Alignment and Proficiency of Virgin Olive Oil Sensory Panels: The OLEUM Approach

Abstract

:1. Introduction

2. Materials and Methods

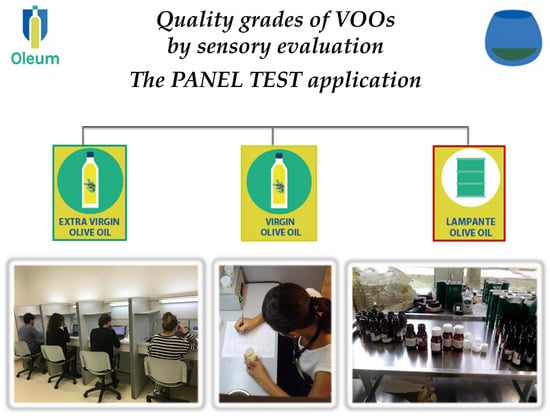

2.1. Sensory Panels

2.2. VOO Samples

2.3. Sensory Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. The Decision Tree

3.2. The Panel’s Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Olive Oil Council. Sensory Analysis of Olive Oil Method for the Organoleptic Assessment of Virgin Olive Oil; IOOC/T.20/Doc.no.3; IOOC: Madrid, Spain, 1987.

- Fernandes, G.D.; Ellis, A.C.; Gámbaro, A.; Barrera-Arellano, D. Sensory evaluation of high-quality virgin olive oil: Panel analysis versus consumer perception. Curr. Opin. Food Sci. 2018, 21, 66–71. [Google Scholar] [CrossRef]

- International Olive Oil Council. Sensory Analysis. General Basic Vocabulary; IOC/T.20/Doc.no.4/Rev.1; IOC: Madrid, Spain, 2007.

- International Olive Council. Sensory Analysis of Olive Oil Standard, Glass for Oil Tasting; IOC/T.20/Doc.no.5/Rev.1; IOC: Madrid, Spain, 2007.

- International Olive Council. Guide for the Installation of a Test Room; IOC/T.20/Doc.no. 6/rev.1; IOC: Madrid, Spain, 2007.

- International Olive Council. Sensory Analysis of Olive Oil Method for the Organoleptic Assessment of Virgin Olive Oil; IOC/T.20/Doc. no.15/Rev.10; IOC: Madrid, Spain, 2018.

- International Olive Council. Guide for the Selection, Training and Monitoring of Skilled Virgin Olive Oil Tasters; IOC/T.20/Doc. no.14/Rev.5; IOC: Madrid, Spain, 2018.

- Official Journal of the European Communities. European Community, Commission Regulation 2568/91 on the Characteristics of Olive Oil and Olive Residue Oil and on the Relevant Methods of Analysis; Official Journal of the European Communities: Brussels, Belgium, 1991; Volume L248, pp. 1–83. [Google Scholar]

- Conte, L.; Bendini, A.; Valli, E.; Lucci, P.; Moret, S.; Maquet, A.; Lacoste, F.; Brereton, P.; García-González, D.L.; Moreda, W.; et al. Olive oil quality and authenticity: A review of current EU legislation, standards, relevant methods of analyses, their drawbacks and recommendations for the future. Trends Food Sci. Technol. 2019, in press. [Google Scholar] [CrossRef]

- Official Journal of the European Communities. European Community, Commission Regulation 796/2002. Amending Regulation (EEC) No 2568/91No 2568/91/EEC; Official Journal of the European Communities: Brussels, Belgium, 2002; Volume L128, pp. 8–28. [Google Scholar]

- Procida, G.; Giomo, A.; Cichelli, A.; Conte, L.S. Study of volatile compounds of defective virgin olive oils and sensory evaluation: A chemometric approach. J. Sci. Food Agric. 2005, 85, 2175–2183. [Google Scholar] [CrossRef]

- Amelio, M. The official method for olive oil sensory evaluation: An expository revision of certain sections of the method and a viable means for confirming the attribute intensities. Trends Food Sci. Technol. 2016, 47, 64–68. [Google Scholar] [CrossRef]

- Amelio, M. Olive oil sensory evaluation: An alternative to the robust coefficient of variation (CVr%) for measuring panel group performance in official tasting sessions. Trends Food Sci. Technol. 2019, 88, 567–570. [Google Scholar] [CrossRef]

- Romero, I.; García-González, D.L.; Aparicio-Ruiz, R.; Morales, M.T. Validation of SPME–GCMS method for the analysis of virgin olive oil volatiles responsible for sensory defects. Talanta 2015, 134, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Quintanilla-Casas, B.; Bustamante, J.; Guardiola, F.; García-GonzáLez, D.L.; Barbieri, S.; Bendini, A.; Gallina Toschi, T.; Vichi, S.; Tres, A. Virgin olive oil volatile fingerprint and chemometrics: Towards an instrumental screening tool to grade the sensory quality. LWT Food Sci. Technol. 2020, 121, 1–8. [Google Scholar] [CrossRef]

- Delgado, C.; Guinard, J.X. How do consumer hedonic ratings for extra virgin olive oil relate to quality ratings by experts and descriptive analysis ratings? Food Qual. Prefer. 2011, 22, 213–225. [Google Scholar] [CrossRef]

- Recchia, A.; Monteleone, E.; Tuorila, H. Responses to extra virgin olive oils in consumers with varying commitment to oils. Food Qual. Prefer. 2012, 24, 153–161. [Google Scholar] [CrossRef]

- Gámbaro, A.; Ellis, A.; Raggio, L. Virgin olive oil acceptability in emerging olive oil-producing countries. Food Nutr. Sci. 2013, 4, 1060–1068. [Google Scholar] [CrossRef] [Green Version]

- Predieri, S.; Medoro, C.; Magli, M.; Gatti, E.; Rotondi, A. Virgin olive oil sensory properties: Comparing trained panel evaluation and consumer preferences. Food Res. Int. 2013, 54, 2091–2094. [Google Scholar] [CrossRef]

- Barbieri, S.; Bendini, A.; Valli, E.; Gallina Toschi, T. Do consumers recognize the positive sensorial attributes of extra virgin olive oils related with their composition? A case study on conventional and organic products. J. Food Compos. Anal. 2015, 44, 186–195. [Google Scholar] [CrossRef]

- Vazquez-Araujo, L.; Adhikari, K.; Chambers, E.T.; Chambers, D.H.; Carbonell-Barrachina, A.A. Cross-cultural perception of six commercial olive oils: A study with Spanish and US consumers. Food Sci. Technol. Int. 2015, 21, 454–466. [Google Scholar] [CrossRef] [PubMed]

- ISO. General Requirements for the Competence of Testing and Calibration Laboratories; EN ISO/IEC 17025:2017; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Official Journal of the European Union. European Union, Commission Regulation 1348/2013. Amending Regulation (EEC) No 2568/91; Official Journal of the European Union: Brussels, Belgium, 2013; Volume L338, pp. 31–67. [Google Scholar]

- ISO. Animal and Vegetable Fats and Oils—Sampling; EN ISO 5555:2001; ISO: Geneva, Switzerland, 2001. [Google Scholar]

- International Olive Council. Guidelines for the Accomplishment of the Requirements of the Norm ISO 17025 by of Sensory Testing Laboratories with Particular Reference to Virgin Olive Oil; IOC/T.28/Doc.no.1/Rev.4; IOC: Madrid, Spain, 2018.

- Barbieri, S.; Brkić Bubola, K.; Bendini, A.; Bučar-Miklavčič, M.; Lacoste, F.; Tibet, U.; Winkelmann, O.; García-González, D.L.; Gallina Toschi, T. OLEUM Project. Sensory Panels Analysis of Commercial Virgin Olive Oil Samples. Results from the First and Second Year of the OLEUM Project; University of Bologna: Bologna, Italy, 2020; Available online: http://doi.org/10.6092/unibo/amsacta/6306[Dataset]. [CrossRef]

- Cerretani, L.; Desamparados Salvador, M.; Bendini, A.; Fregapane, G. Relationship Between Sensory Evaluation Performed by Italian and Spanish Official Panels and Volatile and Phenolic Profiles of Virgin Olive Oils. Chemosens 2008, 1, 258–267. [Google Scholar] [CrossRef]

- Circi, S.; Capitani, D.; Randazzo, A.; Ingallina, C.; Mannina, L.; Sobolev, A.P. Panel test and chemical analyses of commercial olive oils: A comparative study. Chem. Biol. Technol. Agric. 2017, 4, 1–10. [Google Scholar] [CrossRef]

| Panels | UN_44 = UN_55 | UN_59 = UN_60 | UN_66 = UN_69 | |||

|---|---|---|---|---|---|---|

| End | rNd | End | rNd | Enf | rNf | |

| 1 | 0.3 | 0.4 | 0.3 | 1.3 | 2.0 | 14.4 |

| 2 | 0.3 | 0.4 | 1.2 | 5.3 | 0.6 | 1.4 |

| 3 | 0.2 | 0.1 | 1.2 | 5.1 | 0.7 | 2.0 |

| 4 | 0.1 | 0.1 | 0.5 | 1.1 | 0.6 | 1.2 |

| 5 | 0.3 | 0.3 | 0.4 | 0.6 | 0.7 | 2.0 |

| 6 | 0.1 | 0.1 | 1.2 | 5.8 | 0.1 | 0.0 |

| Limits | ≤1 | ≤2 | ≤1 | ≤2 | ≤1 | ≤2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbieri, S.; Brkić Bubola, K.; Bendini, A.; Bučar-Miklavčič, M.; Lacoste, F.; Tibet, U.; Winkelmann, O.; García-González, D.L.; Gallina Toschi, T. Alignment and Proficiency of Virgin Olive Oil Sensory Panels: The OLEUM Approach. Foods 2020, 9, 355. https://doi.org/10.3390/foods9030355

Barbieri S, Brkić Bubola K, Bendini A, Bučar-Miklavčič M, Lacoste F, Tibet U, Winkelmann O, García-González DL, Gallina Toschi T. Alignment and Proficiency of Virgin Olive Oil Sensory Panels: The OLEUM Approach. Foods. 2020; 9(3):355. https://doi.org/10.3390/foods9030355

Chicago/Turabian StyleBarbieri, Sara, Karolina Brkić Bubola, Alessandra Bendini, Milena Bučar-Miklavčič, Florence Lacoste, Ummuhan Tibet, Ole Winkelmann, Diego Luis García-González, and Tullia Gallina Toschi. 2020. "Alignment and Proficiency of Virgin Olive Oil Sensory Panels: The OLEUM Approach" Foods 9, no. 3: 355. https://doi.org/10.3390/foods9030355