3.1. Cell Growth and pH

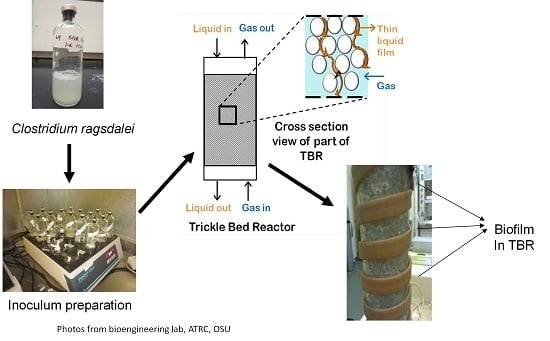

C. ragsdalei cell OD

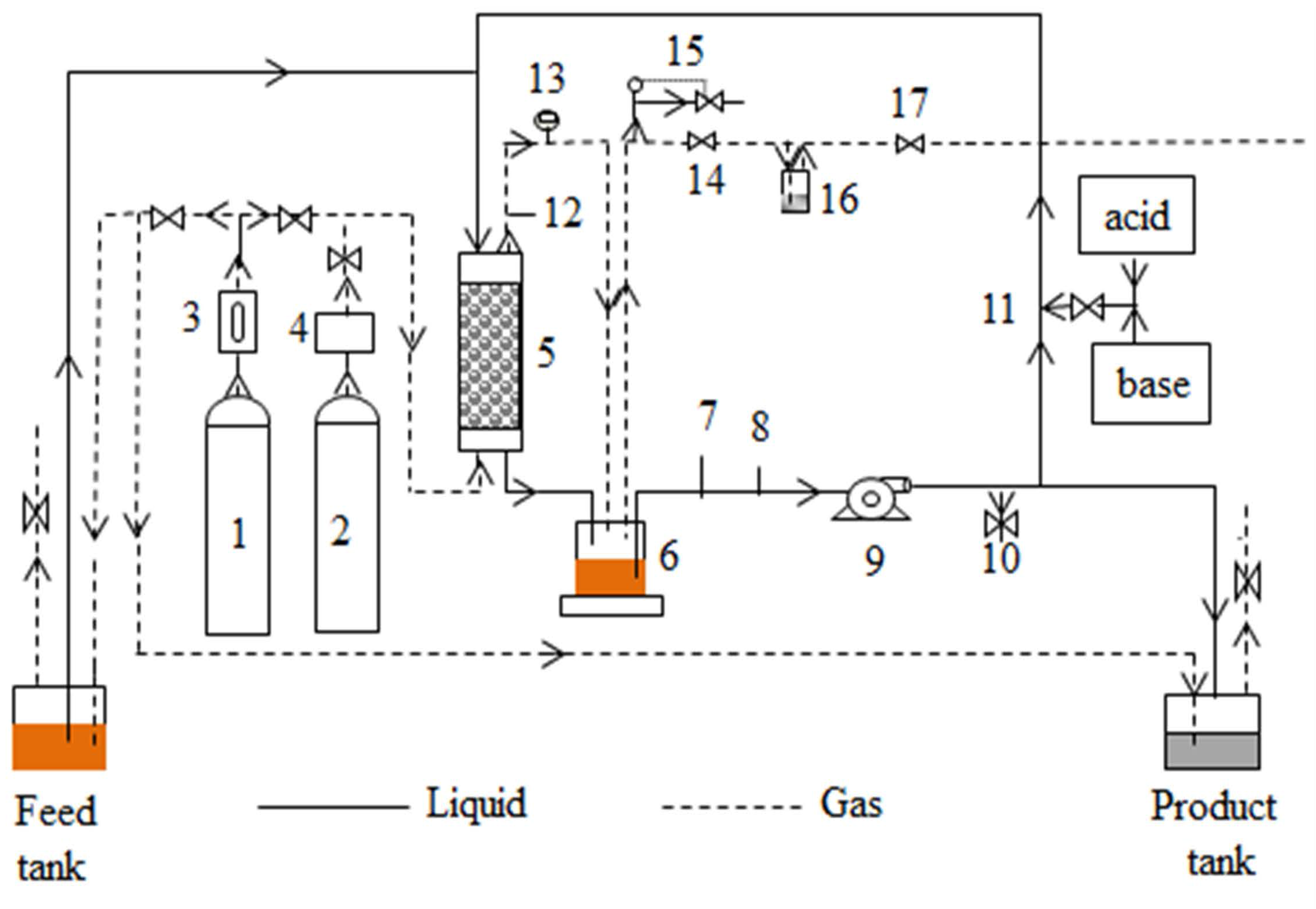

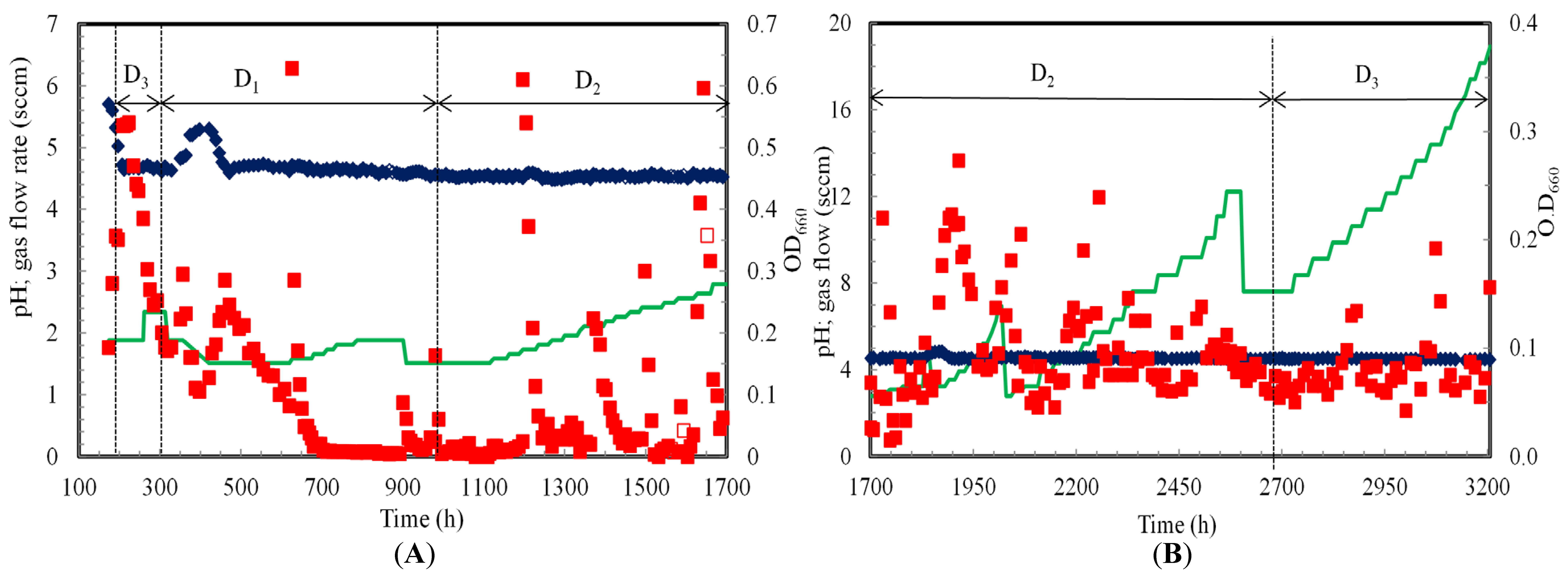

660 and pH profiles in the TBR when continuously operated for 3200 h in counter-current and co-current modes are shown in

Figure 2.

C. ragsdalei started to grow after 174 h of lag phase. The cell OD

660 was 0.35 at 197 h when the TBR was switched to continuous operation with a dilution rate of 0.012 h

−1 and a gas flow rate of 1.9 sccm. Cell OD

660 further increased to 0.53 at 207 h and remained constant until 224 h. However, the cell OD

660 started decreasing slowly to 0.20 at 305 h, most likely due to cell washout. At this point, the dilution rate was decreased by 50% (D = 0.006 h

−1) which resulted in an increase in the cell OD

660 to 0.30 by 357 h.

A brief power interruption between 329 and 351 h resulted in no gas flow to the TBR. This caused a decrease in cell activity (i.e., decrease in CO and H

2 gas uptake rates) up to 398 h. The fermentation slowly recovered when the gas flow and dilution rates were reset to 1.5 sccm and 0.006 h

−1, respectively. The cell OD

660 increased from 0.10 at 398 h to 0.29 at 461 h. The cell OD

660 in the liquid medium dropped to approximately zero around 700 h. However, the gas uptake rates were maintained indicating continued cell activity due to a biofilm in TBR rather than suspended cells. This was also confirmed by measuring the total cell mass concentration at the end of the TBR run, which showed a much higher cell mass concentration attached to the TBR than was suspended in the liquid medium as discussed below. Formation of biofilm refers to all cell mass excluding suspended cells. During counter-current flow mode, cells from the biofilm were resuspended into the medium when the pressure was released to clear the medium between the beads in the flooded TBR at 627, 901 and 909 h. This resulted in a sudden increase in the measured cell OD

660. To avoid flooding issues in counter-current mode, the liquid recirculation rate was intermittently increased from 200 to 500 mL/min for 10 min at various sampling times of 1197, 1371, 1498, 1628, 1643 and 1652 h. Unlike in counter-current mode, cell OD

660 was between 0.05 and 0.3 during co-current mode from 1700 to 3200 h (

Figure 2B).

The TBR and glass beads were washed with DI water to calculate the total amount of cells attached to the beads in the TBR after 3200 h of continuous fermentation. The beads were collected in a tub and washed three times with 1 L DI water. The column was also washed with 1 L of DI water to account of cells attached to the column walls. The cell OD660 in the beads from wash-1, wash-2, wash-3 and column-wash were 8.86, 0.41, 0.13 and 1.97, respectively. Based on this analysis, the estimated overall dry cell weight in the TBR at the end of the fermentation was 4.24 g.

During cell growth, the medium pH decreased from 5.7 at 174 h to 4.7 at 207 h. The pH of the medium was then maintained at 4.6 by addition of about 0.5 to 1 mL of 2 N KOH after every sampling time. After the power interruption between 329 and 351 h, the pH was increased to 5.2 to maintain a pH slightly favorable to cell growth conditions to recover fermentation activity. The pH dropped from 5.2 to 4.7 as cell OD660 increased between 422 to 461 h. After 461 h, the pH was maintained between 4.5 and 4.6.

3.2. Gas Conversion

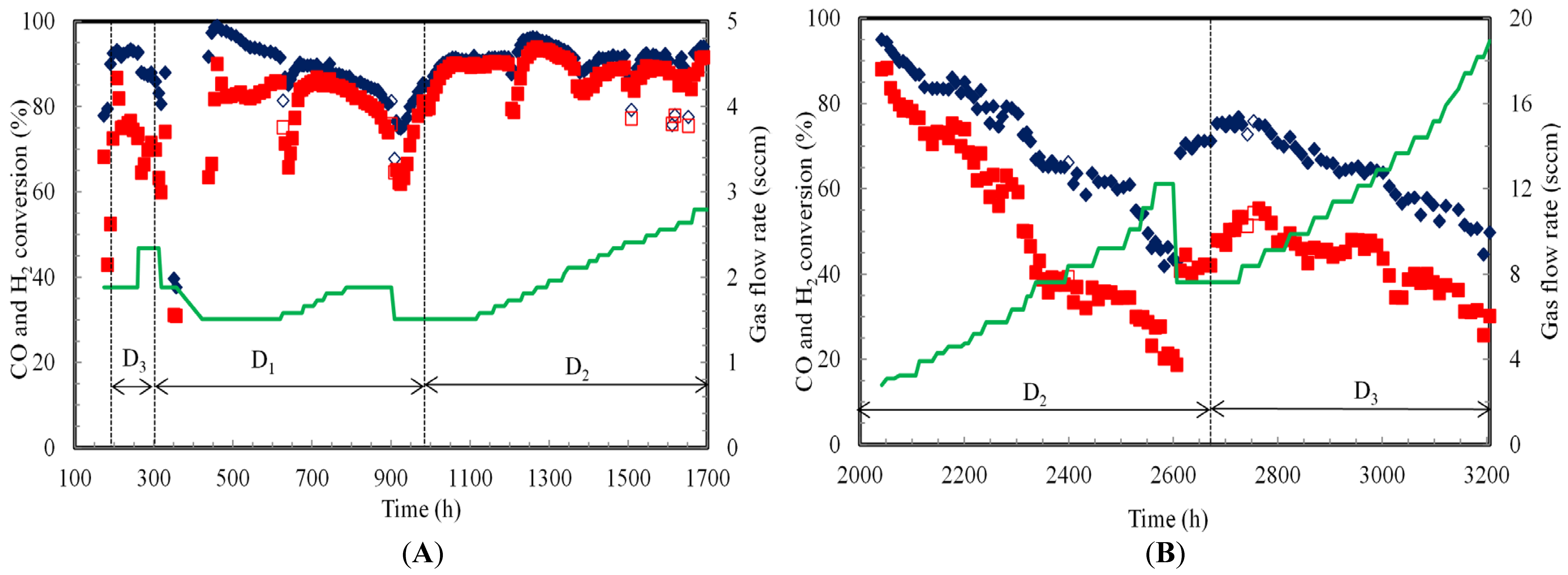

The CO and H

2 conversion efficiencies in the TBR are estimated as the amount utilized divided by the amount flowing into the TBR. The CO and H

2 conversion efficiencies by

C. ragsdalei were 92% and 72%, respectively, when the fermentation was switched from semi-continuous to continuous mode at 197 h (

Figure 3A).

In counter-current mode, the TBR was operated at dilution rates of 0.012 h−1 (D3), 0.006 h−1 (D1) and 0.009 h−1 (D2) from 197 to 305 h, 305 to 989 h and 989 to 1700 h, respectively. The CO and H2 conversion efficiencies were 93% and 74%, respectively, at 0.012 h−1 and gas flow rate of 1.9 sccm. However, when the gas flow rate was increased to 2.3 sccm at the same dilution rate, the CO and H2 conversion efficiencies dropped slightly to 88% and 71%, respectively.

CO and H

2 conversions efficiencies continued to decrease to 81% and 60%, respectively, when the gas flow rate and dilution rate were 2.3 sscm and 0.006 h

−1, respectively, at 305 h. However, the CO and H

2 conversion efficiencies increased to 88% and 74%, respectively, when gas flow rate was reduced to 1.9 sccm at 319 h. The conversion efficiencies of CO and H

2 decreased to 40% and 31%, respectively, due to power shutdown from 329 to 351 h that hindered the fermentation. The fermentation recovered slowly after 398 h with CO and H

2 conversion efficiencies reached to 92% and 86%, respectively at 620 h. As the gas flow rate was increased from 1.5 to 1.9 sccm, the liquid medium flooded the TBR (at 627, 901 and 909 h), which decreased the CO and H

2 conversion efficiencies to about 65% at 909 h (

Figure 3A). The TBR flooding caused gas bypass from the bottom of the TBR to the headspace sump and decreased the availability of syngas to cells in the TBR. The gas flow rate was decreased from 1.9 to 1.5 sccm at 909 h to avoid further flooding. CO and H

2 conversion efficiencies recovered to 85% and 81%, respectively, at 981 h before increasing the dilution rate to 0.009 h

−1.

Gas conversion efficiencies of 91% CO and 90% H2 were achieved between 989 and 1115 h at 0.009 h−1. While the CO conversion efficiency was about the same at both 0.006 and 0.009 h−1, the H2 conversion efficiency was 5% higher at 0.009 h−1 than at 0.006 h−1 at the same gas flow rate. The increase in gas uptake is due to higher cells’ activity due to availability of more nutrients at higher dilution rate. A decrease in CO and H2 conversion efficiencies was observed at various sample points (1197, 1371, 1498 and 1628 h) when the liquid recirculation rate was increased for 10 min to clear the cell debris in the TBR. During the period between 1197 and 1628 h, the gas flow rate was increased from 1.7 sccm to 2.6 sccm. The combination of the increase in gas supply and possible removal of active cells with removal of cell debris likely contributed to the decrease in gas conversion. The TBR operation at 0.009 h−1 from 989 to 1700 h with an increase in gas flow rate from 1.5 sccm to 2.8 sccm resulted in CO and H2 conversion efficiencies of about 91% and 89%, respectively.

The TBR was operated in co-current mode at dilution rates of 0.009 h

−1 (D

2) and 0.012 h

−1 (D

3) from 1700 to 2672 h and from 2672 to 3200 h, respectively, with a gradual increase in gas flow rate from 2.8 sccm to 18.9 sccm (

Figure 3B). The TBR gas inlet leaked from 1700 to 2042 h, which resulted in inaccurate gas flow rate measurements. No gas data was obtained during this time period. During the TBR operation at 0.009 h

−1, the increase in gas flow rate from 2.8 sccm at 2042 h to 12.2 sccm at 2607 h resulted in a decrease in CO and H

2 conversion efficiencies from 95% and 88% to 43% and 19%, respectively. A decrease in conversion is expected since the length of time the gas is in the reactor decreases with increasing flow rate. The gas flow rate was reduced to 7.6 sccm at 2607 h to increase CO and H

2 conversion before a new dilution rate of 0.012 h

−1 was used. CO and H

2 conversion efficiencies increased to 71% and 42%, respectively. The gas conversion efficiencies at 2660 h were slightly higher than those obtained at 2375 h and the same operating conditions.

The dilution rate was increased to 0.012 h

−1 (D

3) at 2672 h with a gas flow rate of 7.6 sccm (

Figure 3B). CO and H

2 conversion efficiencies reached 77% and 53%, respectively, at 2725 h. These gas conversion efficiencies at 0.012 h

−1 and the same gas flow were 8% higher for CO and 21% higher for H

2 than at 0.009 h

−1. This is due to the increase in cells’ activity with additional nutrients at the higher dilution rate. Further, when the gas flow rate was increased from 8.4 sccm at 2732 h to 18.9 sccm at 3200 h, the CO and H

2 conversion efficiencies slowly dropped to 50% CO and 30% H

2, respectively. The differences between CO and H

2 conversion efficiencies at dilution rate of 0.012 h

−1 was lower than at 0.009 h

−1 indicating an increase in gas uptake at higher dilution rates (

Figure 4B). It can also be observed from

Figure 3B that the decrease in CO and H

2 gas conversion efficiencies were lower at 0.012 h

−1 than at 0.009 h

−1 indicating higher cells’ activity at 0.012 h

−1. In two stages of continuous syngas fermentation with

C. ljungdahlii in a CSTR followed by a bubble column with gas and cells recycling, the increase in dilution rate from 0.01 to 0.016 h

−1 was reported to increase the cell OD

600 from 9.9 to 17.8 due to supply of more nutrients [

22]. The same study reported CO and H

2 conversion efficiencies in the CSTR were 46% and 49%, respectively, at 23 sccm compared to CO and H

2 conversion efficiencies of 86% and 82% in the bubble column at 121 sccm. The high gas conversion efficiency in the second stage is attributed to the high cell OD

600 of 17.8 that was achieved with cell recycling.

3.3. Gas Uptake Profiles

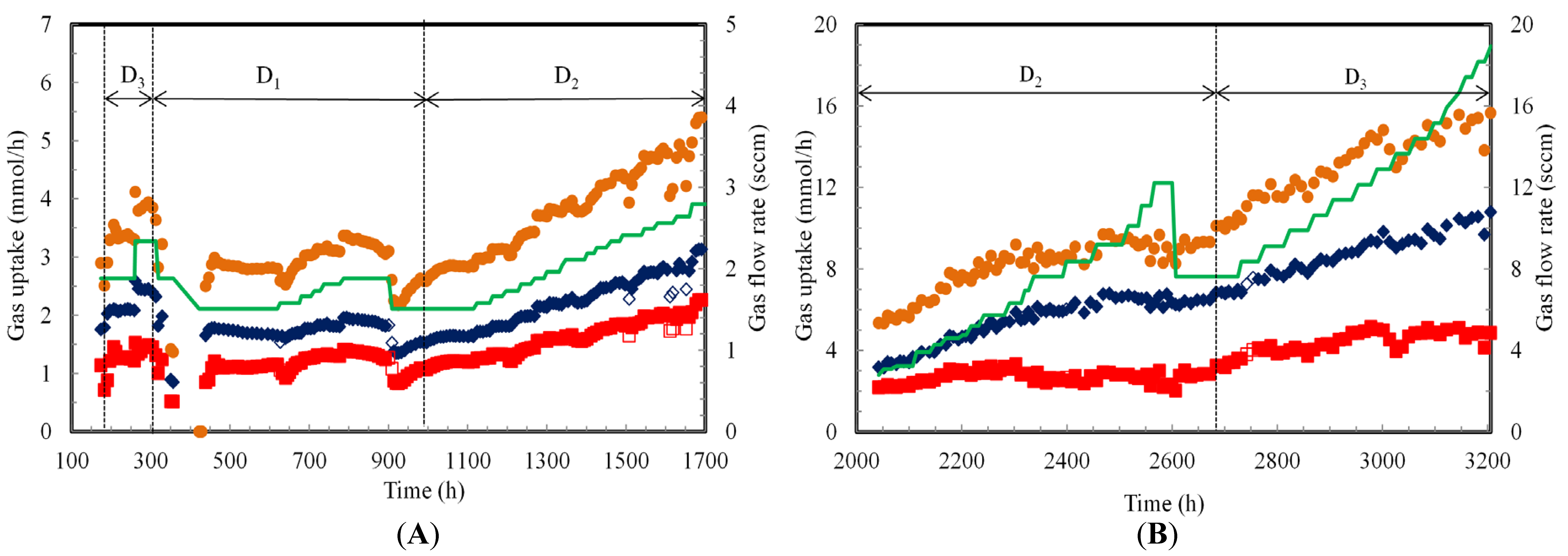

The gas uptake profiles during continuous syngas fermentation by

C. ragsdalei in the TBR are shown in

Figure 4. The specific gas uptake rates in mmol/gcell·h were not calculated because the cell mass concentration in the biofilm during operation was not known and difficult to quantify. Hence, the gas uptakes are described only in terms of mmol/h. CO and H

2 uptake rates at the start of the continuous fermentation at 197 h, 0.012 h

−1 and 1.9 sccm were 2.0 and 1.2 mmol/h, respectively. When the gas flow rate was increased to 2.3 sccm at 261 h, CO and H

2 uptake rates slightly increased. However, cell OD

660 decreased to 0.20 at 305 h due to cell washout (

Figure 2A). Therefore, the dilution rate was decreased to 0.006 h

−1 at 305 h. CO and H

2 uptake rates at 319 h decreased to 1.8 and 1.0 mmol/h, respectively.

To increase gas consumption, the gas flow rate was reduced to 1.9 sccm at 319 h. CO and H2 uptake rates at 329 h recovered back to 2.0 and 1.2 mmol/h, respectively. However, the cell activity decreased when a power failure occurred between 329 and 351 h. The fermentation slowly recovered with CO and H2 uptake rates of 1.7 and 1.1 mmol/h between 375 and 620 h.

The gas flow rate was increased from 1.5 to 1.9 sccm between 620 and 787 h, which resulted in a slight increase in CO and H

2 uptake rates to 2.0 and 1.4 mmol/h at 787 h, respectively. These gas uptakes were maintained up to 900 h. However, flooding at 901 h and 909 h resulted in a decline in CO and H

2 uptake rates to 1.5 and 1.0 mmol/h, respectively. Hence, the gas flow rate was decreased to 1.5 sccm at 909 h and was maintained at this flow rate until 981 h. At 981 h, the CO and H

2 uptake rates were essentially still the same as at 909 h. However, since the same gas uptake rates were achieved at a lower gas flow rate, CO and H

2 conversion efficiencies increased (

Figure 3). The dilution rate was maintained at 0.009 h

−1 during counter-current operation between 989 and 1700 h. A step increment increase in gas flow rate by 5–10% from 1.5 sccm at 989 h to 2.8 sccm at 1700 h resulted in an increase of gas uptake rate to 3.1 mmol/h of CO and 2.1 mmol/h of H

2.

The TBR was switched at 1700 h to co-current mode due to frequent flooding issues. However, there was gas leak in the inlet to the TBR from 1700 to 2042 h, which resulted in inaccurate gas flow rate measurements and no gas uptake data. The gas flow rate was gradually increased from 2.8 to 6.3 sccm in between 2042 and 2313 h, which increased the gas uptake rates to 5.9 mmol/h CO and 3.3 mmol/h H

2 at 2313 h (

Figure 4B). A further increase in the gas flow rate from 6.3 to 12.2 sccm from 2313 to 2672 h resulted in a decrease of H

2 uptake rate to between 2.4 and 3.0 mmol/h, while the CO uptake rate increased between 6.0 and 6.7 mmol/h.

The average total CO and H2 gas uptake rate between 2313 and 2672 h was 8.5 mmol/h. It can be observed that the increase in the dilution rate from 0.009 to 0.012 h−1 and gas flow rate from 2.8 to 18.9 sccm increased the overall CO and H2 uptake rates. In co-current flow, it was also observed that the increase in dilution rate by 36% (0.009 h−1 to 0.012 h−1) resulted in an increase in total CO and H2 uptake rate by 47%. The gas uptake rates in co-current mode were 2.5 fold higher than in counter-current mode. This was attributed to the ability to operate the TBR in co-current mode at higher gas flow rates.

In the previous study with semi-continuous fermentation in co-current mode TBR, the maximum CO and H

2 conversion efficiencies at 4.6 sccm were 80% (CO uptake rate of 4.4 mmol/h) and 55% (H

2 uptake rate of 2.2 mmol/h), respectively [

18]. In the present study during co-current continuous fermentation at 4.6 sccm and 0.009 h

−1, gas conversion efficiencies of 82% CO (CO uptake rate of 4.4 mmol/h) and 72% H

2 (H

2 uptake rate of 2.74 mmol/h) were achieved. The high gas conversion efficiency and uptake rates are due to high cells’ activity with continuous addition of nutrients during the fermentation.

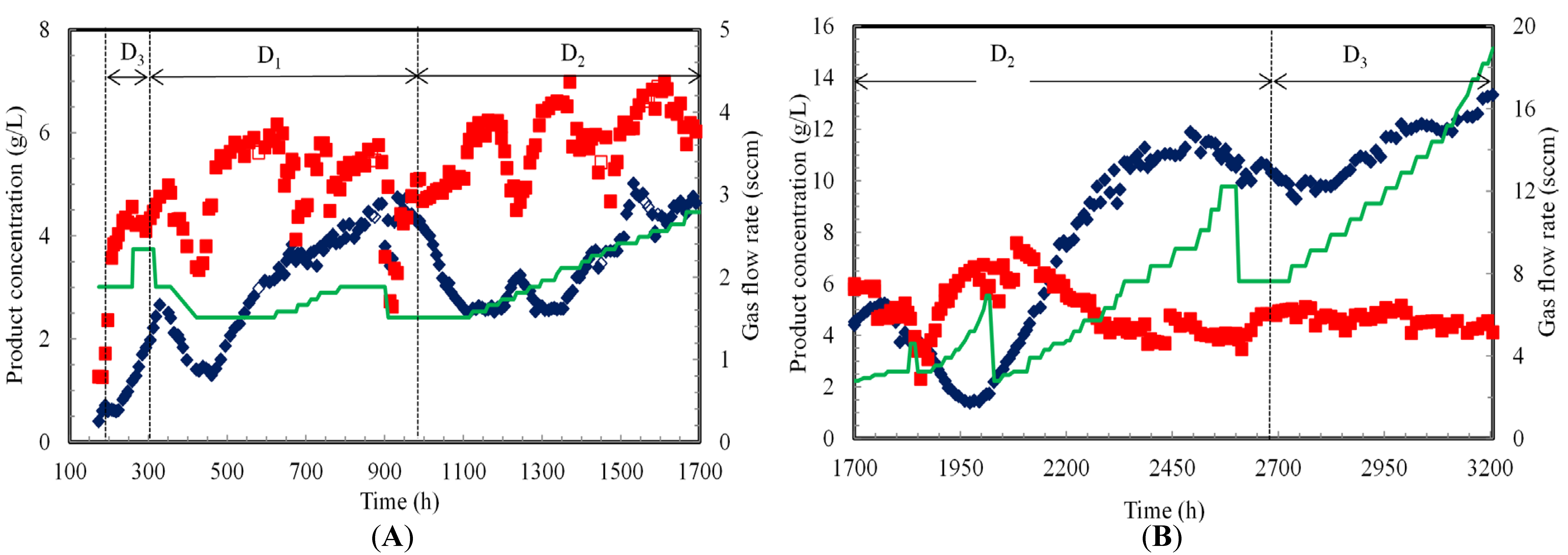

3.4. Product Profiles

At the beginning of continuous fermentation (197 h), ethanol and acetic acid concentrations were 0.8 g/L and 2.4 g/L, respectively (

Figure 5A). Ethanol and acetic acid concentrations increased to 2.0 g/L and 5.0 g/L, respectively between 197 and 305 h at a dilution rate of 0.0012 h

−1. A slight increase in ethanol and acetic acid concentrations was observed when dilution rate was decreased to 0.006 h

−1. However, ethanol and acetic acid concentrations decreased between 329 h and 398 h. This decrease was associated with the power shutdown and washout cells and products.

The fermentation slowly recovered and product concentrations were observed to be stable from 398 to 454 h after which ethanol and acetic acid concentrations at 627 h reached 3.2 and 6.2 g/L, respectively, when the gas flow rate was increased by 20% from 1.5 sccm between 627 and 787 h, ethanol concentration increased by 20% while the acetic acid concentration decreased by 20%. Ethanol concentration slowly increased to 4.3 g/L while acetic acid concentration remained at 5.0 g/L between 787 and 909 h. Due to flooding at 901 and 909 h, the gas flow rate was reduced from 1.9 to 1.5 sccm to recover the fermentation in the TBR.

The dilution rate was increased from 0.006 to 0.009 h

−1 between 989 and 1700 h. This increased the product removal rate from the TBR, which decreased the ethanol concentration by about 40% to 2.5 g/L at 1115 h. However, the acetic acid concentration increased by 15% to around 5.9 g/L at 1115 h. The increase in acetic acid concentration was due to increase in cells’ activity and concentration in the biofilm. The increase in cell concentration is associated with acetic acid production and ATP generation as a high amount of energy is required for cell maintenance [

1].

The gas flow rate was increased from 1.5 to 2.8 sccm in a step increment of 5–10% every 24 to 36 h between 1115 and 1700 h (

Figure 5A). Ethanol and acetic acid concentrations were stable at 2.5 and 6.2 g/L, respectively, when the gas flow rate was increased from 1.5 to 1.7 sccm from 1115 to 1197 h. The liquid recirculation rate was increased from 200 to 500 mL/min for 10 min to clear the cell debris at 1197 h. This resulted in a slow increase in the ethanol concentration to 3.2 g/L and a decrease in the acetic acid concentration to 4.7 g/L at 1245 h. This intermittent increase in liquid recirculation rate could have cleared the cell debris from the packing and caused better gas uptake resulting in a positive effect on ethanol production.

To test the positive effect of the intermittent increase of liquid recirculation rate on ethanol production, the liquid flow rate was again increased to 500 mL/min for 10 min at 1371 h. Ethanol concentration slowly increased to 3.7 g/L while acetic acid remained at 4.7 g/L at 1474 h. Since increasing the liquid recirculation rate intermittently had a positive effect on ethanol production, it was performed when the cell OD660 in the medium decreased to zero. The intermittent increase in liquid recirculation rate and gradual increase in gas flow rate to 2.4 sscm resulted in production of 5.0 g/L ethanol and 6.1 g/L acetic acid at 1532 h. The gas flow rate was further increased to 2.8 sccm between 1532 and 1700 h. Ethanol and acetic acid concentrations were 4.4 and 5.8 g/L, respectively at 1700 h.

In co-current mode, the gas flow rate was gradually increased from 2.8 to 18.9 sccm (

Figure 5B). Similar to the counter-current mode, the gradual increase in gas flow rate with an increase in liquid recirculation rate from 200 to 500 mL/min for 10 min at every sampling time increased ethanol production. Ethanol and acetic acid concentrations were 2.7 and 6.7 g/L, respectively, at 2052 h and 3.1 sccm. An increasing trend in ethanol production and a decreasing trend in acetic acid production were observed as the gas flow rate was increased from 3.1 to 9.2 sccm between 2052 and 2493 h. Ethanol and acetic acid concentrations at 2493 h were 11.9 and 4.6 g/L, respectively. A further increase in the gas flow rate from 9.2 to 11.1 sccm at 2542 h did not increase ethanol production. Additionally, the increase in gas flow rate from 11.1 to 12.2 sccm at 2566 h slightly decreased ethanol and acetic acid concentrations to 10.5 and 4.1 g/L, respectively. This indicates that beyond a gas flow rate of 9.2 sccm, cells reached a kinetic limitation and were not able to process more gas even when more gas was provided (

Figure 4B).

Further, when the gas flow rate was decreased from 12.2 to 7.6 sccm at 2607 h, ethanol and acetic acid concentrations were stable at 10.8 and 3.8 g/L, respectively, until 2672 h. When the dilution rate was increased from 0.009 to 0.012 h−1 at 2510 h, the ethanol concentration dropped slowly to 9.9 g/L. However, the acetic acid concentration slightly increased to 5.0 g/L at 2551 h and 7.6 sccm. Further increase in the gas flow rate from 7.6 to 18.9 sccm resulted in 13.2 g/L ethanol and 4.3 g/L acetic acid at 3200 h. The gas uptake rate at 0.012 h−1 was higher than at 0.009 h−1 due to higher cells’ activity, which resulted in more ethanol production at 0.012 h−1.

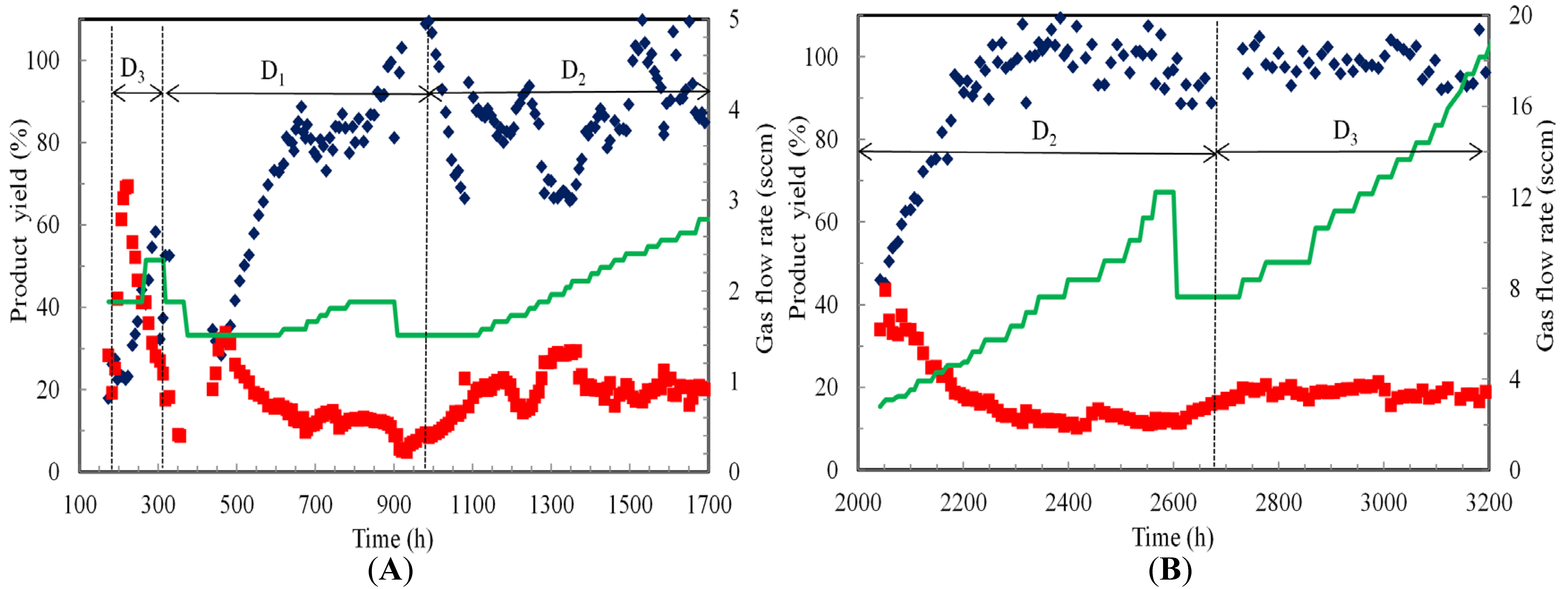

3.5. Productivity and Yields

Ethanol and acetic acid productivities were estimated by multiplying the dilution rate by the product concentration. Ethanol and acetic acid yields were estimated based on CO consumed as previously reported [

27]. One mole of ethanol is formed from six moles of CO and one mole of acetic acid is produced from four moles of CO.

During counter-current operation, the highest ethanol productivity of 45 mg/L·h was obtained during operation at 0.009 h

−1 and 1556 h. However, the highest acetic acid productivity was 63 mg/L·h at 0.009 h

−1 and 1611 h. During counter-current mode, acetic acid productivity was always higher than ethanol productivity. However, ethanol productivity was higher during co-current mode. The maximum ethanol productivity during co-current operation was 158 mg/L·h at 0.012 h

−1 and 3200 h, while a maximum acetic acid productivity of 68 mg/L·h was obtained at 0.009 h

−1 at 2083 h. The ethanol productivity achieved in the present study with continuous syngas fermentation in the TBR was over four times higher than reported during semi-continuous fermentation (37 mg/L·h) in the TBR [

18].

Moreover, the molar ratio of ethanol to acetic acid produced in the present study during continuous fermentation at 0.012 h−1 and 18.9 sccm in the TBR was 4:1, which was higher than in semi-continuous TBR fermentation (1:2). In semi-continuous fermentation, as nutrients were depleted from the medium, the gas conversion efficiencies and uptake rates decreased. Replacement of the medium in semi-continuous fermentations resulted in a nutrient-rich environment at pH 5.8 that promoted cell growth and thus more acetic acid production. However, during continuous fermentation the nutrients levels were maintained by altering the dilution rate and the pH was maintained at 4.5 that favored ethanol production. This clearly shows the advantages of the continuous syngas fermentation process.

During counter-current mode, ethanol yield was 22% while acetic acid yield was 42% at 197 h and 1.9 sccm (

Figure 6). However, acetic acid yield slowly dropped to 15% while ethanol yield increased to 58% at 294 h. At dilution rate of 0.006 h

−1 from 305 h to 989 h, the ethanol yield increased from 28% at 461 h to 85% at 850 h, while acetic acid yield decreased from 38% at 461 h to 13% at 850 h. At a dilution rate of 0.009 h

−1 between 989 and 1700 h, the average ethanol yield was about 85%, while the average acetic acid yield was about 20%. As the gas flow rate was increased and the pH was maintained at 4.5, ethanol yields increased due to the availability of more reductants (CO and H

2) and pH values that favored solvent production conditions.

In co-current operation at 0.009 h−1, ethanol yield increased from 46% at 2042 h to 100% at 2232 h. Ethanol yield remained close to 100% during fermentation from 2232 to 2607 h. However, the acetic acid yield decreased from 34% at 2042 h to 16% at 2232 h. It remained close to about 13% from 2232 to 2607 h. Ethanol and acetic acid yields were about 100% and 20%, respectively, during operation at 0.012 h−1. The higher ethanol yield in co-current mode was due to higher cell activity that processed more gas.