The Impact of Flexographic and Digital Printing of Fruit Drinks on Consumer Attention at the Point of Sale

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location and Stimuli

2.2. Planogram

2.3. Eye Tracking Apparatus

2.4. Experimental Design

2.5. Procedure

2.6. Data Collection and Eye Tracking Metrics

3. Results and Discussion

3.1. Results

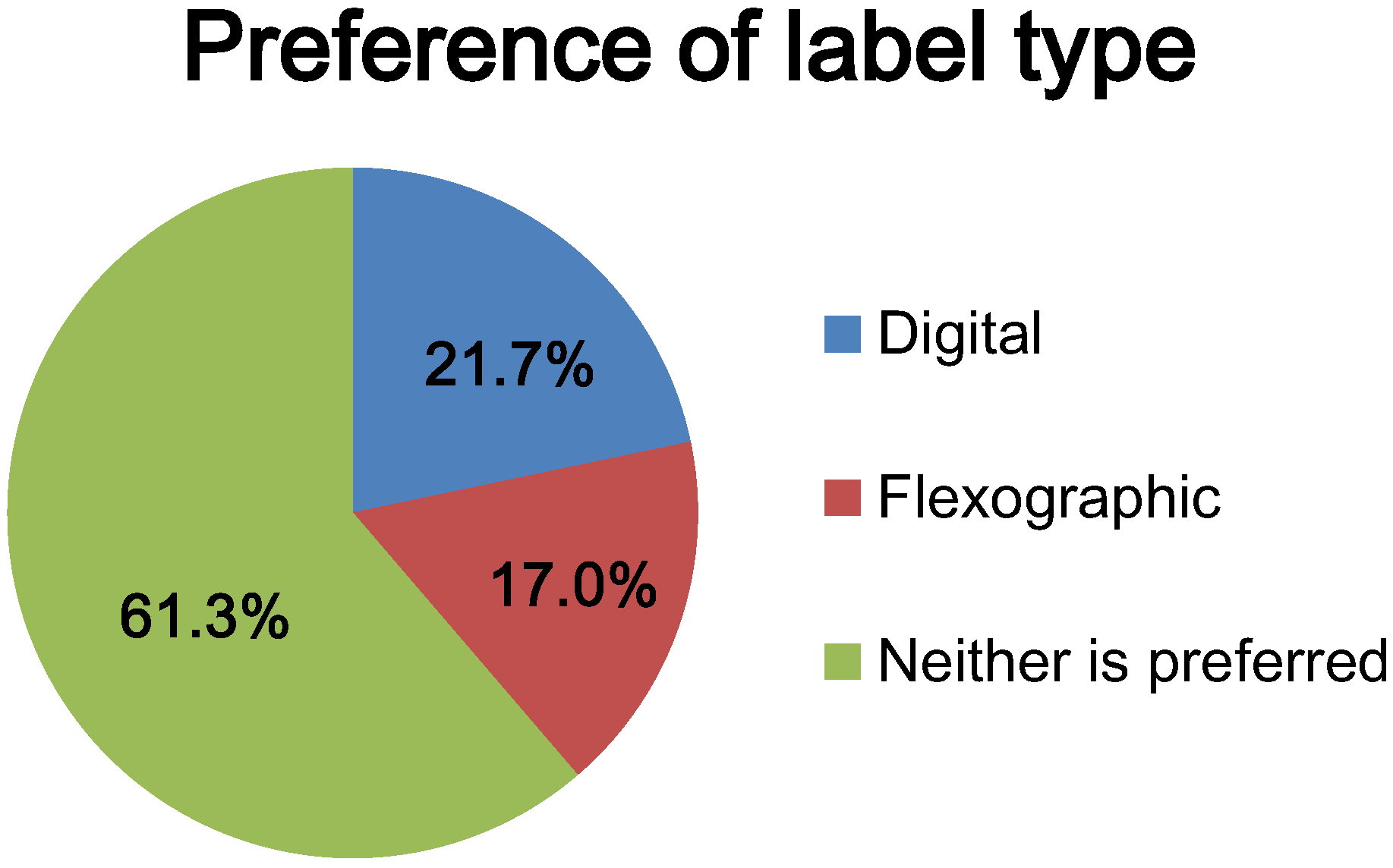

3.1.1. Survey Findings

3.1.2. Eye Tracking Results and Statistical Analysis

| Stimuli | TTFF | TFD | FC |

|---|---|---|---|

| Digital vs. Flexo | 0.344 | 0.730 | 0.381 |

| Digital left vs. right | 0.201 | 0.126 | 0.765 |

| Flexo left vs. right | 0.132 | 0.666 | 0.251 |

| Stimuli | TTFF (s) | TFD (s) | FC (counts) |

|---|---|---|---|

| Digitial | 1.66 | 0.85 | 4.64 |

| Flexo | 1.46 | 0.83 | 4.03 |

3.2. Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Golan, E.; Kuchler, F.; Mitchell, L.; Greene, C.; Jessup, A. Economics of food labeling. J. Consum. Policy 2001, 24, 117–184. [Google Scholar] [CrossRef]

- Rundh, B. The multi-faceted dimension of packaging. Br. Food J. 2005, 107, 670–684. [Google Scholar] [CrossRef]

- Kipphan, H. Handbook of Print Media: Technologies and Production Methods (Illustrated ed.); Springer: New York, NY, USA, 2001; pp. 976–979. [Google Scholar]

- White, S. Flexographic Printing vs. Digital Printing. Understanding the Variables that Affect the Selection of Label Printing Technology. Available online: http://www.labelvalue.com/documents/Flexographi-Printing-vs-Digital-Printing.pdf (accessed on 29 January 2015).

- Dunn, T. Flexible Packaging: Materials, Machinery, and Techniques; William Andrew Applied Science Publishers: New York, NY, USA, 2015; pp. 27–37. [Google Scholar]

- Johansson, K.; Lundberg, P.; Ryberg, R. Guide to Graphic Print Production, 3rd ed.; Wiley & Sons: Somerset, NJ, USA, 2011; pp. 325–326. [Google Scholar]

- Johnson, H. Mastering Digital Printing, 2nd ed.; Thompson Course Technology: Boston, MA, USA, 2005; pp. 19–20. [Google Scholar]

- Hurley, R.A.; Rice, C.J.; Conlon, G.; Tonkin, E.C.; O’Hara, L. The Impact of Simulated Kraft Substrates on Consumer Attention at the Point of Sale. J. Appl. Packag. Res. 2015, 7, 39–47. [Google Scholar] [CrossRef]

- Löfgren, M. Winning at the first and second moment of truth: An exploratory study. Manag. Serv. Qual. 2005, 15, 102–115. [Google Scholar] [CrossRef]

- Rawson, D.; Janes, I.; Jordan, K. Pilot Study to Investigate the Potential of Eye Tracking as a Technique for FSA Food Labelling Behaviour Research (Report for the FSA, 2008). Available online: http://www.food.gov.uk/sites/default/files/multimedia/pdfs/eyetracking.pdf (accessed on 10 May 2015.

- Graham, D.J.; Orquin, J.L.; Visschers, V.H.M. Eye tracking and nutrition label use: A review of literature and recommendations for label enchantment. Food Policy 2012, 37, 378–382. [Google Scholar] [CrossRef]

- Ares, G.; Gimeenez, A.; Bruzzone, F.; Vidal, L.; Antunez, L.; Maiche, A. Consumer Visual Proecessing of Food Labels: Results from an Eye Tracking Study. J. Sensory Sci. 2013, 28, 138–153. [Google Scholar] [CrossRef]

- INVINE. The Effect of the Wine Label. Available online: http://www.invine.com/2013/09/06/the-effect-of-the-wine-label/ (accessed on 24 July 2015).

- Valley Forge Tape & Label Co., Inc. Blog Page. Digital Label Printing vs. Flexographic Label Printing. Available online: http://vftl.com/blog/bid/235862/Digital-Label-Printing-vs-Flexographic-Label-Printing (accessed on 2 February 2015).

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hurley, R.A.; Rice, J.C.; Cottrell, D.; Felty, D. The Impact of Flexographic and Digital Printing of Fruit Drinks on Consumer Attention at the Point of Sale. Beverages 2015, 1, 149-158. https://doi.org/10.3390/beverages1030149

Hurley RA, Rice JC, Cottrell D, Felty D. The Impact of Flexographic and Digital Printing of Fruit Drinks on Consumer Attention at the Point of Sale. Beverages. 2015; 1(3):149-158. https://doi.org/10.3390/beverages1030149

Chicago/Turabian StyleHurley, Rupert Andrew, Julie Christine Rice, David Cottrell, and Drew Felty. 2015. "The Impact of Flexographic and Digital Printing of Fruit Drinks on Consumer Attention at the Point of Sale" Beverages 1, no. 3: 149-158. https://doi.org/10.3390/beverages1030149