Design of Predictive Tools to Estimate Freshness Index in Farmed Sea Bream (Sparus aurata) Stored in Ice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fish, Storage Conditions and Sampling

2.2. Physico–Chemicals Analysis in Seabreams Stored in Ice

2.2.1. Freshness Degree Measured by Torrymeter® (TM)

2.2.2. Temperature Measurements and pH

2.2.3. Total Volatile Basic Nitrogen (TVB-N)

2.3. Microbiological Counts in Fish

2.4. Sensory Analyses for Freshness Assessment (Analytical Procedure)

Sensory Score Sheets Employed

2.5. Statistical Analysis

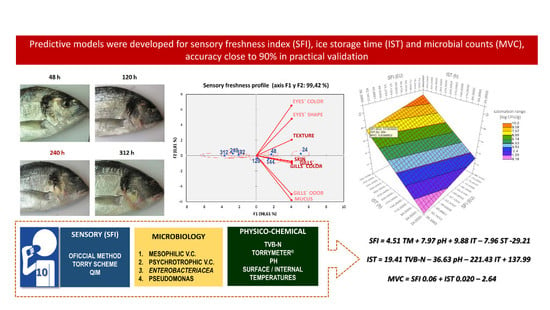

Design of Predictive Tools and External Validation

3. Results and Discussion

3.1. Physico–Chemical Parameters in Seabream Stored in Ice

3.2. Microbial Counts in Seabream Stored in Ice

3.3. Sensory Profiles and Characterization of Fish Spoilage

3.4. Global Analysis and Design of Predictive Tools

3.5. Validation for Predictive Tools Developed

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Smart, G. Problems of sea bass and sea bream quality in the Mediterranean. In Farmed Fish Quality; Kestin, S.C., Warriss, P.D., Eds.; Blackwell: Oxford, UK, 2001; pp. 120–128. [Google Scholar]

- Alasalvar, C.; Taylor, K.; Oksuz, T.; Garthwaite, M.; Alexis, M.; Grigorakis, K. Freshness assessment of cultured sea bream (Sparus aurata) by chemical, physical and sensory methods. Food Chem. 2001, 72, 33–40. [Google Scholar] [CrossRef]

- Fishery Statistics. Eurostat Statistics Explained. 2016. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Fisherystatist (accessed on 5 August 2017).

- APROMAR. The Marine Fish Aquaculture in Spain. 2011. Available online: http://www.apromar.es/Informes/Informe-APROMAR-2011.pdf (accessed on 9 June 2014).

- Ozogul, F.; Gokbulut, C.; Ozyurt, G.; Ozogul, Y.; Dural, M. Quality assessment of gutted wild sea bass (Dicentrarchus labrax) stored in ice, cling film and aluminium foil. Eur. Food Res. Technol. 2005, 220, 292–298. [Google Scholar] [CrossRef]

- Hernández, M.; López, M.; Álvarez, A.; Ferrandini, E.; García, B.; Garrido, M.D. Sensory, physical, chemical and microbiological changes in aquacultured meagre (Argyrosomus regius) fillets during ice storage. Food Chem. 2009, 114, 237–245. [Google Scholar] [CrossRef]

- Huss, H. Quality and Quality Changes in Fresh Fish; FAO fisheries technical paper 348; FAO: Rome, Italy, 1999; Available online: http://www.fao.org/docrep/V7180E/V7180E00.HTM (accessed on 1 April 2019).

- Dalgaard, P. Modelling of microbial activity and prediction of shelf life for packed fresh fish. Int. J. Food Microbiol. 1995, 26, 305–317. [Google Scholar] [CrossRef]

- Limbo, S.; Sinelli, N.; Torri, L.; Riva, M. Freshness decay and shelf life predictive modelling of European sea bass (Dicentrarchus labrax) applying chemical methods and electronic nose. LWT. Sci. Technol. 2009, 42, 977–984. [Google Scholar] [CrossRef]

- Antunes-Rohling, A.; Calero, S.; Halaihel, N.; Marquina, P.; Raso, J.; Calanche, J.; Beltrán Álvarez, I.; Cebrián, G. Characterization of the spoilage microbiota of hake fillets packaged under a Modified Atmosphere (MAP) rich in CO2 (50% CO2/50% N2) and stored at different temperaturas. Foods 2019, 8, 489. [Google Scholar] [CrossRef] [Green Version]

- Membré, J.; Lambert, R. Application of predictive modeling techniques in industry: From food design up to assessment. Int. J. Food Microbiol. 2008, 128, 10–15. [Google Scholar] [CrossRef]

- Vasilis, V.; Cummins, E.; Frías, J. Editorial: Predictive Modelling of Quality and Safety Special Issue. Food Control 2013, 29, 289. [Google Scholar]

- Regulation (EC). No 2074/2005 as Regards the Limit Values of Total Volatile Basic Nitrogen (TVB-N); Regulation (EC): Brussels, Belgium, 2005. [Google Scholar]

- UNE-EN ISO. Microbiología de la Cadena Alimentaria. Método Horizontal para el Recuento de Microorganismos. Parte 1: Recuento de Colonias a 30 °C Mediante la Técnica de Siembra en Profundidad; ISO 4833-1; UNE-EN ISO: Geneva, Switzerland, 2014. [Google Scholar]

- UNE-EN ISO. Microbiología de la Cadena Alimentaria. Método Horizontal para la Detección y el Recuento de Enterobacteriaceae. Parte 2: Técnica para el Recuento de Colonias; ISO 21528-2; UNE-EN ISO: Geneva, Switzerlnad, 2018. [Google Scholar]

- Tryfinopoulou, P.; Drosinos, E.; Nychas, J. Performance of Pseudomonas CFC-selective medium in the fish storage ecosystems. J. Microbiol. Methods 2001, 47, 243–247. [Google Scholar] [CrossRef]

- ISO 8586. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Calanche, J.; Tomas, A.; Martinez, S.; Jover, M.; Alonso, V.; Roncalés, P.; Beltrán, J.A. Relation of quality and sensory perception with changes in free amino acids of thawed seabream (S. aurata). Food Res. Int. 2019, 119, 126–134. [Google Scholar] [CrossRef]

- Distell. User Manual Distell Fish Freshness Meter: Model Torrymeter; Version 2.9; DISTELL.Com: West Lothian, UK, 2011. [Google Scholar]

- FAO. Freezing and Refrigerated Storage in Fisheries; Corporate document repository; FAO: Rome, Italy, 2012; Available online: http://www.fao.org/docrep/003/V3630E/v3630e23.htm (accessed on 5 October 2016).

- Council Regulation (EC) No 2406/96 of 26 November 1996 laying down common marketing standards for certain fishery products. OJ L 1996, 334, 1–15.

- AZTI. Frescura del Pescado: Guía Visual para su Evaluación Sensorial; Publicaciones AZTI-Tecnalia: San Sebastian, Spain, 2008; pp. 123–128. [Google Scholar]

- ISO. Sensory Analysis—General Guidance for the Selection, Training and Monitoring of Assessors—Part 2: Expert Sensory Assessors; 8586-2:2008; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Martens, H.; Anderssen, E.; Flatberg, A.; Gidskehaug, L.; Hoy, M.; Westad Thybo, A.; Martens, M. Regression of a data matrix on descriptors of both its rows and of its columns via latent variables: L-PLSR. Comput. Stat. Data Anal. 2005, 48, 103–123. [Google Scholar] [CrossRef]

- Giménez, A.; Ares, G.; Gámbaro, A. Survival analysis to estimate sensory shelf life using acceptability scores. J. Sens. Stud. 2008, 23, 571–582. [Google Scholar] [CrossRef]

- DTU Aqua (National Institute of Aquatic Resources). Seafood Spoilage and Safety Predictor (SSSP); ver. 3.1 software©; Technical University of Denmark: Lyngby, Denmark, 2009; Available online: http://sssp.dtuaqua.dk/ (accessed on 1 September 2019).

- Lougovois, V.; Kyranas, E.; Kyrana, V. Comparison of selected methods of assessing freshness quality and remaining storage life of iced gilthead sea bream (Sparus aurata). Food Res. Int. 2003, 36, 551–560. [Google Scholar] [CrossRef]

- Commission Regulation (EC). 1022/2008 of October 17, 2008 by Amending Regulation (EC) No 2074/2005 as Regards the Limit Values of Total Volatile Basic Nitrogen (TVB-N); Commission Regulation (EC): Brussels, Belgium, 2008. [Google Scholar]

- Álvarez, A.; García, B.; Garrido, M.D.; Hernández, M. The influence of starvation time prior to slaughter on the quality of commercial-sized gilthead seabream (S. aurata) during ice storage. Aquaculture 2008, 284, 106–114. [Google Scholar] [CrossRef]

- Grigorakis, K.; Taylor, K.; Alexis, M. Seasonal patterns of spoilage of ice-stored cultured gilthead sea bream (Sparus aurata). Food Chem. 2003, 81, 263–268. [Google Scholar] [CrossRef]

- Papadopoulos, V.; Chouliara, I.; Badeka, A.; Savvaidis, I.N.; Kontominas, M. Effect of gutting on microbiological, chemical, and sensory properties of aquacultured sea bass (Dicentrarchus labrax) stored in ice. Food Microbiol. 2003, 20, 411–420. [Google Scholar] [CrossRef]

- Zaragozá, P.; Fuentes, A.; Fernández-Segovia, I.; Vivancos, J.; Rizo, A.; Ros-Lis, J.V.; Barat, J.M.; Martínez-Máñez, R. Evaluation of sea bream (Sparus aurata) shelf life using an optoelectronic nose. Food Chem. 2012, 138, 1374–1380. [Google Scholar] [CrossRef]

- Barat, J.; Gil, L.; García-Breijo EAristoy, M.; Toldra, F.; Martínez-Máñez, R.; Soto, J. Freshness monitoring of sea bream (Sparus aurata) with a potentiometric sensor. Food Chem. 2008, 108, 681–688. [Google Scholar] [CrossRef]

- Parisi, G.; Franci, O.; Poli, B. Application of multivariate analysis to sensorial and instrumental parameters of freshness in refrigerated sea bass (Dicentrarchus labrax) during shelf life. Aquaculture 2002, 214, 153–167. [Google Scholar] [CrossRef]

- Calanche, J.; Samayoa, S.; Alonso, V.; Provincial, L.; Roncalés, P.; Beltrán, J.A. Assessing the effectiveness of a cold chain for fresh fish salmon (Salmo salar) and sardine (Sardina pilchardus) in a food processing plant. Food Control 2013, 33, 126–135. [Google Scholar] [CrossRef]

- Huidobro, A.; Pastor, M.; López-Caballero, M.; Tejada, M. Washing effect on the quality index method (QIM) developed for raw gilthead seabream (Sparus aurata). Eur. Food Res. Technol. 2001, 212, 408–412. [Google Scholar] [CrossRef] [Green Version]

- IFST. Development and Use of Microbiological Criteria in Foods; Institute of Food Science & Technology: London, UK, 1999. [Google Scholar]

- Commission Regulation (EC) 2073/2005 of 15 November 2005 on Microbiological Criteria for Foodstuffs. Available online: https://eur-lex.europa.eu/eli/reg/2005/2073/oj (accessed on 1 October 2019).

- Cakli, S.; Kilinc, B.; Cadun, A.; Dincer, T.; Tolasa, S. Quality differences of whole ungutted sea bream (Sparus aurata) and sea bass (Dicentrarchus labrax) while stored in ice. Food Control 2007, 18, 391–397. [Google Scholar] [CrossRef]

- Mossel, D.; Morris, G.; Struijk, C.; Cowder, J.; Browning, L. Providing microbiologically safe food and drinking water: Contribution of a European vertically integrated approach to educating professionals and consumers. Food Prot. Trends 2003, 23, 14–23. [Google Scholar]

- Corbo, M.R.; Altieri, C.; Bevilacqua, A.; Campaniello, D.; D’Amato, D.; Sinigaglia, M. Estimating packaging atmosphere-temperature effects on the shelf life of cod fillets. Eur. Food Res. Technol. 2005, 220, 509–513. [Google Scholar] [CrossRef]

- Cardinal, M.; Comet, J.; Donnay-Moreno, J.; Gouygou, J.; Bergé, J.; Rocha, E.; Soares, S.; Escorcío CBorges, P.; Valente, L. Seasonal variation of physical, chemical and sensory characteristics of sea bream (Sparus aurata) reared under intensive conditions in Southern Europe. Food Control 2011, 22, 574–585. [Google Scholar] [CrossRef] [Green Version]

- Kılınc, B.; Caklı, S.; Cadun, A.; Dıncer, T.; Tolasa, S. Comparison of effects of slurry ice and flake ice pretreatments on the quality of aquacultured sea bream (Sparus aurata) and sea bass (Dicentrarchus labrax) stored at 4 °C. Food Chem. 2007, 104, 1611–1617. [Google Scholar] [CrossRef]

- Husson, F.; Lê, S.; Pagès, J. SensoMineR dans Evaluation Sensorielle—Manuel Méthodologique, 3rd ed.; SSHA; Lavoisier Tec & Doc.: Rennes Cedex, France, 2009. [Google Scholar]

- ISO. Food Safety Management Systems-Requirements for Any Organization in the Food Chain; 22000:2018; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Carrascosa, C.; Millán, R.; Saavedra, P.; Jaber, J.; Montenegro, T.; Raposo, A.; Pérez, E.; Sanjúan, E. Predictive models for bacterial growth in sea bass (Dicentrarchus labrax) stored in ice. Int. J. Food Sci. Technol. 2014, 49, 354–363. [Google Scholar] [CrossRef] [Green Version]

| Days | TORRY | QIM | EU | TM | TVB-N | pH | ST | IT | PST | MVC | ET | PS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | m | 92.24 a | 89.08 a | 94.76 a | 14.00 a | 5.40 a | 6.50 | 0.26 | 0.10 | ND | ND | ND | ND |

| s | 1.34 | 5.21 | 1.10 | 0.28 | 0.76 | 0.00 | 0.11 | 0.14 | ND | ND | ND | ND | |

| 1 | m | 84.77 a | 85.30 a | 83.33 b | 13.17 a | 8.44 ab | 6.50 | 0.15 | 0.09 | 3.00 a | 3.23 a | 0.43 a | 1.16 a |

| s | 10.25 | 1.71 | 13.77 | 0.06 | 4.27 | 0.00 | 0.13 | 0.07 | 0.76 | 0.53 | 0.74 | 0.33 | |

| 2 | m | 83.72 ab | 69.17 bc | 80.60 b | 12.09 a | 8.59 ab | 6.65 | 0.34 | 0.32 | 4.01 ab | 3.51 a | 1.39 abc | 1.60 a |

| s | 4.85 | 10.03 | 5.68 | 0.53 | 1.76 | 0.28 | 0.41 | 0.35 | 0.51 | 0.76 | 1.32 | 0.44 | |

| 3 | m | 80.61 ab | 63.28 bc | 76.28 bc | 12.52 a | 10.21 bc | 6.41 | 0.25 | −0.04 | 4.36 ab | 3.48 a | 1.82 abc | 1.98 a |

| s | 2.50 | 7.72 | 6.68 | 0.10 | 1.63 | 0.07 | 0.43 | 0.11 | 0.40 | 0.46 | 0.82 | 0.31 | |

| 5 | m | 77.15 abc | 64.13 bc | 69.00 c | 10.87 abc | 12.82 bc | 6.45 | 0.18 | 0.01 | 3.92 b | 3.40 a | 1.59 abcd | 2.55 ab |

| s | 8.97 | 10.58 | 4.48 | 1.03 | 1.37 | 0.16 | 0.09 | 0.06 | 0.94 | 0.12 | 1.42 | 0.42 | |

| 6 | m | 68.45 abc | 52.91 cd | 57.30 d | 9.55 bc | 12.54 bcd | 6.43 | 0.42 | −0.02 | 4.44 bc | 3.60 a | 1.76 abcd | 2.77 b |

| s | 3.41 | 12.52 | 5.29 | 2.24 | 1.89 | 0.17 | 0.42 | 0.14 | 0.63 | 0.15 | 1.22 | 0.33 | |

| 7 | m | 64.40 cde | 42.50 d | 50.08 de | 7.86 bc | 12.85 bcd | 6.30 | 0.31 | −0.09 | 4.97 bcd | 4.02 ab | 2.68 bc | 2.83 b |

| s | 6.37 | 8.42 | 1.97 | 2.42 | 2.64 | 0.00 | 0.28 | 0.10 | 0.72 | 0.66 | 0.20 | 0.25 | |

| 8 | m | 59.99 de | 41.21 d | 49.77 de | 6.64 cd | 13.88 cde | 6.44 | 0.40 | 0.17 | 5.43 cd | 4.32 ab | 3.08 cd | 3.01 b |

| s | 2.44 | 10.08 | 2.41 | 3.15 | 2.33 | 0.28 | 0.07 | 0.50 | 1.00 | 0.63 | 0.33 | 0.24 | |

| 10 | m | 52.62 ef | 37.37 d | 48.10 de | 5.61 e | 17.15 de | 6.47 | 0.19 | 0.23 | 6.89 e | 5.04 b | 3.14 cde | 2.99 b |

| s | 6.67 | 10.37 | 3.81 | 3.40 | 1.45 | 0.44 | 0.10 | 0.36 | 0.09 | 1.01 | 0.25 | 0.37 | |

| 13 | m | 42.54 f | 32.20 e | 44.01 e | 4.44 e | 17.71 e | 6.52 | 0.02 | 0.19 | 8.30 e | 6.42 c | 4.46 e | 3.39 b |

| s | 12.98 | 6.62 | 2.85 | 3.68 | 1.81 | 0.51 | 0.04 | 0.50 | 0.07 | 0.84 | 0.68 | 0.36 | |

| 16 | m | 36.52 f | 33.16 e | 38.40 e | 2.16 e | 17.97 e | 6.83 | 0.07 | 0.48 | 8.85 e | 7.52 d | 4.67 e | 3.71 c |

| s | 19.18 | 0.00 | 0.59 | 2.98 | 3.27 | 0.72 | 0.04 | 0.71 | 0.38 | 0.64 | 0.02 | 0.38 | |

| *** | *** | *** | *** | *** | NS | NS | NS | *** | ** | *** | ** |

| Variable Contrasted | Variable Compared | r2 | Variable Compared | r2 | Variable Compared | r2 |

|---|---|---|---|---|---|---|

| Sensory Analyses (SFI) | ||||||

| TORRY | EU | 0.942 *** | QIM | 0.908 *** | TVB-N | −0.953 *** |

| TORRY | TM | 0.970 *** | PST/ET | ≤−0.965 *** | MVC/PS | ≤−0.925 *** |

| EU | QIM | 0.951 *** | TM | 0.965 *** | TVB-N | −0.908 *** |

| EU | PST | −0.853 *** | MVC | −0.769 ** | ET/PS | ≤−0.917 *** |

| QIM | TM | 0.921 *** | TVB-N | −0.859 *** | PST | −0.853 * |

| QIM | MVC | −0.769 ** | ET | −0.930 *** | PS | −0.915 *** |

| Physicochemical Parameters | ||||||

| TM | TVB-N | −0.910 *** | ET | −0.958 *** | PST | −0.920 *** |

| TM | MVC | −0.861 ** | PS | −0.911 *** | ||

| TVB-N | MVC | 0.860 *** | PS | 0.962 *** | ET/PST | ≥0.901 *** |

| PH | IT | 0.881 *** | ||||

| IT | PST | 0.594 * | MVC | 0.685 * | ||

| TM | TVB-N | −0.761 ** | ST | −0.674 * | ||

| Microbiological Count | ||||||

| PST | MVC | 0.969 *** | ET | 0.962 ** | PS | 0.866 *** |

| MVC | ET | 0.904 *** | PS | 0.780 ** | ||

| ET | PS | 0.895 *** | ||||

| Storage Time (ST) | ||||||

| ST | TORRY | −0.990 *** | EU | −0.925 *** | QIM | −0.880 *** |

| ST | PST | 0.970 *** | ET | 0.958 *** | PS/MVC | 0.936 *** |

| ST | TM | −0.957 *** | TVB-N | 0.960 *** | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calanche, J.; Pedrós, S.; Roncalés, P.; Beltrán, J.A. Design of Predictive Tools to Estimate Freshness Index in Farmed Sea Bream (Sparus aurata) Stored in Ice. Foods 2020, 9, 69. https://doi.org/10.3390/foods9010069

Calanche J, Pedrós S, Roncalés P, Beltrán JA. Design of Predictive Tools to Estimate Freshness Index in Farmed Sea Bream (Sparus aurata) Stored in Ice. Foods. 2020; 9(1):69. https://doi.org/10.3390/foods9010069

Chicago/Turabian StyleCalanche, Juan, Selene Pedrós, Pedro Roncalés, and José Antonio Beltrán. 2020. "Design of Predictive Tools to Estimate Freshness Index in Farmed Sea Bream (Sparus aurata) Stored in Ice" Foods 9, no. 1: 69. https://doi.org/10.3390/foods9010069