1. Introduction

Air curtains consist of plane jets that are frequently used to separate different environmental zones. Air curtains are basically designed to reduce or control both heat and mass transfers, as well as to reduce the spreading of airborne contaminants between two zones. Their application is particularly useful when the physical barriers are not viable, for several reasons. In this framework, air curtains have been employed for several purposes, such as: HVAC (Heating, Ventilation and Air Conditioning) [

1,

2,

3], smoke control in passageways [

4,

5], airborne pollutant, and biological control [

6,

7,

8].

The plane jet induces a shear stress between the airflow and the stagnant ambient air, which promotes air entrainment. In the jets with significant flow rates, the shear stress induces the development of turbulent structures with several length scales. The turbulent structures promote air mass entrainment and mixing from both sides into the jet (‘contaminated’ and ‘non-contaminated’ compartments). Furthermore, the rejection of the jet flow to the clean compartment corresponds to the loss of air curtain tightness (loss of pollutant containment).

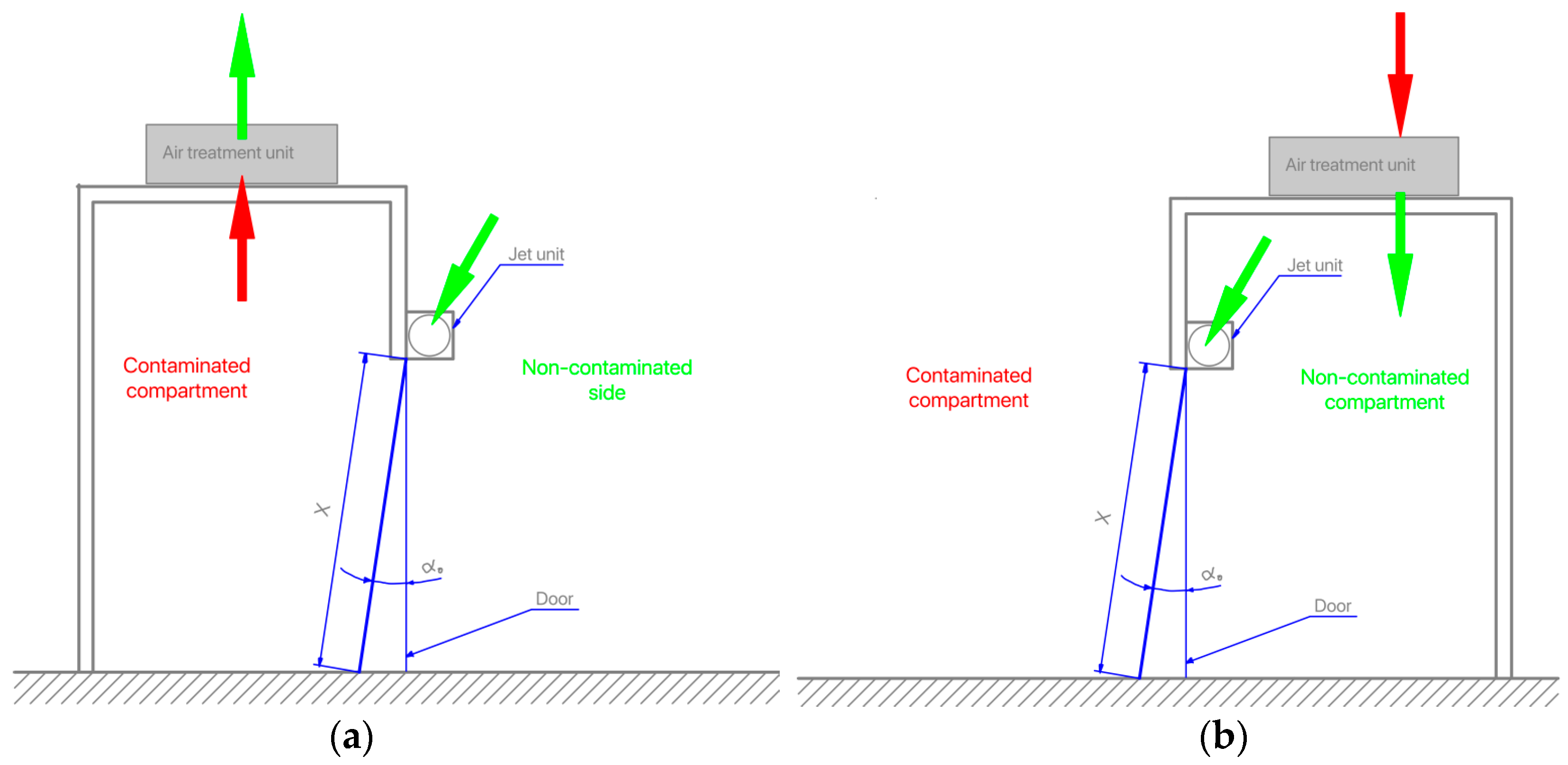

The usual application of this technology to protect the non-contaminated compartment from airborne contaminants (microorganisms, bacteria, fungi, and particles), in an almost isothermal condition, uses low jet velocities for obtaining an approximately laminar flow. The extraction at the contaminated side or at the tip of the jet is necessary in order to avoid the dispersion of the jet flow into the non-contaminated compartment (

Figure 1a). Reversely, this objective can also be attained if clean air is supplied to the non-contaminated compartment (

Figure 1b). Treating the ‘clean’ air before supplying it to the non-contaminated compartment, or treating the ‘dirty’ air removed from the contaminated compartment before releasing it into the environment are expensive procedures. Therefore, it becomes essential to find a technical solution for creating a proper zone separation that will be able to minimize flow rate requirements.

In the context of the Nanoguard2ar project, the basic requirement is to reduce, as far as possible, the exhaust flow rate from the contaminated compartment (or the supply flow rate to the non-contaminated compartment), in order to reduce the air treatment costs. Although, for an undisturbed environment (e.g., isothermal flow), the best solution is just to provide a very small uniform horizontal air stream through the opening, in practice, there are disturbances (e.g., temperature differences, wind, people crossing the opening) that require the use of an air curtain to improve the aerodynamic sealing of the opening. For this purpose, the most effective air curtain is the one that is able to reduce the airborne contaminants, minimizing the exhaust (or supply) flow rate, when exposed to disturbances.

Hayes and Stoecker [

9,

10,

11] studied the aerodynamic sealing performance of vertical air curtains under isothermal and non-isothermal conditions. Hayes [

8] developed the deflection modulus (D

m), which is indicative of the deflection of the air curtain jet and expresses the ratio of the outlet momentum to the transverse forces on the jet [

12]. They defined [

10] the operation condition where the air curtain jet reaches the floor as the ‘optimum condition’ and other operation conditions where the air curtain jet does not reach the floor as ‘break-through condition’, which can be further divided into the ‘inflow breakthrough condition’, where the air curtain flow is curved inward and does not reach the floor, and the ‘outflow breakthrough condition’, where the air curtain flow is curved outwards and does not reach the floor [

13]. In our research, the ideal condition corresponds to the limit between the optimum condition and the inflow breakthrough condition, when having

Figure 1 as reference (

Figure 1a), because in this condition, the contaminant mixed up in the jet flow is not released to the outside of the compartment.

In the air curtain applications at door height openings, the flow is characterized, in practice, by a transition regimen. The overall jet flow rate is reduced if the jet velocity is decreased; and hence, the use of lower jet velocities is also a strategy that can be adopted to reduce the jet flow rate rejected to the ‘non-contaminated’ compartment. Nevertheless, the vertical downward air curtains must be properly designed so as to avoid splitting the jet flow at the floor impingement zone, and consequently losing the air curtain aerodynamic sealing. However, with low air curtain speeds, when people walk through the door, the air curtain reconstitution time is longer, which could increment pollutant leakage through the air curtain. Using air curtains in a transition regimen (rather than in a laminar regimen) can minimize this problem.

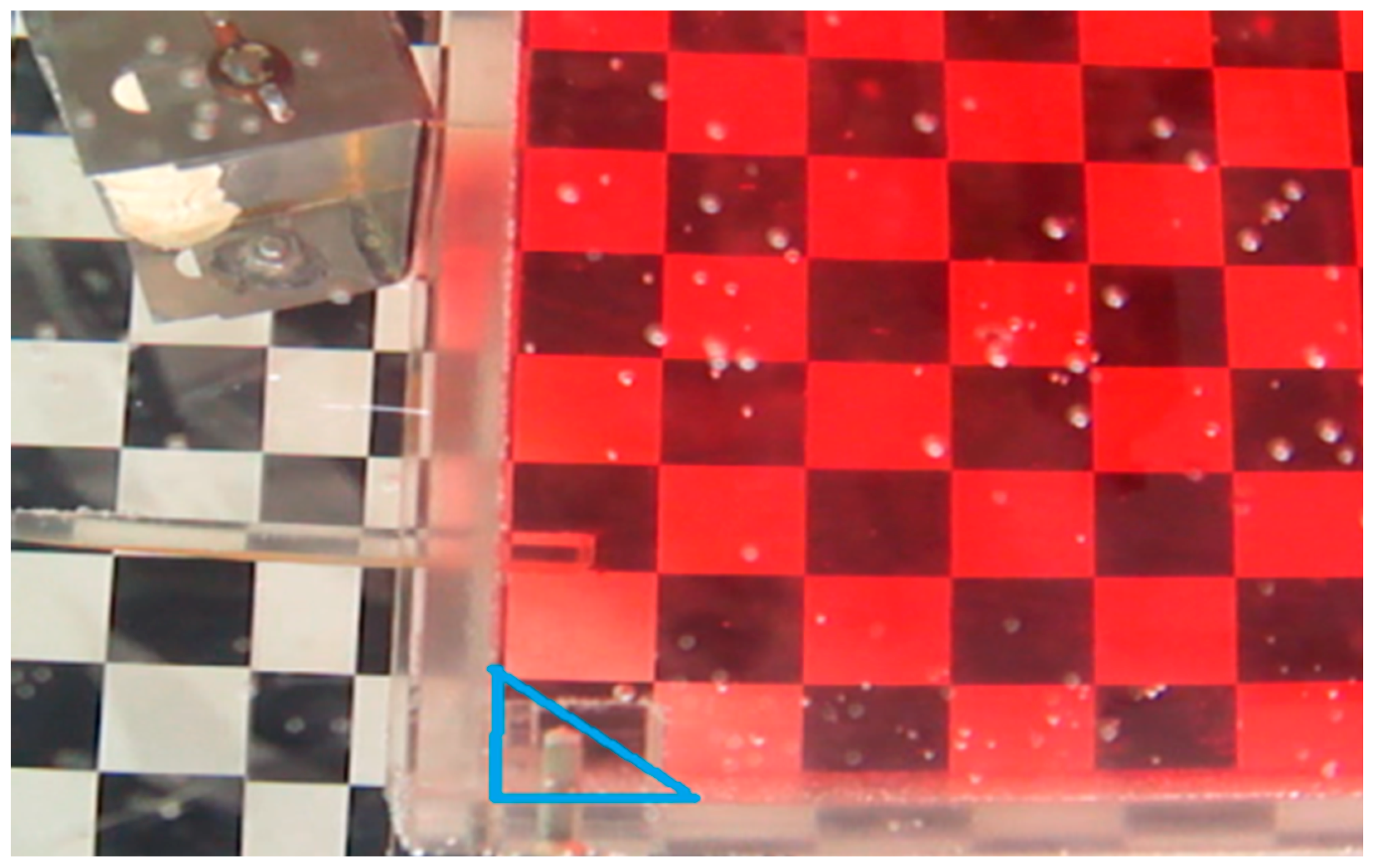

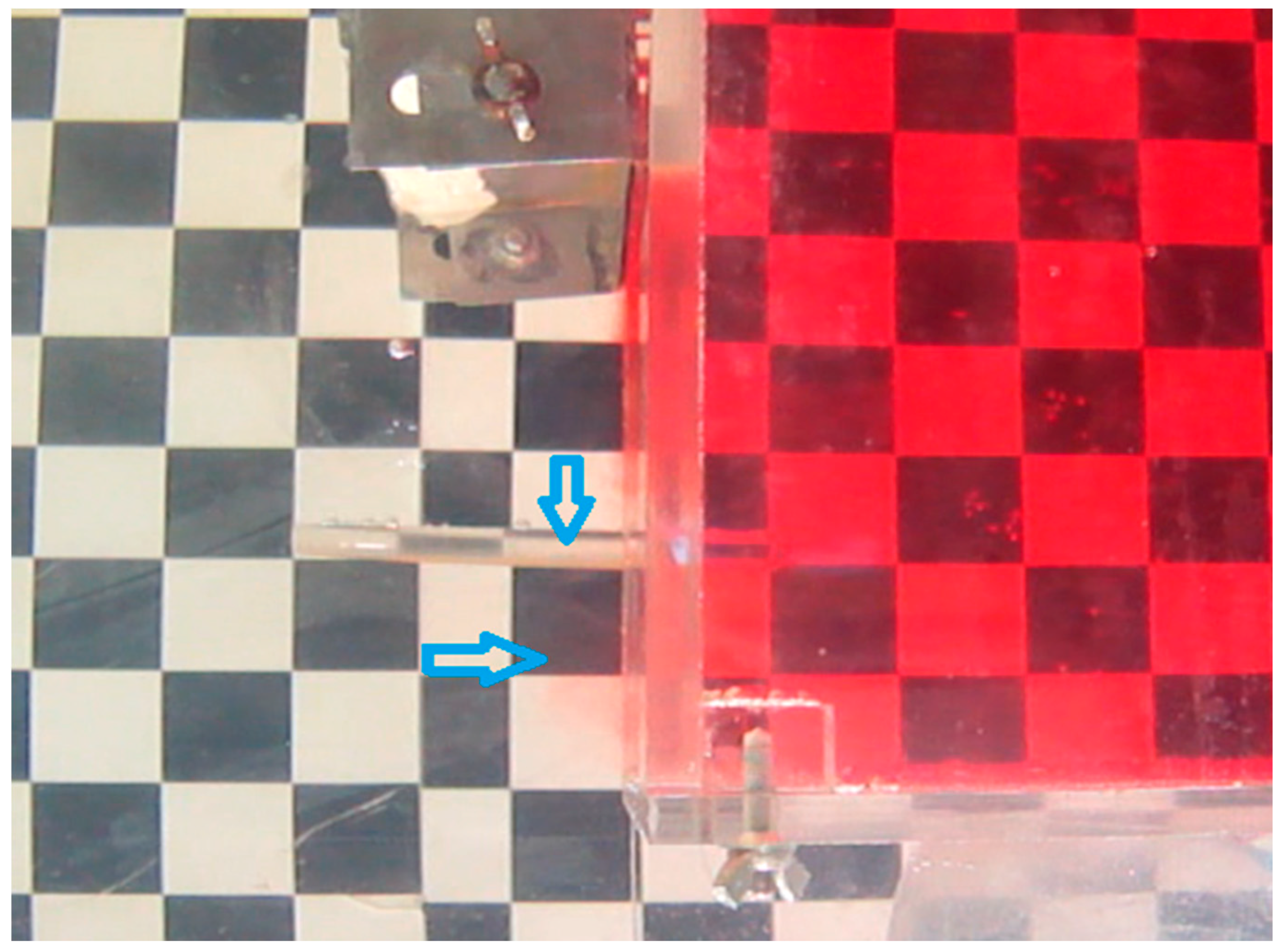

This study is developed within the framework of the Nanoguard2ar project (European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement N 690968). Its main goals are to develop, design, test, validate, and demonstrate an innovative nanomaterial-based ‘microbial free’ engineering solution, to ensure indoor air quality in buildings. To achieve this, an advanced oxidation process will be employed to clean the air extracted from the contaminated compartment (or to clean the external air before supplying it to the non-contaminated compartment), in conjunction with the use of air curtains, ensuring a proper separation between the spaces that are to be kept without cross contamination. Therefore, the purpose of this study is to define the plane jet characteristics that enable the best aerodynamic sealing of the air curtain to be achieved, by ensuring low exhaust flow rates from the contaminated compartment (or supply flow rates to the non-contaminated compartment), in accordance with the air treatment procedures adopted. This research encompasses three phases, namely: (i) small-scale experiments using water as the working fluid; (ii) computational fluid dynamics (CFD) simulations in order to verify if the small-scale test results are applicable to full size air curtains; and (iii) full size air curtain experiments. This paper describes the research carried out in the first phase.

There are several applications of this concept that aim to avoid contaminant spreading, such as: an operating room [

7,

14,

15,

16,

17,

18,

19], a tobacco smoke control [

20,

21], the protection of art works in museums and of cultural heritage [

22,

23], and open refrigerated display cabinets [

24,

25]. Several studies about air curtain efficiency have been conducted on these applications. However, there is no systematic approach to the contaminant aerodynamic sealing in the transition between the optimum condition and the ‘inflow breakthrough condition’. The studies on the application of air curtains have been based on experiments [

13,

26,

27,

28,

29], on CFD models [

23,

29,

30], and on semi-analytical models [

12,

31].

Rydock et al. [

27] presented an experimental study about the efficiency of air curtains in a dedicated-smoking restaurant area. The air curtain was installed at a 0.8 m height and the slot widths corresponded to 10 mm, 5 mm, and 3 mm, respectively, with varying mounting angles (+15, 0, and −15), and varying supply and extraction airflow rates, as well as several non-smoking sections with different air supply configurations. The maximum air curtain efficiency was achieved using the 100 m³/h per meter of air curtain and for a slot width of 5 mm. The results seem to indicate the feasibility of the use of air curtains to achieve improved air quality. However, a smoke free environment cannot be completely attained in a section of a single room. In this study, the air curtain flow was fed by the contaminant air from the smoking zone. The authors of this work concluded that to achieve an aerodynamic sealing for the tobacco smoke, the air curtain flow must be fed by clean air.

Shih et al. [

17] presented a numerical study on ethanol spreading in clean rooms. For the purpose of the study, the authors analysed the influence of air curtain parameters, such as jet velocity, angle, and installation height. The minimum velocity studied was 3 m/s. The maximum efficiency was achieved for a jet speed of 5 m/s and an angle of 15°. In this study, it was observed that the loss of air curtain sealing occurred essentially close to the bottom, where a flow separation takes place.

Santoli, Cumo, and Mariotti [

23] presented a numerical and experimental study on a cultural heritage building, using an air jet with speeds between 4 and 5 m/s, to create a physical barrier to the flow. They concluded that the ventilation system has efficiencies of 70–75%. However, the parameters that allow for maximizing the efficiency of the air curtain were not analysed in this study.

In operating rooms, the critical operating area is often isolated from the external contaminants by the installation of laminar diffusers, in conjunction with the use of air curtains [

16]. Cook and Int-Hout [

18] pointed out that another way to guarantee the asepsis level in the operating room is to ensure a hierarchical pressure in this space, between 10 to 15% of the volume of the room. According to the authors, the difficulty in guaranteeing a high asepsis level is due to the difficulty in achieving a laminar flow in the panels. This difficulty is associated with the undesirable speeds attained by the air entrainment and with the pressure gradient resulting from temperature differences, which eventually increase the turbulence intensity in the room. However, these studies are not conclusive with regards to the speed that should be used to achieve a certain level of asepsis. They only refer to the fact that low speeds are more efficient [

16].

Zhai and Osborne [

14] presented a numerical and experimental study, in which they concluded that there is no correlation between the laminar flow diffuser, the air curtain flow rate, and the concentration of contaminant. It was observed that it was preferable to use one-way diffusers rather than air curtains with high jet velocities. However, this did not demonstrate the existing relation between the inflow and outflow rates.

Goubran et al. [

13] present an experimental study to verify and further investigate the flow characteristics of the building entrances equipped with air curtains. In this study, the working fluid is the air and the nozzle thickness was 0.0635 m. Two different supply velocities were selected, namely: (1) the maximum supply speed of the unit is 13.75 m/s; and (2) a lower speed 9.1 m/s. A small-scale chamber (1/3 scale of the real case) of 2.44 m × 2.44 m × 1.3 m (L × W × H) was used for the measurements of the infiltration/exfiltration and pressure differentials, which were then used for developing the empirical model across the operating air curtain. The flow and pressure measurements confirmed that, for the tested pressure difference range, air curtains can significantly reduce the infiltration. Additionally, the experimental results indicated that the higher the air curtain supply speed, the better the air curtain performs (i.e., it is able to continue to operate in the optimum condition at higher pressure differences). Following this work, Qi et al. [

29] presented a parametric study of air curtain performance based on reduced-scale experiments and full-scale numerical simulations. Using the same experimental setup of previous research [

13], they found that increasing the air curtain supply angle improves the air curtain performance when it is operated under the optimum condition and inflow breakthrough condition, but creates excessive exfiltration under the ‘outflow breakthrough condition’. Increasing the supply speed of the air curtain generally improves the air curtain performance, whereas this improvement deteriorates with the increase of the supply angle under the outflow breakthrough condition.

These works clearly stress the relevance of the pressure difference between inside and outside the compartment, which is due to several effects, such as the buoyancy effect, the head loss of the flow through the opening, and many other factors including the wind effect and indoor systems operation; however, in the absence of the buoyancy effect, this pressure difference through the opening protected by the air curtain is related with the head loss of the flow through the opening protected by the air curtain. As the head loss (that is expressed in these works by a discharge coefficient) is dependent on the characteristics of the opening [

32], in our research, we considered that the average velocity of the flow across the door (

) is the variable of reference.

In the mentioned works, no clear correlation was established between the inlet flow rate (flow entering the door opening) and the velocity at the jet nozzle, which assures both the maximum air curtain effectiveness, and the level of asepsis achieved under isothermal conditions or low temperature differences. As there is no concern in reducing the exhaust flow from the contaminated compartment (or the supply flow to the non-contaminated compartment), in order to increase the effectiveness of the curtain and to reduce the air cleaning costs, both the air velocities and the corresponding Reynolds numbers in these works are quite high when compared with those reported in this research work. Therefore, to the best knowledge of the authors of this work, this study constitutes an added value to research in the field.

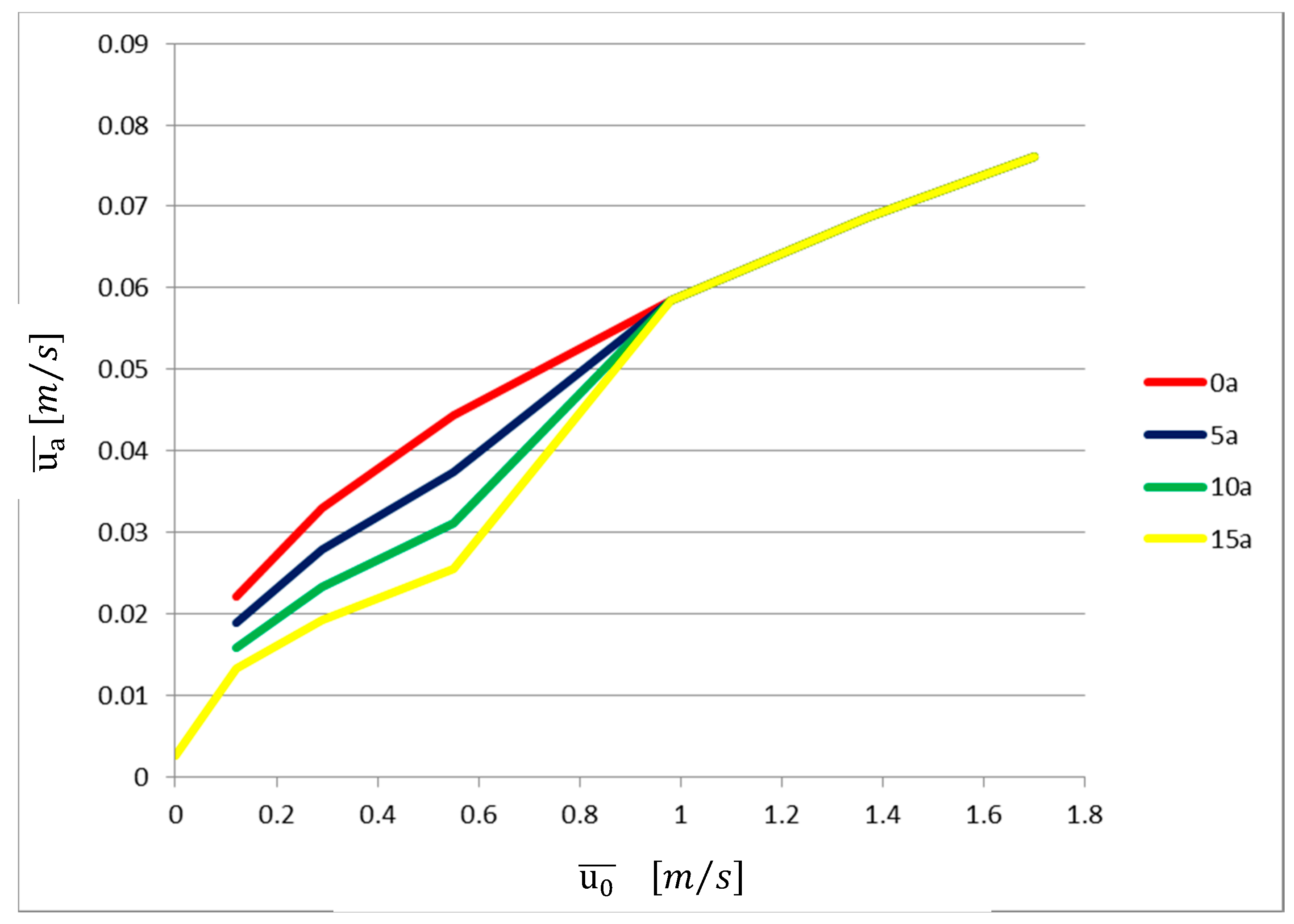

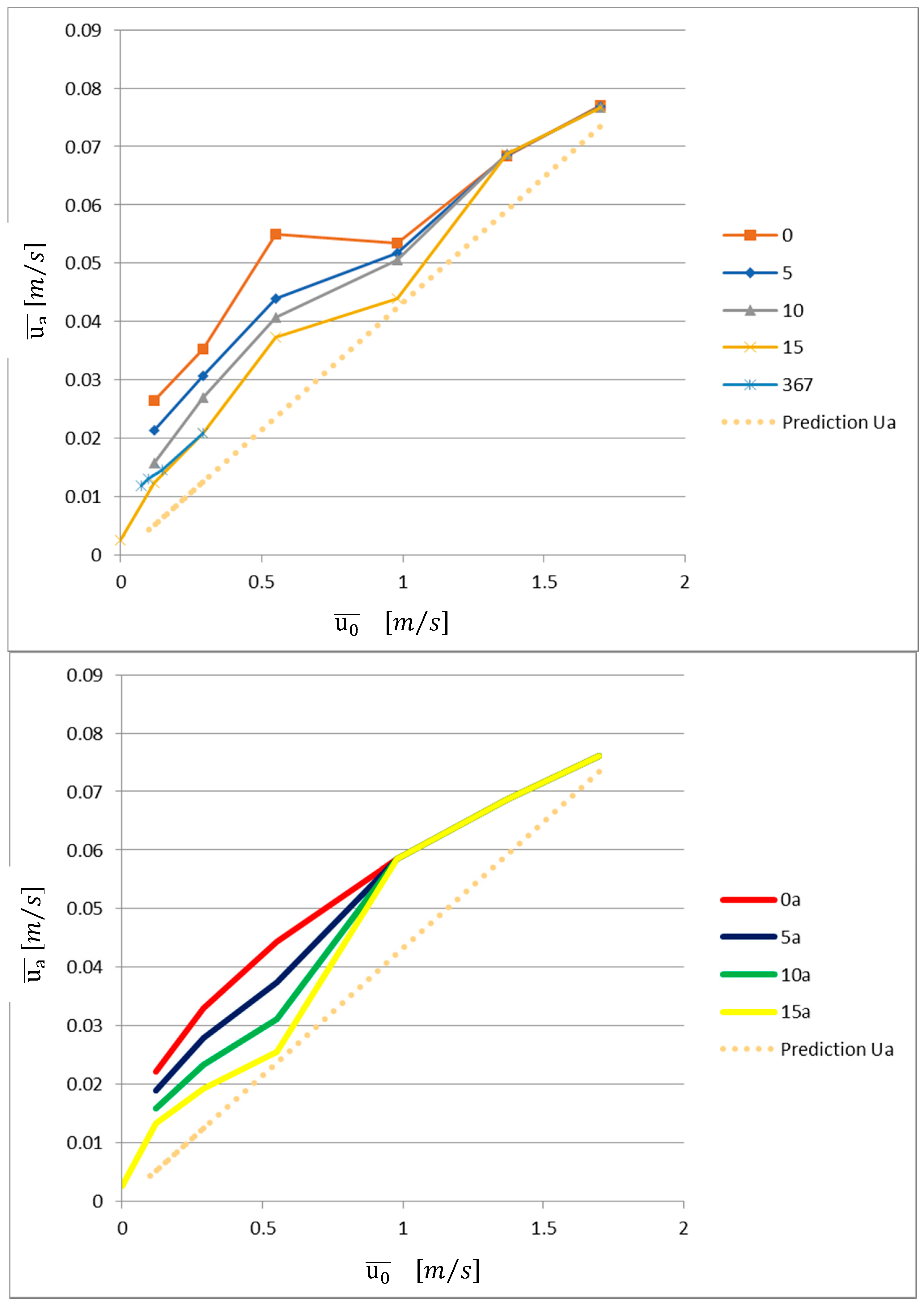

For the purposes of this work, it was considered as relevant to evaluate the balance between the average speed at the door opening and the jet characteristics, with a view to increase the air curtain effectiveness and thus enable its integration into the Nanoguard2ar system. Minimal requirements of average speed at the door are obtained for very low jet velocity. Therefore, very low jet speeds will also be used up to a maximum of 1.70 m/s. In previous research [

4], the extreme condition of the curtain exposed to a high buoyancy action was studied; in our research presented here, the opposed extreme condition of non-buoyant flow is studied.

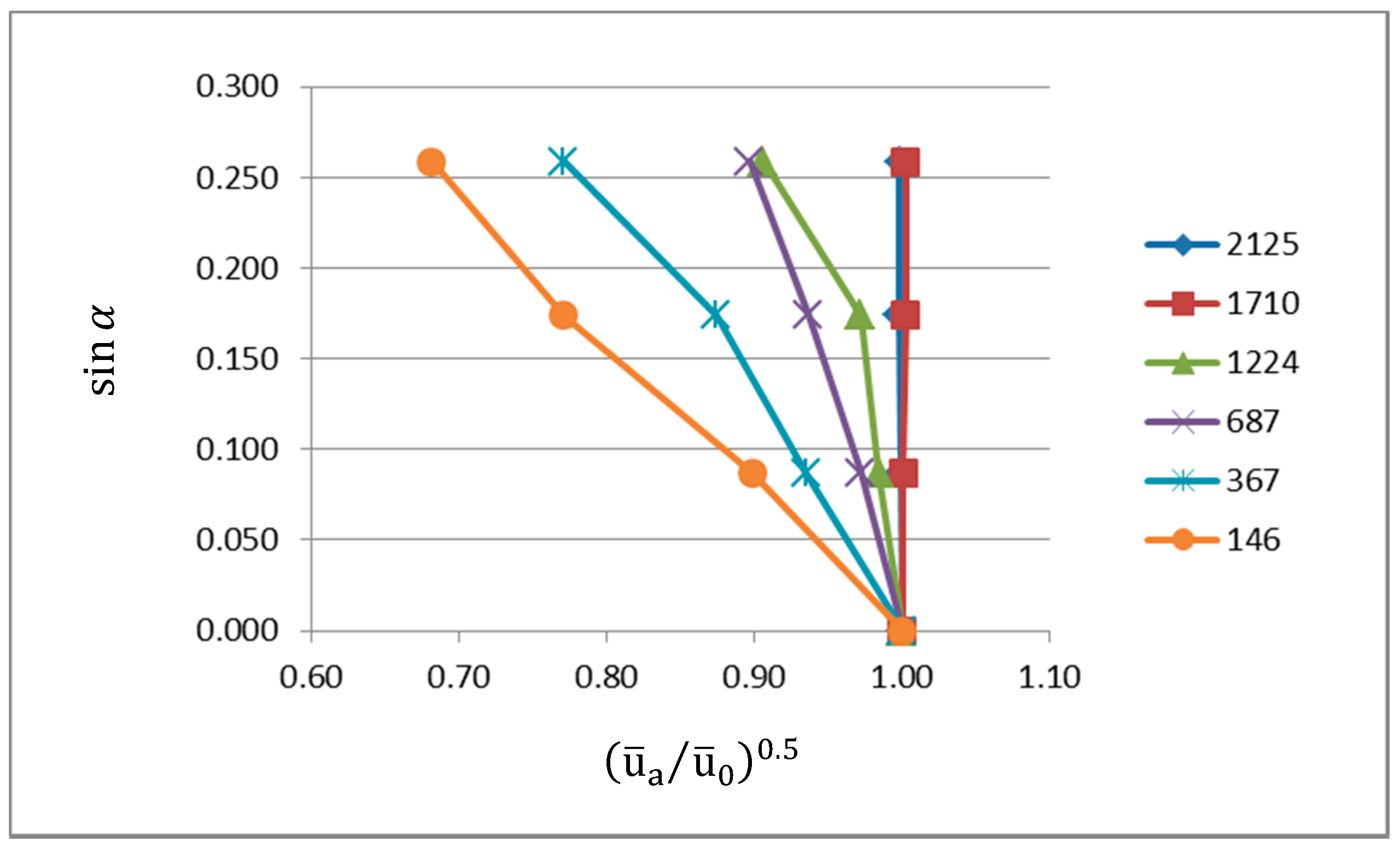

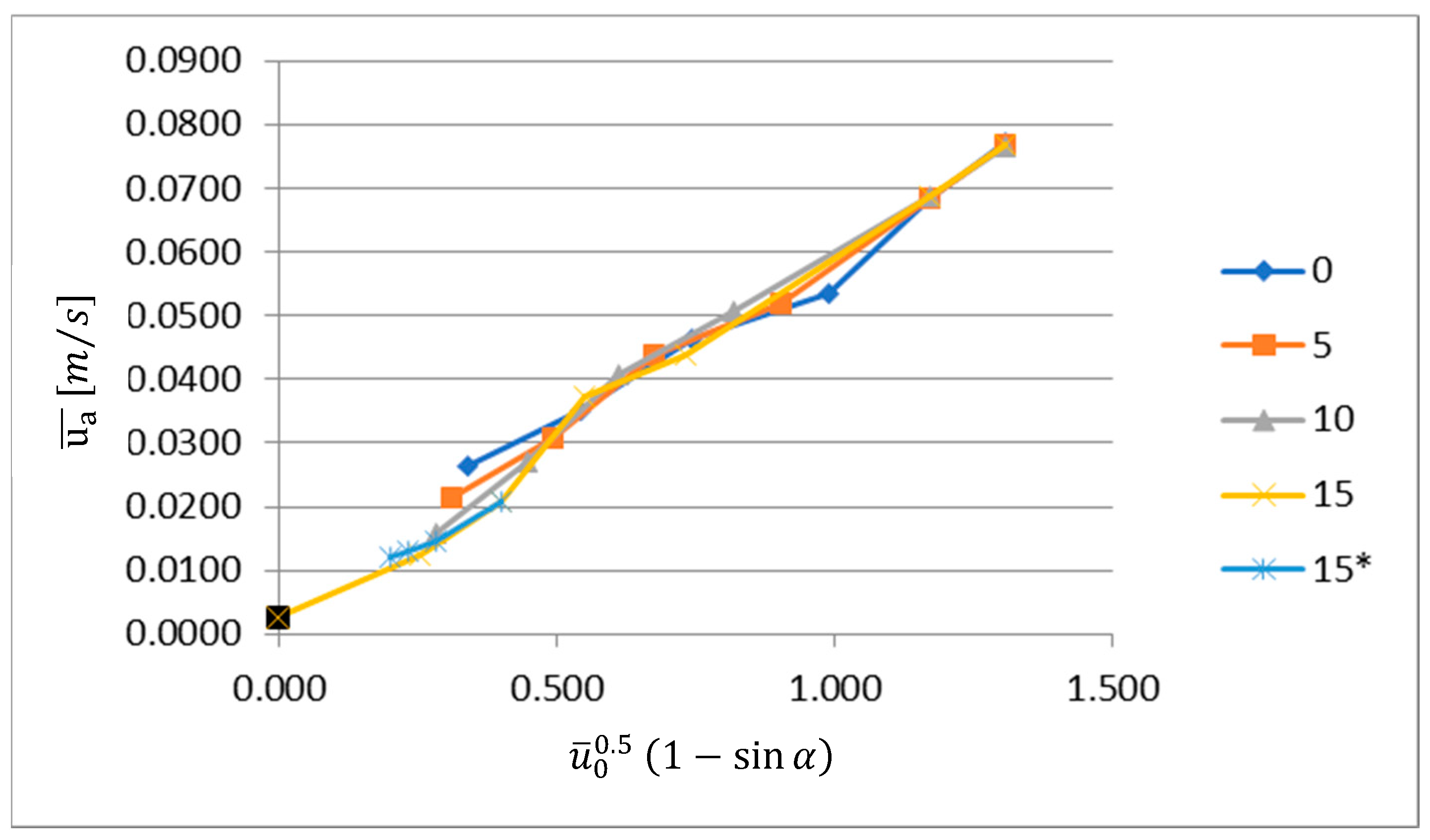

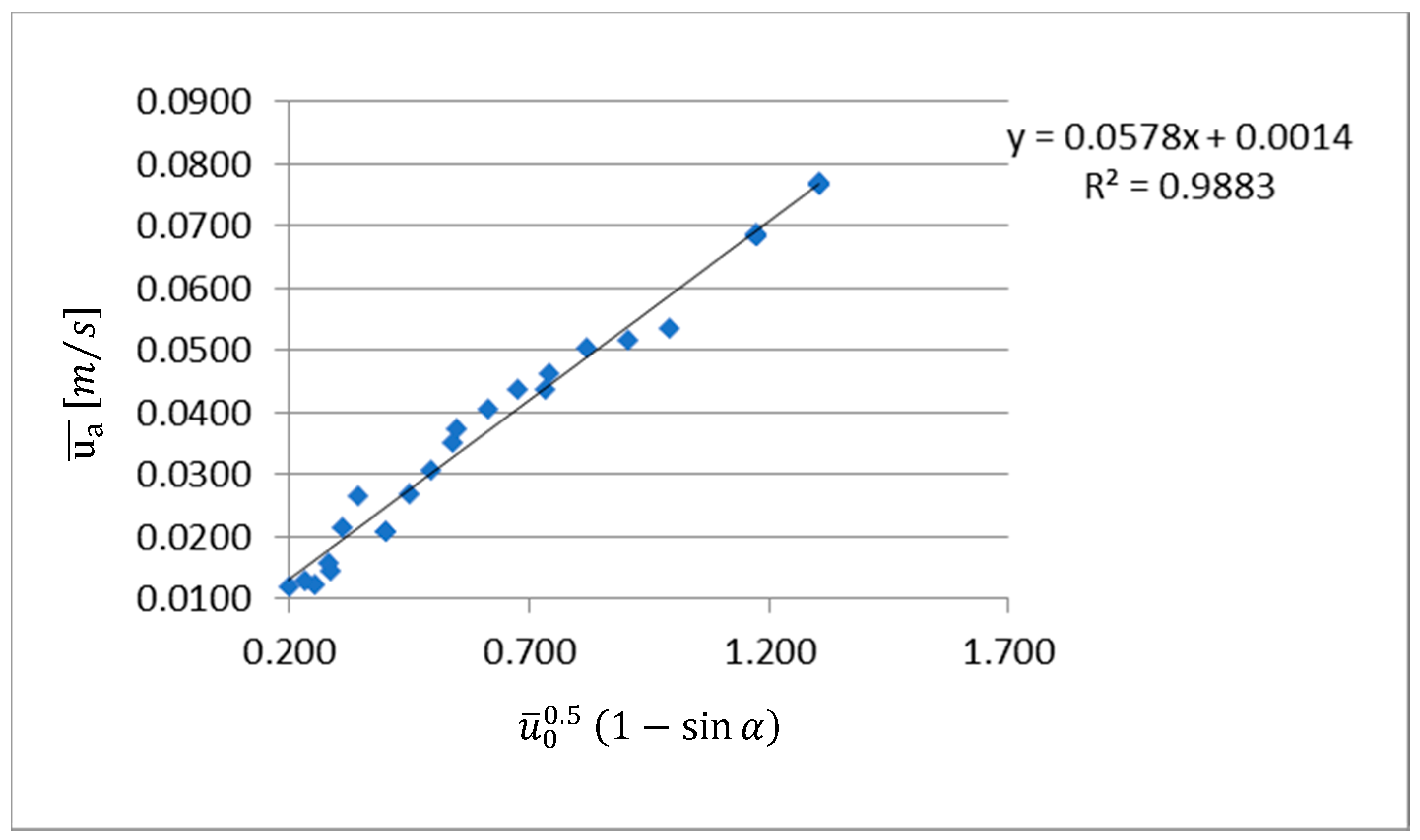

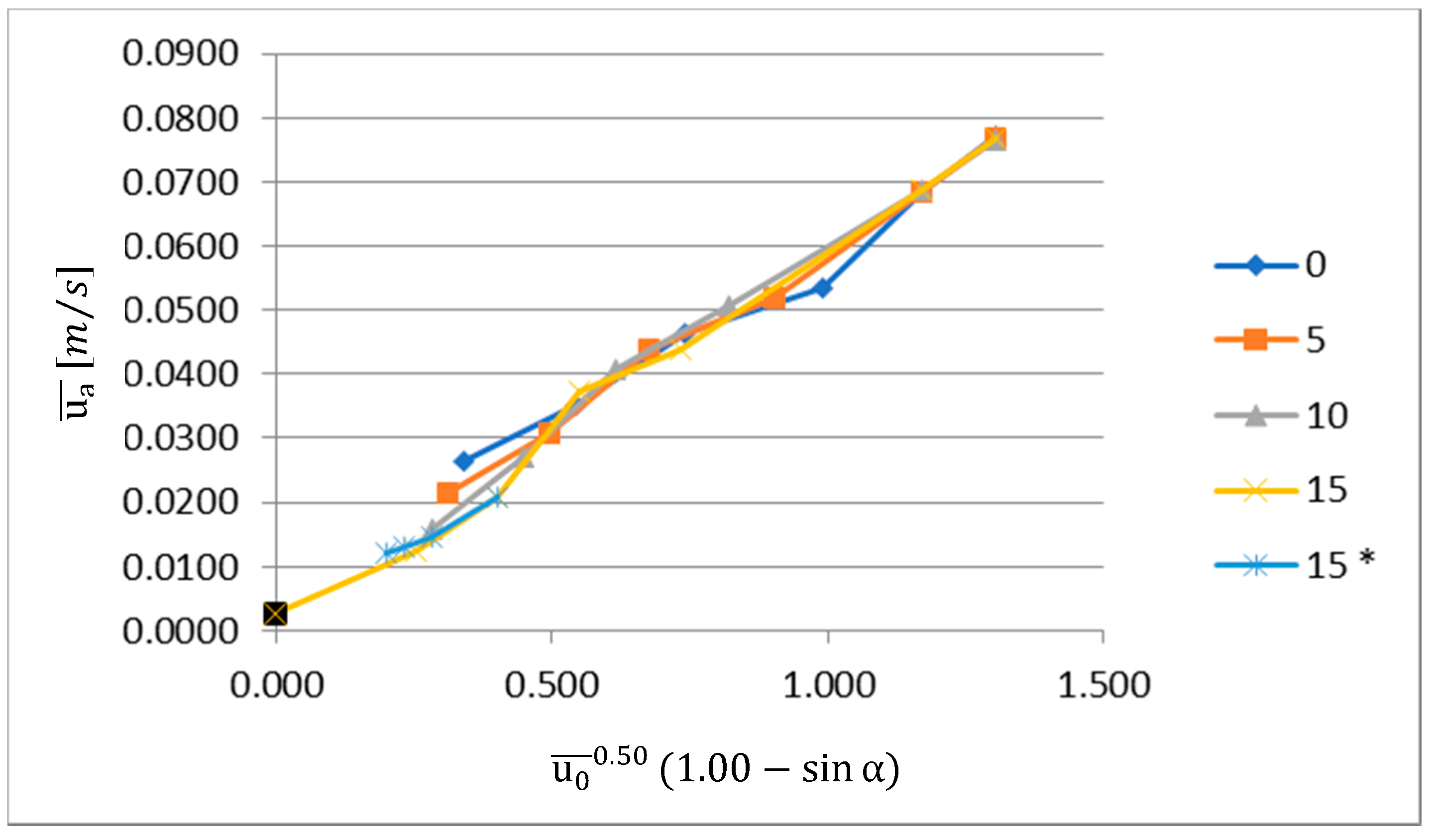

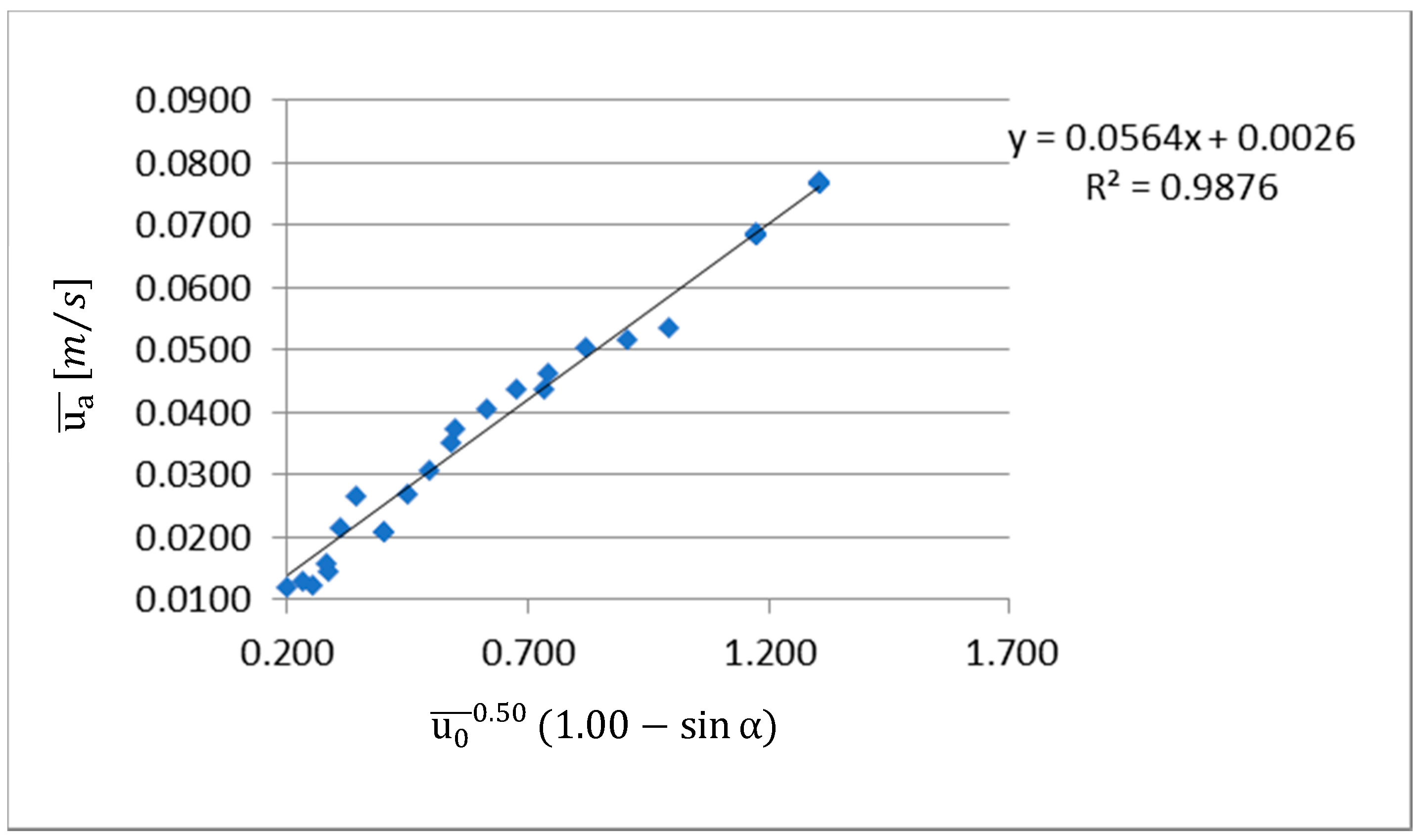

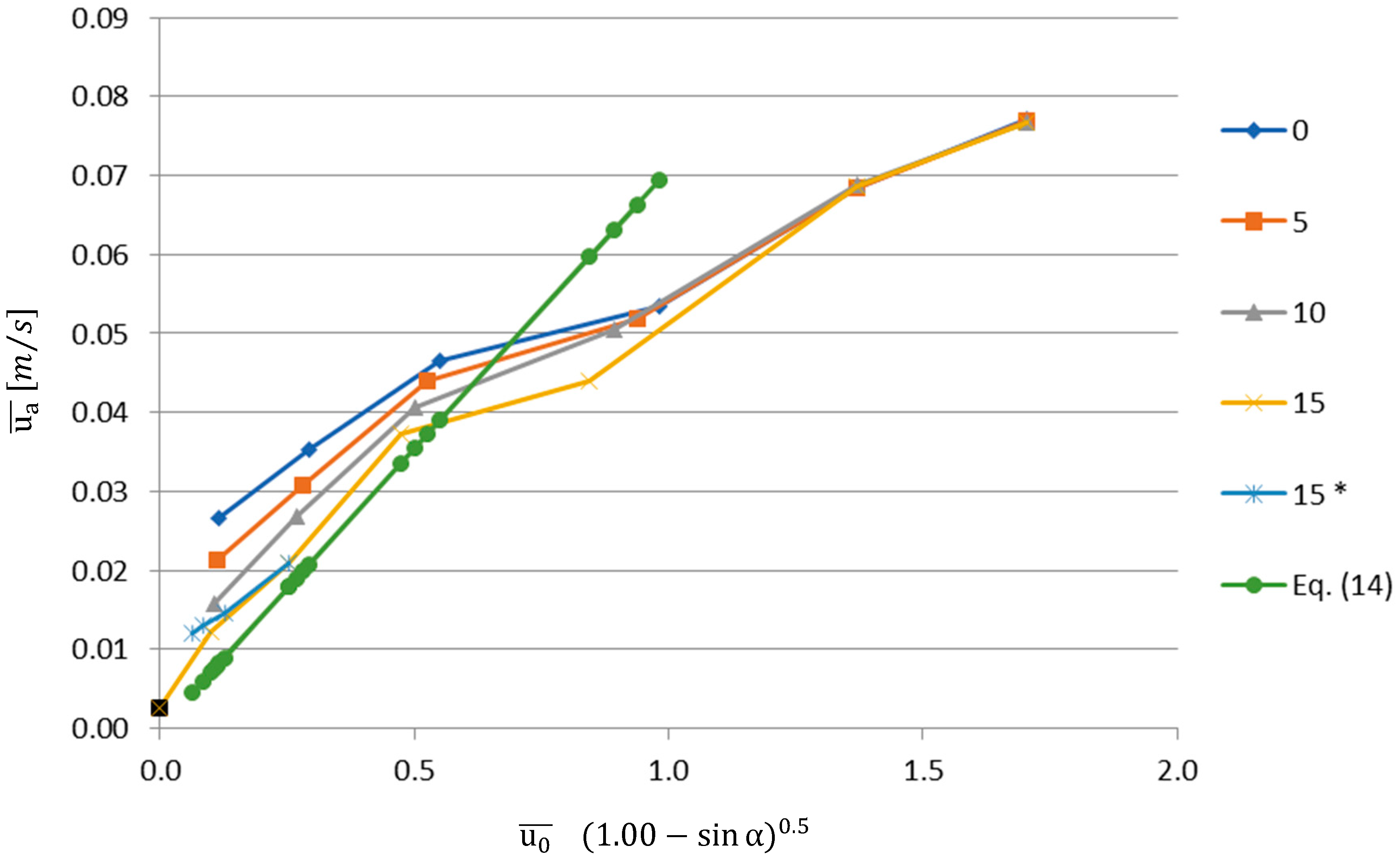

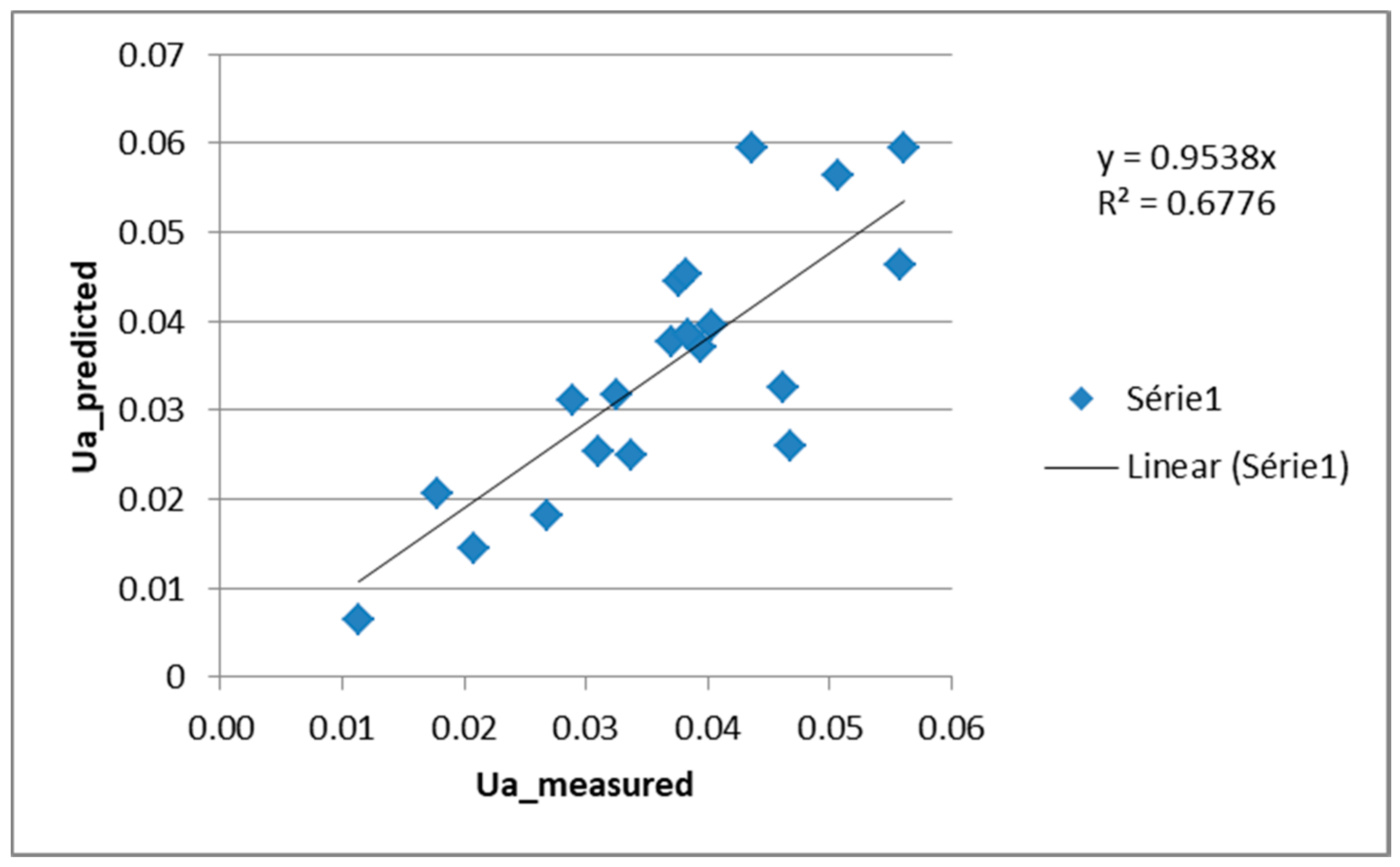

A simplified analytical model is presented in the next sections, with a view to discuss the variables that can influence the performance of the jet planes under a turbulent transition regimen. Two different conditions are analysed, namely the simplified balance of the jet momentum (which demonstrates a strong influence of the jet angle and is relevant for smaller Reynolds Number values—146, 367 and 687) and the comparison between the flow rate entrained by the jet from the non-contaminated zone, and the flow rate across the opening required to avoid the loss of aerodynamic sealing.