Shapes and Rise Velocities of Single Bubbles in a Confined Annular Channel: Experiments and Numerical Simulations

Abstract

:1. Introduction

2. Experiments

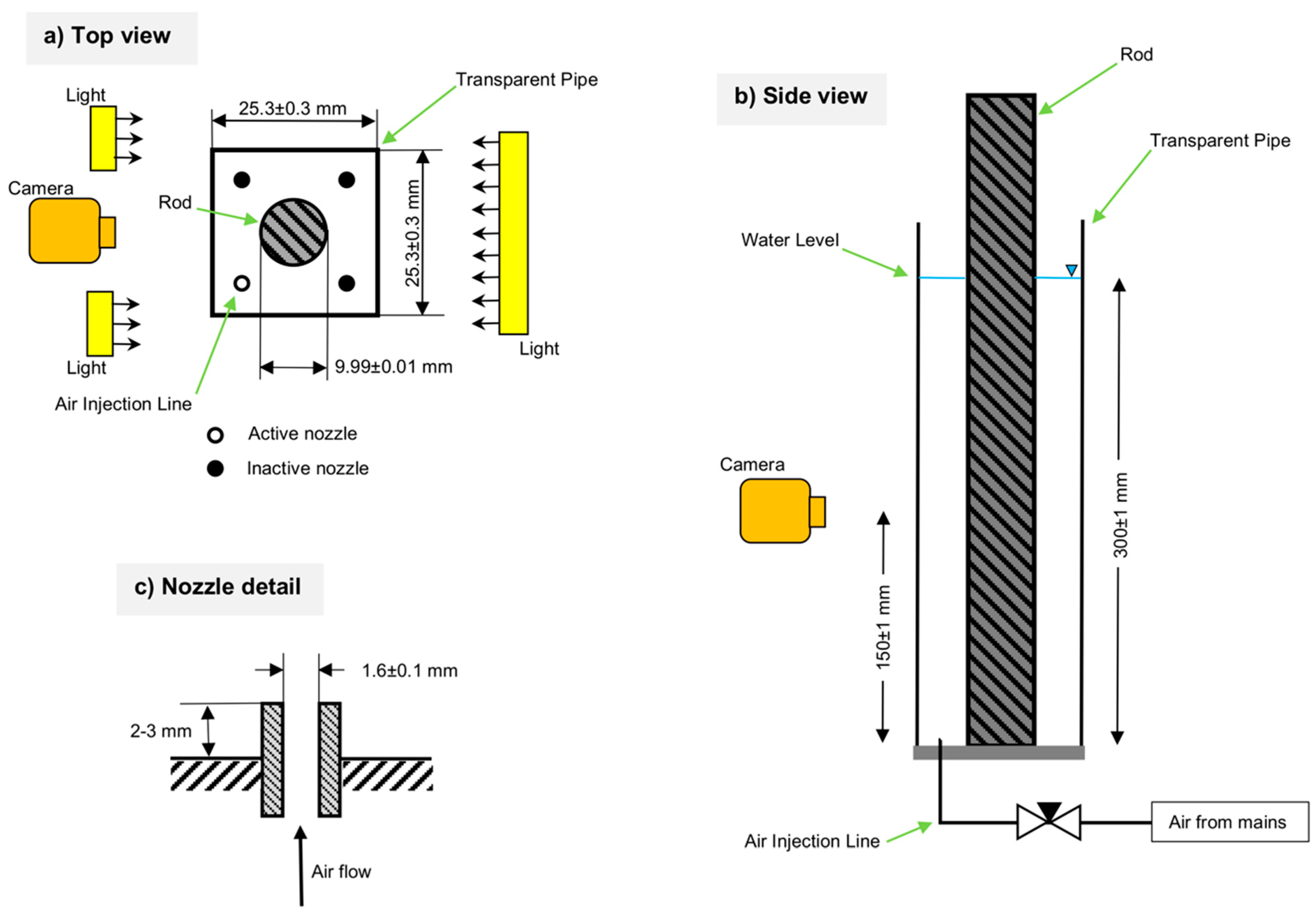

2.1. Experimental Setup

- Single air bubble dynamics in confined stagnant water;

- Multiple air bubble dynamics in confined stagnant water with annular channel operating as a small bubble column running in batch mode;

- Pool boiling in water where bubbling is sustained via Joule heating of the internal rod.

2.2. Measurement Methodology

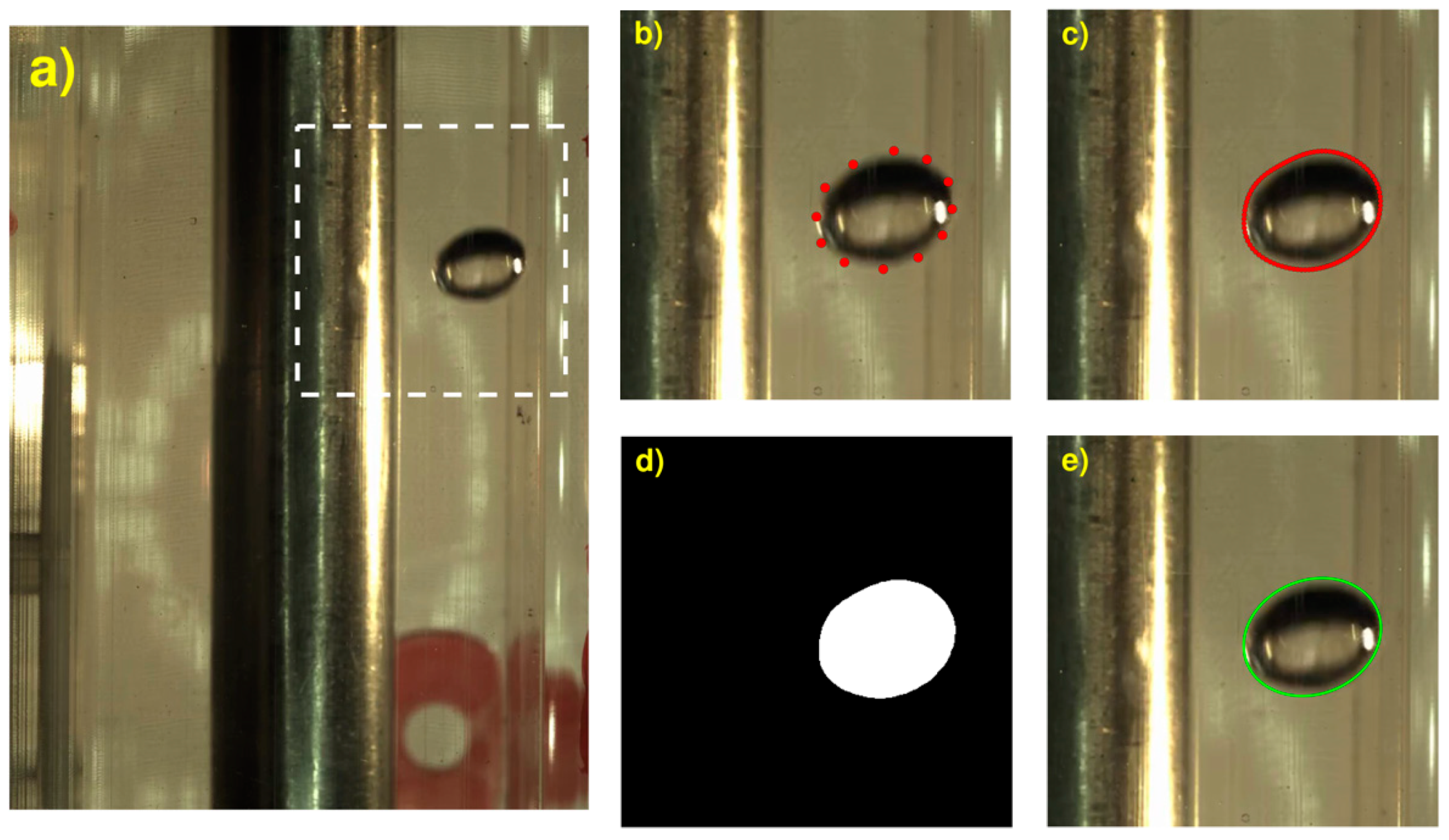

- Discrete points are manually digitized along the bubble border (Figure 2b);

- Cubic spline interpolation is used to increase the density of the points along the bubble border (Figure 2c);

- The polygon representing the bubble border is converted to a binary image of the bubble (Figure 2d);

- Size and shape of the bubble are computed.

3. Numerical Model

3.1. Governing Equations and Discretization Methods

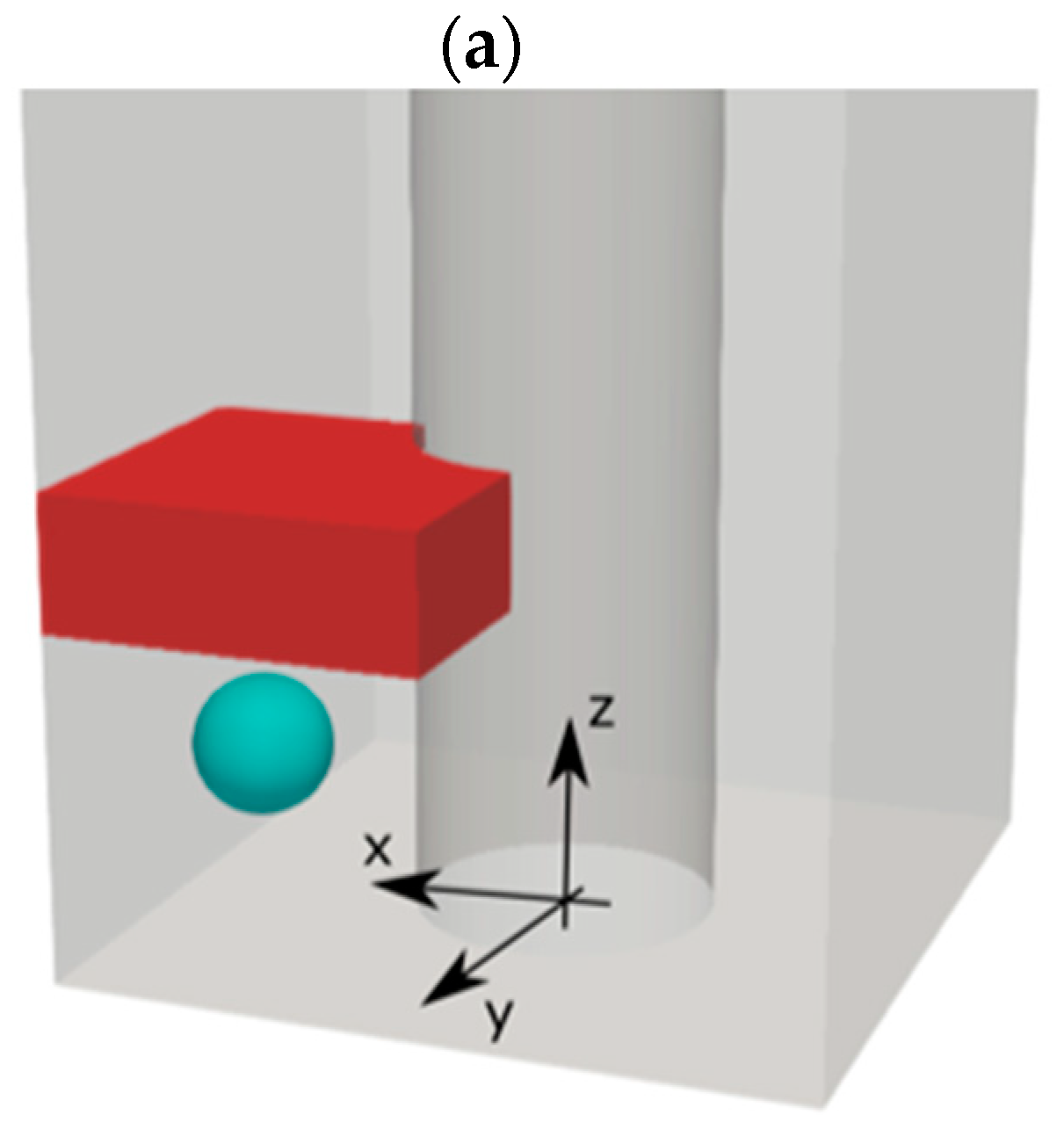

3.2. Geometry and Boundary Conditions

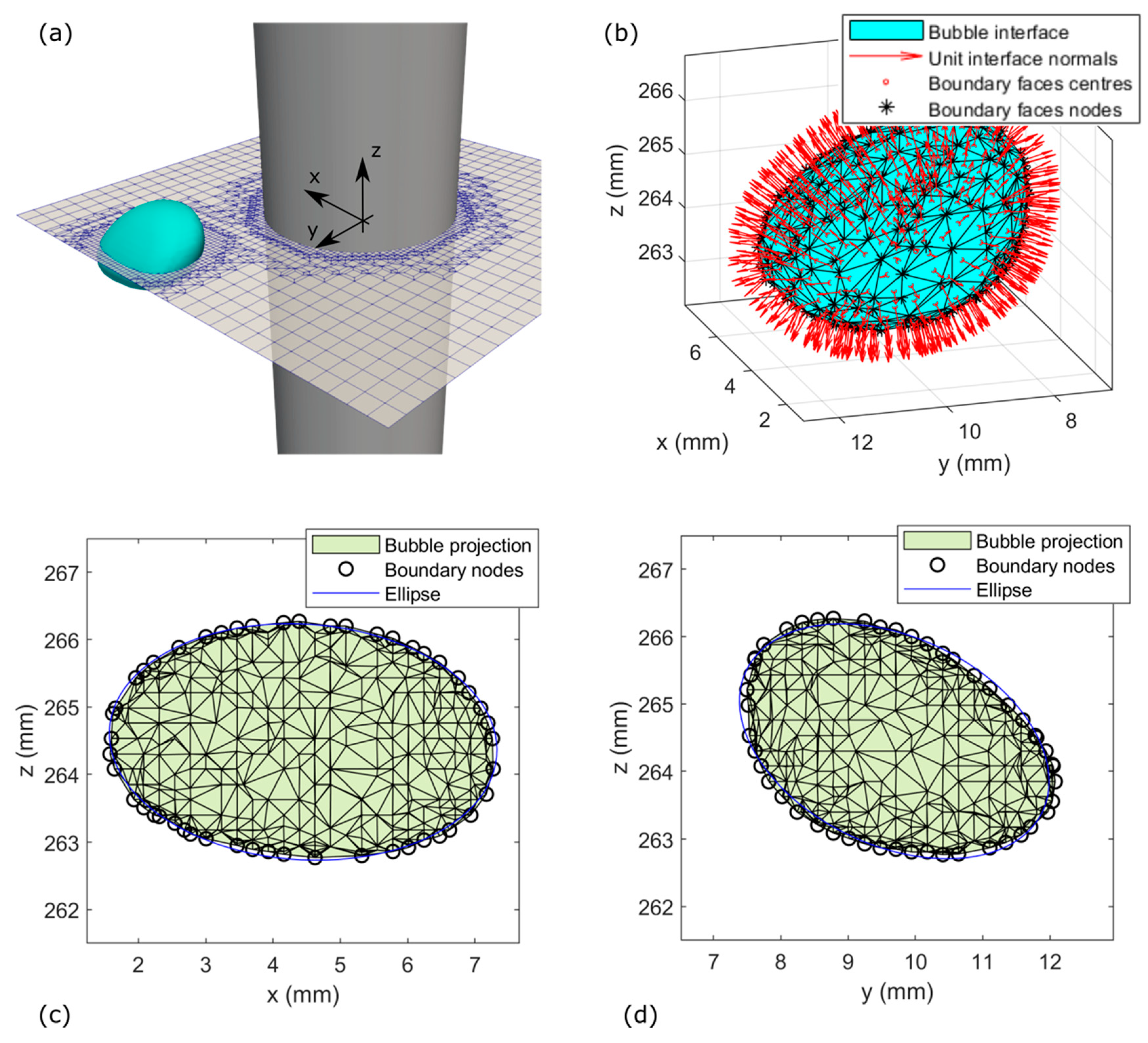

3.3. Postprocessing of Numerical Data

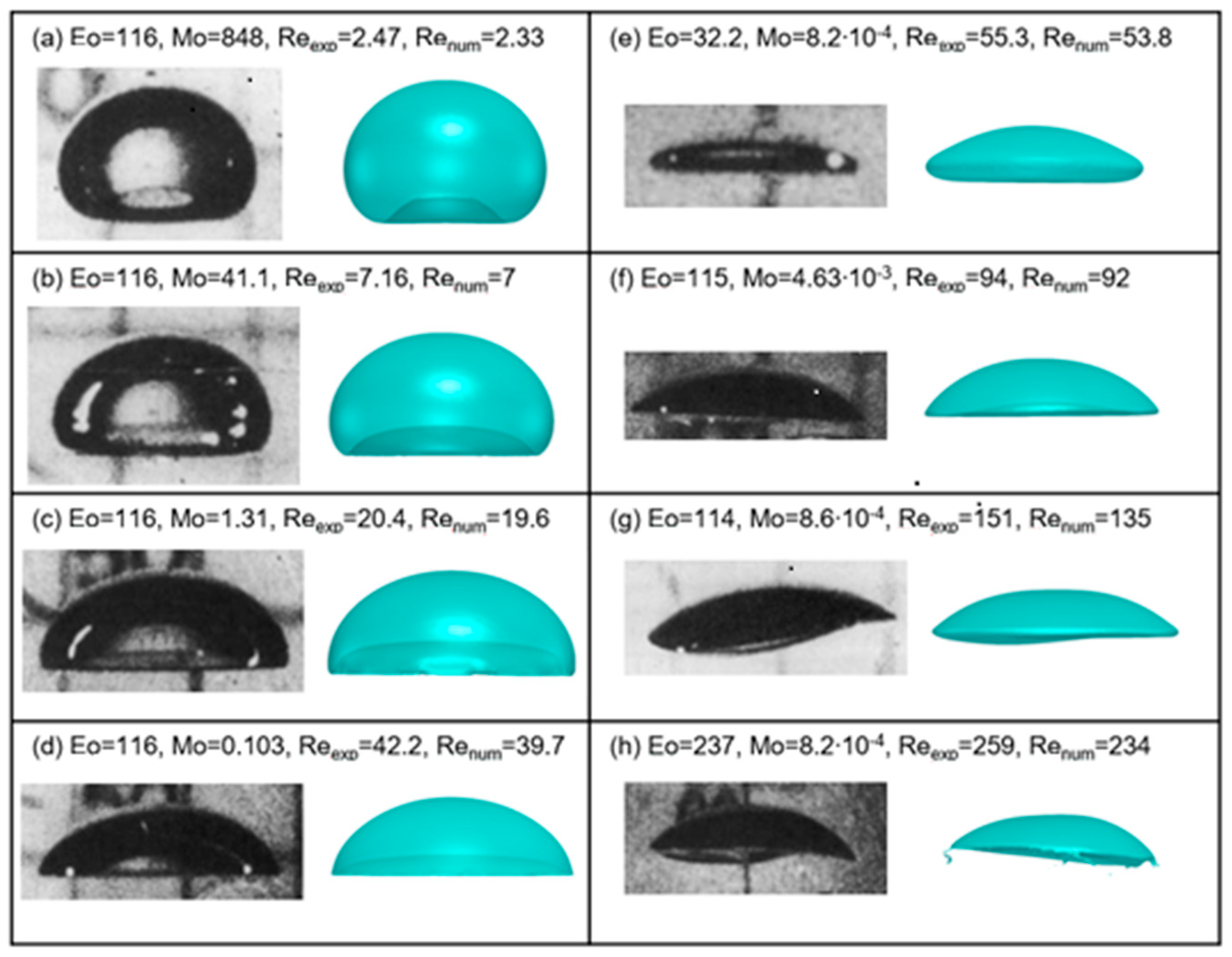

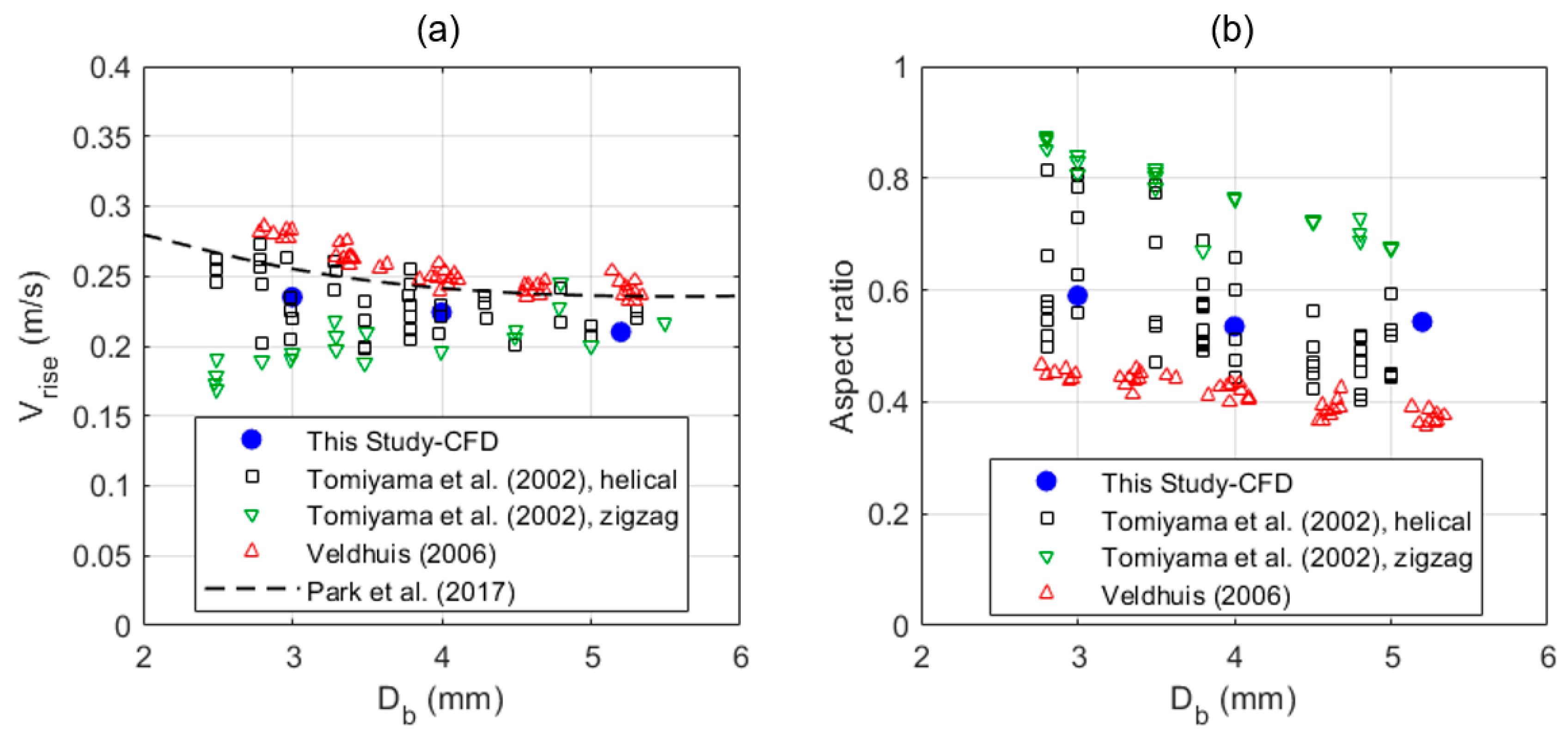

3.4. Validation of the Numerical Model

4. Results and Discussion

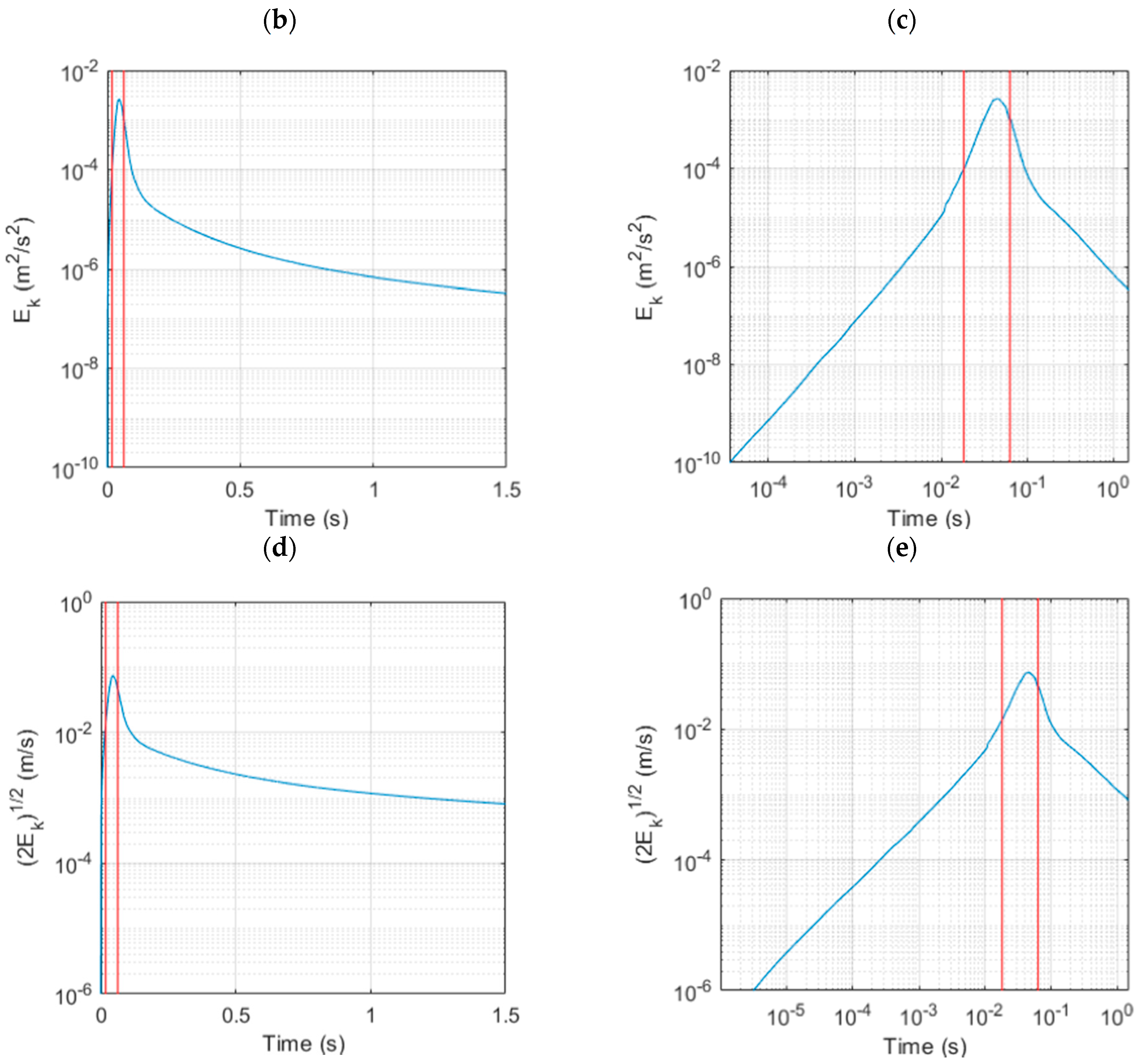

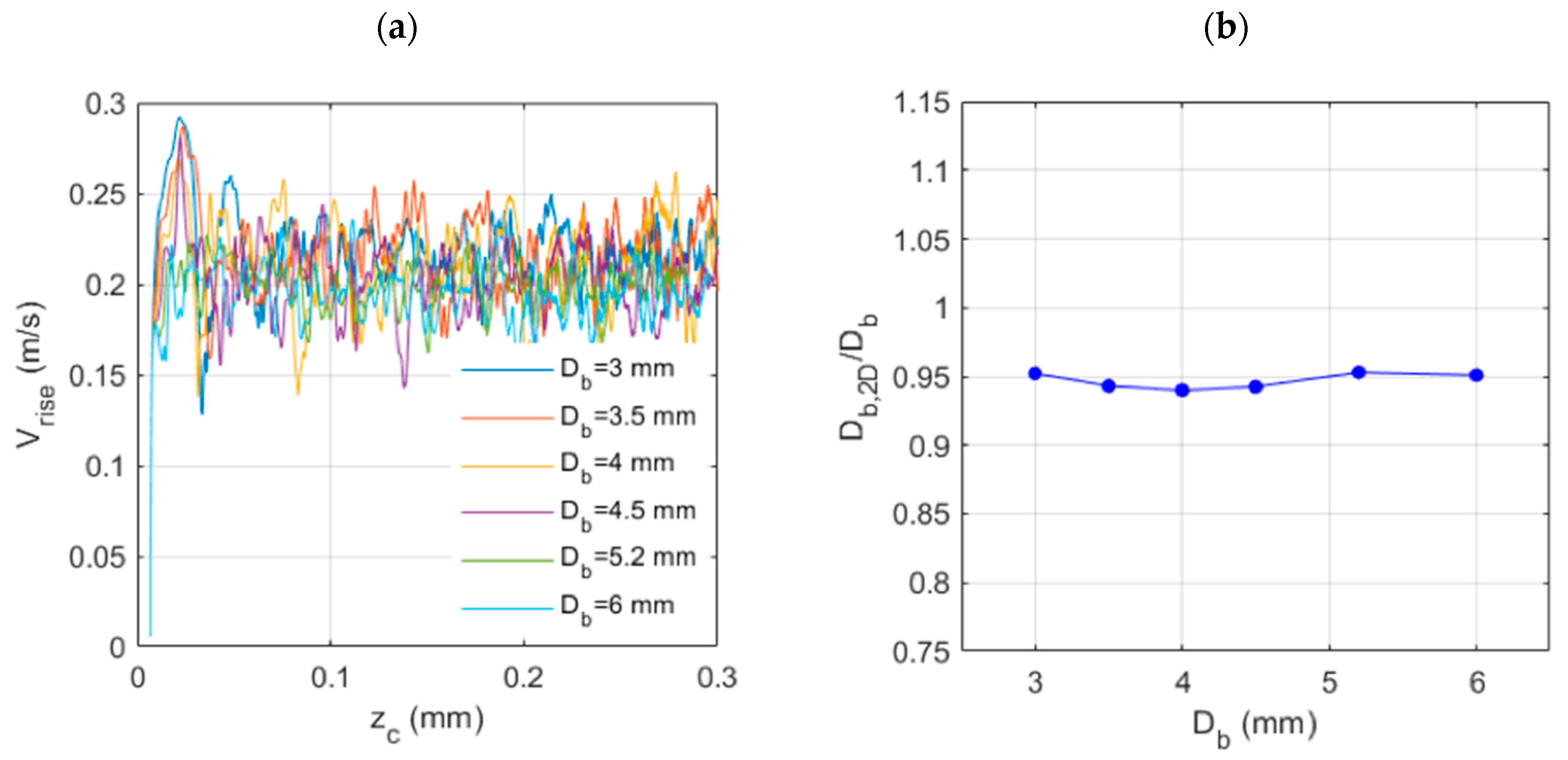

4.1. Preliminary CFD Results

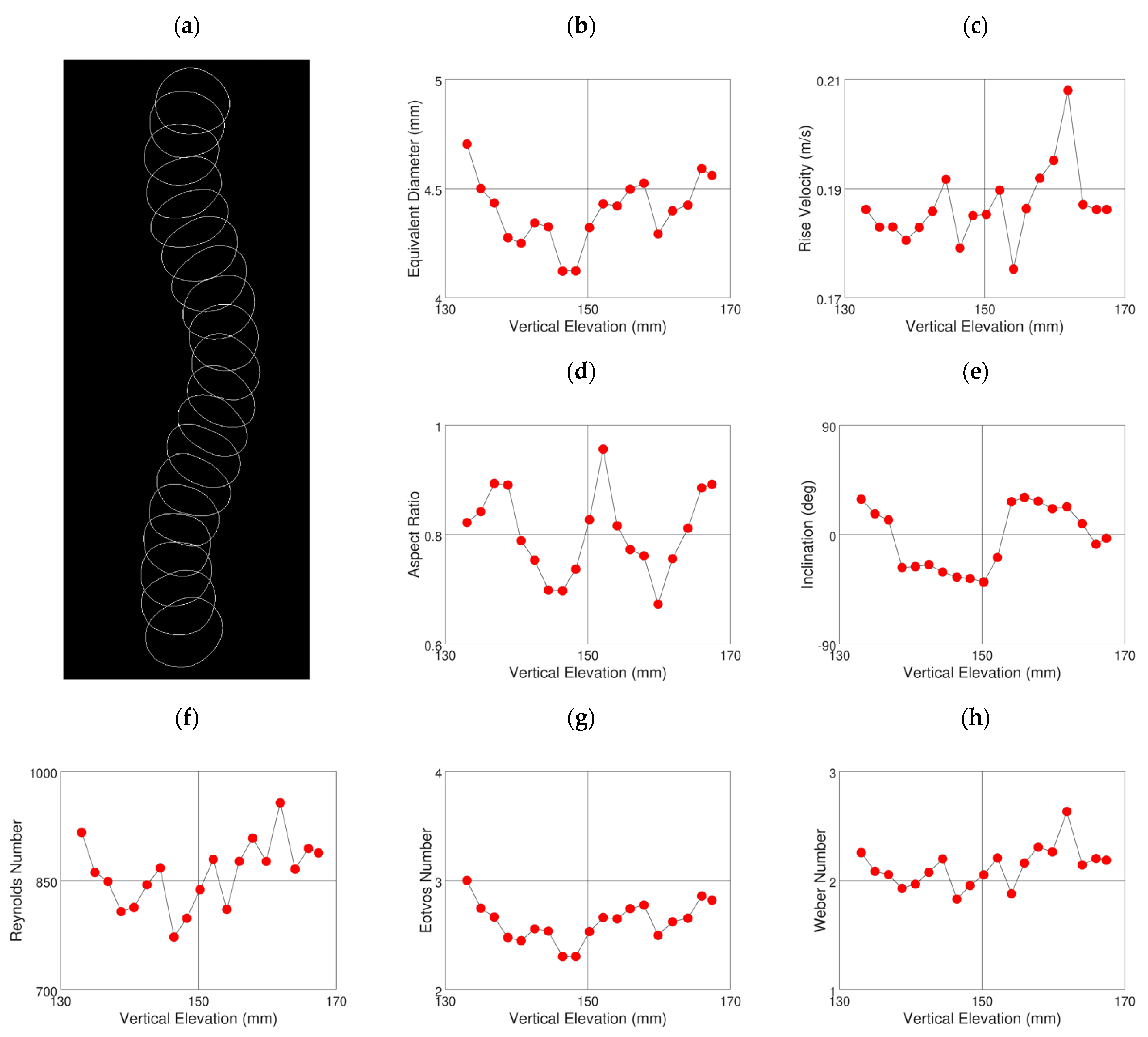

4.2. Instantaneous Bubble Dynamics

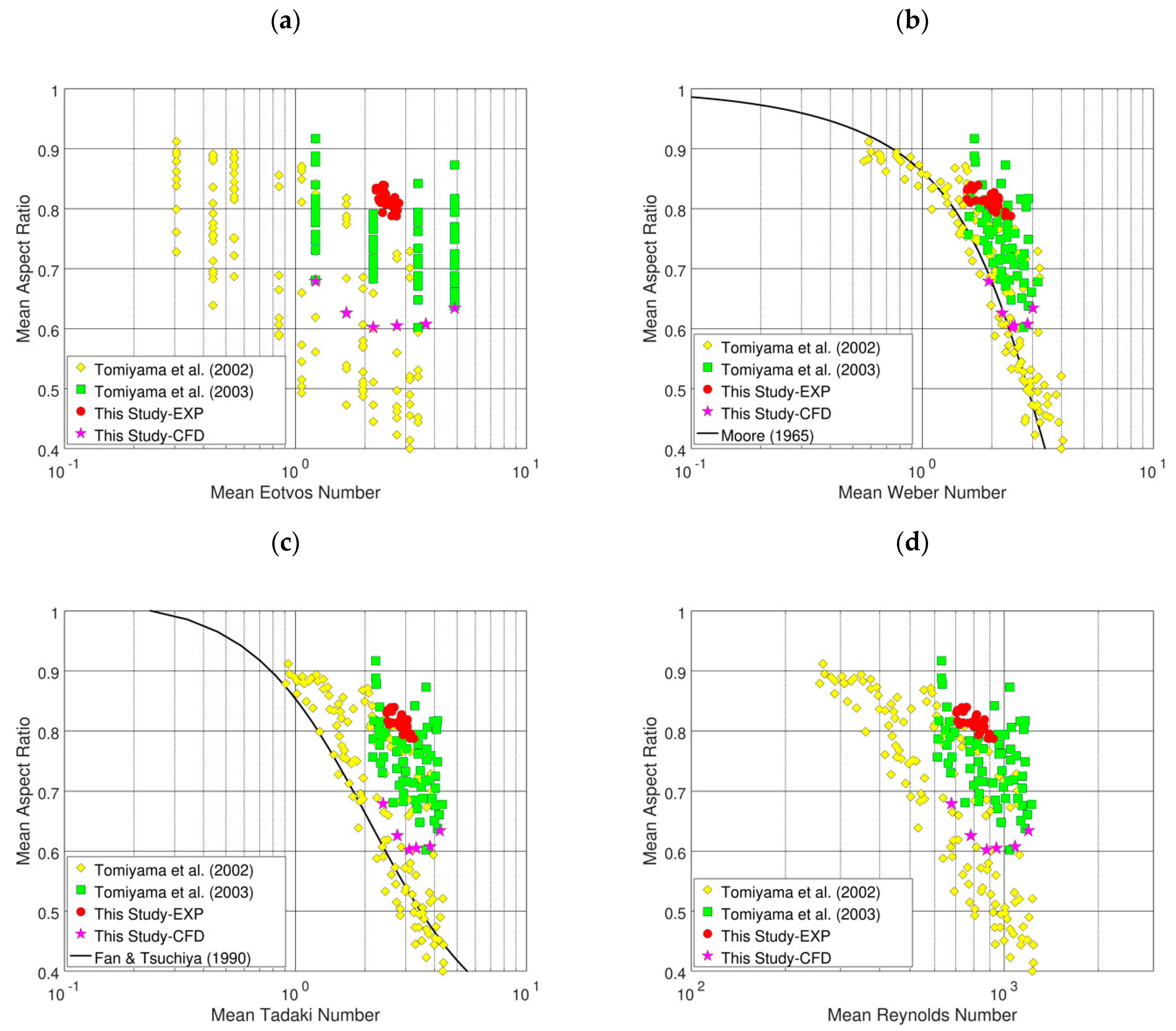

4.3. Bubbles Mean Shape

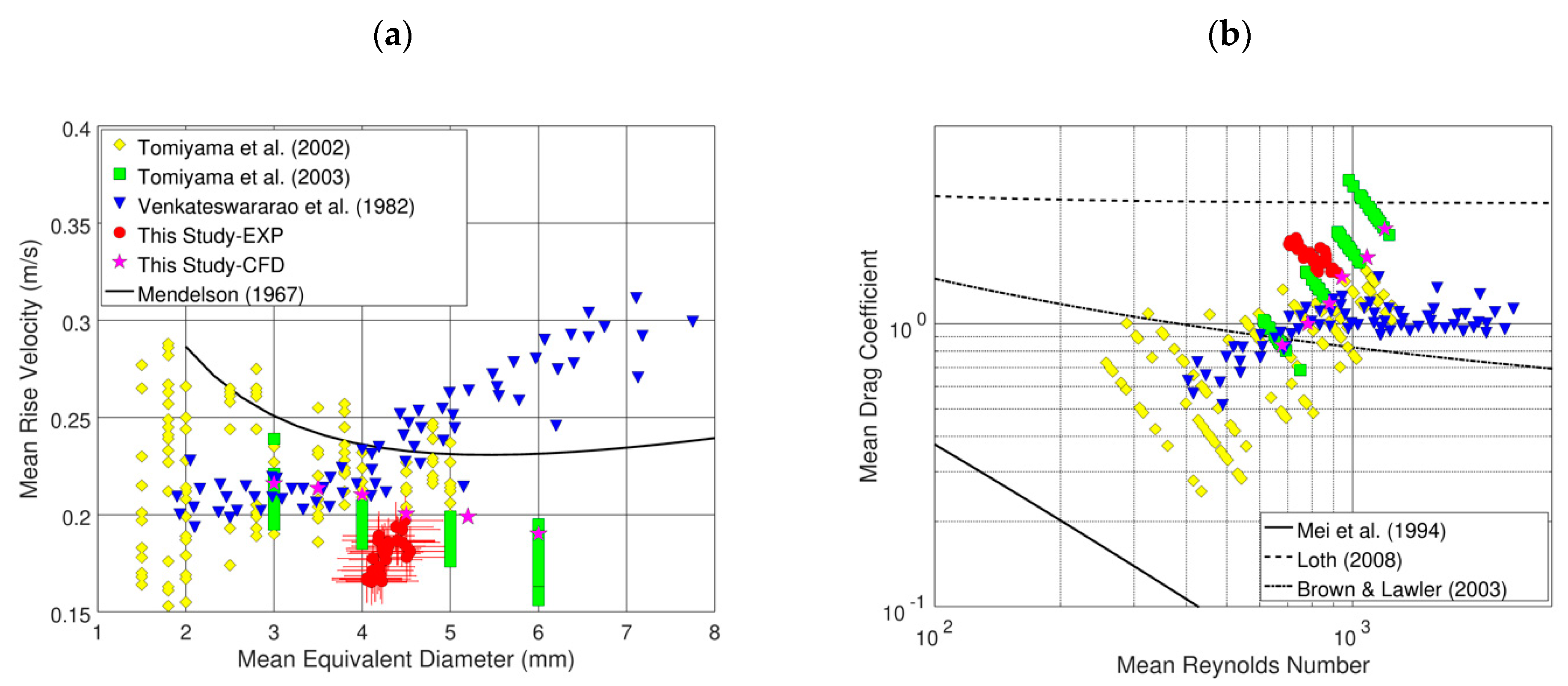

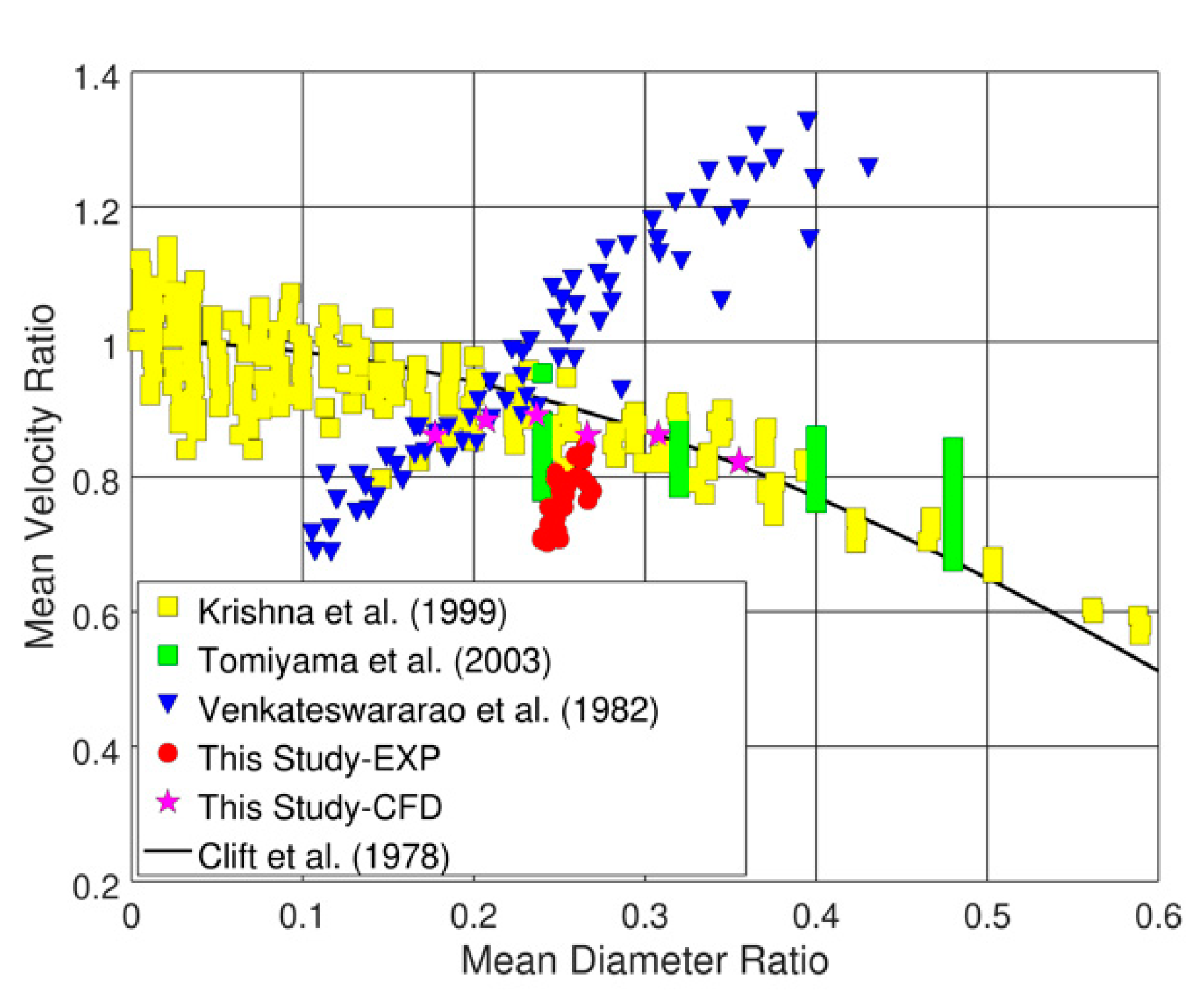

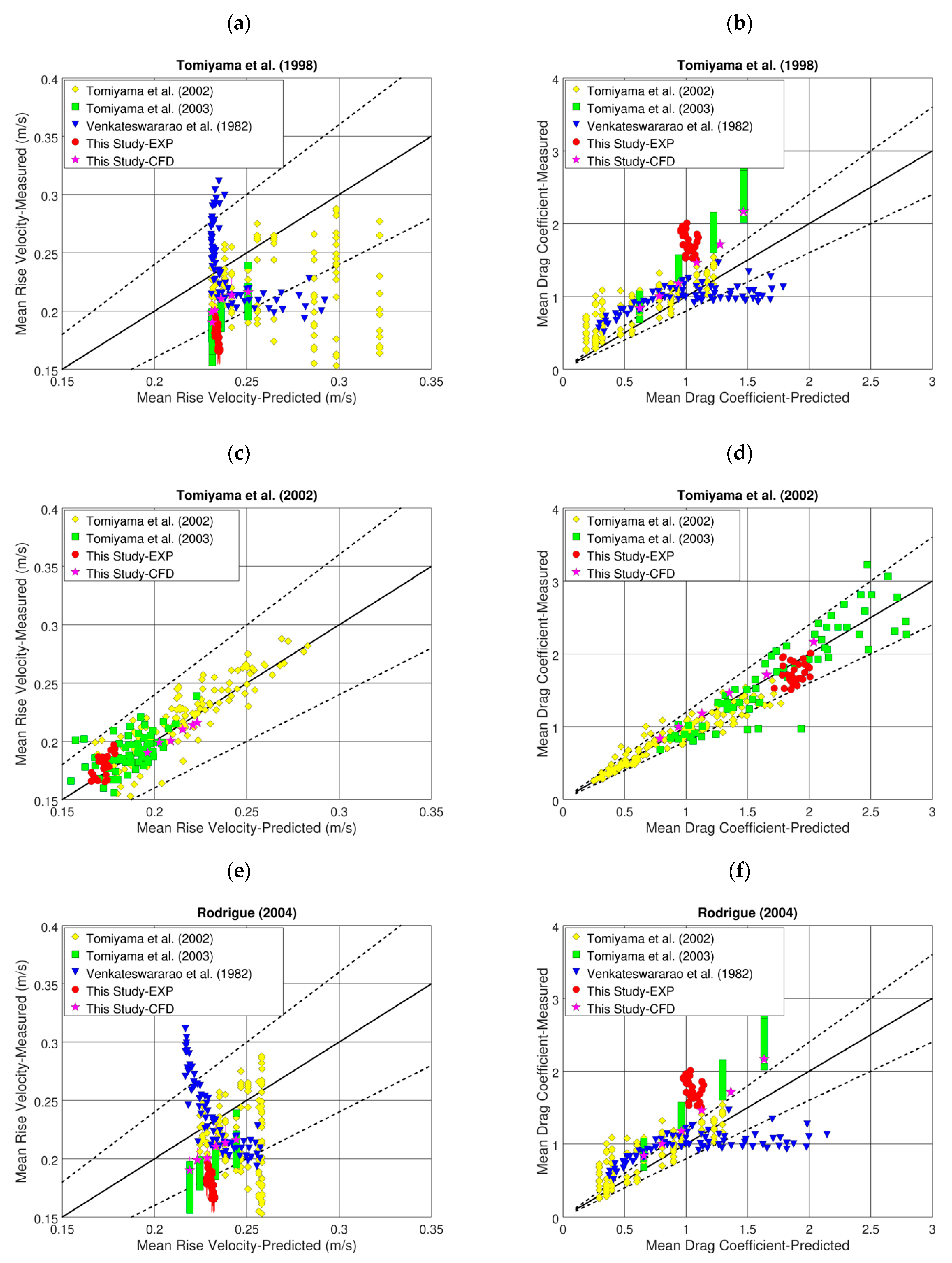

4.4. Bubble Mean Rise Velocity

5. Concluding Remarks

- The confinement of the present annular channel did not affect the qualitative behavior of the bubbles, which exhibited a wobbling rise dynamic similar to that observed with bubbles rising through unconfined liquids. The effect of the confinement was evident on the shape and rise velocity; the bubbles were less deformed and rose more slowly in comparison with bubbles rising through unconfined liquids;

- The present results are in fair agreement with previous observations by Tomiyama et al. [15] on the shape and rise velocity of air bubbles rising though water, confined in a small cross-section subchannel, and with available data on confined rise through circular tubes. However, the observations by Venkateswararao et al. [14] on air bubbles rising through a larger cross-section tubular test section show an increase in rise velocity as consequence of the confinement, which is a trend that was not observed in other studies on confined rise through smaller channels. This indicates that confinement effects with non-circular channels of complex shape could be more complicated than those observed with circular tubes, and both the size of the channel cross-section and its shape may affect the dynamics of the bubbles; therefore, results generated with comparatively small channels may not extrapolate to channel sizes of industrial relevance. The available data are, however, too restricted in scope to draw any definite conclusions, and more investigations are clearly needed;

- The present data and numerical simulations, as well as the other data collected from the literature and used here, indicate that the size, shape, and rise velocity of ellipsoidal bubbles are closely linked together, and this should be considered when designing prediction methods;

- The image processing methodology developed and used here, based on manually digitizing points along the bubble border, is robust and effective at dealing with the variable image background caused by the bubble shadow. This technique can be extended to multiple bubbles of interest in bubble columns;

- The synergetic use of experiments and numerical simulations proved to be an effective approach for the study of single bubble rise in confined geometries. In particular, we found the numerical simulations instrumental in providing a better insight into the measurements, and effective for generalizing the experimental observations, thereby compensating for the limitations of the test setup. Still, we found the numerical simulations somewhat hampered by the current limitations in RANS turbulence models for bubbly flows, and further validation work in this respect would be particularly beneficial.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clift, R.; Grace, J.; Weber, M. Bubbles, Drops, and Particles; Dover Publications: New York, NY, USA, 2005; ISBN 0-486-44580-1. [Google Scholar]

- Kulkarni, A.A.; Joshi, J.B. Bubble Formation and Bubble Rise Velocity in Gas-Liquid Systems: A Review. Ind. Eng. Chem. Res. 2005, 44, 5873–5931. [Google Scholar] [CrossRef]

- Loth, E. Quasi-Steady Shape and Drag of Deformable Bubbles and Drops. Int. J. Multiph. Flow 2008, 34, 523–546. [Google Scholar] [CrossRef]

- Uno, S.; Kintner, R.C. Effect of Wall Proximity on the Rate of Rise of Single Air Bubbles in a Quiescent Liquid. AIChE J. 1956, 2, 420–425. [Google Scholar] [CrossRef]

- Salami, E.; Vignes, A.; Le Goff, P. Hydrodynamique Des Dispersions. II. Effet de Paroi. Mouvement d’une Goutte Ou d’une Bulle Dans Un Fluide Immobile Contenu Dans Un Tube Vertical de Petit Diamètre. Genie Chim. 1965, 94, 67–77. [Google Scholar]

- Krishna, R.; Urseanu, M.I.; van Baten, J.M.; Ellenberger, J. Wall Effects on the Rise of Single Gas Bubbles in Liquids. Int. Commun. Heat Mass Transf. 1999, 26, 781–790. [Google Scholar] [CrossRef]

- Collins, R. A Simple Model of the Plane Gas Bubble in a Finite Liquid. J. Fluid Mech. 1965, 22, 763. [Google Scholar] [CrossRef]

- Bush, J.W.M.; Eames, I. Fluid Displacement by High Reynolds Number Bubble Motion in a Thin Gap. Int. J. Multiph. Flow 1998, 24, 411–430. [Google Scholar] [CrossRef]

- Roig, V.; Roudet, M.; Risso, F.; Billet, A.-M. Dynamics of a High-Reynolds-Number Bubble Rising within a Thin Gap. J. Fluid Mech. 2012, 707, 444–466. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Klaasen, B.; Degrève, J.; Blanpain, B.; Verhaeghe, F. Experimental and Numerical Study of Buoyancy-Driven Single Bubble Dynamics in a Vertical Hele-Shaw Cell. Phys. Fluids 2014, 26, 123303. [Google Scholar] [CrossRef] [Green Version]

- Filella, A.; Ern, P.; Roig, V. Oscillatory Motion and Wake of a Bubble Rising in a Thin-Gap Cell. J. Fluid Mech. 2015, 778, 60–88. [Google Scholar] [CrossRef] [Green Version]

- Hashida, M.; Hayashi, K.; Tomiyama, A. Rise Velocities of Single Bubbles in a Narrow Channel between Parallel Flat Plates. Int. J. Multiph. Flow 2019, 111, 285–293. [Google Scholar] [CrossRef]

- Hashida, M.; Hayashi, K.; Tomiyama, A. Effects of Fine Particles on Terminal Velocities of Single Bubbles in a Narrow Channel between Parallel Flat Plates. Int. J. Multiph. Flow 2020, 127, 103270. [Google Scholar] [CrossRef]

- Venkateswararao, P.; Semiat, R.; Dukler, A.E. Flow Pattern Transition for Gas-Liquid Flow in a Vertical Rod Bundle. Int. J. Multiph. Flow 1982, 8, 509–524. [Google Scholar] [CrossRef]

- Tomiyama, A.; Nakahara, Y.; Adachi, Y.; Hosokawa, S. Shapes and Rising Velocities of Single Bubbles Rising through an Inner Subchannel. J. Nucl. Sci. Tech. 2003, 40, 136–142. [Google Scholar] [CrossRef]

- Wu, M.; Gharib, M. Experimental Studies on the Shape and Path of Small Air Bubbles Rising in Clean Water. Phys. Fluids 2002, 14, L49. [Google Scholar] [CrossRef] [Green Version]

- Tomiyama, A.; Celata, G.P.; Hosokawa, S.; Yoshida, S. Terminal Velocity of Single Bubbles in Surface Tension Force Dominant Regime. Int. J. Multiph. Flow 2002, 28, 1497–1519. [Google Scholar] [CrossRef]

- Okawa, T.; Tanaka, T.; Kataoka, I.; Mori, M. Temperature Effect on Single Bubble Rise Characteristics in Stagnant Distilled Water. Int. J. Heat Mass Transf. 2003, 46, 903–913. [Google Scholar] [CrossRef]

- Peters, F.; Els, C. An Experimental Study on Slow and Fast Bubbles in Tap Water. Chem. Eng. Sci. 2012, 82, 194–199. [Google Scholar] [CrossRef]

- Liu, L.; Yan, H.; Zhao, G. Experimental Studies on the Shape and Motion of Air Bubbles in Viscous Liquids. Exp. Therm. Fluid Sci. 2015, 62, 109–121. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport. Properties-REFPROP, Version 9.1; Natl Std. Ref. Data Series (NIST NSRDS); NIST-National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013.

- Liu, L.; Yan, H.; Zhao, G.; Zhuang, J. Experimental Studies on the Terminal Velocity of Air Bubbles in Water and Glycerol Aqueous Solution. Exp. Therm. Fluid Sci. 2016, 78, 254–265. [Google Scholar] [CrossRef]

- Aoyama, S.; Hayashi, K.; Hosokawa, S.; Tomiyama, A. Shapes of Ellipsoidal Bubbles in Infinite Stagnant Liquids. Int. J. Multiph. Flow 2016, 79, 23–30. [Google Scholar] [CrossRef]

- Rohatgi, A. WebPlotDigitizer. 2021. Available online: https://automeris.io/WebPlotDigitizer/ (accessed on 6 July 2021).

- Eaton, J.W.; Bateman, D.; Hauberg, S.; Wehbring, R. GNU Octave 4.2 Reference Manual; Samurai Media Limited: Hong Kong, 2017. [Google Scholar]

- Solomon, C.; Breckon, T. Fundamentals of Digital Image Processing: A Practical Approach with Examples in Matlab; Wiley-Blackwell: Chichester, UK; Hoboken, NJ, USA, 2011; ISBN 978-0-470-84472-4. [Google Scholar]

- Russ, J.C.; Neal, F.B. The Image Processing Handbook, 7th ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA; New York, NY, USA; London, UK, 2016; ISBN 978-1-138-74749-4. [Google Scholar]

- Besagni, G.; Inzoli, F. Bubble Size Distributions and Shapes in Annular Gap Bubble Column. Exp. Therm. Fluid Sci. 2016, 74, 27–48. [Google Scholar] [CrossRef] [Green Version]

- Besagni, G.; Inzoli, F. Comprehensive Experimental Investigation of Counter-Current Bubble Column Hydrodynamics: Holdup, Flow Regime Transition, Bubble Size Distributions and Local Flow Properties. Chem. Eng. Sci. 2016, 146, 259–290. [Google Scholar] [CrossRef] [Green Version]

- Hirt, C.W.; Nichols, B.D. Volume of Fluid (VOF) Method for the Dynamics of Free Boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Roenby, J.; Bredmose, H.; Jasak, H. A Computational Method for Sharp Interface Advection. R. Soc. Open Sci. 2016, 3, 160405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A Continuum Method for Modeling Surface Tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Hua, J.; Stene, J.F.; Lin, P. Numerical Simulation of 3D Bubbles Rising in Viscous Liquids Using a Front Tracking Method. J. Comput. Phys. 2008, 227, 3358–3382. [Google Scholar] [CrossRef] [Green Version]

- Dijkhuizen, W.; Roghair, I.; Van Sint Annaland, M.; Kuipers, J.A.M. DNS of Gas Bubbles Behaviour Using an Improved 3D Front Tracking Model—Drag Force on Isolated Bubbles and Comparison with Experiments. Chem. Eng. Sci. 2010, 65, 1415–1426. [Google Scholar] [CrossRef]

- Roghair, I.; Mercado, J.M.; Sint Annaland, M.V.; Kuipers, H.; Sun, C.; Lohse, D. Energy Spectra and Bubble Velocity Distributions in Pseudo-Turbulence: Numerical Simulations vs. Experiments. Int. J. Multiph. Flow 2011, 37, 1093–1098. [Google Scholar] [CrossRef]

- Gumulya, M.; Joshi, J.B.; Utikar, R.P.; Evans, G.M.; Pareek, V. Characteristics of Energy Production and Dissipation around a Bubble Rising in Water. Chem. Eng. Sci. 2019, 193, 38–52. [Google Scholar] [CrossRef]

- Loisy, A.; Naso, A.; Spelt, P.D.M. Buoyancy-Driven Bubbly Flows: Ordered and Free Rise at Small and Intermediate Volume Fraction. J. Fluid Mech. 2017, 816, 94–141. [Google Scholar] [CrossRef] [Green Version]

- Balcázar, N.; Lehmkuhl, O.; Jofre, L.; Oliva, A. Level-Set Simulations of Buoyancy-Driven Motion of Single and Multiple Bubbles. Int. J. Heat Fluid Flow 2015, 56, 91–107. [Google Scholar] [CrossRef] [Green Version]

- Esmaeeli, A.; Tryggvason, G. A Direct Numerical Simulation Study of the Buoyant Rise of Bubbles at O(100) Reynolds Number. Phys. Fluids 2005, 17, 093303. [Google Scholar] [CrossRef]

- Cano-Lozano, J.C.; Martínez-Bazán, C.; Magnaudet, J.; Tchoufag, J. Paths and Wakes of Deformable Nearly Spheroidal Rising Bubbles Close to the Transition to Path Instability. Phys. Rev. Fluids 2016, 1, 053604. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, M.K.; Sahu, K.C.; Govindarajan, R. Dynamics of an Initially Spherical Bubble Rising in Quiescent Liquid. Nat. Commun. 2015, 6, 6268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gumulya, M.; Joshi, J.B.; Utikar, R.P.; Evans, G.M.; Pareek, V. Bubbles in Viscous Liquids: Time Dependent Behaviour and Wake Characteristics. Chem. Eng. Sci. 2016, 144, 298–309. [Google Scholar] [CrossRef] [Green Version]

- Brown, R. Fitellipse.m. 2021. Available online: https://www.mathworks.com/matlabcentral/fileexchange/15125-fitellipse-m (accessed on 6 July 2021).

- Yury. Ellipsoid Fit. 2021. Available online: https://www.mathworks.com/matlabcentral/fileexchange/24693-ellipsoid-fit (accessed on 6 July 2021).

- Bhaga, D.; Weber, M.E. Bubbles in Viscous Liquids: Shapes, Wakes and Velocities. J. Fluid Mech. 1981, 105, 61. [Google Scholar] [CrossRef] [Green Version]

- Hua, J.; Lou, J. Numerical Simulation of Bubble Rising in Viscous Liquid. J. Comput. Phys. 2007, 222, 769–795. [Google Scholar] [CrossRef]

- Veldhuis, C.H.J. Leonardo’s Paradox: Path and Shape Instabilities of Particles and Bubbles. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2006. [Google Scholar]

- Park, S.H.; Park, C.; Lee, J.; Lee, B. A Simple Parameterization for the Rising Velocity of Bubbles in a Liquid Pool. Nucl. Eng. Technol. 2017, 49, 692–699. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. In Proceedings of the Fourth International Symposium on Turbulence, Heat and Mass Transfer, Antalya, Turkey, 12–17 October 2003; Begell-House: Antalya, Turkey, 2003. [Google Scholar]

- Lunde, K.; Perkins, R.J. Shape Oscillations of Rising Bubbles. Appl. Sci. Res. 1997, 58, 387–408. [Google Scholar] [CrossRef]

- Moore, D.W. The Velocity of Rise of Distorted Gas Bubbles in a Liquid of Small Viscosity. J. Fluid Mech. 1965, 23, 749–766. [Google Scholar] [CrossRef]

- Fan, L.S.; Tsuchiya, K. Dynamics in Liquids and Liquid-Solid Suspensions; Butterworth-Heinemann: Oxford, UK, 1990. [Google Scholar]

- Mendelson, H.D. The Prediction of Bubble Terminal Velocities from Wave Theory. AIChE J. 1967, 13, 250–253. [Google Scholar] [CrossRef]

- Mei, R.; Klausner, J.F.; Lawrence, C.J. A Note on the History Force on a Spherical Bubble at Finite Reynolds Number. Phys. Fluids 1994, 6, 418–420. [Google Scholar] [CrossRef]

- Brown, P.P.; Lawler, D.F. Sphere Drag and Settling Velocity Revisited. J. Environ. Eng. 2003, 129, 222–231. [Google Scholar] [CrossRef]

- Tomiyama, A.; Kataoka, I.; Zun, I.; Sakaguchi, T. Drag Coefficients of Single Bubbles under Normal and Micro Gravity Conditions. JSME Int. J. Ser. B 1998, 41, 472–479. [Google Scholar] [CrossRef]

- Rodrigue, D. A General Correlation for the Rise Velocity of Single Gas Bubbles. Can. J. Chem. Eng. 2008, 82, 382–386. [Google Scholar] [CrossRef]

| (kg/m3) | (mN/m) | |||

|---|---|---|---|---|

| 998 | 1.18 | 958 | 18.3 | 72.4 |

| EXP | CFD | ||||||

|---|---|---|---|---|---|---|---|

| (mm) * | 4.3 | 3.0 | 3.5 | 4.0 | 4.5 | 5.2 | 6.0 |

| (m/s) | 0.18 | 0.216 | 0.214 | 0.210 | 0.200 | 0.199 | 0.190 |

| 0.81 | 0.679 | 0.626 | 0.602 | 0.605 | 0.608 | 0.634 | |

| 2.49 | 1.22 | 1.66 | 2.17 | 2.75 | 3.67 | 4.88 | |

| 1.93 | 1.94 | 2.21 | 2.45 | 2.50 | 2.85 | 3.00 | |

| 805 | 678 | 782 | 880 | 944 | 1083 | 1194 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cioncolini, A.; Magnini, M. Shapes and Rise Velocities of Single Bubbles in a Confined Annular Channel: Experiments and Numerical Simulations. Fluids 2021, 6, 437. https://doi.org/10.3390/fluids6120437

Cioncolini A, Magnini M. Shapes and Rise Velocities of Single Bubbles in a Confined Annular Channel: Experiments and Numerical Simulations. Fluids. 2021; 6(12):437. https://doi.org/10.3390/fluids6120437

Chicago/Turabian StyleCioncolini, Andrea, and Mirco Magnini. 2021. "Shapes and Rise Velocities of Single Bubbles in a Confined Annular Channel: Experiments and Numerical Simulations" Fluids 6, no. 12: 437. https://doi.org/10.3390/fluids6120437