1. Introduction

The increasing demand for more economical and, at the same time, more environmentally friendly production methods has led to the design of new process equipment. By the term micro-device (μ-device), we refer to devices with at least one characteristic dimension of the order of a few millimeters. Key benefits of μ-devices are the development of energy friendly, productive, and cost-effective performance processes which at the same time provide greater security. For example, μ-reactors—i.e., devices with characteristic dimensions in the submillimeter range—offer significant advantages over conventional reactors, such as increased safety and reliability, as well as better process control and scalability. Due to the small characteristic dimension of the conduit, the flow in μ-reactors is laminar. As the extent of the chemical reactions is governed by the slow diffusive mass transfer, which in turn is proportional to the interfacial area between the reacting phases, the μ-reactor design turns out to be a μ-mixer design problem. That is why mixing in small devices has been studied extensively in recent years.

In general, mixing is achieved by stirring, where, due to the turbulent nature of flow, mixing is accomplished by advection followed by diffusion. In

μ-mixers, the flow is laminar and in this case depending on the way mixing is enhanced,

μ-mixers are distinguished in passive and active ones. In active

μ-mixers, an external source of energy is used [

1]. Active micromixers are unfortunately difficult to integrate and, in general, they have a higher implementation cost. In passive

μ-mixers, whose key advantage is the low operating cost, mixing efficiency is enhanced by incorporating parts that promote secondary flows (e.g., curved sections, backward or forward-facing steps). Several comprehensive reviews of

μ-mixing devices and their principles can be found in the relevant literature [

1,

2,

3,

4,

5,

6]. As it has been reported [

1,

7,

8,

9] in the micro-scale, mixing can be improved by “chaotic advection”, which involves breaking, stretching, and folding of liquid streams leading to an increase of the interfacial contact area of the fluids.

In our laboratory, the mixing efficiency of several types of passive

μ-mixers was investigated both experimentally and numerically [

5,

6,

7,

10].

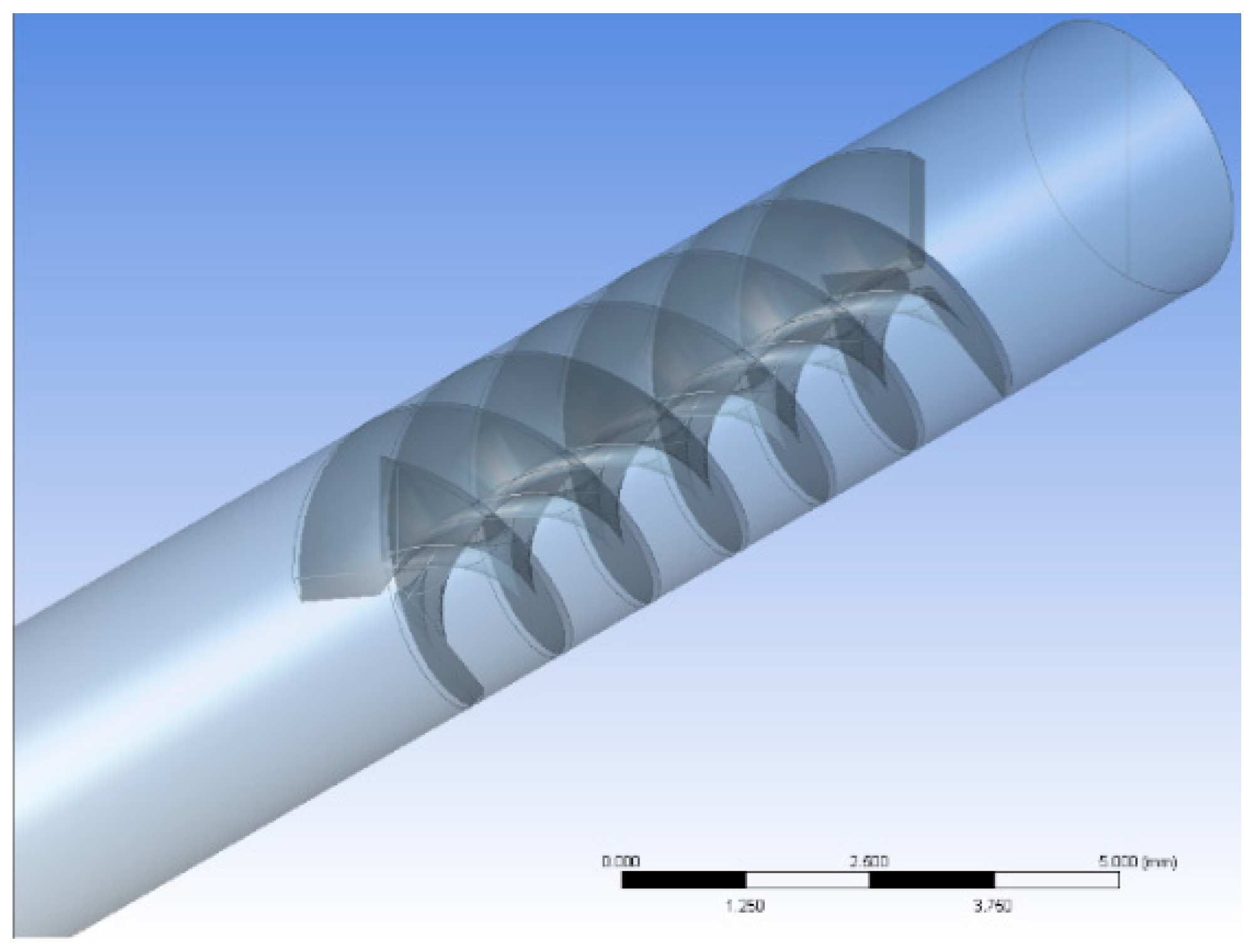

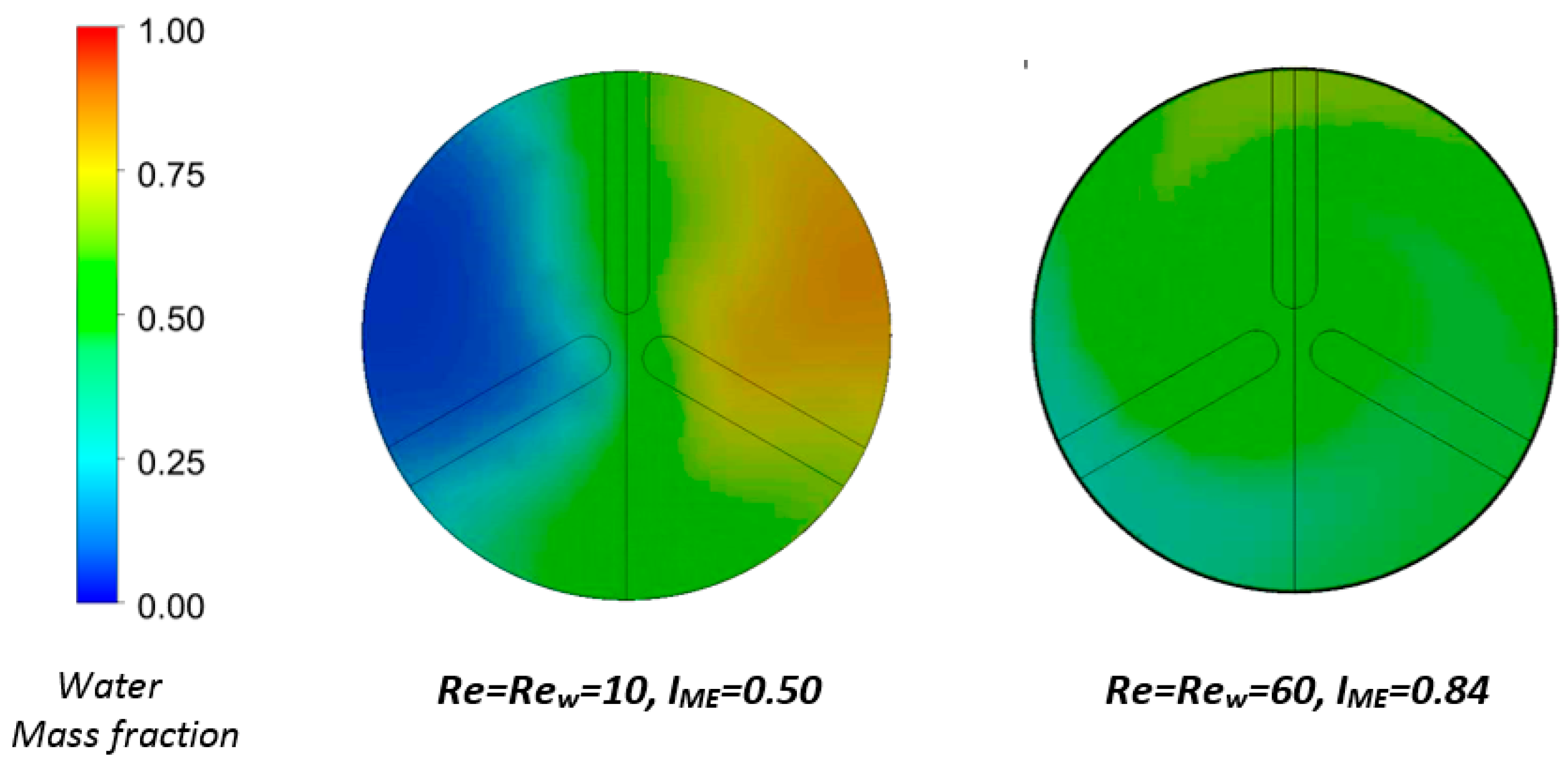

Figure 1 shows a typical passive

μ-mixer (i.e., Dean-type) whose functional characteristics were studied in our previous works [

7,

10]. Static mixers that create swirl flow are common in the macro scale and recently the application of swirl inducing configurations has been also studied in the

μ-scale [

11]. It is also known [

12] that static helical mixers are widely used in the chemical industry for in-line blending of liquids under laminar flow conditions and also that the geometric modification of their elements can significantly improve their mixing performance. Moreover, it is suggested [

13] that the addition of obstructions as part of the channel geometry can be also beneficial to micromixer efficiency.

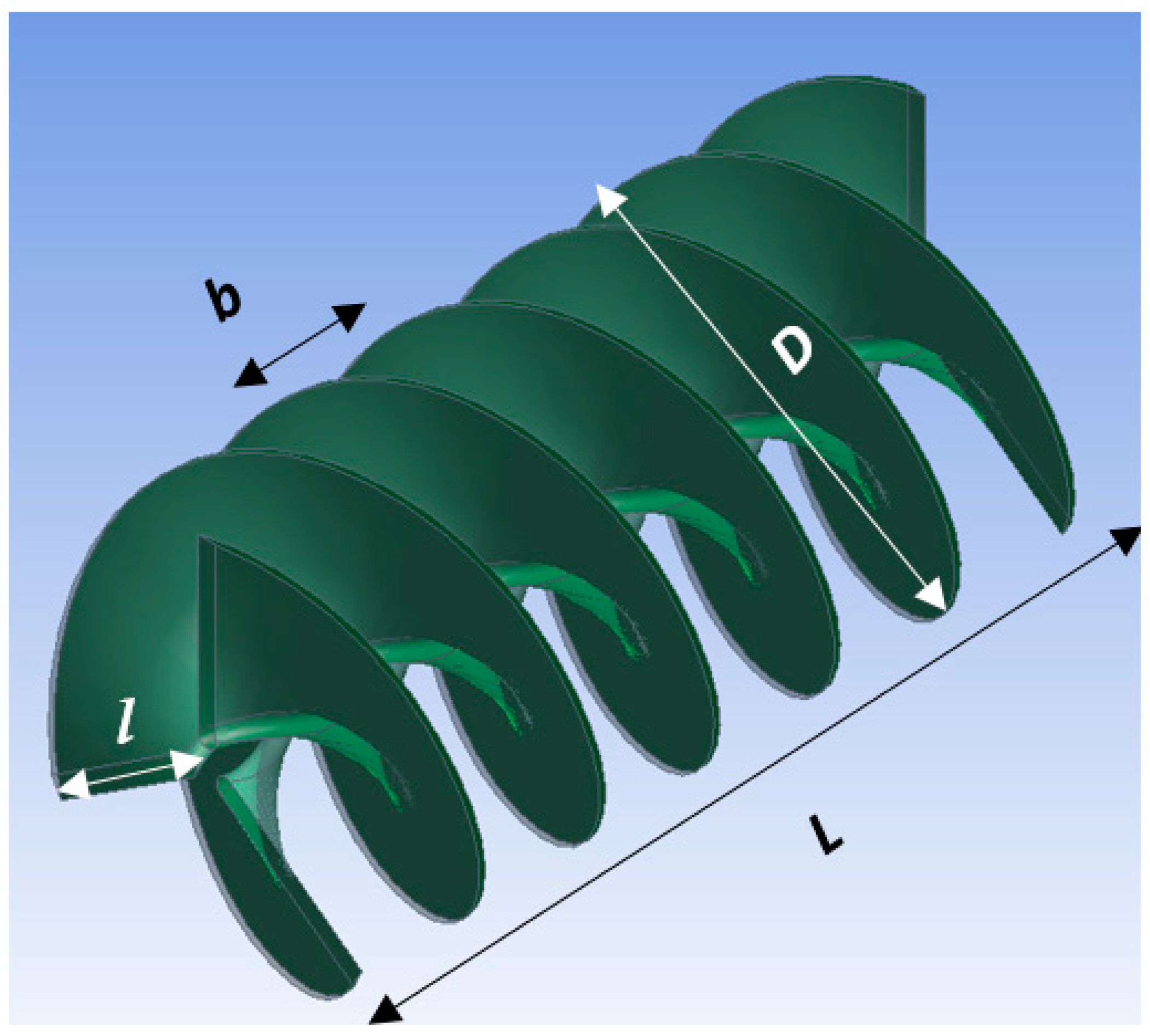

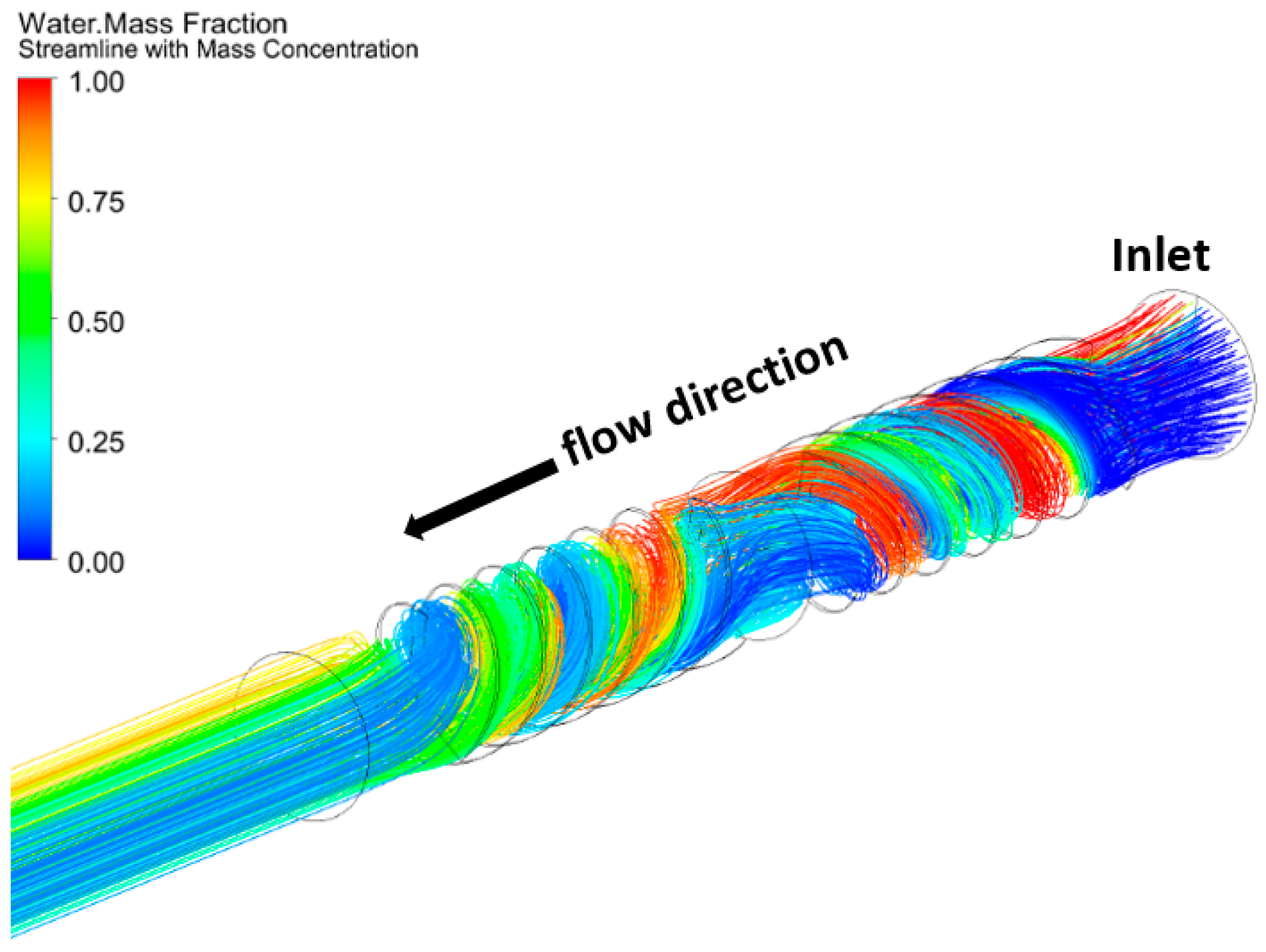

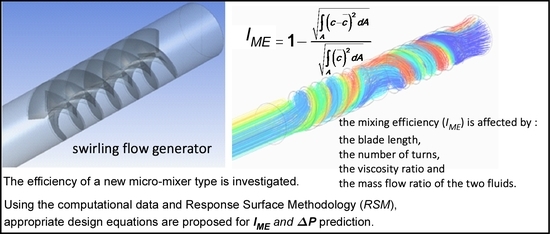

Motivated by the above, the purpose of this study is to investigate the possibility of using a helical insert (

Figure 2) that enhances mixing by generating swirl flow. More precisely, our aim is to numerically assess the effect of the geometric parameters of the helical insert (pitch and length of the insert blades) (

Figure 3) as well as the physical properties of the fluids to be mixed on both the mixing efficiency of the mixing device and the resulting pressure drop.

2. Numerical Methodology

The velocity field was visualized using a computational fluid dynamics (CFD) code (ANSYS CFX 18.1, ANSYS, Inc., Karnosboro, PA, USA) while the computational geometry and the mesh were designed using the parametric features of ANSYS Workbench package. The

μ-channel was modeled as a 3D computational domain. The simulations are performed using the ANSYS-CFX code, which includes the usual parts of a standard CFD code. The flow domain, constructed using the geometry section of the code, is presented in

Figure 4. A grid dependency study was performed for choosing the optimum grid density. Detail of the insert is shown in

Figure 4b, while the geometrical characteristics of the apparatus appear in

Table 1.

In the present calculations, the computational fluid dynamics code uses the laminar flow model of ANSYS CFX and the high-resolution advection scheme for the discretization of the momentum equations. A pressure boundary condition of atmospheric pressure is set on the outlet port, while the convergence criterion is the mass-balance residual value is less than 10−9.

As the numerical diffusion in the CFD calculations can influence the accuracy of the calculations, a thorough grid dependency study was performed to ensure that the solution is independent of the grid density. Pressure drop between inlet and outlet of the device, as well as the water mass fraction profile at the outlet, were considered as metrics for the evaluation of the dependence of the grid density on the solution. The final grid parameters (minimum/maximum element size, number of divisions for the sweep mesh areas, etc.) for a representative screening run were used to define the meshing parameters for the rest of the simulation runs. Number of elements for all cases varied between 850,000 and 3,000,000 elements, approximately. Due to the small characteristic dimension of the conduit the flow is laminar (Re = 9–100) and hence the laminar flow model was selected. The boundary conditions imposed are:

velocities of the two fluids, on each of the two semicircles comprising the inlet,

non-slip boundary condition at all walls,

zero relative pressure at the outlet.

Moreover, and for the sake of simplicity, it was assumed that one of the fluids, the base fluid, has the properties of water, while the diffusion coefficient between the two fluids equals the self-diffusion coefficient of water (1 × 10−9 m2/s).

Design parameters are declared as a mix of geometrical parameters and physical properties. Two geometrical design parameters, namely the number of turns,

n, of the blade within the limits of the length of the insert, and the ratio,

l/

D, are used. The other variables applied are the ratios of density and dynamic viscosity for the two different mixing fluids as well as the ratio of their velocities at the entrance of the conduit. The finite volume method, a fully coupled solver for the pressure and velocity coupling, and the “high order” method to distinguish the momentum equations, all provided by ANSYS CFX, are used in the solver definition section [

14]. Simulations were performed for a number of iterations that ensure a satisfactory reduction in residual mass and momentum (10

−12).

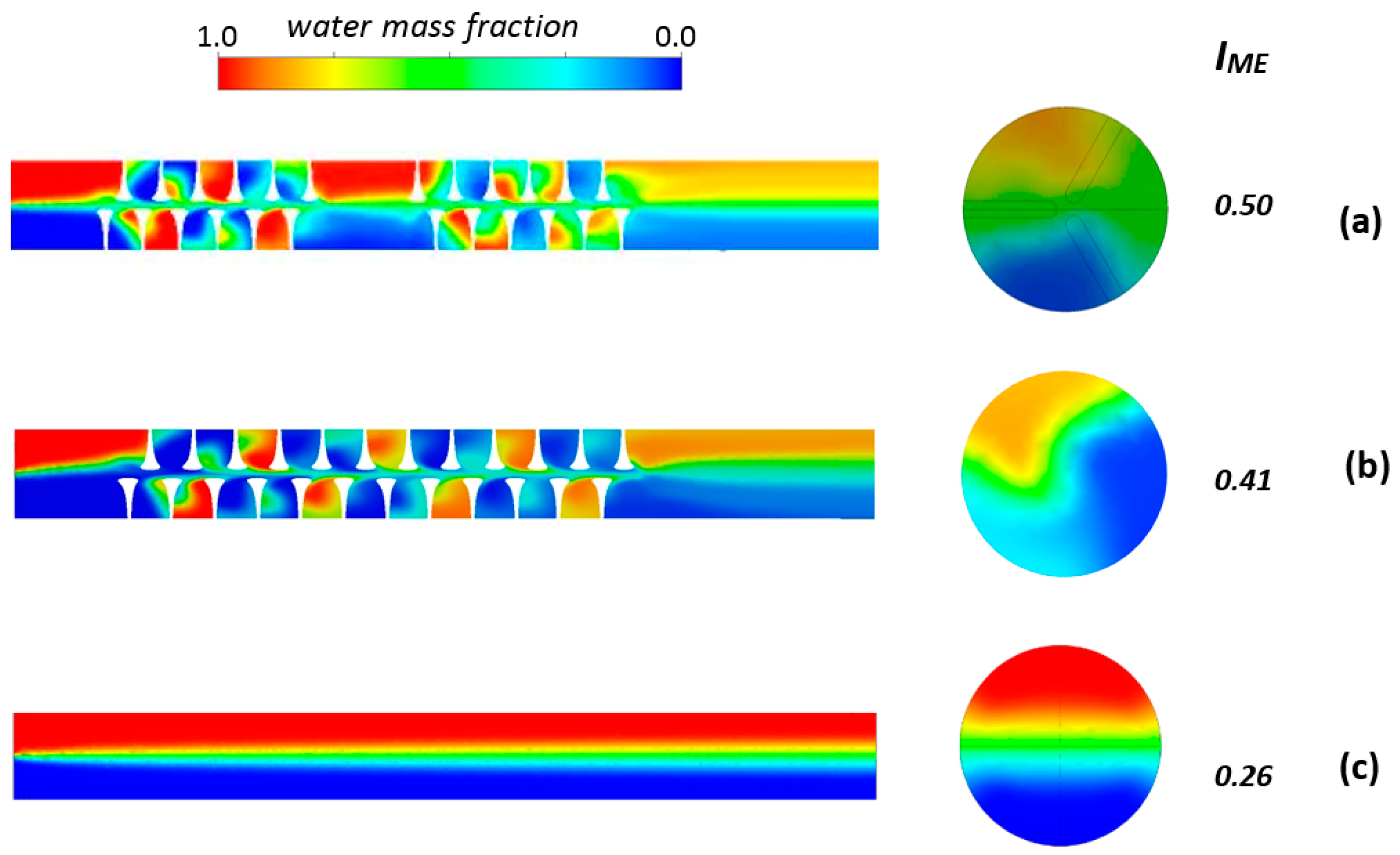

The mixing efficiency over a cross-section

A was quantified by calculating the Index of Mixing Efficiency,

IME, proposed by Kanaris et al. [

5], which is based on the standard deviation of mass fraction from the mean concentration over a cross section

where

c is the mass fraction of the base fluid, in our case the water, in each cross-section unit (i.e., each grid element) and

is the mean concentration of the same fluid over the whole cross-sectional area,

A, of the device. Complete mixing is achieved when the volume fraction of the base fluid in each cross-section unit equals its mean mass fraction,

, which must be calculated for each individual fluid pair by also taking into account the density of the mixing fluids:

A value of ΙΜΕ = 1 denotes perfect mixing, i.e., the variance from the optimal mass fraction is zero.

4. Conclusions

In this study, we have numerically investigated the mixing efficiency as well as the corresponding ΔP inside a novel type of μ-mixer. The device comprises two successive helical inserts that propel the fluid to opposite directions and induces mixing by generating swirling flow. Screening experiments reveal that the addition of the second insert improves mixing considerably. It was also found that for the range of Re numbers investigated, the resulting pressure drop is maintained at low levels (<150 Pa).

Appropriate ‘computational experiments’ were then conducted to investigate the effect of the various geometrical parameters of the novel μ-mixer, i.e., the one with the two inserts, and the parameters of the mixing fluids (physical properties and flow rate) on the mixing performance of the proposed device. Both the number of the required ‘computational experiments’ and the values of the design parameters were selecting using a DOE methodology. Using the data obtained from the ‘computational experiments’ correlations, which are able to predict the mixing efficiency and the associated pressure drop with ±10% accuracy, have been formulated.

In the next stage of the study, experiments will be performed using a prototype helical insert that has been already constructed by 3D printing (

Figure 10). The experimental data acquired using the device will be used for evaluating the CFD code. The aim is to provide a means of constructing the type of helical insert that would be more suitable for a given application.