Croatia, 2012; pp. 53–75. [Google Scholar]

- Magalhães, K.T.; de Pereira, G.V.M.; Dias, D.R.; Schwan, R.F. Microbial Communities and Chemical Changes during Fermentation of Sugary Brazilian Kefir. World J. Microbiol. Biotechnol. 2010, 26, 1241–1250. [Google Scholar] [CrossRef]

- da CP Miguel, M.G.; Cardoso, P.G.; Magalhães, K.T.; Schwan, R.F. Profile of Microbial Communities Present in Tibico (Sugary Kefir) Grains from Different Brazilian States. World J. Microbiol. Biotechnol. 2011, 27, 1875–1884. [Google Scholar] [CrossRef]

- Laureys, D.; De Vuyst, L. The Water Kefir Grain Inoculum Determines the Characteristics of the Resulting Water Kefir Fermentation Process. J. Appl. Microbiol. 2016, 122, 719–732. [Google Scholar] [CrossRef] [PubMed]

- Laureys, D.; De Vuyst, L. Microbial Species Diversity, Community Dynamics, and Metabolite Kinetics of Water Kefir Fermentation. Appl. Environ. Microbiol. 2014, 80, 2564–2572. [Google Scholar] [CrossRef]

- Miranda, J.F.; Ruiz, L.F.; Silva, C.B.; Uekane, T.M.; Silva, K.A.; Gonzalez, A.G.M.; Fernandes, F.F.; Lima, A.R. Kombucha: A Review of Substrates, Regulations, Composition, and Biological Properties. J. Food Sci. 2022, 87, 503–527. [Google Scholar] [CrossRef] [PubMed]

- Coelho, R.M.D.; de Almeida, A.L.; do Amaral, R.Q.G.; da Mota, R.N.; de Sousa, P.H.M. Kombucha: Review. Int. J. Gastron. Food Sci. 2020, 22, 100272. [Google Scholar] [CrossRef]

- Yang, J.; Lagishetty, V.; Kurnia, P.; Henning, S.M.; Ahdoot, A.I.; Jacobs, J.P. Microbial and Chemical Profiles of Commercial Kombucha Products. Nutrients 2022, 14, 670. [Google Scholar] [CrossRef] [PubMed]

- Chakravorty, S.; Bhattacharya, S.; Chatzinotas, A.; Chakraborty, W.; Bhattacharya, D.; Gachhui, R. Kombucha Tea Fermentation: Microbial and Biochemical Dynamics. Int. J. Food Microbiol. 2016, 220, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Watawana, M.I.; Jayawardena, N.; Gunawardhana, C.B.; Waisundara, V.Y. Health, Wellness, and Safety Aspects of the Consumption of Kombucha. J. Chem. 2015, 2015, 591869. [Google Scholar] [CrossRef]

- Jayabalan, R.; Malbaša, R.V.; Sathishkumar, M. Kombucha. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Neffe-Skocińska, K.; Sionek, B.; Ścibisz, I.; Kołożyn-Krajewska, D. Acid Contents and the Effect of Fermentation Condition of Kombucha Tea Beverages on Physicochemical, Microbiological and Sensory Properties. CyTA-J. Food 2017, 15, 601–607. [Google Scholar] [CrossRef]

- Laavanya, D.; Shirkole, S.; Balasubramanian, P. Current Challenges, Applications and Future Perspectives of SCOBY Cellulose of Kombucha Fermentation. J. Clean. Prod. 2021, 295, 126454. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Zarei, M.; Gholami, A.; Lai, C.W.; Chiang, W.H.; Omidifar, N.; Bahrani, S.; Mazraedoost, S. Recent Progress in Chemical Composition, Production, and Pharmaceutical Effects of Kombucha Beverage: A Complementary and Alternative Medicine. Evid.-Based Complement. Altern. Med. 2020, 2020, 4397543. [Google Scholar] [CrossRef]

- Kapp, J.M.; Sumner, W. Kombucha: A Systematic Review of the Empirical Evidence of Human Health Benefit. Ann. Epidemiol. 2019, 30, 66–70. [Google Scholar] [CrossRef]

- Maske, B.L.; Pereira, G.V.d.M.; Carvalho Neto, D.P.d.; Lindner, J.d.D.; Letti, L.A.J.; Pagnoncelli, M.G.; Ssccol, C.R. Presence and Persistence of Pseudomonas Sp. during Caspian Sea-Style Spontaneous Milk Fermentation Highlights the Importance of Safety and Regulatory Concerns for Traditional and Ethnic Foods. Food Sci. Technol. 2021, 41, 273–283. [Google Scholar] [CrossRef]

- Patz, S.; Witzel, K.; Scherwinski, A.-C.; Ruppel, S. Culture Dependent and Independent Analysis of Potential Probiotic Bacterial Genera and Species Present in the Phyllosphere of Raw Eaten Produce. Int. J. Mol. Sci. 2019, 20, 3661. [Google Scholar] [CrossRef]

- Merabti, R.; Madec, M.N.; Chuat, V.; Becila, F.Z.; Boussekine, R.; Bekhouche, F.; Valence, F. First Insight into the Technological Features of Lactic Acid Bacteria Isolated from Algerian Fermented Wheat Lemzeiet. Curr. Microbiol. 2019, 76, 1095–1104. [Google Scholar] [CrossRef]

- Aguilar, G.; Morlon-Guyot, J.; Trejo-Aguilar, B.; Guyot, J.P. Purification and Characterization of an Extracellular α-Amylase Produced by Lactobacillus Manihotivorans LMG 18010T, an Amylolytic Lactic Acid Bacterium. Enzyme Microb. Technol. 2000, 27, 406–413. [Google Scholar] [CrossRef]

- Maske, B.L.; de Melo Pereira, G.V.; da S. Vale, A.; de Carvalho Neto, D.P.; Karp, S.G.; Viesser, J.A.; De Dea Lindner, J.; Pagnoncelli, M.G.; Soccol, V.T.; Soccol, C.R. A Review on Enzyme-Producing Lactobacilli Associated with the Human Digestive Process: From Metabolism to Application. Enzyme Microb. Technol. 2021, 149, 109836. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, T.; Tang, H.; Li, X.; Chen, Y.; Zhang, L.; Zhang, J. Probiotic Potential and Amylolytic Properties of Lactic Acid Bacteria Isolated from Chinese Fermented Cereal Foods. Food Control. 2020, 111, 107057. [Google Scholar] [CrossRef]

- Petrova, P.; Emanuilova, M.; Petrov, K. Amylolytic Lactobacillus Strains from Bulgarian Fermented Beverage Boza. Z. Nat. C 2010, 65, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Bolaños-Núñez, S.; Santiago-Urbina, J.A.; Guyot, J.-P.; Díaz-Ruiz, G.; Wacher, C. Microbial Interactions between Amylolytic and Non-Amylolytic Lactic Acid Bacteria Strains Isolated during the Fermentation of Pozol. Foods 2021, 10, 2607. [Google Scholar] [CrossRef]

- Peyer, L.C.; Zannini, E.; Arendt, E.K. Lactic Acid Bacteria as Sensory Biomodulators for Fermented Cereal-Based Beverages. Trends Food Sci. Technol. 2016, 54, 17–25. [Google Scholar] [CrossRef]

- Gomes, R.J.; de Fatima Borges, M.; de Freitas Rosa, M.; Castro-Gómez, R.J.H.; Spinosa, W.A. Acetic Acid Bacteria in the Food Industry: Systematics, Characteristics and Applications. Food Technol. Biotechnol. 2018, 56, 139. [Google Scholar] [CrossRef] [PubMed]

- WoldemariamYohannes, K.; Wan, Z.; Yu, Q.; Li, H.; Wei, X.; Liu, Y.; Wang, J.; Sun, B. Prebiotic, Probiotic, Antimicrobial, and Functional Food Applications of Bacillus Amyloliquefaciens. J. Agric. Food Chem. 2020, 68, 14709–14727. [Google Scholar] [CrossRef]

- Freire, A.L.; Zapata, S.; Mosquera, J.; Mejia, M.L.; Trueba, G. Bacteria Associated with Human Saliva Are Major Microbial Components of Ecuadorian Indigenous Beers (Chicha). PeerJ 2016, 4, e1962. [Google Scholar] [CrossRef]

- Yerlikaya, O.; Akan, E.; Kinik, Ö. The Metagenomic Composition of Water Kefir Microbiota. Int. J. Gastron. Food Sci. 2022, 30, 100621. [Google Scholar] [CrossRef]

- Maicas, S. The Role of Yeasts in Fermentation Processes. Microorganisms 2020, 8, 1142. [Google Scholar] [CrossRef] [PubMed]

- Walker, G.; Stewart, G. Saccharomyces Cerevisiae in the Production of Fermented Beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- De Melo Pereira, G.V.; Maske, B.L.; de Carvalho Neto, D.P.; Karp, S.G.; De Dea Lindner, J.; Martin, J.G.P.; de Oliveira Hosken, B.; Soccol, C.R. What Is Candida Doing in My Food? A Review and Safety Alert on Its Use as Starter Cultures in Fermented Foods. Microorganisms 2022, 10, 1855. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Woo, S.Y.; Lee, S.Y.; Park, S.B.; Im, J.H.; Chun, H.S. Mycotoxins in Soybean-based Foods Fermented with Filamentous Fungi: Occurrence and Preventive Strategies. Compr. Rev. Food Sci. Food Saf. 2022, 21, 5131–5152. [Google Scholar] [CrossRef]

- Zajc, J.; Gunde-Cimerman, N. The Genus Wallemia—From Contamination of Food to Health Threat. Microorganisms 2018, 6, 46. [Google Scholar] [CrossRef]

- Grijalva-Vallejos, N.; Aranda, A.; Matallana, E. Evaluation of Yeasts from Ecuadorian Chicha by Their Performance as Starters for Alcoholic Fermentations in the Food Industry. Int. J. Food Microbiol. 2020, 317, 108462. [Google Scholar] [CrossRef]

- Dellacassa, E.; Trenchs, O.; Fariña, L.; Debernardis, F.; Perez, G.; Boido, E.; Carrau, F. Pineapple (Ananas comosus L. Merr.) Wine Production in Angola: Characterisation of Volatile Aroma Compounds and Yeast Native Flora. Int. J. Food Microbiol. 2017, 241, 161–167. [Google Scholar] [CrossRef]

- Ashaolu, T.J. Immune Boosting Functional Foods and Their Mechanisms: A Critical Evaluation of Probiotics and Prebiotics. Biomed. Pharmacother. 2020, 130, 110625. [Google Scholar] [CrossRef]

- Rerksuppaphol, S. A Randomized Double-Blind Controlled Trial of Lactobacillus Acidophilus Plus Bifidobacterium Bifidum versus Placebo in Patients with Hypercholesterolemia. J. Clin. Diagn. Res. 2015, 9, KC01. [Google Scholar] [CrossRef]

- Junnarkar, M.; Gaikwad, S.C.; Pawar, S.; Nawani, N. Probiotic Potential of Lactic Acid Bacteria from Fresh Vegetables: Application in Food Preservation. Indian J. Exp. Biol. 2019, 57, 825–838. [Google Scholar]

- Wang, Z.; Feng, Y.; Yang, N.; Jiang, T.; Xu, H.; Lei, H. Fermentation of Kiwifruit Juice from Two Cultivars by Probiotic Bacteria: Bioactive Phenolics, Antioxidant Activities and Flavor Volatiles. Food Chem. 2022, 373, 131455. [Google Scholar] [CrossRef]

- Pinto, A.; Barbosa, J.; Albano, H.; Isidro, J.; Teixeira, P. Screening of Bacteriocinogenic Lactic Acid Bacteria and Their Characterization as Potential Probiotics. Microorganisms 2020, 8, 393. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Kim, S.H. Anti-Inflammatory and Anti-Osteoporotic Potential of Lactobacillus Plantarum A41 and L. Fermentum SRK414 as Probiotics. Probiotics Antimicrob. Proteins 2020, 12, 623–634. [Google Scholar] [CrossRef]

- Shah, N.J.; Swami, O.C. Role of Probiotics in Diabetes: A Review of Their Rationale and Efficacy. EMJ Diabetes 2017, 5, 104–110. [Google Scholar] [CrossRef]

- Speer, H.; D’Cunha, N.M.; Alexopoulos, N.I.; McKune, A.J.; Naumovski, N. Anthocyanins and Human Health—A Focus on Oxidative Stress, Inflammation and Disease. Antioxidants 2020, 9, 366. [Google Scholar] [CrossRef] [PubMed]

- Syiemlieh, I.; Morya, S. Dairy and Non-Dairy Based Probiotics: A Review. Pharma Innov. 2022, 11, 2956–2964. [Google Scholar] [CrossRef]

- Abatenh, E.; Gizaw, B.; Tsegay, Z.; Tefera, G.; Aynalem, E. Health Benefits of Probiotics; 2018. [Google Scholar]

- Markowiak, P.; Śliżewska, K. The Role of Probiotics, Prebiotics and Synbiotics in Animal Nutrition. Gut Pathog. 2018, 10, 21. [Google Scholar] [CrossRef] [PubMed]

- Kahouli, I.; Malhotra, M.; Westfall, S.; Alaoui-Jamali, M.A.; Prakash, S. Design and Validation of an Orally Administrated Active L. Fermentum-L. Acidophilus Probiotic Formulation Using Colorectal Cancer Apc Min/+ Mouse Model. Appl. Microbiol. Biotechnol. 2017, 101, 1999–2019. [Google Scholar] [CrossRef]

- Bedada, T.; Feto, T.K.; Awoke, K.S.; Garedew, A.D.; Yifat, F.T.; Birri, D.J. Probiotics for Cancer Alternative Prevention and Treatment. Biomed. Pharmacother. 2020, 129, 110409. [Google Scholar] [CrossRef] [PubMed]

- Zaharuddin, L.; Mokhtar, N.M.; Nawawi, K.N.M.; Ali, R.A.R. A Randomized Double-Blind Placebo-Controlled Trial of Probiotics in Post-Surgical Colorectal Cancer. BMC Gastroenterol. 2019, 19, 131. [Google Scholar] [CrossRef]

- Górska, A.; Przystupski, D.; Niemczura, M.J.; Kulbacka, J. Probiotic Bacteria: A Promising Tool in Cancer Prevention and Therapy. Curr. Microbiol. 2019, 76, 939–949. [Google Scholar] [CrossRef] [PubMed]

- Blackwood, B.P.; Yuan, C.Y.; Wood, D.R.; Nicolas, J.D.; Grothaus, J.S.; Hunter, C.J. Probiotic Lactobacillus Species Strengthen Intestinal Barrier Function and Tight Junction Integrity in Experimental Necrotizing Enterocolitis. J. Probiotics Health 2017, 5, 159. [Google Scholar] [CrossRef]

- Li, T.; Teng, D.; Mao, R.; Hao, Y.; Wang, X.; Wang, J. A Critical Review of Antibiotic Resistance in Probiotic Bacteria. Food Res. Int. 2020, 136, 109571. [Google Scholar] [CrossRef]

- Jakubczyk, D.; Leszczyńska, K.; Górska, S. The Effectiveness of Probiotics in the Treatment of Inflammatory Bowel Disease (IBD)—A Critical Review. Nutrients 2020, 12, 1973. [Google Scholar] [CrossRef] [PubMed]

- Fijan, S.; Frauwallner, A.; Langerholc, T.; Krebs, B.; ter Haar (née Younes), J.A.; Heschl, A.; Turk, D.M.; Rogelj, I. Efficacy of Using Probiotics with Antagonistic Activity against Pathogens of Wound Infections: An Integrative Review of Literature. Biomed. Res. Int. 2019, 2019, 7585486. [Google Scholar] [CrossRef] [PubMed]

- Szutowska, J.; Gwiazdowska, D. Probiotic Potential of Lactic Acid Bacteria Obtained from Fermented Curly Kale Juice. Arch. Microbiol. 2021, 203, 975–988. [Google Scholar] [CrossRef]

- Guinane, C.M.; Lawton, E.M.; O’Connor, P.M.; O’Sullivan, Ó.; Hill, C.; Ross, R.P.; Cotter, P.D. The Bacteriocin Bactofencin A Subtly Modulates Gut Microbial Populations. Anaerobe 2016, 40, 41–49. [Google Scholar] [CrossRef]

- Jia, B.; Zou, Y.; Han, X.; Bae, J.-W.; Jeon, C.O. Gut Microbiome-Mediated Mechanisms for Reducing Cholesterol Levels: Implications for Ameliorating Cardiovascular Disease. Trends Microbiol. 2023, 31, 76–91. [Google Scholar] [CrossRef]

- Iqbal, Z.; Ahmed, S.; Tabassum, N.; Bhattacharya, R.; Bose, D. Role of Probiotics in Prevention and Treatment of Enteric Infections: A Comprehensive Review. 3 Biotech 2021, 11, 242. [Google Scholar] [CrossRef]

- Li, S.; Tao, Y.; Li, D.; Wen, G.; Zhou, J.; Manickam, S.; Han, Y.; Chai, W.S. Fermentation of Blueberry Juices Using Autochthonous Lactic Acid Bacteria Isolated from Fruit Environment: Fermentation Characteristics and Evolution of Phenolic Profiles. Chemosphere 2021, 276, 130090. [Google Scholar] [CrossRef]

- Chen, C.; Lu, Y.; Yu, H.; Chen, Z.; Tian, H. Influence of 4 Lactic Acid Bacteria on the Flavor Profile of Fermented Apple Juice. Food Biosci. 2019, 27, 30–36. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, P.; Laaksonen, O.; Wei, B.; Zhu, Y.; Zhang, B.; Zhu, B.; Li, H. Lactic Acid Bacteria Incubation and Aging Drives Flavor Enhancement of Goji Berry Juice. J. Food Compos. Anal. 2022, 105, 104202. [Google Scholar] [CrossRef]

- De Oliveira Vieira, K.C.; Ferreira, C.D.S.; Bueno, E.B.T.; De Moraes, Y.A.; Toledo, A.C.C.G.; Nakagaki, W.R.; Pereira, V.C.; Winkelstroter, L.K. Development and Viability of Probiotic Orange Juice Supplemented by Pediococcus Acidilactici CE51. LWT 2020, 130, 109637. [Google Scholar] [CrossRef]

- Adebayo-Tayo, B.C.; Olomitutu, F.O.; Adebami, G.E. Production and Evaluation of Probioticated Mango Juice Using Pediococcus Pentosaceus and Pediococcus Acidilactici during Storage at Different Temperature. J. Agric. Food Res. 2021, 6, 100202. [Google Scholar] [CrossRef]

- Xu, X.; Bi, S.; Lao, F.; Chen, F.; Liao, X.; Wu, J. Comprehensive Investigation on Volatile and Non-Volatile Metabolites in Broccoli Juices Fermented by Animal- and Plant-Derived Pediococcus Pentosaceus. Food Chem. 2021, 341, 128118. [Google Scholar] [CrossRef] [PubMed]

- Kumar, B.V.; Vijayendra, S.V.N.; Reddy, O.V.S. Trends in Dairy and Non-Dairy Probiotic Products—A Review. J. Food Sci. Technol. 2015, 52, 6112–6124. [Google Scholar] [CrossRef]

- Dias, C.O.; dos Santos Opuski de Almeida, J.; Pinto, S.S.; de Oliveira Santana, F.C.; Verruck, S.; Müller, C.M.O.; Prudêncio, E.S.; de Mello Castanho Amboni, R.D. Development and Physico-Chemical Characterization of Microencapsulated Bifidobacteria in Passion Fruit Juice: A Functional Non-Dairy Product for Probiotic Delivery. Food Biosci. 2018, 24, 26–36. [Google Scholar] [CrossRef]

- Terpou, A.; Papadaki, A.; Lappa, I.K.; Kachrimanidou, V.; Bosnea, L.A.; Kopsahelis, N. Probiotics in Food Systems: Significance and Emerging Strategies Towards Improved Viability and Delivery of Enhanced Beneficial Value. Nutrients 2019, 11, 1591. [Google Scholar] [CrossRef]

- Güney, D.; Güngörmüşler, M. Development and Comparative Evaluation of a Novel Fermented Juice Mixture with Probiotic Strains of Lactic Acid Bacteria and Bifidobacteria. Probiotics Antimicrob. Proteins 2021, 13, 495–505. [Google Scholar] [CrossRef] [PubMed]

- Oshiro, M.; Zendo, T.; Nakayama, J. Diversity and Dynamics of Sourdough Lactic Acid Bacteriota Created by a Slow Food Fermentation System. J. Biosci. Bioeng. 2021, 131, 333–340. [Google Scholar] [CrossRef]

- Rios-Corripio, G.; Guerrero-Beltrán, J.Á. Antioxidant and Physicochemical Characteristics of Unfermented and Fermented Pomegranate (Punica granatum L.) Beverages. J. Food Sci. Technol. 2019, 56, 132–139. [Google Scholar] [CrossRef]

- Chan, M.Z.A.; Toh, M.; Liu, S.-Q. Growth, Survival, and Metabolic Activities of Probiotics Lactobacillus Rhamnosus GG and Saccharomyces Cerevisiae Var. Boulardii CNCM-I745 in Fermented Coffee Brews. Int. J. Food Microbiol. 2021, 350, 109229. [Google Scholar] [CrossRef] [PubMed]

- Di Cagno, R.; Filannino, P.; Cantatore, V.; Polo, A.; Celano, G.; Martinovic, A.; Cavoski, I.; Gobbetti, M. Design of Potential Probiotic Yeast Starters Tailored for Making a Cornelian Cherry (Cornus mas L.) Functional Beverage. Int. J. Food Microbiol. 2020, 323, 108591. [Google Scholar] [CrossRef]

- Ferreira, I.; de Sousa Melo, D.; Menezes, A.G.T.; Fonseca, H.C.; de Assis, B.B.T.; Ramos, C.L.; Magnani, M.; Dias, D.R.; Schwan, R.F. Evaluation of Potentially Probiotic Yeasts and Lactiplantibacillus Plantarum in Co-Culture for the Elaboration of a Functional Plant-Based Fermented Beverage. Food Res. Int. 2022, 160, 111697. [Google Scholar] [CrossRef]

- Duan, W.; Guan, Q.; Zhang, H.-L.; Wang, F.-Z.; Lu, R.; Li, D.-M.; Geng, Y.; Xu, Z.-H. Improving Flavor, Bioactivity, and Changing Metabolic Profiles of Goji Juice by Selected Lactic Acid Bacteria Fermentation. Food Chem. 2023, 408, 135155. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, C.; Guo, Y.; Wang, X.; Meng, Y. Polyphenols in Fermented Apple Juice: Beneficial Effects on Human Health. J. Funct. Foods 2021, 76, 104294. [Google Scholar] [CrossRef]

- Do Monte Guedes, C.K.R.; do Monte Guedes, A.F.L.; da Silva, J.R.; da Silva, E.B.B.; dos Santos, E.C.M.; Stamford, T.C.M.; Stamford, T.L.M. Development of Vegetal Probiotic Beverage of Passion Fruit (Passiflora edulis Sims), Yam (Dioscorea cayenensis) and Lacticaseibacillus casei. Food Sci. Technol. 2021, 41, 619–626. [Google Scholar] [CrossRef]

- Angelov, A.; Gotcheva, V.; Kuncheva, R.; Hristozova, T. Development of a New Oat-Based Probiotic Drink. Int. J. Food Microbiol. 2006, 112, 75–80. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Bujna, E.; Fekete, N.; Tran, A.T.M.; Rezessy-Szabo, J.M.; Prasad, R.; Nguyen, Q.D. Probiotic Beverage from Pineapple Juice Fermented With Lactobacillus and Bifidobacterium Strains. Front. Nutr. 2019, 6, 54. [Google Scholar] [CrossRef] [PubMed]

- Grainfields Australia Fermented Foods. Available online: https://agmfoods.com/ (accessed on 5 January 2023).

- Vita Biosa. Available online: https://vitabiosa.com/ (accessed on 5 January 2023).

- Zhang, Y.; Liu, W.; Wei, Z.; Yin, B.; Man, C.; Jiang, Y. Enhancement of Functional Characteristics of Blueberry Juice Fermented by Lactobacillus Plantarum. LWT 2021, 139, 110590. [Google Scholar] [CrossRef]

- Isas, A.S.; Celis, M.S.M.; Correa, J.R.P.; Fuentes, E.; Rodríguez, L.; Palomo, I.; Mozzi, F.; Nieuwenhove, C. Van Functional Fermented Cherimoya (Annona cherimola Mill.) Juice Using Autochthonous Lactic Acid Bacteria. Food Res. Int. 2020, 138, 109729. [Google Scholar] [CrossRef] [PubMed]

- Costa, M.G.M.; Fonteles, T.V.; de Jesus, A.L.T.; Rodrigues, S. Sonicated Pineapple Juice as Substrate for L. Casei Cultivation for Probiotic Beverage Development: Process Optimisation and Product Stability. Food Chem. 2013, 139, 261–266. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Hamid, N.; Gutierrez-Maddox, N.; Kantono, K.; Kitundu, E. Development of a Probiotic Beverage Using Breadfruit Flour as a Substrate. Foods 2019, 8, 214. [Google Scholar] [CrossRef] [PubMed]

- Hatami, S.; Tajabadi, N.; Massoud, R.; Sharifan, A. Chemical and Sensorial Properties of Probiotic Beverage Based on Rice Bran Extract and Honey. Biomass Convers. Biorefin 2021, 13, 5151–5156. [Google Scholar] [CrossRef]

- Panghal, A.; Virkar, K.; Kumar, V.; Dhull, S.B.; Gat, Y.; Chhikara, N. Development of Probiotic Beetroot Drink. Curr. Res. Nutr. Food Sci. J. 2017, 5, 257–262. [Google Scholar] [CrossRef]

- Chavan, M.; Gat, Y.; Harmalkar, M.; Waghmare, R. Development of Non-Dairy Fermented Probiotic Drink Based on Germinated and Ungerminated Cereals and Legume. LWT 2018, 91, 339–344. [Google Scholar] [CrossRef]

- Ogundipe, O.O.; Fasogbon, B.M.; Ogundipe, F.O.; Oredope, O.; Amaezenanbu, R.U. Nutritional Composition of Non-dairy Yogurt from Sprouted Tigernut Tubers. J. Food Process. Preserv. 2021, 45, e15884. [Google Scholar] [CrossRef]

- Marnpae, M.; Chusak, C.; Balmori, V.; Kamonsuwan, K.; Dahlan, W.; Nhujak, T.; Hamid, N.; Adisakwattana, S. Probiotic Gac Fruit Beverage Fermented with Lactobacillus Paracasei: Physiochemical Properties, Phytochemicals, Antioxidant Activities, Functional Properties, and Volatile Flavor Compounds. LWT 2022, 169, 113986. [Google Scholar] [CrossRef]

- Mongkontanawat, N.; Boonna, S.; Wasikadilok, N. Probiotic Beverage from Mangosteen Juice Fermented with Lactobacillus Strains. Trends Sci. 2022, 19, 6305. [Google Scholar] [CrossRef]

- Goderska, K.; Dombhare, K.; Radziejewska-Kubzdela, E. Evaluation of Probiotics in Vegetable Juices: Tomato (Solanum lycopersicum), Carrot (Daucus carota Subsp. Sativus) and Beetroot Juice (Beta vulgaris). Arch. Microbiol. 2022, 204, 300. [Google Scholar] [CrossRef]

- Lumina intelligence. Reserarch and Markets Probiotic Drink Market: Insights on the Probiotic Drinks Global Market to 2031—Asia-Pacific Has Been Dominating the Industry. Available online: https://www.lumina-intelligence.com/ (accessed on 10 April 2023).

- Pimentel, T.C.; Klososki, S.J.; Rosset, M.; Barão, C.E.; Marcolino, V.A. Fruit Juices as Probiotic Foods. Sport. Energy Drink. 2019, 10, 483–513. [Google Scholar]

- Rodríguez-Roque, M.J.; Rojas-Graü, M.A.; Elez-Martínez, P.; Martín-Belloso, O. In Vitro Bioaccessibility of Health-Related Compounds as Affected by the Formulation of Fruit Juice- and Milk-Based Beverages. Food Res. Int. 2014, 62, 771–778. [Google Scholar] [CrossRef]

- Fenster, K.; Freeburg, B.; Hollard, C.; Wong, C.; Laursen, R.R.; Ouwehand, A. The Production and Delivery of Probiotics: A Review of a Practical Approach. Microorganisms 2019, 7, 83. [Google Scholar] [CrossRef] [PubMed]

- Perricone, M.; Bevilacqua, A.; Altieri, C.; Sinigaglia, M.; Corbo, M. Challenges for the Production of Probiotic Fruit Juices. Beverages 2015, 1, 95–103. [Google Scholar] [CrossRef]

- Rakin, M.; Vukasinovic, M.; Siler-Marinkovic, S.; Maksimovic, M. Contribution of Lactic Acid Fermentation to Improved Nutritive Quality Vegetable Juices Enriched with Brewer’s Yeast Autolysate. Food Chem. 2007, 100, 599–602. [Google Scholar] [CrossRef]

- Žuntar, I.; Petric, Z.; Kovačević, D.B.; Putnik, P. Safety of Probiotics: Functional Fruit Beverages and Nutraceuticals. Foods 2020, 9, 947. [Google Scholar] [CrossRef]

- Nielsen, D.E.; El-Sohemy, A. Applying Genomics to Nutrition and Lifestyle Modification. Per Med. 2012, 9, 739–749. [Google Scholar] [CrossRef]

- Pradhan, D.; Mallappa, R.H.; Grover, S. Comprehensive Approaches for Assessing the Safety of Probiotic Bacteria. Food Control. 2020, 108, 106872. [Google Scholar] [CrossRef]

- Sotoudegan, F.; Daniali, M.; Hassani, S.; Nikfar, S.; Abdollahi, M. Reappraisal of Probiotics’ Safety in Human. Food Chem. Toxicol. 2019, 129, 22–29. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva Vale, A.; Venturim, B.C.; da Silva Rocha, A.R.F.; Martin, J.G.P.; Maske, B.L.; Balla, G.; De Dea Lindner, J.; Soccol, C.R.; de Melo Pereira, G.V. Exploring Microbial Diversity of Non-Dairy Fermented Beverages with a Focus on Functional Probiotic Microorganisms. Fermentation 2023, 9, 496. https://doi.org/10.3390/fermentation9060496

da Silva Vale A, Venturim BC, da Silva Rocha ARF, Martin JGP, Maske BL, Balla G, De Dea Lindner J, Soccol CR, de Melo Pereira GV. Exploring Microbial Diversity of Non-Dairy Fermented Beverages with a Focus on Functional Probiotic Microorganisms. Fermentation. 2023; 9(6):496. https://doi.org/10.3390/fermentation9060496

Chicago/Turabian Styleda Silva Vale, Alexander, Bárbara Côgo Venturim, André Ricardo Ferreira da Silva Rocha, José Guilherme Prado Martin, Bruna Leal Maske, Gabriel Balla, Juliano De Dea Lindner, Carlos Ricardo Soccol, and Gilberto Vinícius de Melo Pereira. 2023. "Exploring Microbial Diversity of Non-Dairy Fermented Beverages with a Focus on Functional Probiotic Microorganisms" Fermentation 9, no. 6: 496. https://doi.org/10.3390/fermentation9060496