Synergistic Effects of High-Intensity Ultrasound Combined with L-Lysine for the Treatment of Porcine Myofibrillar Protein Regarding Solubility and Flavour Adsorption Capacity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of MPs

2.3. Sample Treatment

2.4. Solubility Measurements

2.5. Turbidity Measurements

2.6. pH Measurements

2.7. Particle Size and Zeta Potential Measurements

2.8. Fourier Transform Infrared Spectroscopy (FT-IR)

2.9. Measurements of Reactive and Total Sulfhydryl Contents

2.10. Fluorescence Measurements

2.11. Differential Scanning Calorimetry (DSC)

2.12. Solid-Phase Microextraction (SPME) and Gas Chromatography–Mass Spectrometry (GC/MS) Analysis

2.13. Statistical Analysis

3. Results and Discussion

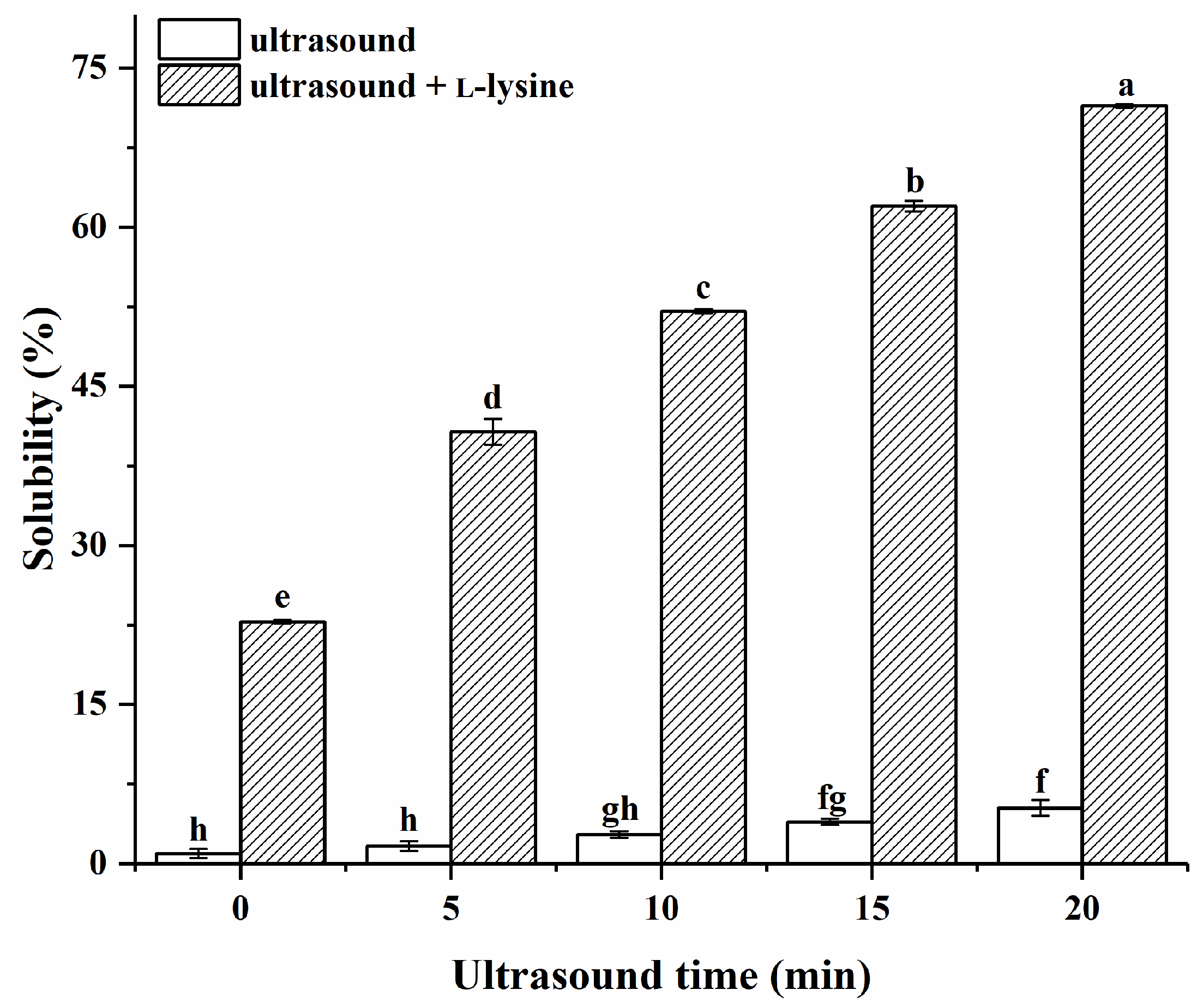

3.1. Protein Solubility

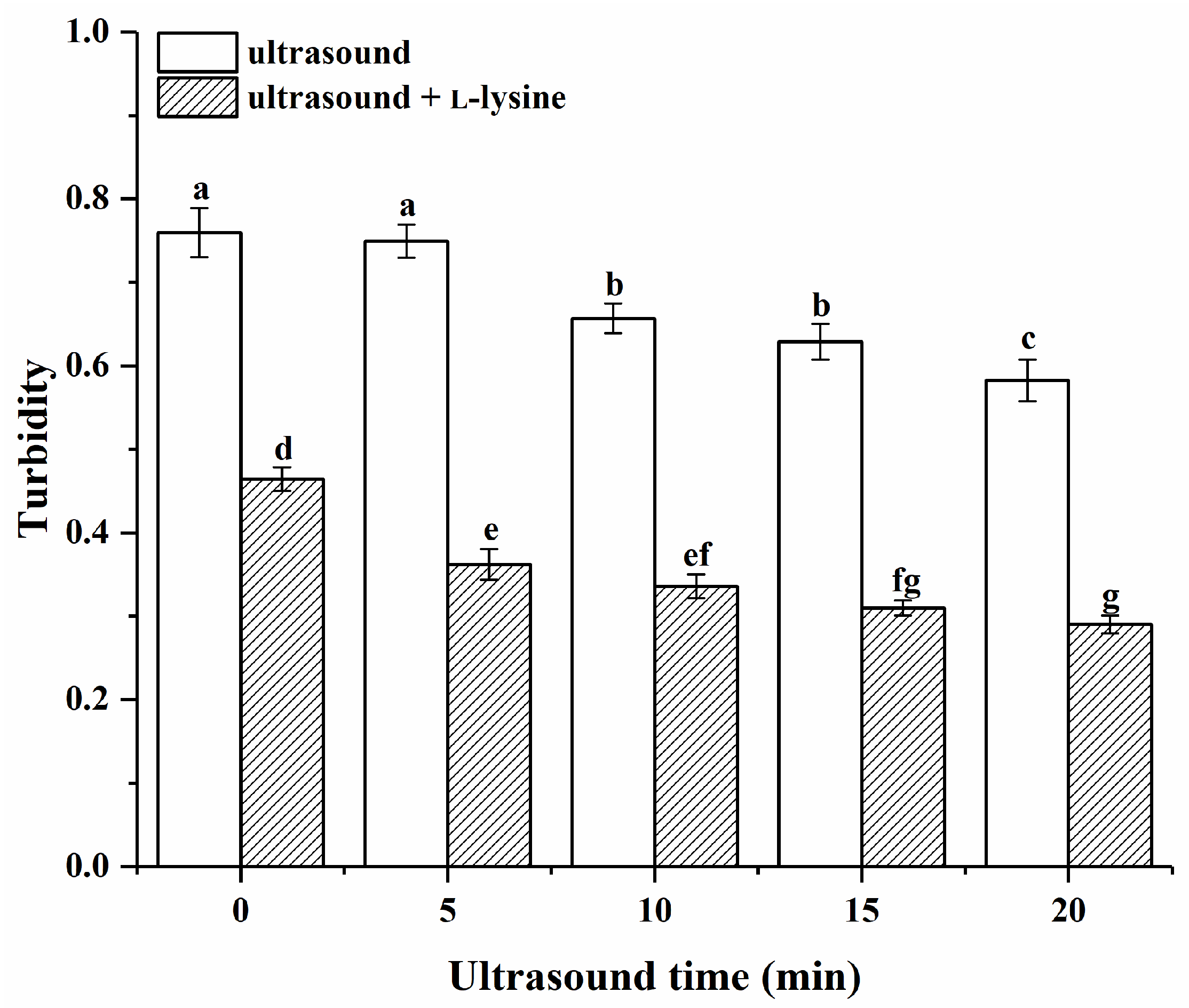

3.2. Protein Turbidity

3.3. pH of Protein

3.4. Particle Size of Protein

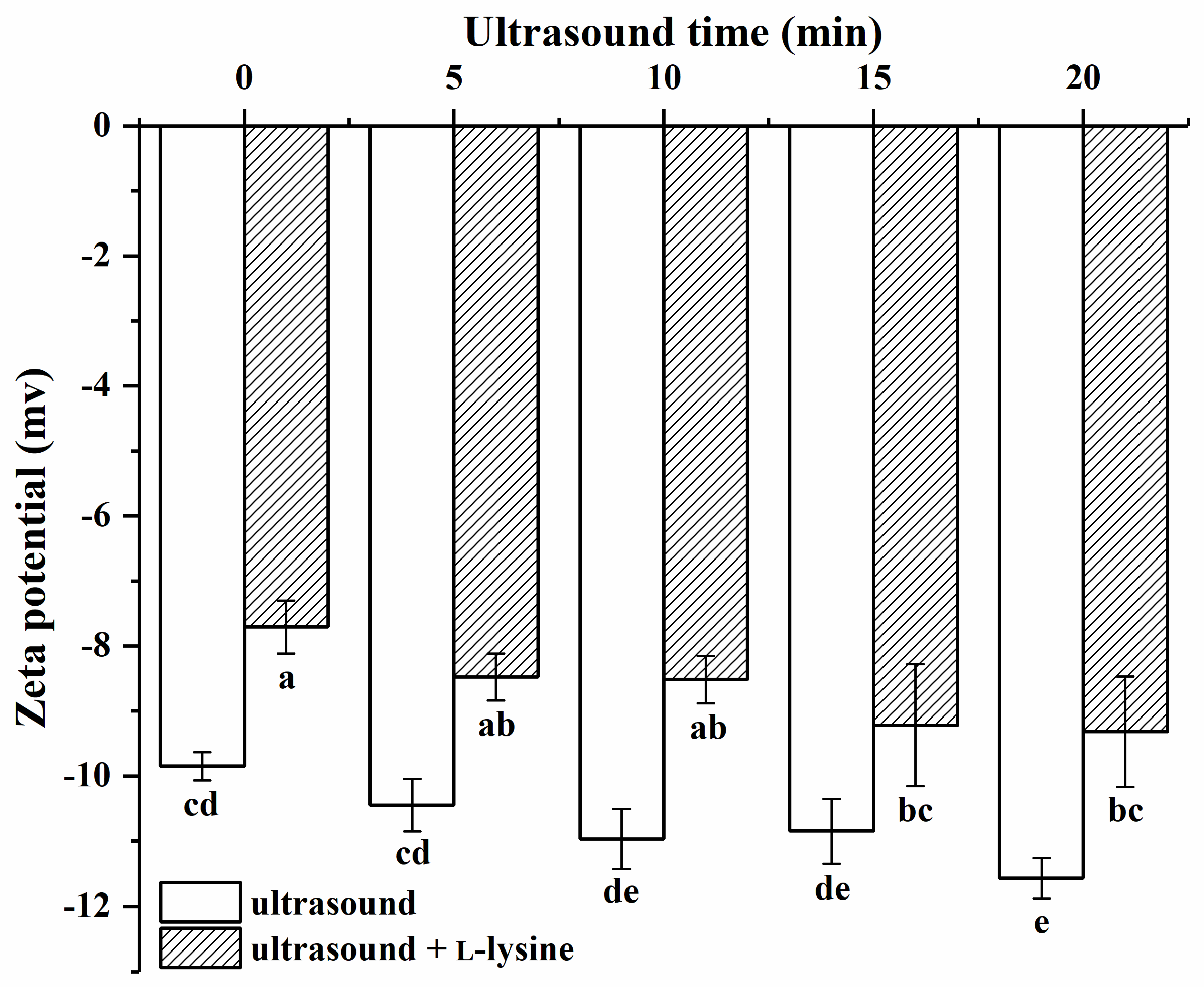

3.5. Zeta potential of Protein

3.6. Fourier Transform Infrared Spectroscopy (FT-IR) Analysis

3.7. Total and Reactive Sulfhydryl Analysis

3.8. Fluorescence Intensity Analysis

3.9. DSC of Protein

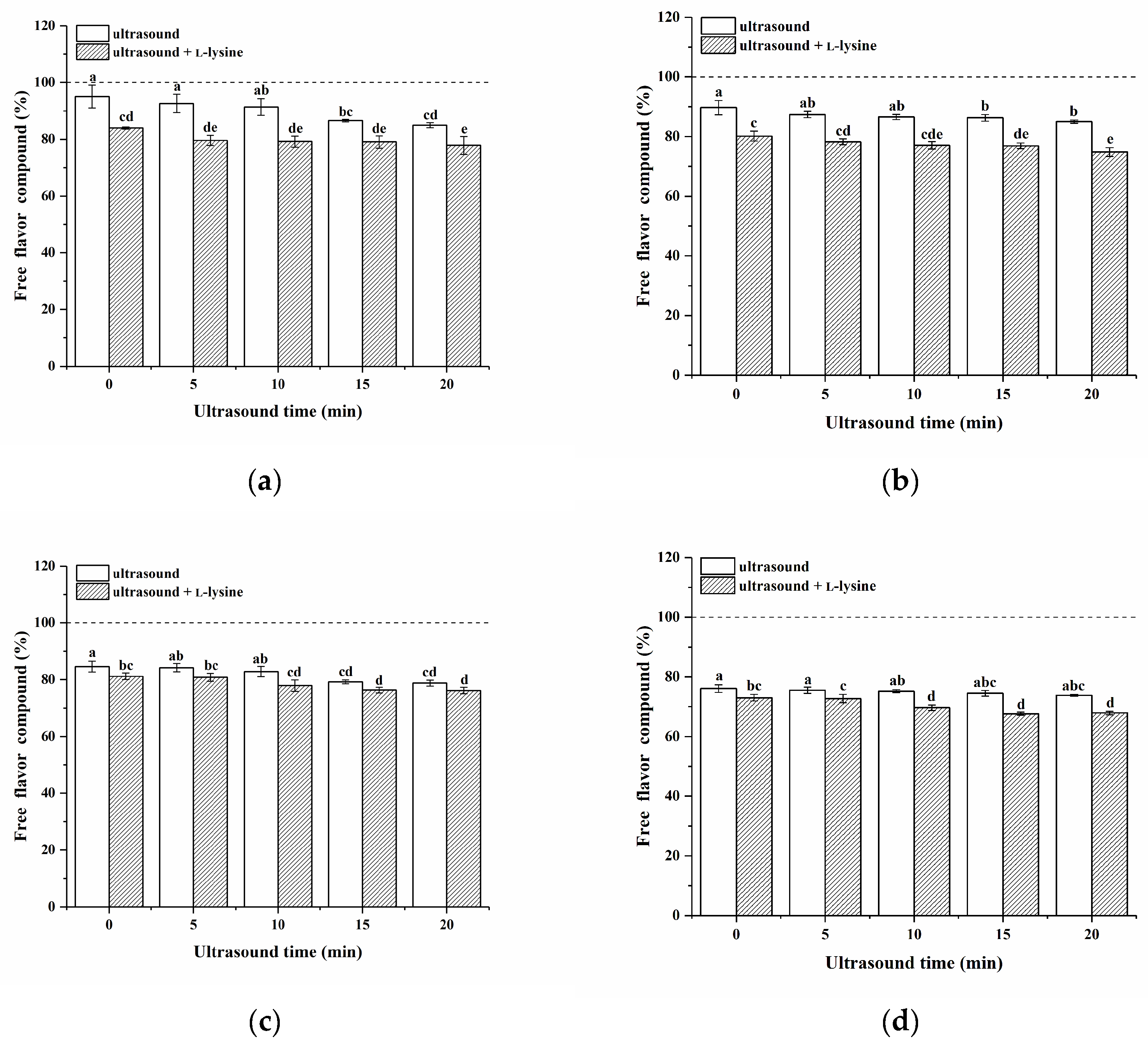

3.10. Binding of MPs to Ketone Compounds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pereira, P.; Vicente, A. Meat nutritional composition and nutritive role in the human diet. Meat Sci. 2013, 93, 586–592. [Google Scholar] [CrossRef]

- Bohrer, B.M. Review: Nutrient density and nutritional value of meat products and non-meat foods high in protein. Trends Food Sci. Technol. 2017, 65, 103–112. [Google Scholar] [CrossRef]

- Streimikyte, P.; Kersiene, M.; Eisinaite, V.; Jasutiene, I.; Lesauskaite, V.; Damuleviciene, G.; Knasiene, J.; Leskauskaite, D. Formulating protein-based beverages for the dysphagia diets of the elderly: Viscosity, protein quality, in vitro digestion, and consumers acceptability. J. Sci. Food Agric. 2020, 100, 3895–3901. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Li, Y.; Zhang, Y.; Luo, X.; Sun, J. Improving myofibrillar proteins solubility and thermostability in low-ionic strength solution: A review. Meat Sci. 2022, 189, 108822. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Juan, M.; Flores, M.; Toldrá, F. Effect of pork meat proteins on the binding of volatile compounds. Food Chem. 2008, 108, 1226–1233. [Google Scholar] [CrossRef]

- Chen, X.; Tume, R.K.; Xu, X.L.; Zhou, G.H. Solubilization of myofibrillar proteins in water or low ionic strength media: Classical techniques, basic principles, and novel functionalities. Crit. Rev. Food Sci. 2017, 57, 3260–3280. [Google Scholar] [CrossRef] [PubMed]

- Petit, G.; Jury, V.; de Lamballerie, M.; Duranton, F.; Pottier, L.; Martin, J.L. Salt Intake from Processed Meat Products: Benefits, Risks and Evolving Practices. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1453–1473. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, H.; Liu, Q.; Chen, Q.; Kong, B. Solubilization and stable dispersion of myofibrillar proteins in water through the destruction and inhibition of the assembly of filaments using high-intensity ultrasound. Ultrason. Sonochem. 2020, 67, 105160. [Google Scholar] [CrossRef]

- He, X.L.; Zhao, H.L.; Xu, Y.X.; Yi, S.M.; Li, J.R.; Li, X.P. Synergistic effects of oat β-glucan combined with ultrasound treatment on gel properties of silver carp surimi. Ultrasonics Sonochem. 2023, 95, 106406. [Google Scholar] [CrossRef]

- Ito, Y.; Tatsumi, R.; Wakamatsu, J.-I.; Nishimura, T.; Hattori, A. The solubilization of myofibrillar proteins of vertebrate skeletal muscle in water. Anim. Sci. J. 2003, 74, 417–425. [Google Scholar] [CrossRef]

- Guo, X.Y.; Peng, Z.Q.; Zhang, Y.W.; Liu, B.; Cui, Y.Q. The solubility and conformational characteristics of porcine myosin as affected by the presence of L-lysine and L-histidine. Food Chem. 2015, 170, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Takai, E.; Yoshizawa, S.; Ejima, D.; Arakawa, T.; Shiraki, K. Synergistic solubilization of porcine myosin in physiological salt solution by arginine. Int. J. Biol. Macromol. 2013, 62, 647–651. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, W.; Wang, S.; Shen, Y.; Pan, J.; Dong, X.; Li, S. The Solubility and Structures of Porcine Myofibrillar Proteins under Low-Salt Processing Conditions as Affected by the Presence of L-Lysine. Foods 2022, 11, 855. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, J.; Wang, Y.; Wu, D.; Liang, D.; Ye, H.; Cai, Z.; Ma, M.; Geng, F. Effects of high-intensity ultrasonic (HIU) treatment on the functional properties and assemblage structure of egg yolk. Ultrason. Sonochem. 2020, 60, 104767. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.J.; Zhang, M.; Wang, Y.C.A.; Bhandari, B. Novel Technologies for Flavor Formation in the Processing of Meat Products: A Review. Food Rev. Int. 2023, 39, 802–826. [Google Scholar] [CrossRef]

- Liu, X.M.; Powers, J.R.; Swanson, B.G.; Hill, H.H.; Clark, S. High hydrostatic pressure affects flavor-binding properties of whey protein concentrate. J. Food Sci. 2005, 70, C581–C585. [Google Scholar] [CrossRef]

- Sun, X.; Yu, Y.; Saleh, A.S.M.; Yang, X.; Ma, J.; Gao, Z.; Li, W.; Wang, Z.; Zhang, D. Structural changes induced by ultrasound improve the ability of the myofibrillar protein to bind flavor compounds from spices. Ultrason. Sonochem. 2023, 98, 106510. [Google Scholar] [CrossRef]

- Khan, S.A.; Dar, A.H.; Bhat, S.A.; Fayaz, J.; Makroo, H.A.; Dwivedi, M. High Intensity Ultrasound Processing in Liquid Foods. Food Rev. Int. 2022, 38, 1123–1148. [Google Scholar] [CrossRef]

- Zhao, X.; Qi, J.; Fan, C.; Wang, B.; Yang, C.; Liu, D. Ultrasound treatment enhanced the ability of the porcine myofibrillar protein to bind furan compounds: Investigation of underlying mechanisms. Food Chem. 2022, 384, 132472. [Google Scholar] [CrossRef]

- Chen, Q.; Kong, B.; Han, Q.; Liu, Q.; Xu, L. The role of bacterial fermentation in the hydrolysis and oxidation of sarcoplasmic and myofibrillar proteins in Harbin dry sausages. Meat Sci. 2016, 121, 196–206. [Google Scholar] [CrossRef]

- Gornall, A.G.; Bardawill, C.J.; David, M.M. Determination of serum proteins by means of the biuret reaction. J. Biol. Chem. 1949, 177, 751–766. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Zhao, M.; Sun, W. Effect of pH on the interaction of porcine myofibrillar proteins with pyrazine compounds. Food Chem. 2019, 287, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Luo, Y.; Shen, H. Effect of frozen storage on thermal stability of sarcoplasmic protein and myofibrillar protein from common carp (Cyprinus carpio) muscle. Int. J. Food Sci. Technol. 2013, 48, 1962–1969. [Google Scholar] [CrossRef]

- Chen, X.; Zou, Y.; Han, M.; Pan, L.; Xing, T.; Xu, X.; Zhou, G. Solubilisation of myosin in a solution of low ionic strength L-histidine: Significance of the imidazole ring. Food Chem. 2016, 196, 42–49. [Google Scholar] [CrossRef]

- Kaewprachu, P.; Osako, K.; Benjakul, S.; Rawdkuen, S. Effect of protein concentrations on the properties of fish myofibrillar protein based film compared with PVC film. J. Food Sci. Technol. 2016, 53, 2083–2091. [Google Scholar] [CrossRef]

- Ellman, G.L. Tissue sulfhydryl groups. Arch. Biochem. Biophys. 1959, 82, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Qiu, H.; Deng, X.; Mao, X.; Guo, X.; Xu, C.; Zhang, J. Effect of Chlorogenic Acid on the Physicochemical and Functional Properties of Coregonus Peled Myofibrillar Protein through Hydroxyl Radical Oxidation. Molecules 2019, 24, 3205. [Google Scholar] [CrossRef]

- Zhou, F.; Zhao, M.; Su, G.; Sun, W. Binding of aroma compounds with myofibrillar proteins modified by a hydroxyl-radical-induced oxidative system. J. Agric. Food Chem. 2014, 62, 9544–9552. [Google Scholar] [CrossRef]

- Qian, S.Y.; Li, X.; Wang, H.; Mehmood, W.; Zhong, M.; Zhang, C.H.; Blecker, C. Effects of low voltage electrostatic field thawing on the changes in physicochemical properties of myofibrillar proteins of bovine (Longissimus dorsi) muscle. J. Food Eng. 2019, 261, 140–149. [Google Scholar] [CrossRef]

- Li, S.; Zheng, Y.; Xu, P.; Zhu, X.; Zhou, C. l-Lysine and l-arginine inhibit myosin aggregation and interact with acidic amino acid residues of myosin: The role in increasing myosin solubility. Food Chem. 2018, 242, 22–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, L.; Cai, L.; Liu, Y.; Li, J. Effect of combined ultrasonic and alkali pretreatment on enzymatic preparation of angiotensin converting enzyme (ACE) inhibitory peptides from native collagenous materials. Ultrason. Sonochem. 2017, 36, 88–94. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.C.; Shi, T.; Sun, Q.C.; Li, X.T.; McClements, D.J.; Yuan, L. Effects of L-arginine and L-histidine on heat-induced aggregation of fish myosin: Bighead carp (Aristichthys nobilis). Food Chem. 2019, 295, 320–326. [Google Scholar] [CrossRef]

- Park, J.D.; Yongsawatdigul, J.; Choi, Y.J.; Park, J.W. Biochemical and conformational changes of myosin purified from Pacific sardine at various pHs. J. Food Sci. 2008, 73, C191–C197. [Google Scholar] [CrossRef] [PubMed]

- Amiri, A.; Mousakhani-Ganjeh, A.; Shafiekhani, S.; Mandal, R.; Singh, A.P.; Kenari, R.E. Effect of high voltage electrostatic field thawing on the functional and physicochemical properties of myofibrillar proteins. Innov. Food Sci. Emerg. 2019, 56, 102191. [Google Scholar] [CrossRef]

- Yongsawatdigul, J.; Park, J.W. Effects of alkali and acid solubilization on gelation characteristics of rockfish muscle proteins. J. Food Sci. 2004, 69, C499–C505. [Google Scholar] [CrossRef]

- Li, K.; Fu, L.; Zhao, Y.-Y.; Xue, S.-W.; Wang, P.; Xu, X.-L.; Bai, Y.-H. Use of high-intensity ultrasound to improve emulsifying properties of chicken myofibrillar protein and enhance the rheological properties and stability of the emulsion. Food Hydrocolloid 2020, 98, 105275. [Google Scholar] [CrossRef]

- Zhao, X.; Wu, T.; Xing, T.; Xu, X.L.; Zhou, G.H. Rheological and physical properties of O/W protein emulsions stabilized by isoelectric solubilization/precipitation isolated protein: The underlying effects of varying protein concentrations. Food Hydrocolloid 2019, 95, 580–589. [Google Scholar] [CrossRef]

- Shigeru, H.; Shuryo, N. Contribution of Hydrophobicity, Net Charge and Sulfhydryl Groups to Thermal Properties of Ovalbumin. Can. Inst. Food Sci. Technol. J. 1985, 18, 290–295. [Google Scholar] [CrossRef]

- Bao, P.Q.; Chen, L.; Hu, Y.; Wang, Y.; Zhou, C.L. L-Arginine and L-lysine retard aggregation and polar residue modifications of myofibrillar proteins: Their roles in solubility of myofibrillar proteins in frozen porcine (Longissimus lumborum). Food Chem. 2022, 393, 133347. [Google Scholar] [CrossRef]

- Song, X.Z.; Zhou, C.J.; Fu, F.; Chen, Z.L.; Wu, Q.L. Effect of high-pressure homogenization on particle size and film properties of soy protein isolate. Ind. Crop Prod. 2013, 43, 538–544. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Regenstein, J.M.; Zhou, P.; Yang, Y.L. Effects of high intensity ultrasound modification on physicochemical property and water in myofibrillar protein gel. Ultrason. Sonochem. 2017, 34, 960–967. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Li, Q.R.; Miao, S.; Zhang, Y.; Zheng, B.D.; Zhang, L.T. Effect of ultrasound on physicochemical properties of emulsion stabilized by fish myofibrillar protein and xanthan gum. Innov. Food Sci. Emerg. 2019, 54, 225–234. [Google Scholar] [CrossRef]

- Wang, K.Q.; Sun, D.W.; Pu, H.B.; Wei, Q.Y. Principles and applications of spectroscopic techniques for evaluating food protein conformational changes: A review. Trends Food Sci. Technol. 2017, 67, 207–219. [Google Scholar] [CrossRef]

- Kato, A.; Tsutsui, N.; Matsudomi, N.; Kobayashi, K.; Nakai, S. Effects of Partial Denaturation on Surface Properties of Ovalbumin and Lysozyme. Agr. Biol. Chem. 1981, 45, 2755–2760. [Google Scholar]

- Zhang, B.; Fang, C.D.; Hao, G.J.; Zhang, Y.Y. Effect of kappa-carrageenan oligosaccharides on myofibrillar protein oxidation in peeled shrimp (Litopenaeus vannamei) during long-term frozen storage. Food Chem. 2018, 245, 254–261. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.M.; Park, J.W. Solubility of salmon myosin as affected by conformational changes at various ionic strengths and pH. J. Food Sci. 1998, 63, 215–218. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Badar, I.H.; Liu, Q.; Chen, Q.; Kong, B. Combination of high-intensity ultrasound and hydrogen peroxide treatment suppresses thermal aggregation behaviour of myofibrillar protein in water. Food Chem. 2022, 367, 130756. [Google Scholar] [CrossRef]

- Lametsch, R.; Lonergan, S.; Huff-Lonergan, E. Disulfide bond within μ-calpain active site inhibits activity and autolysis. Biochim. Biophys. Acta Proteins Proteom. 2008, 1784, 1215–1221. [Google Scholar] [CrossRef]

- Estévez, M.; Ollilainen, V.; Heinonen, M. Analysis of Protein Oxidation Markers α-Aminoadipic and γ-Glutamic Semialdehydes in Food Proteins Using Liquid Chromatography (LC)-Electrospray Ionization (ESI)-Multistage Tandem Mass Spectrometry (MS). J. Agric. Food Chem. 2009, 57, 3901–3910. [Google Scholar] [CrossRef]

- Fu, Q.Q.; Liu, R.; Wang, H.O.; Hua, C.; Song, S.X.; Zhou, G.H.; Zhang, W.G. Effects of Oxidation (in Vitro) on Structures and Functions of Myofibrillar Protein from Beef Muscles. J. Agric. Food Chem. 2019, 67, 5866–5873. [Google Scholar] [CrossRef]

- Liu, G.; Xiong, Y.L.L. Electrophoretic pattern, thermal denaturation, and in vitro digestibility of oxidized myosin. J. Agric. Food Chem. 2000, 48, 624–630. [Google Scholar] [CrossRef] [PubMed]

- Grönroos, A.; Pentti, P.; Hanna, K. Ultrasonic degradation of aqueous carboxymethylcellulose: Effect of viscosity, molecular mass, and concentration. Ultrason. Sonochem. 2008, 15, 644–648. [Google Scholar] [CrossRef]

- Feng, X.; Ahn, D.U. Volatile profile, lipid oxidation and protein oxidation of irradiated ready-to-eat cured turkey meat products. Radiat. Phys. Chem. 2016, 127, 27–33. [Google Scholar] [CrossRef]

- Wu, M.G.; Xiong, Y.L.; Chen, J. Role of disulphide linkages between protein-coated lipid droplets and the protein matrix in the rheological properties of porcine myofibrillar protein-peanut oil emulsion composite gels. Meat Sci. 2011, 88, 384–390. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.Y.; Ma, L.; Chen, X.K.; Li, X.Y.; Zhang, Y.H. Physicochemical and structural properties of composite gels prepared with myofibrillar protein and lecithin at various ionic strengths. Food Hydrocolloid 2018, 82, 135–143. [Google Scholar] [CrossRef]

- Keerati-u-rai, M.; Miriani, M.; Iametti, S.; Bonomi, F.; Corredig, M. Structural changes of soy proteins at the oil-water interface studied by fluorescence spectroscopy. Colloids Surf. B 2012, 93, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; He, W.J.; Yi, Y.; Wang, H.X.; Xu, W.; Guo, D.J. The impacting mechanism of β-sanshool in Zanthoxylum bungeanum Maxim on the structure of myofibrillar protein in duck meat. LWT Food Sci. Technol. 2023, 182, 114838. [Google Scholar] [CrossRef]

- Xue, C.; You, J.; Zhang, H.M.; Xiong, S.B.; Yin, T.; Huang, Q.L. Capacity of myofibrillar protein to adsorb characteristic fishy-odor compounds: Effects of concentration, temperature, ionic strength, pH and yeast glucan addition. Food Chem. 2021, 363, 130304. [Google Scholar] [CrossRef]

- Bi, C.H.; Chi, S.Y.; Zhou, T.; Zhang, J.Y.; Wang, X.Y.; Li, J.; Shi, W.T.; Tian, B.; Huang, Z.G.; Liu, Y. Effect of low-frequency high-intensity ultrasound (HIU) on the physicochemical properties of chickpea protein. Food Res. Int. 2022, 159, 111474. [Google Scholar] [CrossRef]

- Khatkar, A.B.; Kaur, A.; Khatkar, S.K.; Bala, M.; Maan, S.; Tyagi, S.K. Valorization of ultrasound assisted restructured soy protein: Impact on the quality characteristics of instant noodles. LWT Food Sci. Technol. 2021, 147, 111599. [Google Scholar] [CrossRef]

- Sun, X.X.; Yu, Y.M.; Saleh, A.S.M.; Yang, X.Y.; Ma, J.L.; Li, W.H.; Zhang, D.Q.; Wang, Z.Y. Understanding interactions among flavor compounds from spices and myofibrillar proteins by multi-spectroscopy and molecular docking simulation. Int. J. Biol. Macromol. 2023, 229, 188–198. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Huang, M.Q.; Zhao, M.M.; Sun, W.Z. Interactions of selected ketone flavours with porcine myofibrillar proteins: The role of molecular structure of flavour compounds. Food Chem. 2019, 298, 125060. [Google Scholar] [CrossRef] [PubMed]

- Lou, X.W.; Yang, Q.L.; Sun, Y.Y.; Pan, D.D.; Cao, J.X. The effect of microwave on the interaction of flavour compounds with G-actin from grass carp (Catenopharyngodon idella). J. Sci. Food Agric. 2017, 97, 3917–3922. [Google Scholar] [CrossRef] [PubMed]

- Andriot, I.; Harrison, M.; Fournier, N.; Guichard, E. Interactions between methyl ketones and beta-lactoglobulin: Sensory analysis, headspace analysis, and mathematical modeling. J. Agric. Food Chem. 2000, 48, 4246–4251. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, X.; Wang, Y.; Pan, D.D.; Sun, Y.Y.; Cao, J.X. Study on the volatile compounds generated from lipid oxidation of Chinese bacon (unsmoked) during processing. Eur. J. Lipid Sci. Technol. 2017, 119, 1600512. [Google Scholar] [CrossRef]

- Chen, X.; Xu, X.L.; Han, M.Y.; Zhou, G.H.; Chen, C.G.; Li, P.J. Conformational changes induced by high-pressure homogenization inhibit myosin filament formation in low ionic strength solutions. Food Res. Int. 2016, 85, 1–9. [Google Scholar] [CrossRef]

| Ultrasound Time (min) | pH | |

|---|---|---|

| Ultrasound | Ultrasound + L-Lysine | |

| 0 | 6.86 ± 0.02 b | 9.35 ± 0.02 a |

| 5 | 6.87 ± 0.01 b | 9.35 ± 0.03 a |

| 10 | 6.88 ± 0.02 b | 9.36 ± 0.01 a |

| 15 | 6.87 ± 0.01 b | 9.38 ± 0.01 a |

| 20 | 6.88 ± 0.01 b | 9.36 ± 0.01 a |

| Group | Particle Size (μm) | ||||

|---|---|---|---|---|---|

| Ultrasound Time (min) | D50 | D90 | D43 | D32 | |

| ultrasound | 0 | 38.39 ± 0.73 bc | 137.63 ± 2.75 d | 61.12 ± 2.07 de | 22.76 ± 0.47 b |

| 5 | 20.96 ± 1.37 cd | 74.41 ± 3.22 e | 33.94 ± 2.13 ef | 16.59 ± 1.12 bcd | |

| 10 | 15.63 ± 1.25 cd | 66.70 ± 0.72 e | 29.11 ± 1.06 f | 13.29 ± 1.16 bc | |

| 15 | 12.03 ± 3.92 d | 48.30 ± 2.98 e | 22.99 ± 4.08 f | 10.30 ± 2.69 d | |

| 20 | 11.03 ± 4.01 d | 28.80 ± 14.46 e | 15.89 ± 7.30 f | 9.79 ± 3.19 d | |

| ultrasound + L-lysine | 0 | 86.67 ± 2.75 a | 528.48 ± 10.14 a | 184.04 ± 4.57 a | 39.63 ± 1.22 a |

| 5 | 57.50 ± 13.82 b | 466.14 ± 28.58 b | 141.84 ± 8.21 b | 17.61 ± 3.75 bcd | |

| 10 | 57.04 ± 21.73 b | 200.95 ± 16.07 c | 90.59 ± 11.69 c | 19.65 ± 6.26 bc | |

| 15 | 56.60 ± 13.66 b | 167.65 ± 34.76 cd | 82.22 ± 16.99 cd | 19.61 ± 5.71 bc | |

| 20 | 38.99 ± 4.95 bc | 163.63 ± 12.47 cd | 75.16 ± 6.69 cd | 19.71 ± 1.31 bc | |

| Group | Relative Content of Secondary Structures (%) | ||||

|---|---|---|---|---|---|

| Ultrasound Time (min) | β-Sheet | Random Coil | α-Helix | β-Turn | |

| ultrasound | 0 | 20.58 ± 0.52 c | 22.65 ± 0.91 a | 24.49 ± 0.25 a | 32.28 ± 0.21 b |

| 5 | 20.67 ± 0.23 bc | 22. 15 ± 0.17 a | 24.09 ± 0.37 ab | 33.09 ± 0.25 b | |

| 10 | 21.71 ± 0.59 bc | 21.98 ± 0.25 a | 23.74 ± 0.64 ab | 32.58 ± 0.36 b | |

| 15 | 22.70 ± 0.87 b | 21.41 ± 0.56 a | 23.49 ± 0.58 ab | 32.40 ± 0.51 b | |

| 20 | 28.57 ± 0.32 a | 22.39 ± 0.52 a | 22.18 ± 0.28 bc | 26.86 ± 0.56 c | |

| ultrasound + L-lysine | 0 | 16.62 ± 0.29 d | 18.33 ± 0.32 b | 21. 10 ± 0.23 c | 43.94 ± 0.45 a |

| 5 | 17.22 ± 0.43 d | 18. 16 ± 0.28 b | 20.79 ± 0.49 c | 43.83 ± 0.39 a | |

| 10 | 17.40 ± 0.52 d | 18.29 ± 0.24 b | 20.78 ± 0.36 c | 43.53 ± 0.27 a | |

| 15 | 17.41 ± 0.65 d | 18.70 ± 0.31 b | 21.08 ± 0.32 c | 42.80 ± 0.36 a | |

| 20 | 17.57 ± 0.53 d | 18.99 ± 0.56 b | 20.70 ± 0.21 c | 42.43 ± 0.62 a | |

| Ultrasound Time (min) | Denaturation Temperature (Td) (°C) | |

|---|---|---|

| Ultrasound | Ultrasound + L-Lysine | |

| 0 | 98.6 ± 1.62 f | 109.5 ± 0.16 c |

| 5 | 100.3 ± 0.16 f | 109.9 ± 0.23 c |

| 10 | 104 ± 0.81 e | 112.5 ± 0.24 b |

| 15 | 107.3 ± 0.17 d | 113.6 ± 0.26 a |

| 20 | 112.1 ± 0.08 b | 114.5 ± 0.43 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Chen, D.; Cao, J.; Wang, X.; Yin, X. Synergistic Effects of High-Intensity Ultrasound Combined with L-Lysine for the Treatment of Porcine Myofibrillar Protein Regarding Solubility and Flavour Adsorption Capacity. Foods 2024, 13, 629. https://doi.org/10.3390/foods13040629

Xie Y, Chen D, Cao J, Wang X, Yin X. Synergistic Effects of High-Intensity Ultrasound Combined with L-Lysine for the Treatment of Porcine Myofibrillar Protein Regarding Solubility and Flavour Adsorption Capacity. Foods. 2024; 13(4):629. https://doi.org/10.3390/foods13040629

Chicago/Turabian StyleXie, Yongkang, De Chen, Jianxin Cao, Xuejiao Wang, and Xiaoyu Yin. 2024. "Synergistic Effects of High-Intensity Ultrasound Combined with L-Lysine for the Treatment of Porcine Myofibrillar Protein Regarding Solubility and Flavour Adsorption Capacity" Foods 13, no. 4: 629. https://doi.org/10.3390/foods13040629